light CHRYSLER 300 2020 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2020, Model line: 300, Model: CHRYSLER 300 2020Pages: 328, PDF Size: 14.28 MB

Page 218 of 328

216IN CASE OF EMERGENCY

43–20 Amp Yellow Rear Heated Seats – If Equipped / Heated Steering Wheel –

If Equipped

44 –10 Amp Red Park Assist / Blind Spot / Rear View Camera

45 –15 Amp Blue Cluster / Rearview Mirror / Lane Departure

46 – –Fuse – Spare

47 –10 Amp Red Adaptive Front Lighting / Day Time Running Lamps – If Equipped

48 –20 Amp Yellow Active Suspension – (6.4L)

49 – –Fuse – Spare

50 – –Fuse – Spare

51 –20 Amp Yellow Front Heated / Vented Seats – If Equipped

52 –10 Amp RedHeated/Cooled Cup Holders/Rear Heated Seat Switches –

If Equipped

53 –10 Amp Red HVAC Module/In Vehicle Temperature Sensor

54 – –Fuse – Spare

55 – –Fuse – Spare

56 – –Fuse – Spare

57 – –Fuse – Spare

58 –10 Amp Red Airbag Module

59 –20 Amp Yellow Adjustable Pedals – Police

Cavity Cartridge Fuse Mini-FuseDescription

20_LX_OM_EN_USC_t.book Page 216

Page 219 of 328

IN CASE OF EMERGENCY217

(Continued)

(Continued)

JACKING AND TIRE CHANGING

60

– –Fuse – Spare

61 – –Fuse – Spare

62 – –Fuse – Spare

63 – –Fuse – Spare

64 –25 Amp Breaker Rear Windows (Charger/300)

65 –10 Amp Red Airbag Module

66 – –Fuse – Spare

67 –10 Amp RedRain and Light Sensor / Sunroof / Inside RearView Mirror /

Police Run Acc Relay

68 –10 Amp Red Rear USB Timer / Rear Sunshade – If Equipped

69 – –Fuse – Spare

70 – –Fuse – Spare

Cavity Cartridge Fuse Mini-FuseDescription

WARNING!

Do not attempt to change a tire on the side

of the vehicle close to moving traffic. Pull

far enough off the road to avoid the danger

of being hit when operating the jack or

changing the wheel.

Being under a jacked-up vehicle is

dangerous. The vehicle could slip off the

jack and fall on you. You could be crushed.

Never put any part of your body under a

vehicle that is on a jack. If you need to get

under a raised vehicle, take it to a service

center where it can be raised on a lift.

WARNING! (Continued)

Never start or run the engine while the

vehicle is on a jack.

The jack is designed to be used as a tool for

changing tires only. The jack should not be

used to lift the vehicle for service purposes.

The vehicle should be jacked on a firm level

surface only. Avoid ice or slippery areas.

WARNING! (Continued)

6

20_LX_OM_EN_USC_t.book Page 217

Page 223 of 328

IN CASE OF EMERGENCY221

6. Remove the lug nuts and tire.

7. Mount the spare tire.

Mounting Spare Tire

NOTE:

For vehicles so equipped, do not attempt to

install a center cap or wheel cover on the

compact spare.

Refer to “Compact Spare Tire” and to

“Limited-Use Spare” under “Tires” in

“Servicing And Maintenance” for additional

warnings, cautions, and information about

the spare tire, its use, and operation.

8. Install the lug nuts with the cone shaped end of the lug nut toward the wheel. Lightly

tighten the lug nuts.

9. Lower the vehicle to the ground by turning the jack handle counterclockwise. 10. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. For the correct lug nut

torque, refer to “Wheel And Tire Torque

Specifications” in “Technical Specifi -

cations”. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

11. Stow the jack, tools and flat tire. Make sure the base of the jack faces the front of the

vehicle before tightening down the fastener.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

CAUTION!

Be sure to mount the spare tire with the valve

stem facing outward. The vehicle could be

damaged if the spare tire is mounted

incorrectly.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

6

20_LX_OM_EN_USC_t.book Page 221

Page 224 of 328

222IN CASE OF EMERGENCY

(Continued)

ROAD TIRE INSTALLATION

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Refer to “Wheel And Tire Torque Specifi -

cations” in “Technical Specifications” for

proper lug nut torque.

5. After 25 miles (40 km), check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.

JUMP STARTING

If your vehicle has a discharged battery, it can

be jump started using a set of jumper cables

and a battery in another vehicle, or by using a

portable battery booster pack. Jump starting

can be dangerous if done improperly, so please

follow the procedures in this section carefully.

NOTE:

When using a portable battery booster pack,

follow the manufacturer's operating instruc -

tions and precautions.

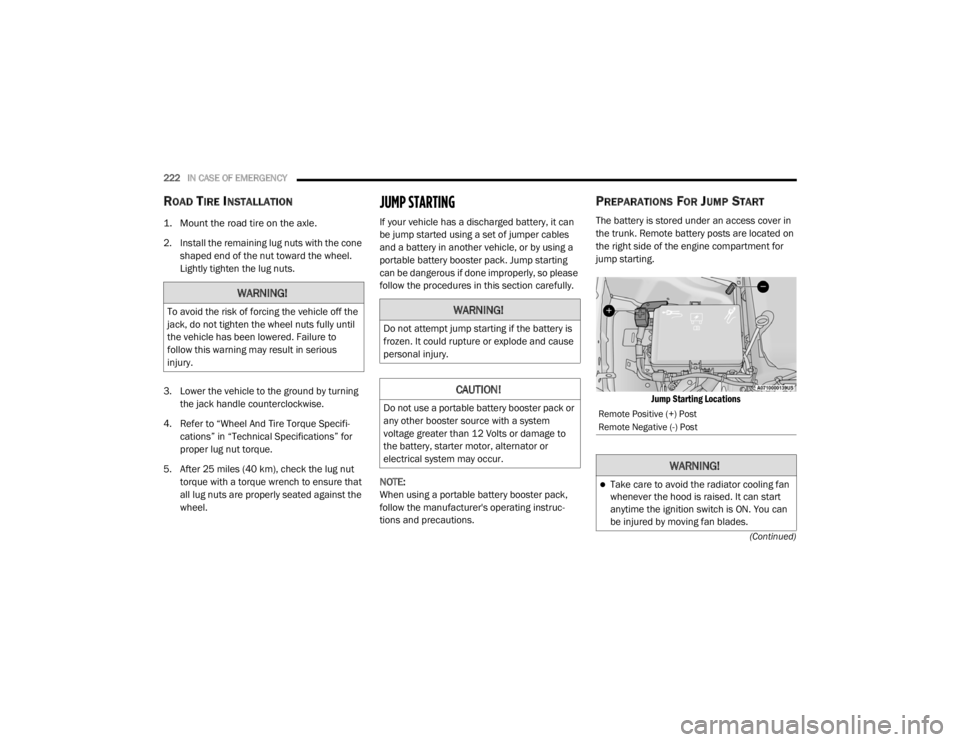

PREPARATIONS FOR JUMP START

The battery is stored under an access cover in

the trunk. Remote battery posts are located on

the right side of the engine compartment for

jump starting.

Jump Starting Locations

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system

voltage greater than 12 Volts or damage to

the battery, starter motor, alternator or

electrical system may occur.Remote Positive (+) Post

Remote Negative (-) Post

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can

be injured by moving fan blades.

20_LX_OM_EN_USC_t.book Page 222

Page 233 of 328

231

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

This vehicle is equipped with an automatic oil

change indicator system. The oil change

indicator system will remind you that it is time to

take your vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for the vehicle.

Operating conditions such as frequent

short-trips, trailer tow, and extremely hot or cold

ambient temperatures will influence when the

“Change Oil” or “Oil Change Required” message

is displayed. Severe Operating Conditions can

cause the change oil message to illuminate as

early as 3,500 miles (5,600 km) since last

reset. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).

The “Oil Change Required” message will be

displayed in the instrument cluster and a single

chime will sound, indicating that an oil change

is necessary.An authorized dealer will reset the oil change

indicator message after completing the

scheduled oil change. If a scheduled oil change

is performed by someone other than an

authorized dealer, the message can be reset by

referring to “Instrument Cluster Display” in

“Getting To Know Your Instrument Panel” for

further information.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Severe Duty All Models

Change Engine Oil at 4,000 miles (6,500 km) or

350 hours of engine run time if the vehicle is

operated in a dusty and off-road environment,

or is operated predominantly at idle or only very

low engine RPM. This type of vehicle use is

considered Severe Duty.Once A Month Or Before A Long Trip:Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual

wear or damage. Rotate tires at the first sign

of irregular wear, even if it occurs before your

next scheduled service.

Check the fluid levels of the coolant reservoir,

brake master cylinder, and power steering (if

equipped) and fill as needed.

Check function of all interior and exterior

lights.

7

20_LX_OM_EN_USC_t.book Page 231

Page 242 of 328

240SERVICING AND MAINTENANCE

ENGINE OIL

Change Engine Oil

The oil change indicator system will remind you

that it is time to take your vehicle in for scheduled

maintenance. Refer to “Scheduled Servicing” in

this section for the proper maintenance intervals.

NOTE:

Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Engine Oil Selection — 3.6L And 5.7L

Engine

For best performance and maximum protection

under all types of operating conditions, the

manufacturer only recommends engine oils

that are API Certified and meet the

requirements of FCA Material Standard

MS-6395.

NOTE:

Hemi engines (5.7L) at times can tick right after

startup and then quiet down after approxi -

mately 30 seconds. This is normal and will not harm the engine. This characteristic can be

caused by short drive cycles. For example, if the

vehicle is started then shut off after driving a

short distance. Upon restarting, you may experi

-

ence a ticking sound. Other causes could be if

the vehicle is unused for an extended period of

time, incorrect oil, extended oil changes or

extended idling. If the engine continues to tick

or if the Malfunction Indicator Light (MIL) comes

on, see the nearest authorized dealer

American Petroleum Institute (API) Engine

Oil Identification Symbol

This symbol means that the oil has

been certified by the American

Petroleum Institute (API). The

manufacturer only recommends

API Certified engine oils.

This symbol certifies 0W-20, 5W-20, 0W-30,

5W-30 and 10W-30 engine oils.

Engine Oil Viscosity (SAE Grade) — 3.6L

Engine

Mopar SAE 5W-20 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix Ultra or equivalent is recommended

for all operating temperatures. This engine oil

improves low temperature starting and vehicle

fuel economy.

The engine oil filler cap also shows the

recommended engine oil viscosity for your

engine. For information on engine oil filler cap

location, refer to the “Engine Compartment”

illustration in this section.

NOTE:

Mopar SAE 5W-30 engine oil approved to FCA

Material Standard MS-6395 such as Pennzoil,

Shell Helix Ultra or equivalent may be used

when SAE 5W-20 engine oil meeting MS-6395

is not available.

Lubricants which do not have both the engine

oil certification mark and the correct SAE

viscosity grade number should not be used.

CAUTION!

Do not use chemical flushes in your engine oil

as the chemicals can damage your engine.

Such damage is not covered by the New

Vehicle Limited Warranty.

20_LX_OM_EN_USC_t.book Page 240

Page 253 of 328

SERVICING AND MAINTENANCE251

(Continued)

Fluid Level Check — Brake Master Cylinder

Check the fluid level in the master cylinder

immediately if the brake system warning light

indicates system failure.

Check the fluid level in the master cylinder

when performing underhood services.

Clean the top of the master cylinder area before

removing the cap. Add fluid to bring the level up

to the top of the “FULL” mark on the side of the

master cylinder reservoir.

Overfilling of fluid is not recommended because

it may cause leaking in the system.

Add enough fluid to bring the level up to the

requirements described on the brake fluid

reservoir. With disc brakes, fluid level can be

expected to fall as the brake pads wear.

However, low fluid level may be caused by a

leak and a checkup may be needed.

Use only brake fluid that has been

recommended by the manufacturer, and has

been kept in a tightly closed container to avoid

contamination from foreign matter or moisture.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

AUTOMATIC TRANSMISSION

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubri -

cants” in “Technical Specifications” for

further information. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory

installed hydraulic master cylinder reser -

voir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or

fluid that has been in a tightly closed

container. Keep the master cylinder reser -

voir cap secured at all times. Brake fluid in

a open container absorbs moisture from

the air resulting in a lower boiling point. This

may cause it to boil unexpectedly during

hard or prolonged braking, resulting in

sudden brake failure. This could result in a

collision.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING! (Continued)

7

20_LX_OM_EN_USC_t.book Page 251

Page 255 of 328

SERVICING AND MAINTENANCE253

ALL WHEEL DRIVE (AWD) — IF

E

QUIPPED

The All Wheel Drive system consists of a

transfer case and front differential. The exterior

surface of these components should be

inspected for evidence of fluid leaks. Confirmed

leaks should be repaired as soon as possible.

The transfer case fluid fill/inspection plug is

located in the middle of the rear housing. To

inspect the transfer case fluid level, remove the

fill/inspection plug. The fluid level should be

even with the bottom of the hole. Use this plug

to add fluid as required.

The front differential fill plug is located on the

outer cover near the halfshaft attachment. To

inspect the differential fluid level, remove the fill

plug. The fluid level should be even with or

slightly below the bottom of the hole.

Fluid Changes

Refer to “Scheduled Servicing” in “Servicing

And Maintenance” for the proper maintenance

intervals.

REAR AXLE

For normal service, periodic fluid level checks

are not required. When the vehicle is serviced

for other reasons the exterior surfaces of the

axle assembly should be inspected. If gear oil

leakage is suspected inspect the fluid level.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for further information.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

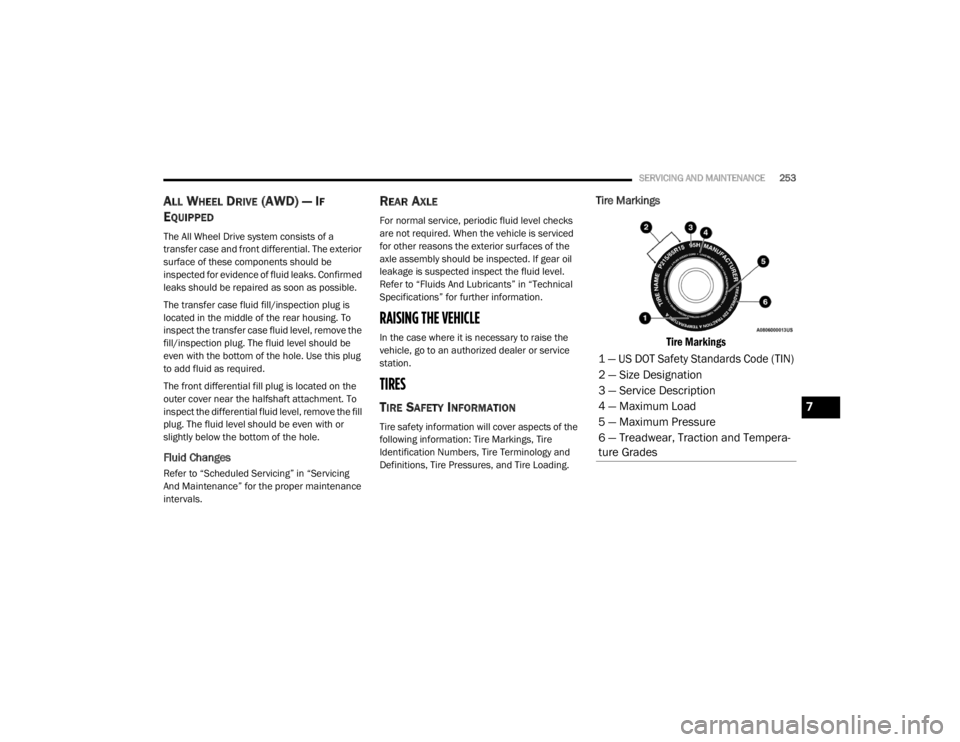

Tire Markings

Tire Markings

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

7

20_LX_OM_EN_USC_t.book Page 253

Page 256 of 328

254SERVICING AND MAINTENANCE

NOTE:

P (Passenger) — Metric tire sizing is based on

US design standards. P-Metric tires have the

letter “P” molded into the sidewall preceding

the size designation. Example: P215/65R15

95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

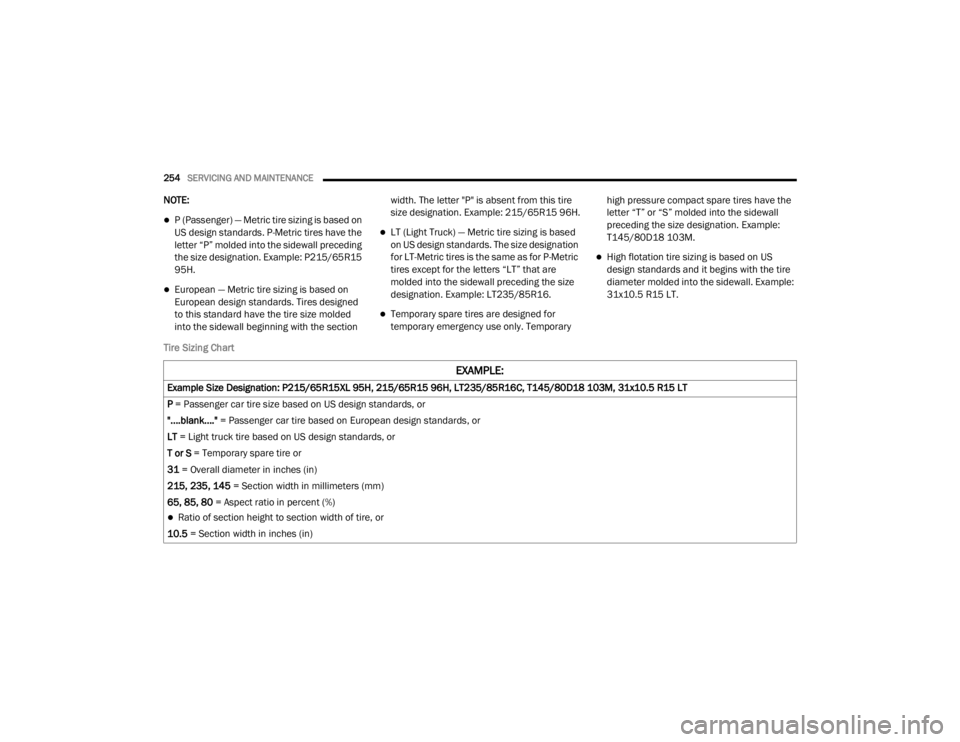

Tire Sizing Chart

EXAMPLE:

Example Size Designation: P215/65R15XL 95H, 215/65R15 96H, LT235/85R16C, T145/80D18 103M, 31x10.5 R15 LT

P = Passenger car tire size based on US design standards, or

"....blank...." = Passenger car tire based on European design standards, or

LT = Light truck tire based on US design standards, or

T or S = Temporary spare tire or

31 = Overall diameter in inches (in)

215, 235, 145 = Section width in millimeters (mm)

65, 85, 80 = Aspect ratio in percent (%)

Ratio of section height to section width of tire, or

10.5 = Section width in inches (in)

20_LX_OM_EN_USC_t.book Page 254

Page 257 of 328

SERVICING AND MAINTENANCE255

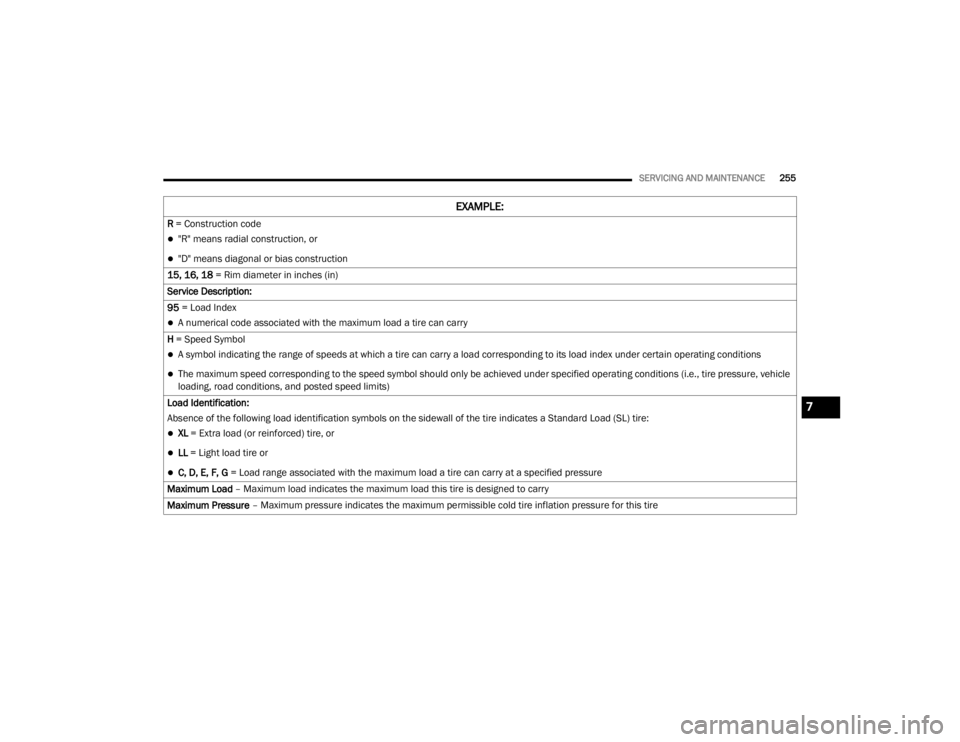

R = Construction code

"R" means radial construction, or

"D" means diagonal or bias construction

15, 16, 18 = Rim diameter in inches (in)

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

7

20_LX_OM_EN_USC_t.book Page 255