brake CHRYSLER ASPEN 2008 2.G Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: ASPEN, Model: CHRYSLER ASPEN 2008 2.GPages: 479, PDF Size: 4.3 MB

Page 362 of 479

NOTE:The NV 244 Generation II transfer case must be

shifted into NEUTRAL for recreational towing. The NEU-

TRAL selection button is located on the lower left-hand

corner of the 4WD Control Switch. Shifts into and out of

transfer case NEUTRAL can take place with the selector

switch in any mode position.

Shifting into NEUTRAL

Use the following procedure to prepare your vehicle for

recreational towing.

CAUTION!

It is necessary to follow these steps to be certain that

the transfer case is fully in NEUTRAL before recre-

ational towing to prevent damage to internal parts.

1. Bring vehicle to a complete stop.

2. Shut engine OFF.3. Turn the ignition key to the ON position without

starting the engine.

4. Depress brake pedal.

5. Shift automatic transmission to NEUTRAL.

6. Using the point of a ballpoint pen or similar object,

depress the recessed transfer case NEUTRAL button for

four seconds.

7. After shift is completed and the NEUTRAL light

comes on, release the NEUTRAL button.

8. Start the engine.

9. Shift the automatic transmission into REVERSE.

10. Release brake pedal for five seconds and ensure that

there is no vehicle movement.

11. Repeat steps 9 and 10 with the transmission in

DRIVE.

STARTING AND OPERATING 361

5

Page 363 of 479

12. Turn ignition key to the unlocked OFF position.

13. Shift the automatic transmission into PARK.

14. Attach vehicle to tow vehicle with tow bar.

NOTE:Items 1 through 5 are requirements that must be

met prior to depressing the NEUTRAL selection button,

and must continue to be met until the four seconds

elapses and the shift has been completed.

If any of these requirements (with the exception of Step 3

- Key ON) are not met prior to depressing the NEUTRAL

button or are no longer met during the four second timer,

then the NEUTRAL indicator light will flash continu-

ously until all requirements are met or until the NEU-

TRAL button is released.

NOTE:The ignition key must be ON for a shift to take

place and for the position indicator lights to be operable.

If the key is not ON, the shift will not take place and no

position indicator lights will be on or flashing.CAUTION!

Damage to the transmission may occur if the trans-

mission is shifted into PARK with the transfer case in

NEUTRAL and the engine RUNNING. With the

transfer case in NEUTRAL, ensure that the engine is

OFF prior to shifting the transmission into PARK.

Shifting Out of NEUTRAL

Use the following procedure to prepare your vehicle for

normal usage.

1. Bring vehicle to a complete stop.

2. Shut engine OFF.

3. Turn the ignition key to the ON position without

starting the engine.

4. Depress brake pedal.

362 STARTING AND OPERATING

Page 372 of 479

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the shift

lever in PARK (automatic transmission). On 4-wheel

drive vehicles, shift the transfer case to the ª4Lº position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the hazard warning flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

Jack Warning Label

WHAT TO DO IN EMERGENCIES 371

6

Page 376 of 479

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely

careful of motor traffic.

²To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Rotate the winch mechanism until the wheel is drawn

into place against the underside of the vehicle. Continue

to rotate until you feel the winch mechanism slip or click

two times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

WHAT TO DO IN EMERGENCIES 375

6

Page 377 of 479

JUMP±STARTING PROCEDURES

WARNING!

²Battery fluid is a corrosive acid solution; do not

allow battery fluid to contact eyes, skin or cloth-

ing. Don't lean over battery when attaching

clamps or allow the clamps to touch each other. If

acid splashes in eyes or on skin, flush the contami-

nated area immediately with large quantities of

water.

²A battery generates hydrogen gas which is flam-

mable and explosive. Keep flame or spark away

from the vent holes. Do not use a booster battery

or any other booster source with an output that

exceeds 12 volts.Check the Battery Test Indicator (if equipped). If a light or

bright colored dot is visible in the indicator (if equipped),

DO NOT jump-start the battery.

If the indicator (if equipped) is dark or shows a green dot,

proceed as follows:

1. Wear eye protection and remove all metal jewelry such

as watch bands or bracelets which might make an

unintended electrical contact.

2. Park the booster vehicle within cable reach but with-

out letting the vehicles touch. Set the parking brake, place

the automatic transmission in PARK and turn the ignition

OFF on both vehicles.

3. Turn OFF heater, radio and all unnecessary electrical

loads.

376 WHAT TO DO IN EMERGENCIES

Page 383 of 479

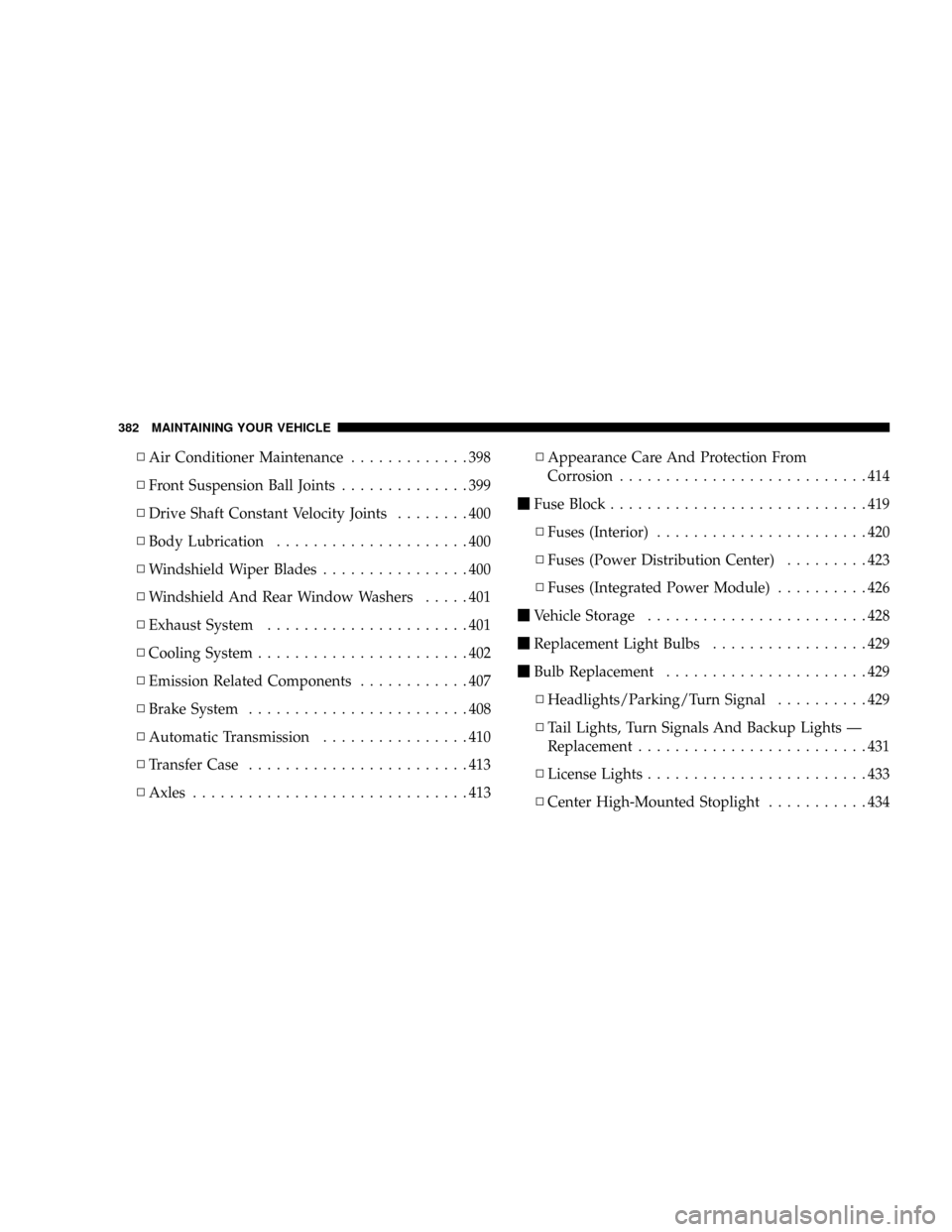

NAir Conditioner Maintenance.............398

NFront Suspension Ball Joints..............399

NDrive Shaft Constant Velocity Joints........400

NBody Lubrication.....................400

NWindshield Wiper Blades................400

NWindshield And Rear Window Washers.....401

NExhaust System......................401

NCooling System.......................402

NEmission Related Components............407

NBrake System........................408

NAutomatic Transmission................410

NTransfer Case........................413

NAxles..............................413NAppearance Care And Protection From

Corrosion...........................414

mFuse Block............................419

NFuses (Interior).......................420

NFuses (Power Distribution Center).........423

NFuses (Integrated Power Module)..........426

mVehicle Storage........................428

mReplacement Light Bulbs.................429

mBulb Replacement......................429

NHeadlights/Parking/Turn Signal..........429

NTail Lights, Turn Signals And Backup Lights Ð

Replacement.........................431

NLicense Lights........................433

NCenter High-Mounted Stoplight...........434

382 MAINTAINING YOUR VEHICLE

Page 409 of 479

Ensure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only the manufacturer's specified

hoses and clamps, or their equivalent in material and

specification, in any fuel system servicing. It is manda-

tory to replace all clamps that have been loosened or

removed during service. Care should be taken in install-

ing new clamps to ensure they are properly torqued.Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in the

PCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve ±Do not

attempt to clean the PCV valve!Check ventilating hose

for indication of damage or plugging with deposits.

Replace if necessary.

Brake System

Power Disc Brakes (Front and Rear)

Disc brakes do not require adjustment; however, several

hard stops during the break-in period are recommended

to seat the linings and wear off any foreign material.

408 MAINTAINING YOUR VEHICLE

Page 410 of 479

Brake Master Cylinders

The fluid level in the master cylinders should be checked

whenever the vehicle is serviced, or immediately if the

brake system warning light is on. If necessary, add fluid

to bring level to the full mark on the side of the reservoir

of the brake master cylinder. Be sure to clean the top of

the master cylinder area before removing the cap. With

disc brakes, fluid level can be expected to fall as the brake

pads wear. Brake fluid level should be checked when

pads are replaced. If the brake fluid level is abnormally

low, check system for leaks.

For correct fluid type, refer to ºBrake Master Cylinderº

under ªFluids, Lubricants and Genuine Partsº in this

section.WARNING!

Use of brake fluid that may have a lower initial

boiling point, or is unidentified as to specifications

may result in sudden brake failure during hard

prolonged braking. You could have an accident.

WARNING!

Overfilling the brake fluid reservoir can result in

spilling brake fluid on hot engine parts and the

brake fluid catching on fire.

Use only brake fluid that has been in a tightly closed

container to avoid contamination from foreign matter or

moisture.

MAINTAINING YOUR VEHICLE 409

7

Page 411 of 479

CAUTION!

Do not allow a petroleum-base fluid to contaminate

the brake fluid. Seal damage may result.

Brake Hoses

Inspection should be performed whenever the brake

system is serviced or at intervals specified. Inspect hy-

draulic brake hoses for surface cracking, scuffing or worn

spots. If there is any evidence of cracking, scuffing, or

worn spots, the hose should be replaced immediately!

Eventual deterioration of the hose can take place with

possible burst failure.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any sign of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

Automatic Transmission

Fluid Level Check

NOTE:If equipped with a dipstick, use the following

procedure. If your vehicle has a capped dipstick, it is

sealed and should not be tampered with. Your authorized

dealer has the proper tools to ensure that the fluid level

is set properly.

Check the fluid level while the transmission is at normal

operating temperature 180ÉF (82ÉC). This occurs after at

410 MAINTAINING YOUR VEHICLE

Page 412 of 479

least 15 miles (24 km) of driving. At normal operating

temperature the fluid cannot be held comfortably be-

tween the fingertips.

To check the automatic transmission fluid level properly,

the following procedure must be used:

1. Operate the engine at idle speed and normal operating

temperature.

2. The vehicle must be on level ground.

3. Fully apply the parking brake and press the brake

pedal.

4. Place the shift lever momentarily in each gear position

ending with the lever in PARK.

5. Remove the dipstick, wipe it clean and reinsert it until

seated.6. Remove the dipstick again and note the fluid level on

both sides. The fluid level should be between the ªHOTº

(upper) reference holes on the dipstick at normal operat-

ing temperature. Verify that solid coating of oil is seen on

both sides of the dipstick. If the fluid is low, add as

required into the dipstick tube.Do not overfill.After

adding any quantity of oil through the oil fill tube, wait

a minimum of two minutes for the oil to fully drain into

the transmission before rechecking the fluid level.

NOTE:If it is necessary to check the transmissionbelow

the operating temperature, the fluid level should be

between the two ªCOLDº (lower) holes on the dipstick

with the fluid at approximately 70ÉF (21ÉC) (room tem-

perature). If the fluid level is correctly established at

room temperature, it should be between the ªHOTº

(upper) reference holes when the transmission reaches

180ÉF ( 82ÉC). Remember it is best to check the level at the

normal operating temperature.

MAINTAINING YOUR VEHICLE 411

7