wheel CHRYSLER ASPEN 2008 2.G Repair Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: ASPEN, Model: CHRYSLER ASPEN 2008 2.GPages: 479, PDF Size: 4.3 MB

Page 371 of 479

3. Turn the wrench counterclockwise to lower the spare

tire. Continue to turn the wrench until the spare tire can

be pulled out from under the vehicle.

It is recommended that you stow the flat tire or spare to

avoid tangling the loose cable.

CAUTION!

The winch mechanism is designed for use with the

jack extension tube only. Use of an air wrench or

other power tools is not recommended and can dam-

age the winch.

Tire Changing Procedure

WARNING!

Getting under a jacked-up vehicle is dangerous. The

vehicle could slip off the jack and fall on you. You

could be crushed. Never get any part of your body

under a vehicle that is on a jack. Never start or run

the engine while the vehicle is on a jack. If you need

to get under a raised vehicle, take it to a service center

where it can be raised on a lift.

Do not raise this vehicle using a bumper jack. The scissor

jack is designed as a tool for changing tires on this vehicle

only. It is not recommended that the jack be used for

service purposes or to lift more than one wheel at a time.

370 WHAT TO DO IN EMERGENCIES

Page 372 of 479

Preparations

Park the vehicle on a firm level surface, avoiding ice or

slippery areas. Set the parking brake and place the shift

lever in PARK (automatic transmission). On 4-wheel

drive vehicles, shift the transfer case to the ª4Lº position.

WARNING!

Do not attempt to change a tire on the side of the

vehicle close to moving traffic. Pull far enough off

the road to avoid the danger of being hit when

operating the jack or changing the wheel.

²Turn on the hazard warning flasher.

²Block both the front and rear

of the wheel diagonally oppo-

site the jacking position. For

example, if the right front

wheel is being changed, block

the left rear wheel.

²Passengers should not remain in the vehicle when the

vehicle is being jacked.

Instructions

Jack Warning Label

WHAT TO DO IN EMERGENCIES 371

6

Page 373 of 479

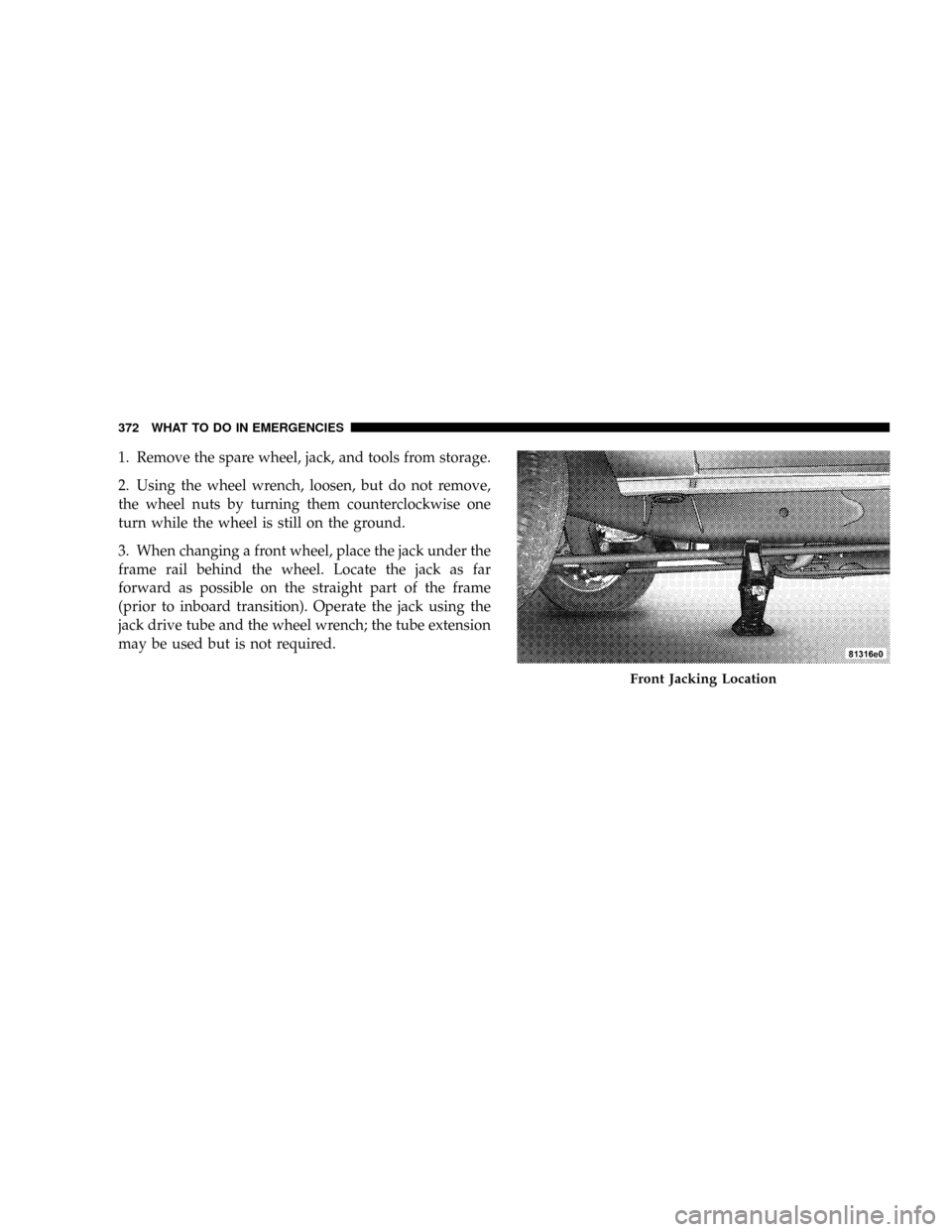

1. Remove the spare wheel, jack, and tools from storage.

2. Using the wheel wrench, loosen, but do not remove,

the wheel nuts by turning them counterclockwise one

turn while the wheel is still on the ground.

3. When changing a front wheel, place the jack under the

frame rail behind the wheel. Locate the jack as far

forward as possible on the straight part of the frame

(prior to inboard transition). Operate the jack using the

jack drive tube and the wheel wrench; the tube extension

may be used but is not required.

Front Jacking Location

372 WHAT TO DO IN EMERGENCIES

Page 374 of 479

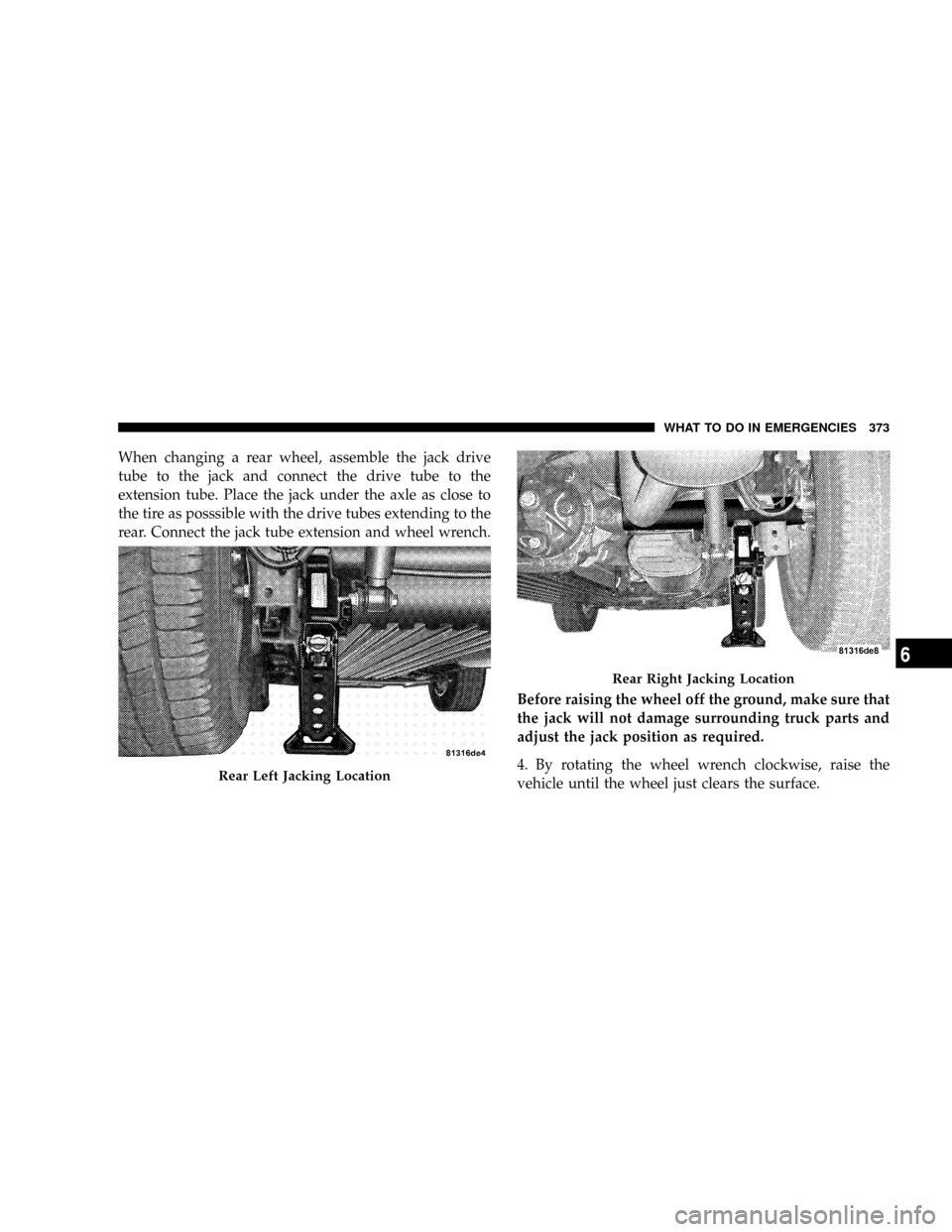

When changing a rear wheel, assemble the jack drive

tube to the jack and connect the drive tube to the

extension tube. Place the jack under the axle as close to

the tire as posssible with the drive tubes extending to the

rear. Connect the jack tube extension and wheel wrench.

Before raising the wheel off the ground, make sure that

the jack will not damage surrounding truck parts and

adjust the jack position as required.

4. By rotating the wheel wrench clockwise, raise the

vehicle until the wheel just clears the surface.

Rear Left Jacking Location

Rear Right Jacking Location

WHAT TO DO IN EMERGENCIES 373

6

Page 375 of 479

WARNING!

Raising the vehicle higher than necessary can make

the vehicle unstable and cause an accident. It could

slip off the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

5. Remove the wheel nuts and pull the wheel off. Install

the spare wheel and wheel nuts with the cone shaped end

of the nuts toward the wheel. Lightly tighten the nuts. To

avoid risk of forcing the vehicle off the jack, do not fully

tighten the nuts until the vehicle has been lowered.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

6. Using the wheel wrench, finish tightening the nuts in

a crisscross pattern. Correct nut tightness is 135 10 ft lbs

(183 14 N´m) dynamic torque. If in doubt about thecorrect tightness, have them checked with a torque

wrench by your authorized dealer or at a service station.WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could injure someone in the vehicle. Al-

ways stow the jack, tools and the extra tire and wheel

in the places provided.

7. Remove wheel blocks. Do not install chrome or alu-

minum wheel center caps on the spare wheel. This may

result in cap damage.

8. Lower the jack to its fully closed position. Stow the

replaced tire, jack, and tools as previously described.

9. Adjust the tire pressure when possible.

NOTE:Do not oil wheel studs. For chrome wheels, do

not substitute with chrome plated wheel nuts.

374 WHAT TO DO IN EMERGENCIES

Page 376 of 479

WARNING!

Carefully follow these tire changing warnings to help

prevent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the

edge of the roadway as possible before raising the

vehicle.

²Block the wheel diagonally opposite the wheel to

be raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a

jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely

careful of motor traffic.

²To assure that spare tires, flat or inflated, are

securely stowed, spares must be stowed with the

valve stem facing the ground.

To Stow The Flat Or Spare

Turn the wheel so that the valve stem is down. Slide the

wheel retainer through the center of the wheel and

position it properly across the wheel opening.

For convenience in checking the spare tire inflation, stow

with the valve stem toward the rear of the vehicle.

Rotate the winch mechanism until the wheel is drawn

into place against the underside of the vehicle. Continue

to rotate until you feel the winch mechanism slip or click

two times. It cannot be overtightened. Push against the

tire several times to be sure it is firmly in place.

WHAT TO DO IN EMERGENCIES 375

6

Page 379 of 479

WARNING!

Any procedure other than above could result in:

1. Personal injury caused by electrolyte squirting out

the battery vent;

2. Personal injury or property damage due to battery

explosion;

3. Damage to charging system of booster vehicle or

of immobilized vehicle.

FREEING A STUCK VEHICLE

If vehicle becomes stuck in snow, sand, or mud, it can

often be moved by a rocking motion. Move the gear

selector rhythmically between FIRST and REVERSE,

while applying slight pressure to the accelerator.The least amount of accelerator pedal pressure to main-

tain the rocking motion without spinning the wheels or

racing the engine is most effective. Allow the engine to

idle with the shift lever in NEUTRAL for at least one

minute after every five rocking-motion cycles. This will

minimize overheating and reduce the risk of transmis-

sion failure during prolonged efforts to free a stuck

vehicle.

EMERGENCY TOW HOOKS Ð IF EQUIPPED

Your vehicle may be equipped with emergency tow

hooks.

NOTE:For off-road recovery, it is recommended to use

both of the front tow hooks to minimize the risk of

damage to the vehicle.

378 WHAT TO DO IN EMERGENCIES

Page 381 of 479

Four-Wheel Drive Vehicles

The manufacturer recommends towing with all wheels

OFFthe ground. Acceptable methods are to tow the

vehicle on a flatbed or with one end of the vehicle raised

and the opposite end on a towing dolly.

Two-Wheel Drive Vehicles

Provided that the transmission is operable, tow with the

transmission in NEUTRAL and the ignition key in the

OFF position, along with the front wheels raised and the

rear wheels on the ground. The speed must not exceed 30

mph (50 km/h), and the distance must not exceed 15 mi

(25 km).If the vehicle is to be towed more than 15 mi (25 km) or

faster than 30 mph (50 km/h), it must be towed on a

flatbed, or with the rear wheels raised and the front

wheels on the ground, or with the front end raised and

the rear wheels on a towing dolly.

NOTE:Towing the vehicle with the rear wheels on the

ground at more than 30 mph (50 km/h) or for more than

15 mi (25 km), can cause severe transmission damage.

380 WHAT TO DO IN EMERGENCIES

Page 401 of 479

Drive Shaft Constant Velocity Joints

All 4-wheel drive models are equipped with four con-

stant velocity joints. Periodic lubrication of these joints is

not required. However, the joint boot should be inspected

for external leakage or damage periodically. If external

leakage or damage is evident, the joint boot and grease

should be replaced immediately. Continued operation

could result in failure of the joint due to water and dirt

contamination of the grease. This would require com-

plete replacement of the joint assembly. Refer to the

Service Manual for the detailed replacement procedure.

Body Lubrication

Locks and all body pivot points, including such items as

seat tracks, doors, liftgate, and hood hinges should be

lubricated periodically to assure quiet, easy operation

and to protect against rust and wear. Prior to the appli-

cation of any lubricant, the parts concerned should be

wiped clean to remove dust and grit; after lubricating

excess oil and grease should be removed. Particularattention should also be given to hood latching compo-

nents to ensure proper function. When performing other

underhood services, the hood latch release mechanism

and safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated twice a

year, preferably in the fall and spring. Apply a small

amount of a high quality lubricant such as MopartLock

Cylinder Lubricant directly into the lock cylinder.

Windshield Wiper Blades

The rubber edges of the wiper blades and the windshield

should be cleaned periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove accu-

mulations of salt or road film.

Operation of the wipers on dry glass for long periods

may cause deterioration of the wiper blades. Always use

washer fluid when using the wipers to remove salt or dirt

from a dry windshield.

400 MAINTAINING YOUR VEHICLE

Page 417 of 479

²If you detect any stone chips or scratches in the paint,

touch them up immediately. The cost of such repairs is

considered the responsibility of the owner.

²If your vehicle is damaged due to an accident or

similar cause which destroys the paint and protective

coating have your vehicle repaired as soon as possible.

The cost of such repairs is considered the responsibil-

ity of the owner.

²If you carry special cargo such as chemicals, fertilizers,

de-icer salt, etc., be sure that such materials are well

packaged and sealed.

²If a lot of driving is done on gravel roads, consider

mud or stone shields behind each wheel.

²Use Moparttouch up paint on scratches as soon as

possible. Your authorized dealer has touch up paint to

match the color of your vehicle.

Wheel and Wheel Trim Care

All wheels and wheel trim, especially aluminum and

chrome plated wheels, should be cleaned regularly with

a mild soap and water to prevent corrosion. To remove

heavy soil, use MopartWheel Cleaner or select a non-

abrasive, non-acidic cleaner. Do not use scouring pads,

steel wool, a bristle brush or metal polishes. Only

Mopartcleaners are recommended. Do not use oven

cleaner. Avoid automatic car washes that use acidic

solutions or harsh brushes that may damage the wheels'

protective finish.

YES EssentialstFabric Cleaning Procedure ± If

Equipped

YES Essentialstseats may be cleaned in the following

manner:

²Remove as much of the stain as possible by blotting

with a clean, dry towel.

²Blot any remaining stain with a clean, damp towel.

416 MAINTAINING YOUR VEHICLE