brake sensor CHRYSLER CARAVAN 2000 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2000Pages: 436, PDF Size: 3.4 MB

Page 2 of 436

TABLE OF CONTENTS - Continued

7.0 DIAGNOSTIC INFORMATION AND PROCEDURES...........................19

7.1GENERAL TROUBLESHOOTING....................................19

TROUBLE CODE TESTS

TEST DTCCHECKING FOR DIAGNOSTIC TROUBLE CODES.............20

TC-1AREPAIRING - A/C CONTROL SHORT CIRCUIT.................22

TC-2AREPAIRING - A/C CONTROL OPEN CIRCUIT..................28

TC-3AREPAIRING - A/C SYSTEM PRESSURE SIGNAL HIGH

EXCEEDED..............................................34

TC-4AREPAIRING - A/C SYSTEM PRESSURE SIGNAL LOW

EXCEEDED..............................................38

TC-5AREPAIRING - A/C SYSTEM PRESSURE SUPPLY HIGH

EXCEEDED..............................................42

TC-6AREPAIRING - A/C SYSTEM PRESSURE SUPPLY LOW

EXCEEDED..............................................46

TC-7AREPAIRING - ACCELERATOR PEDAL SENSOR TROUBLE

CODES.................................................50

TC-14AREPAIRING - BATTERY VOLTAGE SRC HIGH EXCEEDED.......60

TC-15AREPAIRING - TURBOCHARGER BOOST SENSOR SIGNAL HIGH

EXCEEDED..............................................62

TC-16AREPAIRING - TURBOCHARGER BOOST SENSOR SIGNAL LOW

EXCEEDED..............................................70

TC-17AREPAIRING - TURBOCHARGER BOOST SENSOR SUPPLY HIGH

EXCEEDED..............................................74

TC-18AREPAIRING - TURBOCHARGER BOOST SENSOR SUPPLY LOW

EXCEEDED..............................................78

TC-19AREPAIRING - TURBOCHARGER BOOST SENSOR PLAUSIBILITY.82

TC-20AREPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT

CONTACT...............................................86

TC-21AREPAIRING - CLUTCH SIGNAL PLAUSIBILITY.................94

TC-22AREPAIRING - CONTROL SLEEVE SENSOR SIGNAL HIGH

EXCEEDED..............................................98

TC-23AREPAIRING - CONTROL SLEEVE SENSOR START END POSITION

NOT ATTAINED..........................................102

TC-24AREPAIRING - CONTROL SLEEVE SENSOR STOP END POSITION

NOT ATTAINED..........................................104

TC-25AREPAIRING - CRUISE STATUS INDICATOR LAMP SHORT

CIRCUIT................................................106

TC-26AREPAIRING - DIAGNOSTIC LAMP OPEN CIRCUIT............110

TC-27AREPAIRING - DIAGNOSTIC LAMP SHORT CIRCUIT...........114

TC-30AREPAIRING - DIESEL POWER RELAY SHUTS OFF TOO EARLY .118

TC-31AREPAIRING - DIESEL POWER RELAY SHUTS OFF TOO LATE . .122

TC-33AREPAIRING - EGR OPEN CIRCUIT.........................126

TC-34AREPAIRING - EGR SHORT CIRCUIT........................130

TC-35AREPAIRING - ENGINE SPEED SENSOR DYNAMIC

PLAUSIBILITY...........................................134

TC-36AREPAIRING - ENGINE SPEED SENSOR OVERSPEED

RECOGNITION..........................................138

TC-38AREPAIRING - ENGINE SPEED SENSOR STATIC PLAUSIBILITY .140

TC-39AREPAIRING - FAN CONTROL OPEN CIRCUIT FAN 1..........144

TC-40AREPAIRING - FAN CONTROL OPEN CIRCUIT FAN 2..........148

TC-41AREPAIRING - FAN CONTROL SHORT CIRCUIT FAN 1.........152

ii

ProCarManuals.com

Page 11 of 436

3.3.2 Intermittent Code

A diagnostic trouble code that is not there every time the engine control module/SKIM checks the

circuit is an ªintermittentº code. Most intermittent codes are caused by wiring or connector

problems. Defects that come and go like this are the most difficult to diagnose; they must be

looked for under specific conditions that cause them. The following checks may assist you in

identifying a possible intermittent problem:

²Visually inspect related wire harness connectors. Look for broken, bent, pushed out, or

corroded terminals.

²Visually inspect the related harnesses. Look for chafed, pierced, or partially broken wire.

²Refer to any hotlines or technical service bulletins that may apply.

NOTE: Electromagnetic (radio) interference can cause an intermittent system malfunction. This

interference can interrupt communication between the ignition key transponder and the SKIM.

3.3.3 Reset Counter

The reset counter counts the number of times the vehicle has been started since codes were last

set, erased, or the battery was disconnected. The reset counter will count up to 255 start counts.

The number of starts helps determine when the trouble code actually happened. This is recorded

by the ECM and can be viewed on the DRB as the RESET COUNTER.

When there are no trouble codes stored in memory, the DRB will display ªNO TROUBLE CODES

FOUNDº and the reset counter will show ªRESET COUNT = XXX.º

3.3.4 ECM Diagnostic Trouble Codes

A/C CONTROL SHORT CIRCUIT

A/C CONTROL OPEN CIRCUIT

A/C SYSTEM PRESSURE SIGNAL HIGH EXCEEDED

A/C SYSTEM PRESSURE SIGNAL LOW EXCEEDED

A/C SYSTEM PRESSURE SUPPLY HIGH EXCEEDED

A/C SYSTEM PRESSURE SUPPLY LOW EXCEEDED

ACCELERATOR PEDAL SENSOR SIGNAL HIGH EXCEEDED

ACCELERATOR PEDAL SENSOR PLAUSIBILITY

ACCELERATOR PEDAL SENSOR PWG PLAUS WITH LOW IDLE SWITCH

ACCELERATOR PEDAL SENSOR PWG PLAUS WITH POTENTIOMETER

ATMOSPHERIC PRESSURE SENSOR SRC HIGH EXCEEDED

ATMOSPHERIC PRESSURE SENSOR SRC LOW EXCEEDED

BATTERY VOLTAGE SRC HIGH EXCEEDED

BRAKE SIGNAL PLAUS WITH REDUNDANT CONTACT

CLUTCH SIGNAL PLAUSIBILITY

CONTROL SLEEVE SENSOR SIGNAL HIGH EXCEEDED

CONTROL SLEEVE SENSOR START END POS. NOT ATTAINED

CONTROL SLEEVE SENSOR STOP END POS. NOT ATTAINED

CRUISE STATUS INDICATOR LAMP SHORT CIRCUIT

DIAGNOSTIC LAMP OPEN CIRCUIT

DIAGNOSTIC LAMP SHORT CIRCUIT

DIESEL POWER RELAY SHUTS OFF TOO EARLY

DIESEL POWER RELAY SHUTS OFF TOO LATE

EEPROM PLAUSIBILITY CHECKSUM ERROR FOR ADJ. (EGR)

EEPROM PLAUSIBILITY CHECKSUM ERROR IN CC212

EEPROM PLAUSIBILITY COMMUNICATION WITH EEPROM

EEPROM PLAUSIBILITY FUNC. SWITCH WRONG OR MISSING

EEPROM PLAUSIBILITY VER. NUMBER NOT CORRESPONDING

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

5

ProCarManuals.com

Page 15 of 436

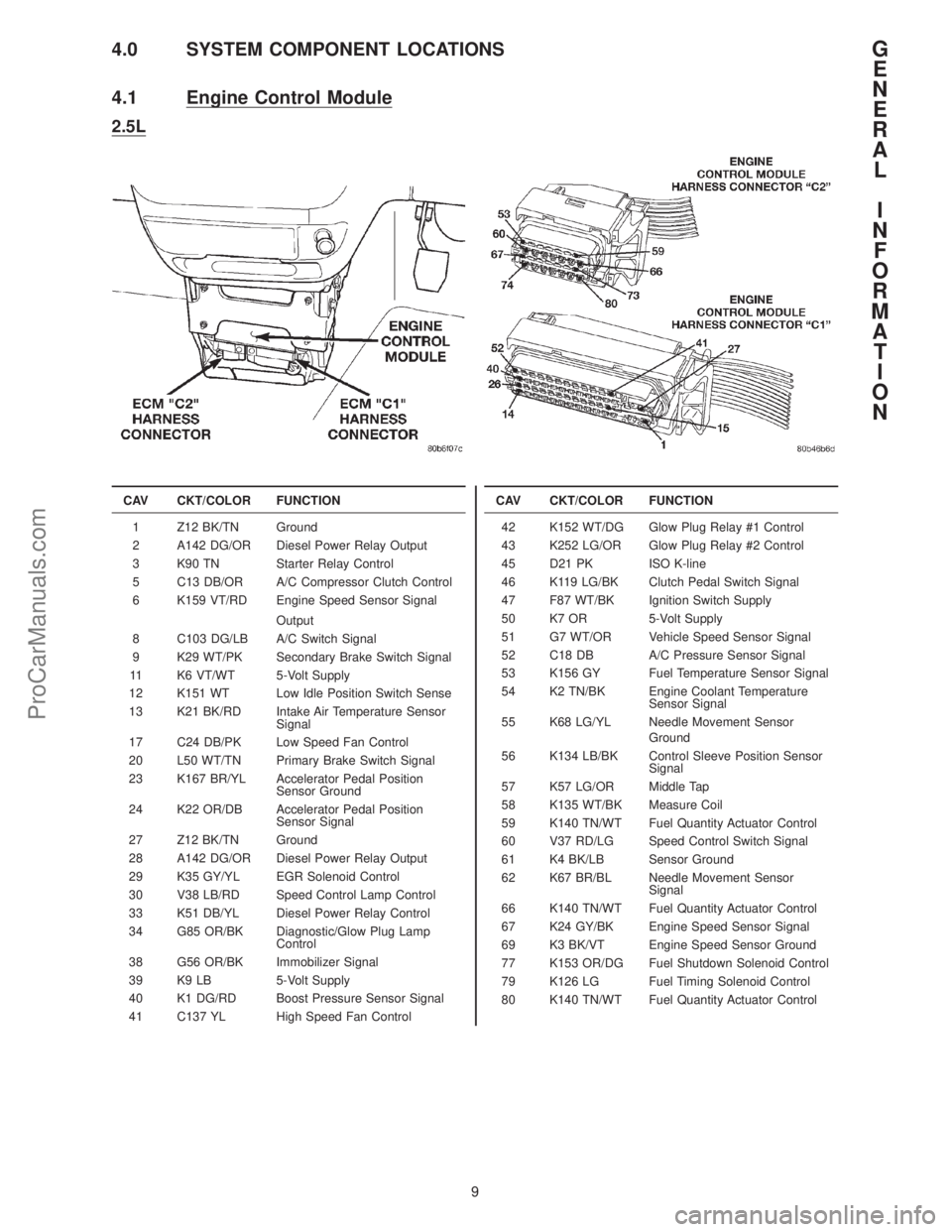

4.0 SYSTEM COMPONENT LOCATIONS

4.1 Engine Control Module

2.5L

CAV CKT/COLOR FUNCTION

1 Z12 BK/TN Ground

2 A142 DG/OR Diesel Power Relay Output

3 K90 TN Starter Relay Control

5 C13 DB/OR A/C Compressor Clutch Control

6 K159 VT/RD Engine Speed Sensor Signal

Output

8 C103 DG/LB A/C Switch Signal

9 K29 WT/PK Secondary Brake Switch Signal

11 K6 VT/WT 5-Volt Supply

12 K151 WT Low Idle Position Switch Sense

13 K21 BK/RD Intake Air Temperature Sensor

Signal

17 C24 DB/PK Low Speed Fan Control

20 L50 WT/TN Primary Brake Switch Signal

23 K167 BR/YL Accelerator Pedal Position

Sensor Ground

24 K22 OR/DB Accelerator Pedal Position

Sensor Signal

27 Z12 BK/TN Ground

28 A142 DG/OR Diesel Power Relay Output

29 K35 GY/YL EGR Solenoid Control

30 V38 LB/RD Speed Control Lamp Control

33 K51 DB/YL Diesel Power Relay Control

34 G85 OR/BK Diagnostic/Glow Plug Lamp

Control

38 G56 OR/BK Immobilizer Signal

39 K9 LB 5-Volt Supply

40 K1 DG/RD Boost Pressure Sensor Signal

41 C137 YL High Speed Fan ControlCAV CKT/COLOR FUNCTION

42 K152 WT/DG Glow Plug Relay #1 Control

43 K252 LG/OR Glow Plug Relay #2 Control

45 D21 PK ISO K-line

46 K119 LG/BK Clutch Pedal Switch Signal

47 F87 WT/BK Ignition Switch Supply

50 K7 OR 5-Volt Supply

51 G7 WT/OR Vehicle Speed Sensor Signal

52 C18 DB A/C Pressure Sensor Signal

53 K156 GY Fuel Temperature Sensor Signal

54 K2 TN/BK Engine Coolant Temperature

Sensor Signal

55 K68 LG/YL Needle Movement Sensor

Ground

56 K134 LB/BK Control Sleeve Position Sensor

Signal

57 K57 LG/OR Middle Tap

58 K135 WT/BK Measure Coil

59 K140 TN/WT Fuel Quantity Actuator Control

60 V37 RD/LG Speed Control Switch Signal

61 K4 BK/LB Sensor Ground

62 K67 BR/BL Needle Movement Sensor

Signal

66 K140 TN/WT Fuel Quantity Actuator Control

67 K24 GY/BK Engine Speed Sensor Signal

69 K3 BK/VT Engine Speed Sensor Ground

77 K153 OR/DG Fuel Shutdown Solenoid Control

79 K126 LG Fuel Timing Solenoid Control

80 K140 TN/WT Fuel Quantity Actuator Control

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

9

ProCarManuals.com

Page 26 of 436

TEST DTCCHECKING FOR DIAGNOSTIC TROUBLE CODES

NOTE: The battery must be fully charged for any test in this manual.

1. Attempt to start the engine. Crank for up to 10 seconds if necessary.

2. Connect the DRB to the data link connector. Write down the trouble codes that are displayed.

3. If the DRB displays ``No Response'', go toTEST NS-2A.

4. If the DRB screen is blank or has a DRB error message, go toGeneral Information Section

3.5in this manual.

5. Iftrouble code messagesare displayed, refer to the trouble code list below and on the

following page for the appropriate test.

6. If there are no ECM trouble codes displayed, refer to one of the following:

For Immobilizer problems..................................................SK-1A

For Driveability problems.................................................NTC-1A

For No Start problems....................................................NS-1A

For Speed Control problems...............................................SC-1A

NOTE:For all component locations see General Information Section 4.0 in this manual.

DRB DIAGNOSTIC TROUBLE CODE (DTC) DISPLAYEDDIAGNOSTIC

TESTSCAN

TOOL

AC Control Short CircuitTC-1 P1655

A/C Control Open CircuitTC-2 P1655

A/C System Pressure Signal High Exceeded TC-3 P1695

A/C System Pressure Signal Low Exceeded TC-4 P1695

A/C System Pressure Supply High Exceeded TC-5 P1695

A/C System Pressure Supply Low Exceeded TC-6 P1695

Accelerator Pedal Sensor High Exceeded TC-7 P1515

Accelerator Pedal Sensor PlausibilityTC-7 P1515

Accelerator Pedal Sensor Pwg Plaus With Low Idle Switch TC-7 P1515

Accelerator Pedal Sensor Pwg Plaus With Potentiometer TC-7 P1515

Atmospheric Pressure Sensor SRC High Exceeded ** P1105

Atmospheric Pressure Sensor SRC Low Exceeded ** P1105

Battery Voltage SRC High Exceeded TC-14 P1600

Turbocharger Boost Sensor Signal High Exceeded TC-15 P0235

Turbocharger Boost Sensor Signal Low Exceeded TC-16 P0235

Turbocharger Boost Sensor Supply High Exceeded TC-17 P0235

Turbocharger Boost Sensor Supply Low Exceeded TC-18 P0235

Turbocharger Boost Sensor Plausibility TC-19 P0235

Brake Signal Plaus With Redundant Contact TC-20 P1703

Clutch Signal PlausibilityTC-21 P1740

Control Sleeve Sensor Signal High Exceeded TC-22 P1225

Control Sleeve Sensor Start End Pos. Not Attained TC-23 P1225

Control Sleeve Sensor Stop End Pos. Not Attained TC-24 P1225

Cruise Status Indicator Lamp Short Circuit TC-25 P1665

Diagnostic Lamp Open CircuitTC-26 P1650

Diagnostic Lamp Short CircuitTC-27 P1650

Diesel Power Relay Shuts Off Too Early TC-30 P1625

Diesel Power Relay Shuts Off Too Late TC-31 P1625

EEPROM Plausibility Checksum Error For Adj. ** P1680

EEPROM Plausibility Checksum Error in CC212 ** P1680

EEPROM Plausibility Communication with EEPROM ** P1680

EEPROM Plausibility Func. Switch Wrong or Missing ** P1680

EEPROM Plausibility Ver. Number Not Corresponding ** P1680

EGR Open CircuitTC-33 P0400

EGR Short CircuitTC-34 P0400

Engine Speed Sensor Dynamic Plausibility TC-35 P0725

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

20

ProCarManuals.com

Page 285 of 436

TEST TC-91BREPAIRING - VEHICLE SPEED SENSOR TROUBLE CODES

Perform TEST TC-91A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

USING THE DRB

START TEST RECONNECT THE VSS RAISE AND SUPPORT OSCILLOSCOPE

TC-91B. AND ECM HARNESS THE VEHICLE DRIVE FUNCTION SELECT

CONNECTORS. AXLE. "LAB SCOPE".

SET VOLTAGE RANGE USING THE

TO +10.0v. SET TIME RANGE TO OSCILLOSCOPE LEAD,

SET PROBE TO x10. 40ms/Div. BACKPROBE ECM

HARNESS CONNECTOR

FIG.1 FIG.2 CAVITY 51. FIG.3

START THE ENGINE. SHIFT TRANSMISSION

INTO FIRST GEAR

ENGAGE THE PARKING AND ALLOW THE

BRAKE. WHEELS TO ROTATE

AT IDLE SPEED.

NOTE: A VALID VSS DOES THE DRB

OBSERVE THE DRB SIGNAL WILL CYCLE DISPLAY THE 5.0 NO REPLACE THE

OSCILLOSCOPE HI TO LOW SIMILAR VOLT VSS SIGNAL VEHICLE SPEED

PATTERN. TO THE PATTERN CYCLING HI AND SENSOR.*

SHOWN IN FIGURE 2. LOW?

YES

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

279

ProCarManuals.com

Page 373 of 436

TEST NTC-12ACHECKING THE ENGINE MECHANICAL SYSTEMS

Perform TEST NTC-1A Before Proceeding

At this point in the diagnostic test procedure, you have determined that all of theengine electrical

systemsare operating as designed; therefore, theyare not the cause of the driveability problem.

The following additional items should be checked as possible mechanical causes of the problem.

1. ENGINE VALVE TIMING- must be within specifications

2. ENGINE COMPRESSION- must be within specifications

3. CAMSHAFT LOBES- check for abnormal wear

4. ENGINE SPEED SENSOR PICK-UP- check flywheel slots for debris/deterioration

5. ENGINE EXHAUST SYSTEM- must be free of any restrictions

6. ENGINE DRIVE SPROCKET- must be properly positioned

7. POWER BRAKE BOOSTER- no internal vacuum leaks

8. FUEL- must be free of contamination

9. FUEL INJECTOR- plugged or restricted injector

10. FUEL INJECTION PUMP- must be properly timed

NOTE:Always look for any Technical Service Bulletins that may relate to the problem.

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

367

ProCarManuals.com

Page 379 of 436

TEST SC-1ACHECKING SPEED CONTROL OPERATION

*Perform Verification TEST VER-3A. **Check connectors - Clean / repair as necessary.

START TEST KEY ON. WITH THE

SC-1A. DRB, SELECT

"SENSOR DISPLAY".

PRESS EACH OF THE PRESSING EACH SWITCH DID EACH SWITCH

CRUISE SWITCH SHOULD RESULT IN A PROVIDE THE NO PERFORM TEST

BUTTONS WHILE VOLTAGE INPUT SHOWN CORRECT VOLTAGE SC-2A.

OBSERVING CRUISE IN FIG.1. INPUT.

SWITCH VOLTS.

YES

WITH THE DRB, DID THE DRB INDICATE

MONITOR THE WHILE PRESSING AND THE CORRECT CHANGE NO PERFORM TEST

PRIMARY AND RELEASING THE OF STATE FROM SC-3A.

SECONDARY BRAKE BRAKE PEDAL. "RELEASED" TO

SWITCH INPUT... "PRESSED".

YES

DID THE DRB INDICATE

WITH THE DRB, WHILE PRESSING AND THE CORRECT CHANGE NO PERFORM TEST

MONITOR THE CLUTCH RELEASING THE OF STATE FROM SC-4A.

SWITCH INPUT. CLUTCH PEDAL. "RELEASED" TO

"PRESSED".

YES

WITH THE DRB,

MONITOR VEHICLE DOES THE DRB NO PERFORM TEST

SPEED WHILE DISPLAY ACCURATE SC-6A.

DRIVING THE VEHICLE SPEED?

VEHICLE.

YES

DRIVE VEHICLE AND ATTEMPT TO SET DID THE SPEED YES

GENERATE A SPEED SPEED CONTROL. CONTROL MAINTAIN TEST COMPLETED.*

ABOVE 35KM/H. SET VEHICLE SPEED?

NO

CONTINUE TEST

SC-1A ON THE

NEXT PAGE.

S

P

E

E

D

C

O

N

T

R

O

L

T

E

S

T

S

373

ProCarManuals.com