fuse CHRYSLER CARAVAN 2000 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2000, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2000Pages: 436, PDF Size: 3.4 MB

Page 9 of 436

After-Run- When fused ignition switch output is removed from the ECM cavity 47, the ECM

performs a self-diagnostic check in the following order:

1. Electrical shut-off test

2. Fuel quantity actuator test

3. Monitoring module test

4. Voltage regulator test

5. Main relay test (if tests 1-4 pass)

If any of tests 1-4 fail, the fault is stored in memory, and can be retrieved during the next ignition

cycle using the DRB.

3.2.3 Monitored Circuits

The ECM is able to monitor and identify most driveability related trouble conditions. Some circuits

are directly monitored through ECM feedback circuitry. In addition, the ECM monitors the voltage

state of some circuits and compares those states with expected values. Other systems are

monitored indirectly when the ECM conducts a rationality test to identify problems.

Although most subsystems of the powertrain control module are either directly or indirectly

monitored, there may be occasions when diagnostic trouble codes are not immediately identified.

For a trouble code to set, specific conditions must be met and unless these conditions are

encountered, a code will not set.

3.2.4 SKIS On-Board Diagnostics

The SKIS module has been programmed to transmit and monitor many different coded messages

as well as CCD Bus messages. This monitoring is called ``On-Board Diagnosis''.

Certain criteria must be met for a diagnostic trouble code to be entered into the Sentry Key

Immobilizer Module (SKIM) memory. The criteria may be a range of: input voltage, CCD Bus

messages, or coded messages to the SKIM. If all of the criteria for monitoring a circuit or function

are met and a fault is sensed, a diagnostic trouble code will be stored in the SKIM memory.

3.2.5 SKIS Overview

The Sentry Key Immobilizer System (SKIS) is an immobilizer system designed to prevent

unauthorized vehicle operation. The system consists of a Sentry Key Immobilizer Module (SKIM),

ignition key(s) equipped with a transponder chip, engine controller and body controller. When the

ignition switch is turned on, the SKIM interrogates the ignition key. If the ignition key is ªValidº the

SKIM sends a CCD Bus message to the body controller indicating the presence of a valid ignition

key. The BCM then supplies the ECM with a valid immobilizer signal allowing the engine to

continue to operate.

3.2.6 SKIS Operation

When ignition power is supplied to the SKIM, the SKIM performs an internal self-test. After the

self-test is completed, the SKIM energizes the antenna (this activates the transponder chip) and

sends a challenge to the transponder chip. The transponder chip responds to the challenge by

generating an encrypted response message using the following:

Secret Key þ This is an electronically stored value (identification number) that is unique to each

SKIS. The secret key is stored in the SKIM, BCM and all ignition key transponders.

Challenge þ This is a random number that is generated by the SKIM at each ignition key cycle.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

3

ProCarManuals.com

Page 24 of 436

²Choose the proper range and function for the measurement. Do not try voltage or current

measurements that may exceed the rated capacity.

²Do not exceed the limits shown in the table below:

FUNCTION INPUT LIMIT

Volts 0 - 500 peak volts AC

0 - 500 volts DC

Ohms (resistance)* 0 - 1.12 megohms

Frequency Measured

Frequency Generated0-10kHz

Temperature -58 - 1100É F

-50 - 600É C

* Ohms cannot be measured if voltage is

present. Ohms can be measured only in a

non-powered circuit.

²Voltage between any terminal and ground must not exceed 500v DC or 500v peak AC.

²Use caution when measuring voltage above 25v DC or 25v AC.

²The circuit being tested must be protected by a 10A fuse or circuit breaker.

²Use the low current shunt to measure circuits up to 10A. Use the high current clamp to

measure circuits exceeding 10A.

²When testing for the presence of voltage or current, make sure the meter is functioning

correctly. Take a reading of a known voltage or current before accepting a zero reading.

²When measuring current, connect the meter in series with the load.

²Disconnect the live test lead before disconnecting the common test lead.

5.3 Warnings

5.3.1 Vehicle Damage Warnings

Before disconnecting any control module, make sure the ignition is ``off''. Failure to do so could

damage the module.

When testing voltage or continuity at any control module, use the terminal side (not the wire end)

of the connector. Do not probe a wire through the insulation; this will damage it and eventually

cause it to fail because of corrosion.

Be careful when performing electrical tests so as to prevent accidental shorting of terminals. Such

mistakes can damage fuses or components. Also, other codes could be set, making diagnosis of

the original problem more difficult.

5.3.2 Road Testing a Complaint Vehicle

Some complaints will require a test drive as part of the repair verification procedure. The purpose

of the test drive is to try to duplicate the diagnostic code or symptom condition.

CAUTION: Before road testing a vehicle, be sure that all components are reassembled.

During the test drive, do not try to read the DRB screen while in motion. Do not hang the

DRB from the rear view mirror or operate it yourself. Have an assistant available to operate

the DRB.

G

E

N

E

R

A

L

I

N

F

O

R

M

A

T

I

O

N

18

ProCarManuals.com

Page 95 of 436

TEST TC-20ACONTINUED - REPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT

CONTACT

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TEST TC-20A KEY OFF.

CONTINUED FROM DISCONNECT THE

THE PREVIOUS BRAKE LAMP SWITCH

PAGE. HARNESS

CONNECTOR.**

USING A VOLTMETER,

PROBE BRAKE SWITCH IS THE VOLTAGE NO REPAIR OPEN FUSED

HARNESS CONNECTOR ABOVE 9.0 VOLTS? BATTERY SUPPLY

CAVITY 6. CIRCUIT.*

FIG.1

YES

CONNECT A JUMPER

WIRE ACROSS THE DID THE DRB CHANGE YES ADJUST OR REPLACE

BRAKE LAMP FROM "RELEASED" TO THE BRAKE LAMP

HARNESS CONNECTOR "PRESSED"? SWITCH.*

CAV 5 AND 6. FIG.1

NO

KEY ON. USING A AT THE BRAKE LAMP REPAIR THE PRIMARY

VOLTMETER, MEASURE SWITCH HARNESS IS THE VOLTAGE YES BRAKE LAMP SWITCH

THE PRIMARY SWITCH CONNECTOR CAVITY 5. ABOVE 1.0 VOLT? SIGNAL CIRCUIT FOR

SIGNAL VOLTAGE... A SHORT TO

FIG.1 VOLTAGE.*

NO

KEY OFF. USING AN OHMMETER, REPAIR THE OPEN

DISCONNECT THE ECM MEASURE RESISTANCE IS THE RESISTANCE NO PRIMARY BRAKE LAMP

HARNESS OF THE PRIMARY BRAKE BELOW 5.0 OHMS? SWITCH SIGNAL

CONNECTORS.** LAMP SWITCH SIGNAL CIRCUIT.*

CIRCUIT. FIG.2

YES

REPLACE THE ENGINE

CONTROL MODULE.* SW

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

89

ProCarManuals.com

Page 97 of 436

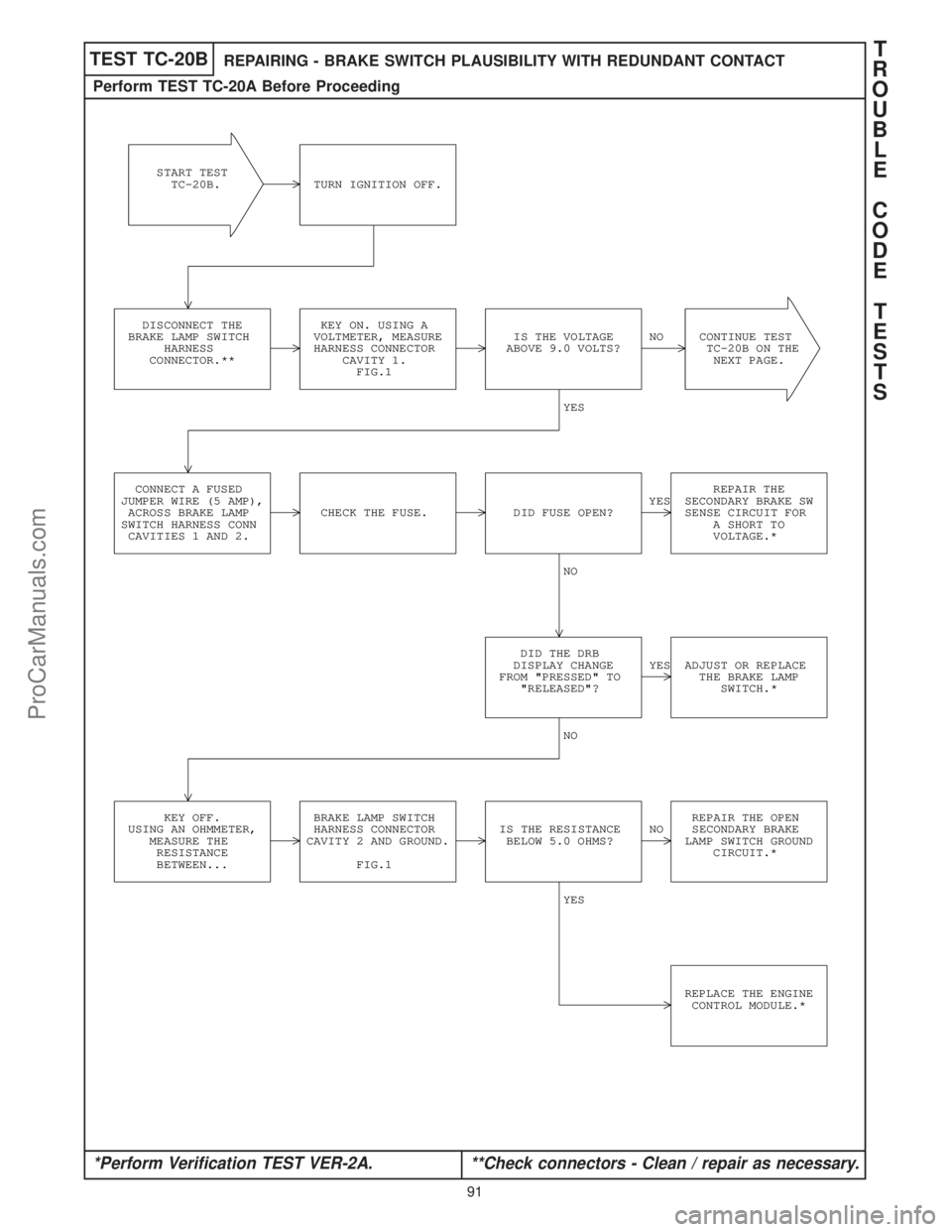

TEST TC-20BREPAIRING - BRAKE SWITCH PLAUSIBILITY WITH REDUNDANT CONTACT

Perform TEST TC-20A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

START TEST

TC-20B. TURN IGNITION OFF.

DISCONNECT THE KEY ON. USING A

BRAKE LAMP SWITCH VOLTMETER, MEASURE IS THE VOLTAGE NO CONTINUE TEST

HARNESS HARNESS CONNECTOR ABOVE 9.0 VOLTS? TC-20B ON THE

CONNECTOR.** CAVITY 1. NEXT PAGE.

FIG.1

YES

CONNECT A FUSEDREPAIR THE

JUMPER WIRE (5 AMP),YES SECONDARY BRAKE SW

ACROSS BRAKE LAMP CHECK THE FUSE. DID FUSE OPEN? SENSE CIRCUIT FOR

SWITCH HARNESS CONN A SHORT TO

CAVITIES 1 AND 2. VOLTAGE.*

NO

DID THE DRB

DISPLAY CHANGE YES ADJUST OR REPLACE

FROM "PRESSED" TO THE BRAKE LAMP

"RELEASED"? SWITCH.*

NO

KEY OFF. BRAKE LAMP SWITCH REPAIR THE OPEN

USING AN OHMMETER, HARNESS CONNECTOR IS THE RESISTANCE NO SECONDARY BRAKE

MEASURE THE CAVITY 2 AND GROUND. BELOW 5.0 OHMS? LAMP SWITCH GROUND

RESISTANCE CIRCUIT.*

BETWEEN... FIG.1

YES

REPLACE THE ENGINE

CONTROL MODULE.*

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

91

ProCarManuals.com

Page 279 of 436

TEST TC-91ACONTINUED - REPAIRING - VEHICLE SPEED SENSOR TROUBLE CODES

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

KEY OFF.

TEST TC-91A

CONTINUED FROM DISCONNECT THE VSS

PREVIOUS PAGE. HARNESS

CONNECTOR.**

USING A VOLTMETER, REPAIR THE

MEASURE THE FUSED IS THE VOLTAGE NO IGNITION SWITCH

TURN IGNITION ON. IGNITION SWITCH ABOVE 10.0 VOLTS? OUTPUT CIRCUIT FOR

OUTPUT CKT. AN OPEN OR SHORT

FIG.1 TO GROUND.*

YES

USING A VOLTMETER,

MEASURE THE VSS IS THE VOLTAGE NO CONTINUE TEST

SIGNAL CIRCUIT. BETWEEN TC-91A ON THE

4.0 AND 6.0 VOLTS? NEXT PAGE.

FIG.1

YES

KEY OFF. USING AN OHMMETER,

MEASURE RESISTANCE IS THE RESISTANCE NO REPAIR THE OPEN

DISCONNECT THE ECM OF SENSOR GROUND CKT BELOW 5.0 OHMS? SENSOR GROUND

HARNESS BETWEEN ECM AND VSS. CIRCUIT.*

CONNECTORS.** FIG.2

YES

PERFORM TEST

TC-91B.

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

273

ProCarManuals.com

Page 333 of 436

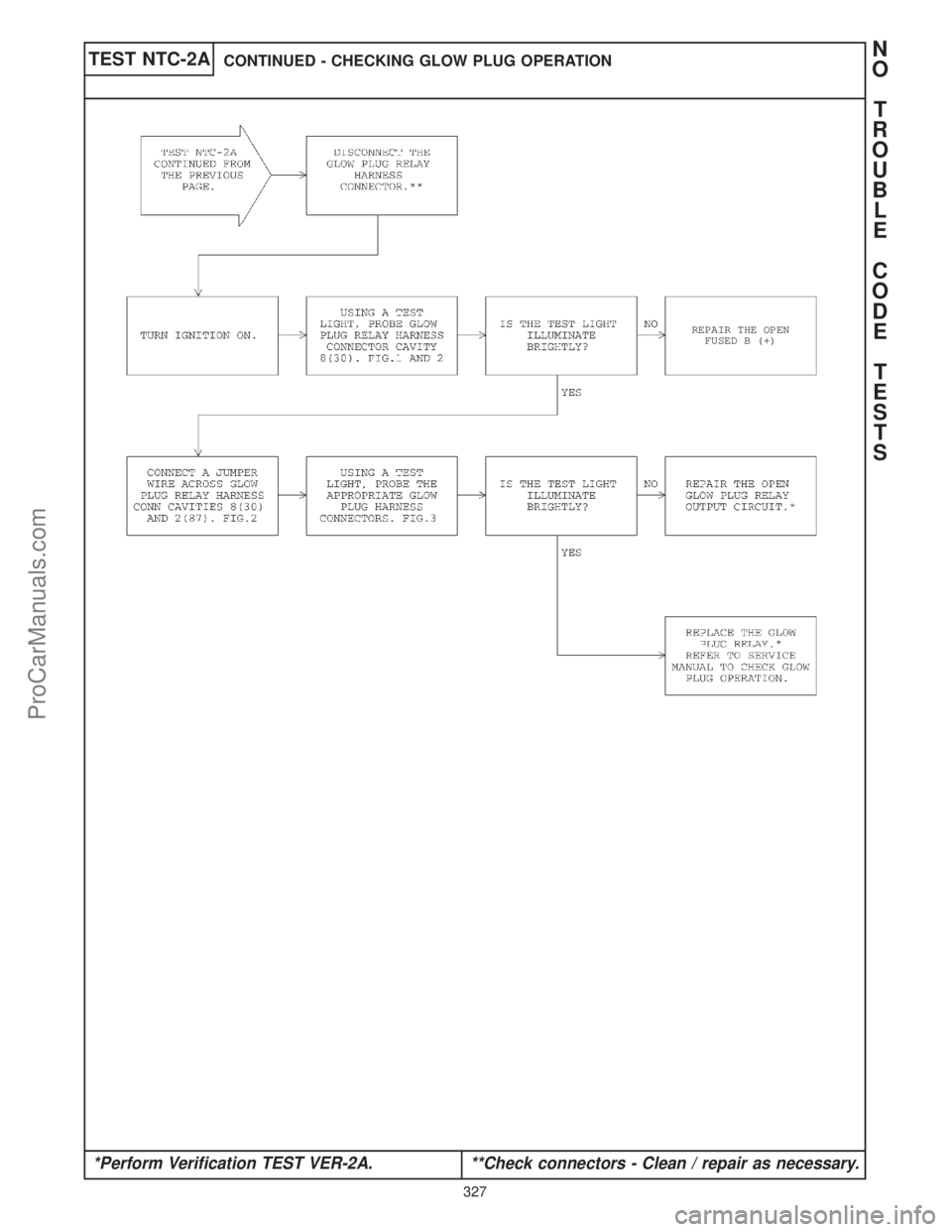

TEST NTC-2ACONTINUED - CHECKING GLOW PLUG OPERATION

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

REPAIR THE OPEN

FUSED B (+)

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

327

ProCarManuals.com

Page 337 of 436

TEST NTC-4ACHECKING THE PCM POWER AND GROUNDS

Perform TEST NTC-1A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

NOTE: THE BATTERY

START TEST MUST BE FULLY

NTC-4A. CHARGED TO PERFORM

THIS TEST.

TURN IGNITION OFF. WITH AN OHMMETER,

DISCONNECT THE ECM MEASURE ECM IS THE RESISTANCE NO REPAIR THE OPEN

HARNESS HARNESS CONNECTOR BELOW 5.0 OHMS FOR GROUND CIRCUIT.*

CONNECTORS.** CAVITIES 1 AND 27 ALL MEASUREMENTS?

TO GROUND. FIG.1

YES

PROBE DIESEL POWER

USE A TEST LIGHT RELAY CONNECTOR DOES THE TEST NO REPAIR OPEN

IN THE FOLLOWING CAVITY (PDC) 3(30). LIGHT ILLUMINATE BATTERY SUPPLY TO

STEPS. BRIGHTLY? RELAY.

FIG.2

YES

REMOVE THE DIESEL 3(30) AND 5(87). DOES THE TEST

POWER RELAY. CONNECT WITH A TEST LIGHT, LIGHT ILLUMINATE NO REPAIR OPEN DIESEL

A JUMPER WIRE ACROSS PROBE ECM HARNESS BRIGHTLY FOR EACH POWER RELAY OUTPUT

RELAY CONNECTOR CONNECTOR CAVITIES CAVITY? CIRCUIT.*

(PDC) CAVITIES... 2 AND 28. FIG.2

YES

WITH A TEST LIGHT,

PROBE ECM HARNESS DOES THE TEST NO REPAIR THE OPEN

TURN IGNITION ON. CONNECTOR CAVITY 47. LIGHT ILLUMINATE FUSED IGNITION

BRIGHTLY? SWITCH CIRCUIT.*

FIG.1

YES

ECM GROUND

AND POWER

CIRCUITS ARE

OK. TEST

PASSED.

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

331

ProCarManuals.com

Page 349 of 436

TEST NTC-10ACHECKING THE FUEL HEATER AND THE CRANKCASE VENT HEATER

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TURN IGNITION OFF.

START TEST YES PERFORM TEST

NTC-10A. INSPECT FUSE #16 IS THE FUSE OPEN? NTC-10B.

IN THE PDC.

NO

USING A TEST

REMOVE THE FUEL LIGHT, PROBE RELAY IS THE TEST LIGHT NO REPLACE THE POWER

HEATER RELAY.** CONNECTOR CAVITY ON? DISTRIBUTION

30 (IN PDC). CENTER.*.

FIG. 1

YES

USING A TEST REPAIR THE FUSED

LIGHT, PROBE FUSED IS THE TEST LIGHT NO IGNITION SWITCH

TURN IGNITION ON. IGNITION SW OUTPUT ON? OUTPUT CIRCUIT FOR

CKT (IN PDC). AN OPEN OR SHORT

FIG. 1 TO GROUND.*

YES

WITH IGNITION RELAY CONNECTOR

STILL ON, CONNECT CAVITIES 85 AND 86 IS THE TEST LIGHT NO REPAIR THE OPEN

A TEST LIGHT (IN PDC). ON? RELAY GROUND

ACROSS...CIRCUIT.*

FIG. 1

YES

KEY OFF. DISCONNECT THE

FUEL HEATER AND CONTINUE TEST

INSTALL THE FUEL CRANKCASE VENT TURN IGNITION ON. NTC-10A ON THE

HEATER RELAY. HEATER HARNESS NEXT PAGE.

CONNECTORS.**

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

343

ProCarManuals.com

Page 357 of 436

TEST NTC-10BCHECKING THE FUEL HEATER AND THE CRANKCASE VENT HEATER

Perform TEST NTC-10A Before Proceeding

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

START TEST

NTC-10B. TURN IGNITION OFF.

REPLACE FUSE #16.

NO

TURN IGNITION ON IS THE FUSE OPEN? TEST COMPLETE.*

AND INSPECT FUSE

#16.

YES

CONNECT A JUMPER

REMOVE FUEL HEATER WIRE ACROSS FUEL

RELAY. HEATER RELAY

CAVITIES 30 & 87

(IN PDC). FIG. 1

REPLACE FUSE #6 NO REPLACE THE FUEL

IS THE FUSE OPEN? HEATER RELAY.*

TURN IGNITION ON.

YES

KEY OFF. REPLACE FUSE #16 AND

TURN IGNITION ON. NO REPLACE THE FUEL

DISCONNECT THE IS THE FUSE OPEN? HEATER.*

FUEL HEATER INSPECT FUSE #16.

HARNESS CONNECTOR.

YES

KEY OFF. REPLACE FUSE #16 AND

DISCONNECT THE TURN IGNITION ON. NO REPLACE THE

CRANKCASE VENT IS THE FUSE OPEN? CRANKCASE VENT

HEATER HARNESS INSPECT FUSE #16. HEATER.*

CONNECTOR.

YES

REPAIR THE FUEL

HEATER RELAY

OUTPUT CIRCUIT FOR

A SHORT TO

GROUND.*

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

351

ProCarManuals.com

Page 365 of 436

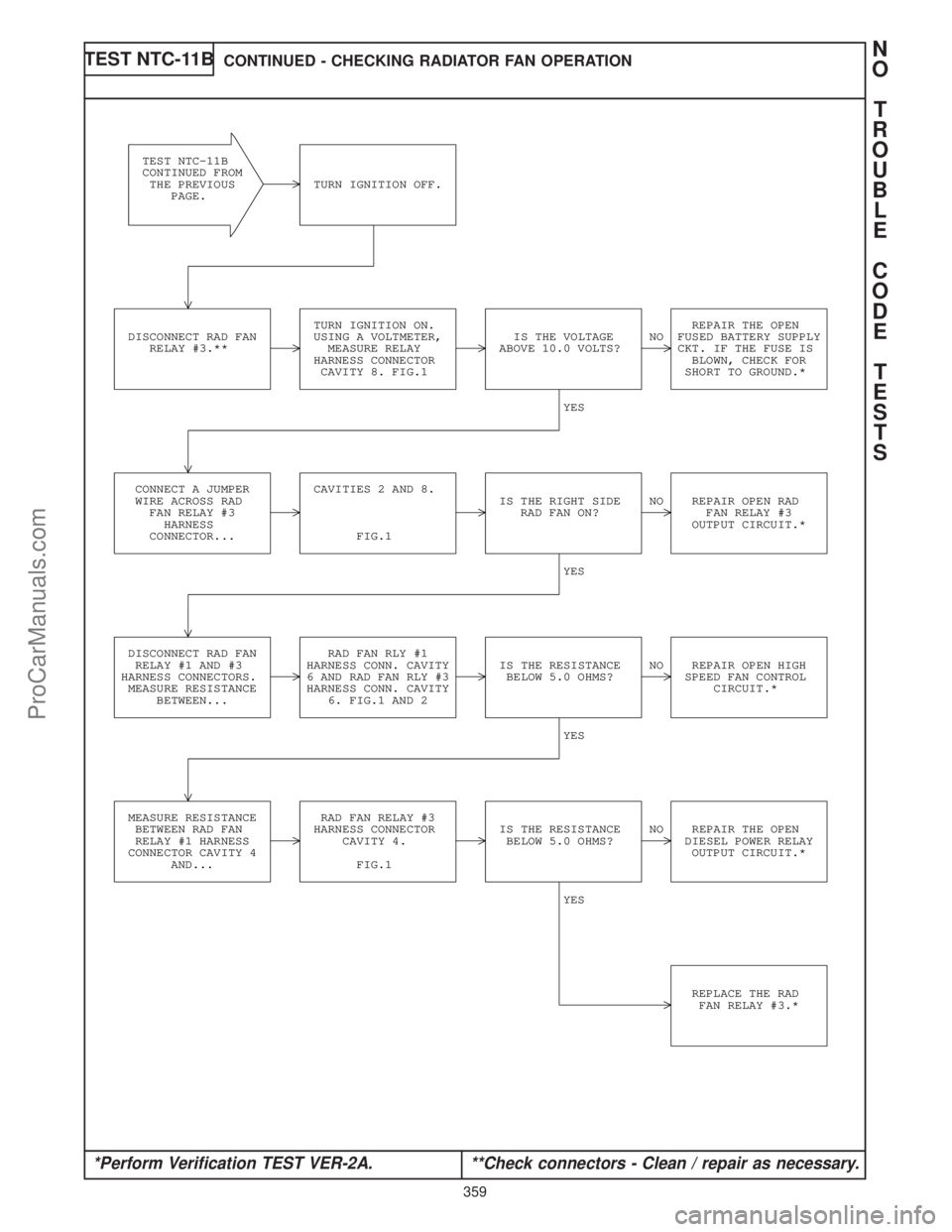

TEST NTC-11BCONTINUED - CHECKING RADIATOR FAN OPERATION

*Perform Verification TEST VER-2A. **Check connectors - Clean / repair as necessary.

TEST NTC-11B

CONTINUED FROM

THE PREVIOUS TURN IGNITION OFF.

PAGE.

TURN IGNITION ON. REPAIR THE OPEN

DISCONNECT RAD FAN USING A VOLTMETER, IS THE VOLTAGE NO FUSED BATTERY SUPPLY

RELAY #3.** MEASURE RELAY ABOVE 10.0 VOLTS? CKT. IF THE FUSE IS

HARNESS CONNECTOR BLOWN, CHECK FOR

CAVITY 8. FIG.1 SHORT TO GROUND.*

YES

CONNECT A JUMPER CAVITIES 2 AND 8.

WIRE ACROSS RAD IS THE RIGHT SIDE NO REPAIR OPEN RAD

FAN RELAY #3 RAD FAN ON? FAN RELAY #3

HARNESSOUTPUT CIRCUIT.*

CONNECTOR... FIG.1

YES

DISCONNECT RAD FAN RAD FAN RLY #1

RELAY #1 AND #3 HARNESS CONN. CAVITY IS THE RESISTANCE NO REPAIR OPEN HIGH

HARNESS CONNECTORS. 6 AND RAD FAN RLY #3 BELOW 5.0 OHMS? SPEED FAN CONTROL

MEASURE RESISTANCE HARNESS CONN. CAVITY CIRCUIT.*

BETWEEN... 6. FIG.1 AND 2

YES

MEASURE RESISTANCE RAD FAN RELAY #3

BETWEEN RAD FAN HARNESS CONNECTOR IS THE RESISTANCE NO REPAIR THE OPEN

RELAY #1 HARNESS CAVITY 4. BELOW 5.0 OHMS? DIESEL POWER RELAY

CONNECTOR CAVITY 4OUTPUT CIRCUIT.*

AND... FIG.1

YES

REPLACE THE RAD

FAN RELAY #3.*

N

O

T

R

O

U

B

L

E

C

O

D

E

T

E

S

T

S

359

ProCarManuals.com