wheel CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 225 of 2399

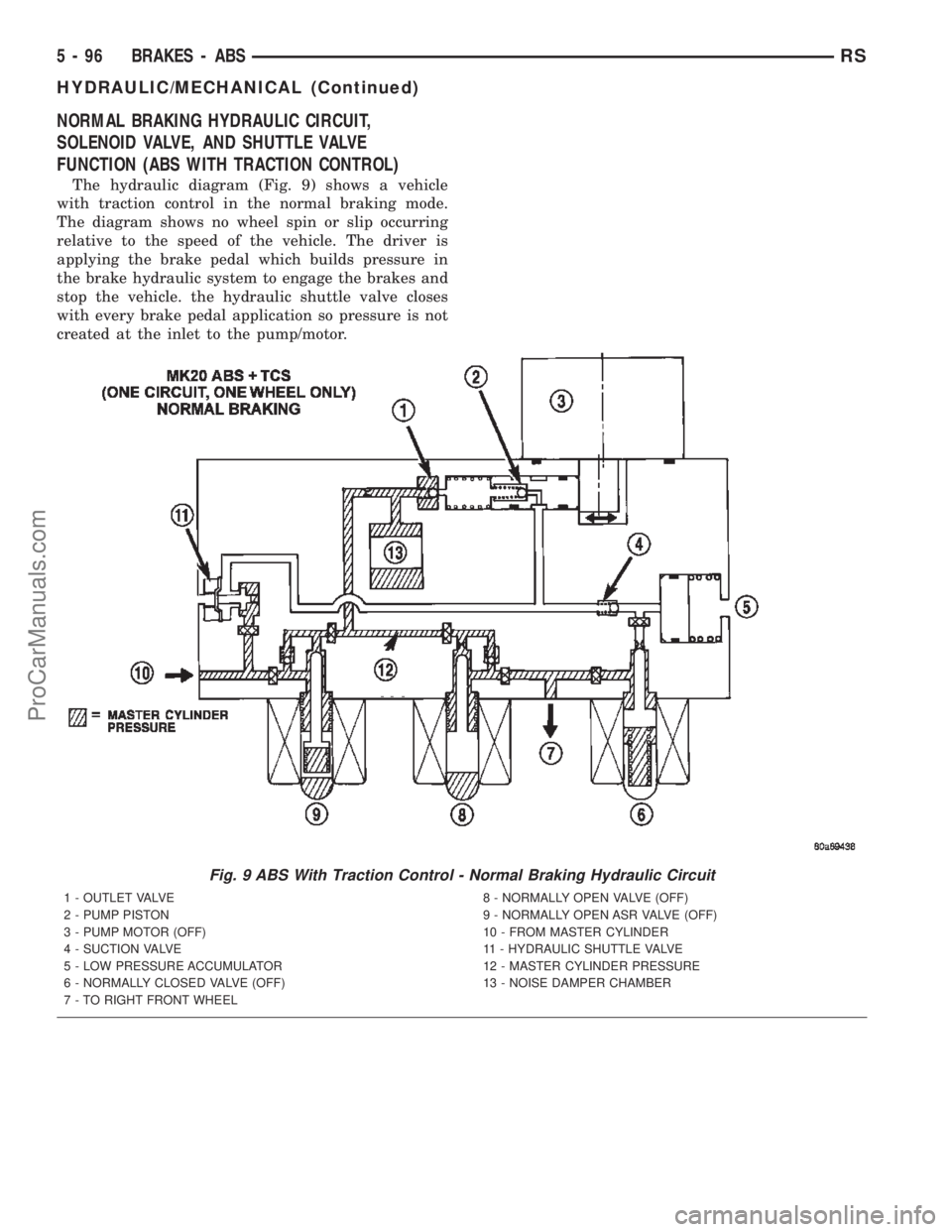

NORMAL BRAKING HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 9) shows a vehicle

with traction control in the normal braking mode.

The diagram shows no wheel spin or slip occurring

relative to the speed of the vehicle. The driver is

applying the brake pedal which builds pressure in

the brake hydraulic system to engage the brakes and

stop the vehicle. the hydraulic shuttle valve closes

with every brake pedal application so pressure is not

created at the inlet to the pump/motor.

Fig. 9 ABS With Traction Control - Normal Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (OFF)

4 - SUCTION VALVE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (OFF)

7 - TO RIGHT FRONT WHEEL8 - NORMALLY OPEN VALVE (OFF)

9 - NORMALLY OPEN ASR VALVE (OFF)

10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - MASTER CYLINDER PRESSURE

13 - NOISE DAMPER CHAMBER

5 - 96 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 226 of 2399

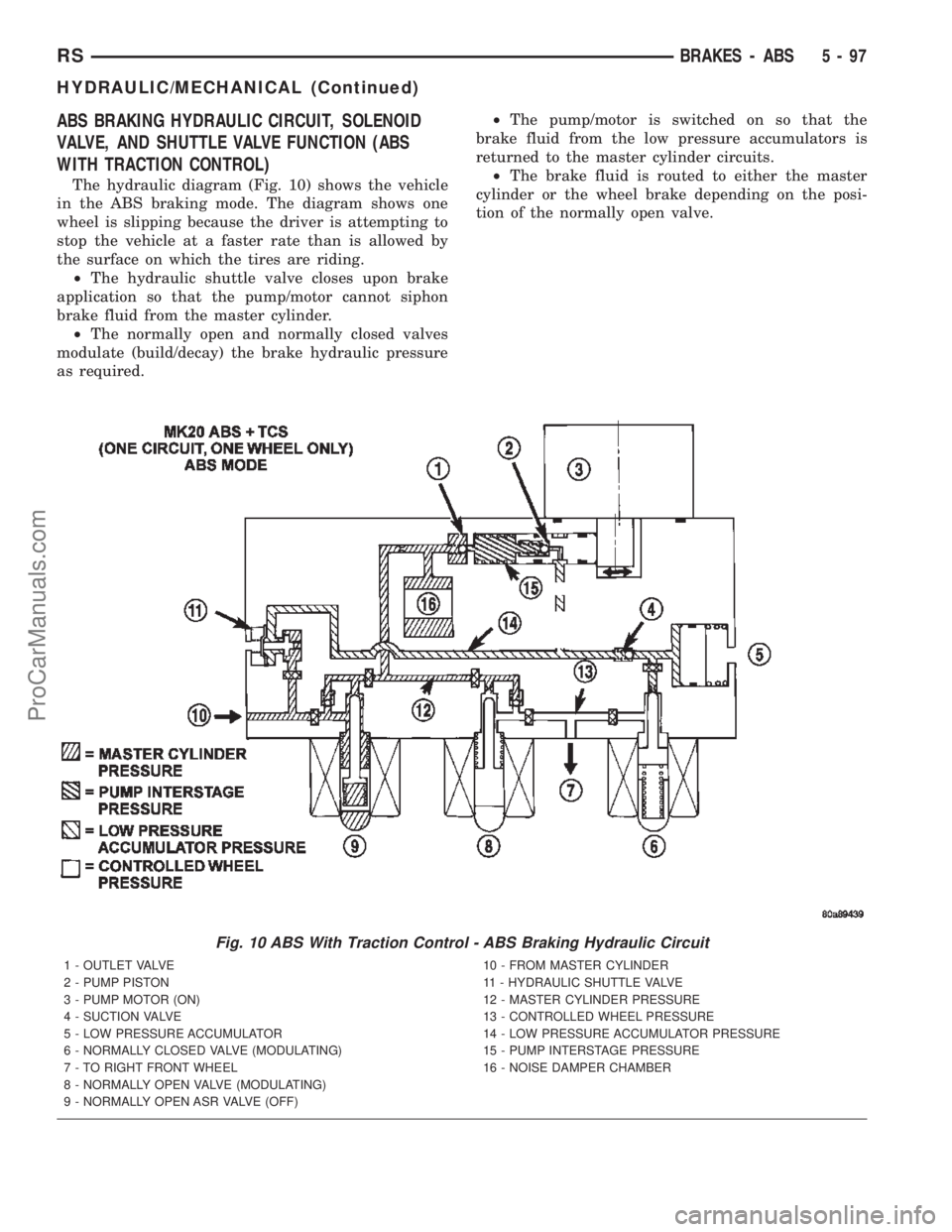

ABS BRAKING HYDRAULIC CIRCUIT, SOLENOID

VALVE, AND SHUTTLE VALVE FUNCTION (ABS

WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 10) shows the vehicle

in the ABS braking mode. The diagram shows one

wheel is slipping because the driver is attempting to

stop the vehicle at a faster rate than is allowed by

the surface on which the tires are riding.

²The hydraulic shuttle valve closes upon brake

application so that the pump/motor cannot siphon

brake fluid from the master cylinder.

²The normally open and normally closed valves

modulate (build/decay) the brake hydraulic pressure

as required.²The pump/motor is switched on so that the

brake fluid from the low pressure accumulators is

returned to the master cylinder circuits.

²The brake fluid is routed to either the master

cylinder or the wheel brake depending on the posi-

tion of the normally open valve.

Fig. 10 ABS With Traction Control - ABS Braking Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - SUCTION VALVE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL

8 - NORMALLY OPEN VALVE (MODULATING)

9 - NORMALLY OPEN ASR VALVE (OFF)10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - MASTER CYLINDER PRESSURE

13 - CONTROLLED WHEEL PRESSURE

14 - LOW PRESSURE ACCUMULATOR PRESSURE

15 - PUMP INTERSTAGE PRESSURE

16 - NOISE DAMPER CHAMBER

RSBRAKES - ABS5-97

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 227 of 2399

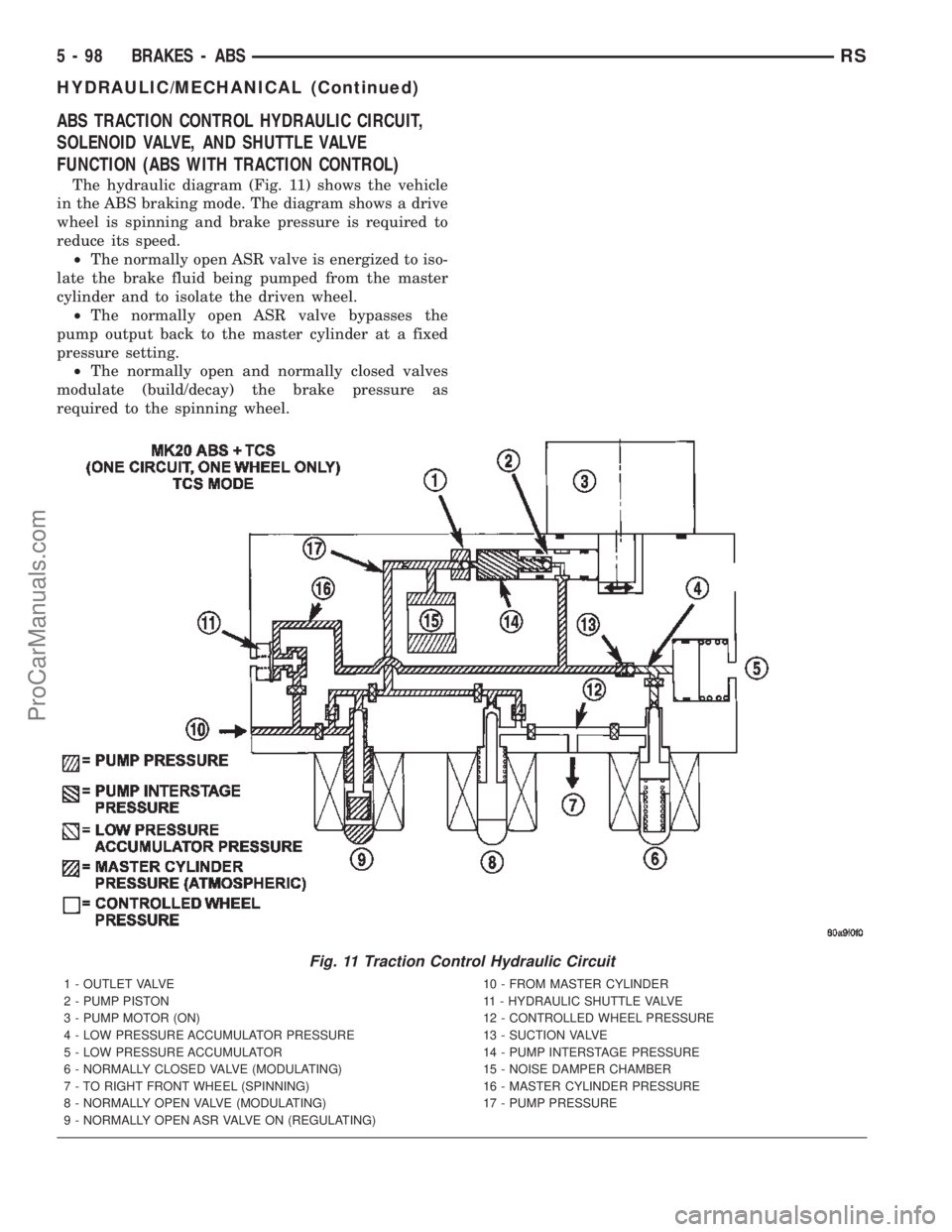

ABS TRACTION CONTROL HYDRAULIC CIRCUIT,

SOLENOID VALVE, AND SHUTTLE VALVE

FUNCTION (ABS WITH TRACTION CONTROL)

The hydraulic diagram (Fig. 11) shows the vehicle

in the ABS braking mode. The diagram shows a drive

wheel is spinning and brake pressure is required to

reduce its speed.

²The normally open ASR valve is energized to iso-

late the brake fluid being pumped from the master

cylinder and to isolate the driven wheel.

²The normally open ASR valve bypasses the

pump output back to the master cylinder at a fixed

pressure setting.

²The normally open and normally closed valves

modulate (build/decay) the brake pressure as

required to the spinning wheel.

Fig. 11 Traction Control Hydraulic Circuit

1 - OUTLET VALVE

2 - PUMP PISTON

3 - PUMP MOTOR (ON)

4 - LOW PRESSURE ACCUMULATOR PRESSURE

5 - LOW PRESSURE ACCUMULATOR

6 - NORMALLY CLOSED VALVE (MODULATING)

7 - TO RIGHT FRONT WHEEL (SPINNING)

8 - NORMALLY OPEN VALVE (MODULATING)

9 - NORMALLY OPEN ASR VALVE ON (REGULATING)10 - FROM MASTER CYLINDER

11 - HYDRAULIC SHUTTLE VALVE

12 - CONTROLLED WHEEL PRESSURE

13 - SUCTION VALVE

14 - PUMP INTERSTAGE PRESSURE

15 - NOISE DAMPER CHAMBER

16 - MASTER CYLINDER PRESSURE

17 - PUMP PRESSURE

5 - 98 BRAKES - ABSRS

HYDRAULIC/MECHANICAL (Continued)

ProCarManuals.com

Page 228 of 2399

HCU (HYDRAULIC CONTROL

UNIT)

DESCRIPTION

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 22). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

The HCU on a vehicle equipped with ABS and

traction control has a valve block housing that is

approximately 1 inch longer on the low pressure fluid

accumulators side than a HCU on a vehicle that is

equipped with only ABS.

For more information, (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ICU (INTEGRATED CON-

TROL UNIT) - DESCRIPTION)

OPERATION

For information on the operation of the HCU as a

whole, refer to Hydraulic Circuits And Valve Opera-

tion which can be found elsewhere in this section.

For information on the operation of the components

within the HCU, refer to the following three topics.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet valves. The inlet valves are spring-loaded in

the open position and the outlet valves are spring-

loaded in the closed position during normal braking.

The fluid is allowed to flow from the master cylinder

to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

On vehicles with traction control, there is an extra

set of valves and solenoids. The ASR valves, mounted

in the HCU valve block, are normally in the open

position and close only when the traction control is

applied.

These isolator valves are used to isolate the rear

(non-driving) wheels of the vehicle from the hydraulicpressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is being

applied so the rear wheels do not drag. For more

information, refer to Traction Control System in this

section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU±one

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 5 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

On ABS-only vehicles, there is a mini-accumulator

on the secondary hydraulic circuit that protects the

master cylinder seals during an ABS stop, and there

is a noise dampening chamber on the primary circuit.

On ABS with traction control vehicles, there are

two noise dampening chambers in the HCU.

PUMP/MOTOR

There are two pump assemblies in the HCUÐone

for the primary hydraulic circuit and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor. This DC-type motor is inte-

gral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, one piston

draws fluid from the accumulators, and the opposing

piston pumps fluid to the master cylinder circuits.

When the antilock stop is complete, the pump/motor

drains the accumulators.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

RSBRAKES - ABS5-99

ProCarManuals.com

Page 230 of 2399

(7) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder once the

brake tubes are removed from the HCU.

CAUTION: Do not apply a 12±volt power source to

any terminals of the 24-way CAB connector when

disconnected.

(8) Disconnect the wiring harness connector from

the speed control servo.

(9) Remove the speed control servo mounting nuts

and move the servo out of the way.

(10) Disconnect the 24±way connector from the

CAB. To disconnect the 24±way connector, grasp the

lock on the 24±way connector and pull it as far up as

possible. This will unlock the 24±way connector from

the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.

(11) Thoroughly clean all surfaces of the ICU and

brake tube nuts. Use only a solvent such as Mopart

Brake Parts Cleaner or equivalent to clean the ICU.

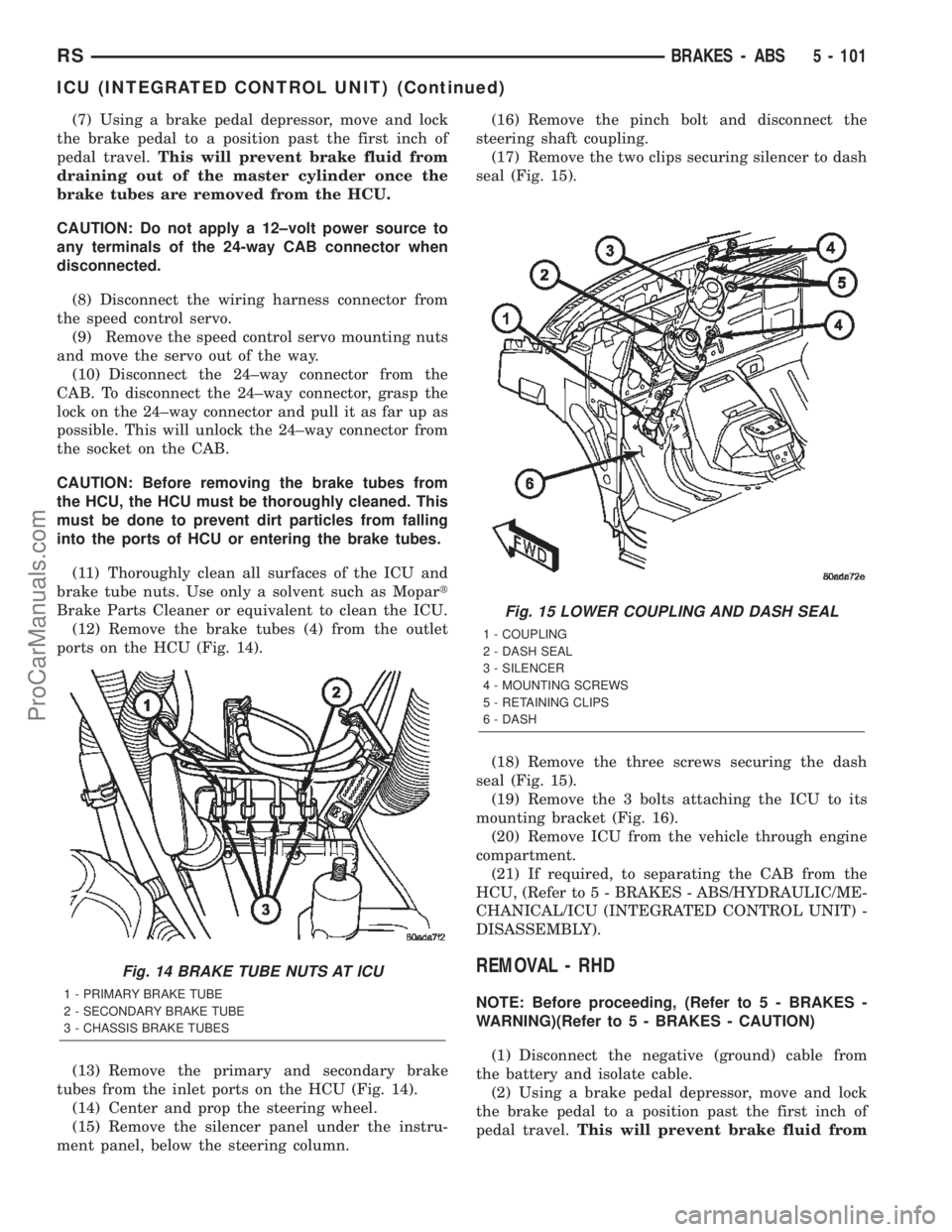

(12) Remove the brake tubes (4) from the outlet

ports on the HCU (Fig. 14).

(13) Remove the primary and secondary brake

tubes from the inlet ports on the HCU (Fig. 14).

(14) Center and prop the steering wheel.

(15) Remove the silencer panel under the instru-

ment panel, below the steering column.(16) Remove the pinch bolt and disconnect the

steering shaft coupling.

(17) Remove the two clips securing silencer to dash

seal (Fig. 15).

(18) Remove the three screws securing the dash

seal (Fig. 15).

(19) Remove the 3 bolts attaching the ICU to its

mounting bracket (Fig. 16).

(20) Remove ICU from the vehicle through engine

compartment.

(21) If required, to separating the CAB from the

HCU, (Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/ICU (INTEGRATED CONTROL UNIT) -

DISASSEMBLY).

REMOVAL - RHD

NOTE: Before proceeding, (Refer to 5 - BRAKES -

WARNING)(Refer to 5 - BRAKES - CAUTION)

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

Fig. 14 BRAKE TUBE NUTS AT ICU

1 - PRIMARY BRAKE TUBE

2 - SECONDARY BRAKE TUBE

3 - CHASSIS BRAKE TUBES

Fig. 15 LOWER COUPLING AND DASH SEAL

1 - COUPLING

2 - DASH SEAL

3 - SILENCER

4 - MOUNTING SCREWS

5 - RETAINING CLIPS

6 - DASH

RSBRAKES - ABS5 - 101

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 232 of 2399

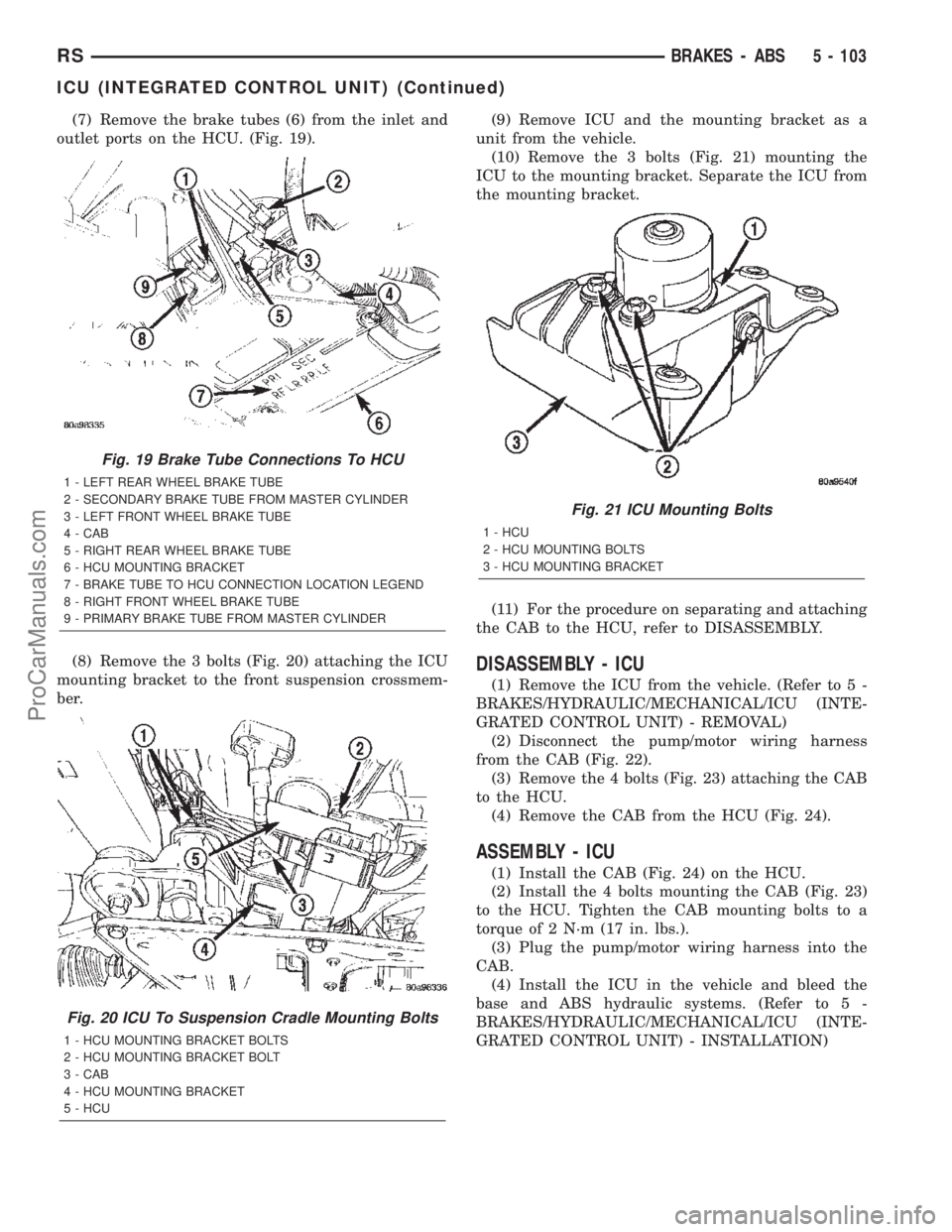

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

(8) Remove the 3 bolts (Fig. 20) attaching the ICU

mounting bracket to the front suspension crossmem-

ber.(9) Remove ICU and the mounting bracket as a

unit from the vehicle.

(10) Remove the 3 bolts (Fig. 21) mounting the

ICU to the mounting bracket. Separate the ICU from

the mounting bracket.

(11) For the procedure on separating and attaching

the CAB to the HCU, refer to DISASSEMBLY.

DISASSEMBLY - ICU

(1) Remove the ICU from the vehicle. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - REMOVAL)

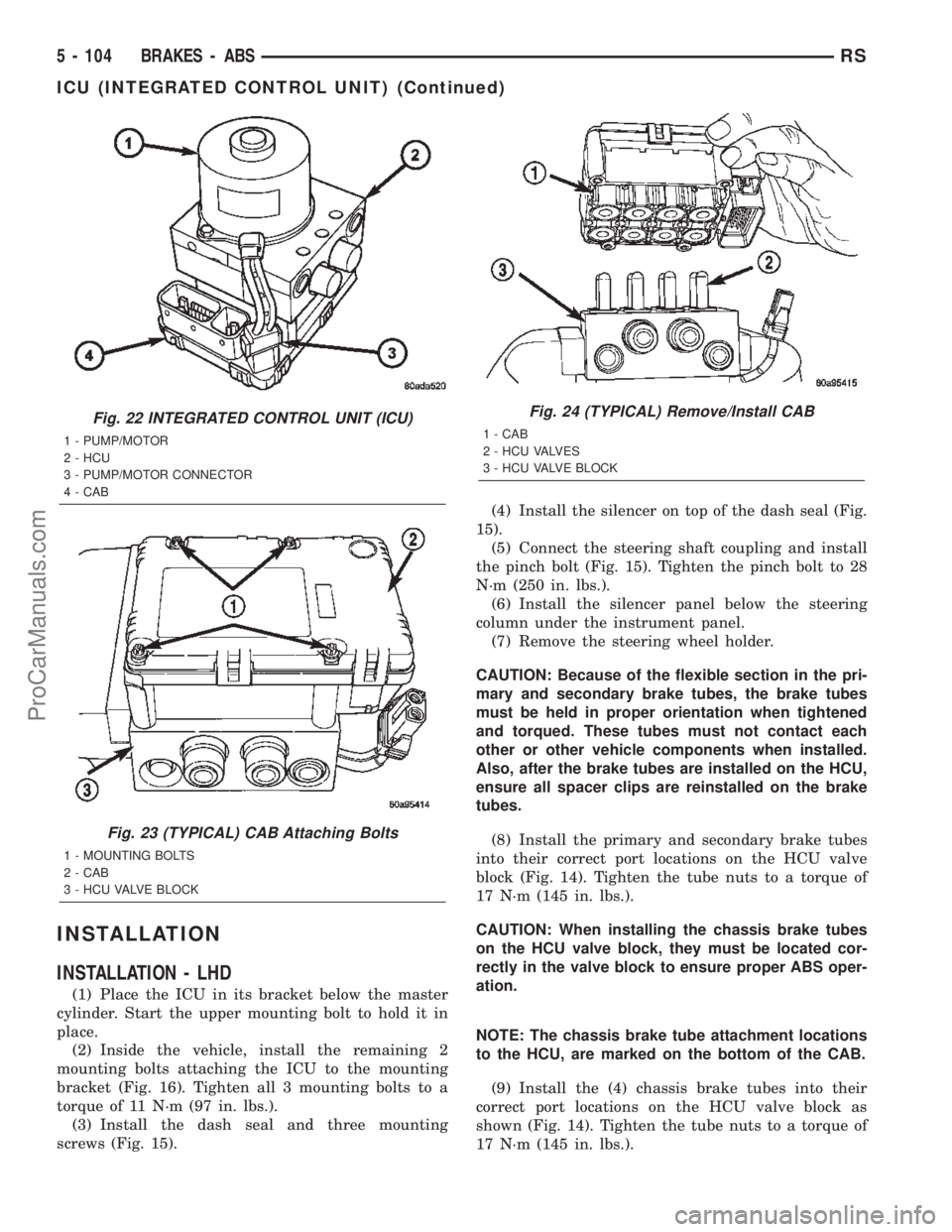

(2) Disconnect the pump/motor wiring harness

from the CAB (Fig. 22).

(3) Remove the 4 bolts (Fig. 23) attaching the CAB

to the HCU.

(4) Remove the CAB from the HCU (Fig. 24).

ASSEMBLY - ICU

(1) Install the CAB (Fig. 24) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 23)

to the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB.

(4) Install the ICU in the vehicle and bleed the

base and ABS hydraulic systems. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - INSTALLATION)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

Fig. 20 ICU To Suspension Cradle Mounting Bolts

1 - HCU MOUNTING BRACKET BOLTS

2 - HCU MOUNTING BRACKET BOLT

3 - CAB

4 - HCU MOUNTING BRACKET

5 - HCU

Fig. 21 ICU Mounting Bolts

1 - HCU

2 - HCU MOUNTING BOLTS

3 - HCU MOUNTING BRACKET

RSBRAKES - ABS5 - 103

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 233 of 2399

INSTALLATION

INSTALLATION - LHD

(1) Place the ICU in its bracket below the master

cylinder. Start the upper mounting bolt to hold it in

place.

(2) Inside the vehicle, install the remaining 2

mounting bolts attaching the ICU to the mounting

bracket (Fig. 16). Tighten all 3 mounting bolts to a

torque of 11 N´m (97 in. lbs.).

(3) Install the dash seal and three mounting

screws (Fig. 15).(4) Install the silencer on top of the dash seal (Fig.

15).

(5) Connect the steering shaft coupling and install

the pinch bolt (Fig. 15). Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(6) Install the silencer panel below the steering

column under the instrument panel.

(7) Remove the steering wheel holder.

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, the brake tubes

must be held in proper orientation when tightened

and torqued. These tubes must not contact each

other or other vehicle components when installed.

Also, after the brake tubes are installed on the HCU,

ensure all spacer clips are reinstalled on the brake

tubes.

(8) Install the primary and secondary brake tubes

into their correct port locations on the HCU valve

block (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the CAB.

(9) Install the (4) chassis brake tubes into their

correct port locations on the HCU valve block as

shown (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

Fig. 22 INTEGRATED CONTROL UNIT (ICU)

1 - PUMP/MOTOR

2 - HCU

3 - PUMP/MOTOR CONNECTOR

4 - CAB

Fig. 23 (TYPICAL) CAB Attaching Bolts

1 - MOUNTING BOLTS

2 - CAB

3 - HCU VALVE BLOCK

Fig. 24 (TYPICAL) Remove/Install CAB

1 - CAB

2 - HCU VALVES

3 - HCU VALVE BLOCK

5 - 104 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 236 of 2399

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH

SYSTEM.............................3

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT.......................5

DIAGNOSIS AND TESTING - CLUTCH

COVER AND DISC RUNOUT..............6

DIAGNOSIS AND TESTING - CLUTCH

CHATTER COMPLAINTS.................6

SPECIAL TOOLS - T850 TRANSAXLE........6

CLUTCH RELEASE LEVER AND BEARING

REMOVAL.............................6

INSTALLATION..........................7

MASTER CYLINDER - RHD

REMOVAL.............................8INSTALLATION..........................8

MASTER CYLINDER - LHD

REMOVAL.............................9

INSTALLATION.........................10

MODULAR CLUTCH ASSY - 2.4L GAS

REMOVAL.............................11

INSTALLATION.........................11

SLAVE CYLINDER

REMOVAL.............................11

INSTALLATION.........................11

CLUTCH DISC AND PRESSURE PLATE - 2.5L

TD

REMOVAL.............................12

INSTALLATION.........................12

FLYWHEEL

REMOVAL.............................13

INSTALLATION.........................13

CLUTCH

DESCRIPTION

CLUTCH COMPONENTS

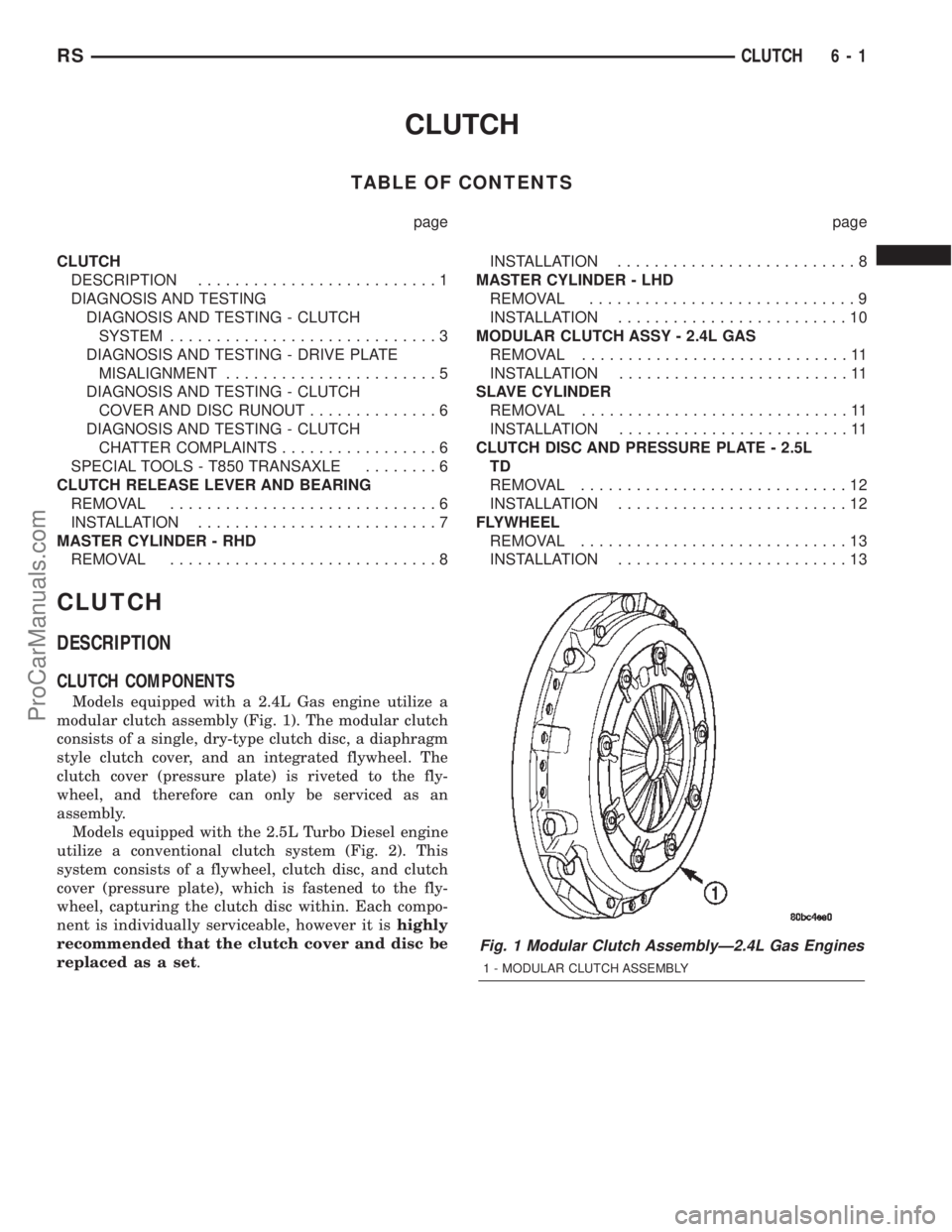

Models equipped with a 2.4L Gas engine utilize a

modular clutch assembly (Fig. 1). The modular clutch

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover (pressure plate) is riveted to the fly-

wheel, and therefore can only be serviced as an

assembly.

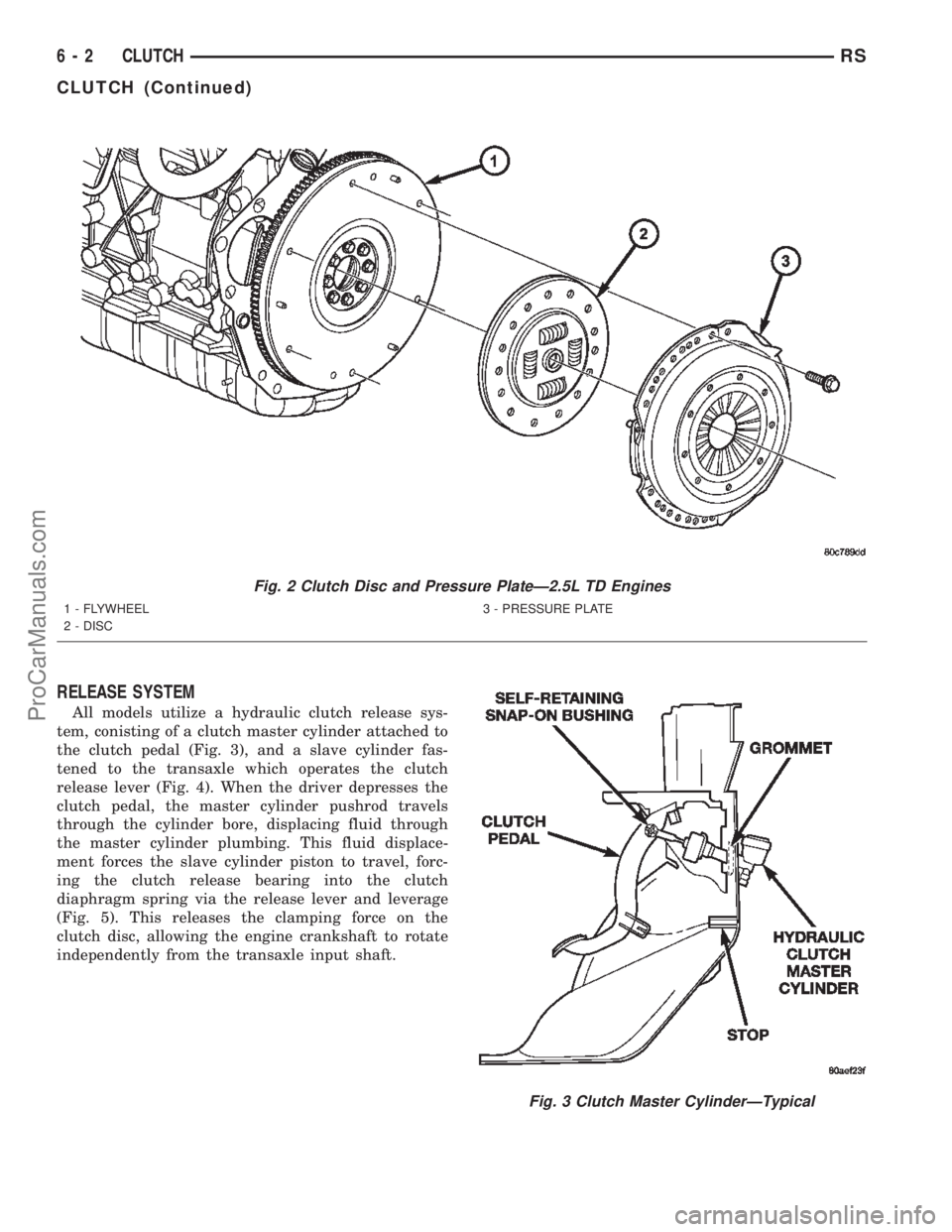

Models equipped with the 2.5L Turbo Diesel engine

utilize a conventional clutch system (Fig. 2). This

system consists of a flywheel, clutch disc, and clutch

cover (pressure plate), which is fastened to the fly-

wheel, capturing the clutch disc within. Each compo-

nent is individually serviceable, however it ishighly

recommended that the clutch cover and disc be

replaced as a set.

Fig. 1 Modular Clutch AssemblyÐ2.4L Gas Engines

1 - MODULAR CLUTCH ASSEMBLY

RSCLUTCH6-1

ProCarManuals.com

Page 237 of 2399

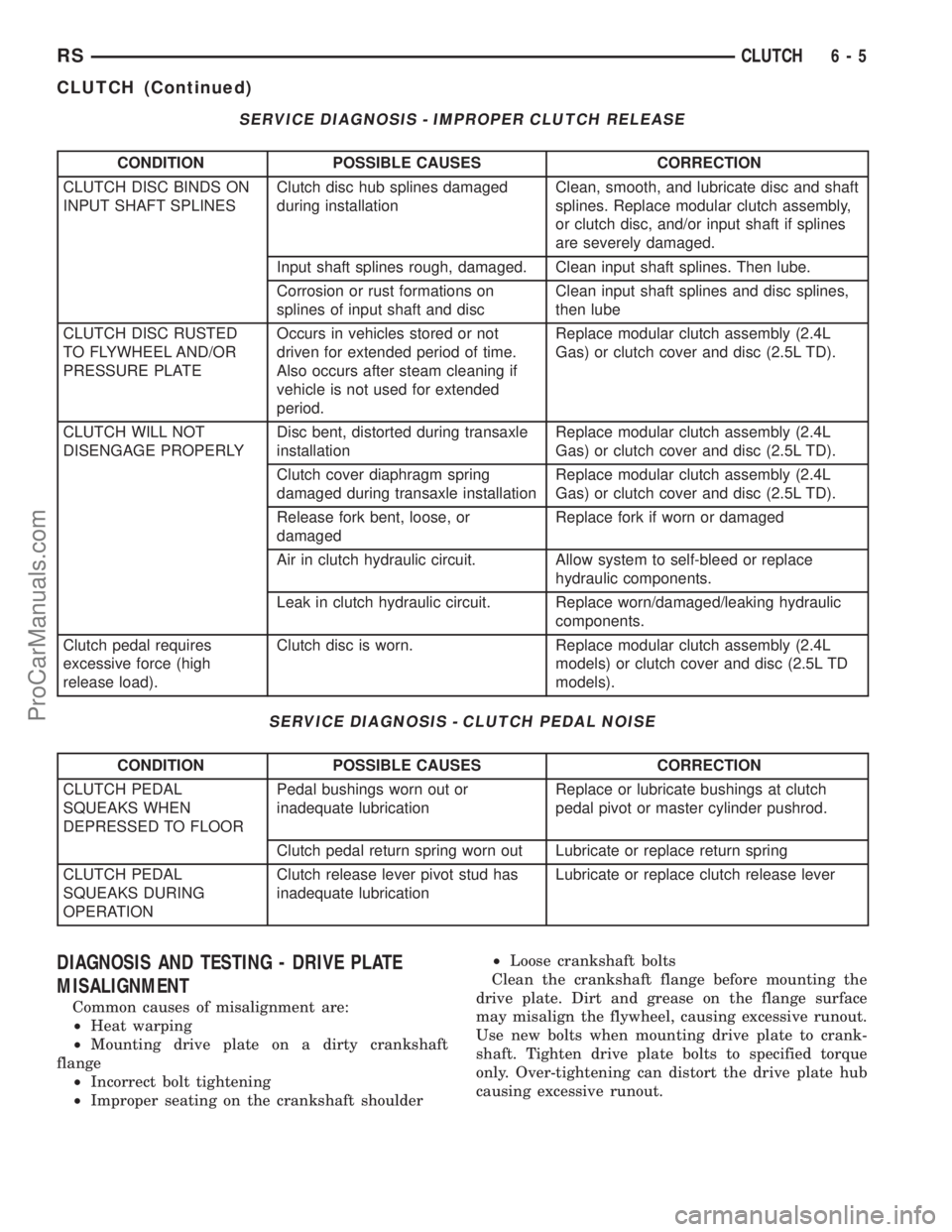

RELEASE SYSTEM

All models utilize a hydraulic clutch release sys-

tem, conisting of a clutch master cylinder attached to

the clutch pedal (Fig. 3), and a slave cylinder fas-

tened to the transaxle which operates the clutch

release lever (Fig. 4). When the driver depresses the

clutch pedal, the master cylinder pushrod travels

through the cylinder bore, displacing fluid through

the master cylinder plumbing. This fluid displace-

ment forces the slave cylinder piston to travel, forc-

ing the clutch release bearing into the clutch

diaphragm spring via the release lever and leverage

(Fig. 5). This releases the clamping force on the

clutch disc, allowing the engine crankshaft to rotate

independently from the transaxle input shaft.

Fig. 2 Clutch Disc and Pressure PlateÐ2.5L TD Engines

1 - FLYWHEEL

2 - DISC3 - PRESSURE PLATE

Fig. 3 Clutch Master CylinderÐTypical

6 - 2 CLUTCHRS

CLUTCH (Continued)

ProCarManuals.com

Page 240 of 2399

SERVICE DIAGNOSIS - IMPROPER CLUTCH RELEASE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC BINDS ON

INPUT SHAFT SPLINESClutch disc hub splines damaged

during installationClean, smooth, and lubricate disc and shaft

splines. Replace modular clutch assembly,

or clutch disc, and/or input shaft if splines

are severely damaged.

Input shaft splines rough, damaged. Clean input shaft splines. Then lube.

Corrosion or rust formations on

splines of input shaft and discClean input shaft splines and disc splines,

then lube

CLUTCH DISC RUSTED

TO FLYWHEEL AND/OR

PRESSURE PLATEOccurs in vehicles stored or not

driven for extended period of time.

Also occurs after steam cleaning if

vehicle is not used for extended

period.Replace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

CLUTCH WILL NOT

DISENGAGE PROPERLYDisc bent, distorted during transaxle

installationReplace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Clutch cover diaphragm spring

damaged during transaxle installationReplace modular clutch assembly (2.4L

Gas) or clutch cover and disc (2.5L TD).

Release fork bent, loose, or

damagedReplace fork if worn or damaged

Air in clutch hydraulic circuit. Allow system to self-bleed or replace

hydraulic components.

Leak in clutch hydraulic circuit. Replace worn/damaged/leaking hydraulic

components.

Clutch pedal requires

excessive force (high

release load).Clutch disc is worn. Replace modular clutch assembly (2.4L

models) or clutch cover and disc (2.5L TD

models).

SERVICE DIAGNOSIS - CLUTCH PEDAL NOISE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH PEDAL

SQUEAKS WHEN

DEPRESSED TO FLOORPedal bushings worn out or

inadequate lubricationReplace or lubricate bushings at clutch

pedal pivot or master cylinder pushrod.

Clutch pedal return spring worn out Lubricate or replace return spring

CLUTCH PEDAL

SQUEAKS DURING

OPERATIONClutch release lever pivot stud has

inadequate lubricationLubricate or replace clutch release lever

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

RSCLUTCH6-5

CLUTCH (Continued)

ProCarManuals.com