coolant CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 2303 of 2399

PLUMBING - FRONT

WARNING

WARNING

WARNING: DO NOT OPERATE DCHA IN AN

ENCLOSED AREA SUCH AS A GARAGE THAT

DOES NOT HAVE EXHAUST VENTILATION FACILI-

TIES. ALWAYS VENT THE DCHA'S EXHAUST WHEN

OPERATING THE DCHA. FAILURE TO FOLLOW

THESE INSTRUCTION MAY RESULT IN PERSONAL

INJURY OR DEATH.

ALLOW THE DCHA ASSEMBLY TO COOL BEFORE

PERFORMING A COMPONENT INSPECTION/RE-

PAIR/REPLACEMENT. FAILURE TO FOLLOW THESE

INSTRUCTIONS MY RESULT IN PERSONAL INJURY.

VERIFY THAT ALL DCHA FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE THIS PROCEDURE.

WARNING

WARNING:: THE ENGINE COOLING SYSTEM IS

DESIGNED TO DEVELOP INTERNAL PRESSURES

OF 97 TO 123 KILOPASCALS (14 TO 18 POUNDS

PER SQUARE INCH). DO NOT REMOVE OR

LOOSEN THE COOLANT PRESSURE CAP, CYLIN-

DER BLOCK DRAIN PLUGS, RADIATOR DRAIN,

RADIATOR HOSES, HEATER HOSES, OR HOSE

CLAMPS WHILE THE SYSTEM IS HOT AND UNDER

PRESSURE. FAILURE TO OBSERVE THIS WARNING

CAN RESULT IN SERIOUS BURNS FROM THE

HEATED ENGINE COOLANT. ALLOW THE VEHICLE

TO COOL FOR A MINIMUM OF 15 MINUTES

BEFORE OPENING THE COOLING SYSTEM FOR

SERVICE.

WARNING: THE ENGINE COOLING SYSTEM CON-

TAINS ANTIFREEZE. ANTIFREEZE IS AN ETHYLENE

GLYCOL BASED COOLANT AND IS HARMFUL IF

SWALLOWED OR IF THE VAPORS ARE INHALED. IF

SWALLOWED, DRINK TWO GLASSES OF WATER

AND INDUCE VOMITING. IF VAPORS ARE INHALED,

MOVE TO AN AREA FOR FRESH AIR. SEEK MEDI-

CAL ATTENTION IMMEDIATELY. DO NOT STORE IN

OPEN OR UNMARKED CONTAINERS. WASH SKIN

AND CLOTHING THOROUGHLY AFTER COMING IN

CONTACT WITH ETHYLENE GLYCOL. KEEP OUT

OF REACH OF CHILDREN.

WARNING: DISPOSE OF ETHYLENE GLYCOL

BASED COOLANT PROPERLY. CONTACT YOURDEALER OR A LOCAL GOVERNMENT AGENCY FOR

THE LOCATION OF AN APPROVED ETHYLENE GLY-

COL COLLECTION AND/OR RECYCLING CENTER IN

YOUR AREA.

WARNING - A/C PLUMBING

WARNING:: THE AIR CONDITIONING SYSTEM CON-

TAINS REFRIGERANT UNDER HIGH PRESSURE.

SEVERE PERSONAL INJURY MAY RESULT FROM

IMPROPER SERVICE PROCEDURES. REPAIRS

SHOULD ONLY BE PERFORMED BY QUALIFIED

SERVICE PERSONNEL.

WARNING: AVOID BREATHING THE REFRIGERANT

AND REFRIGERANT OIL VAPOR OR MIST. EXPO-

SURE MAY IRRITATE THE EYES, NOSE, AND/OR

THROAT. WEAR EYE PROTECTION WHEN SERVIC-

ING THE AIR CONDITIONING REFRIGERANT SYS-

TEM. SERIOUS EYE INJURY CAN RESULT FROM

DIRECT CONTACT WITH THE REFRIGERANT. IF

EYE CONTACT OCCURS, SEEK MEDICAL ATTEN-

TION IMMEDIATELY.

WARNING: DO NOT EXPOSE THE REFRIGERANT

TO OPEN FLAME. POISONOUS GAS IS CREATED

WHEN REFRIGERANT IS BURNED. AN ELEC-

TRONIC LEAK DETECTOR IS RECOMMENDED.

WARNING: IF ACCIDENTAL SYSTEM DISCHARGE

OCCURS, VENTILATE THE WORK AREA BEFORE

RESUMING SERVICE. LARGE AMOUNTS OF

REFRIGERANT RELEASED IN A CLOSED WORK

AREA WILL DISPLACE THE OXYGEN AND CAUSE

SUFFOCATION.

WARNING: THE EVAPORATION RATE OF R-134a

REFRIGERANT AT AVERAGE TEMPERATURE AND

ALTITUDE IS EXTREMELY HIGH. AS A RESULT,

ANYTHING THAT COMES IN CONTACT WITH THE

REFRIGERANT WILL FREEZE. ALWAYS PROTECT

THE SKIN OR DELICATE OBJECTS FROM DIRECT

CONTACT WITH THE REFRIGERANT.

WARNING: THE R-134a SERVICE EQUIPMENT OR

THE VEHICLE REFRIGERANT SYSTEM SHOULD

NOT BE PRESSURE TESTED OR LEAK TESTED

WITH COMPRESSED AIR. SOME MIXTURES OF AIR

AND R-134a HAVE BEEN SHOWN TO BE COMBUS-

TIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS, AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

24 - 60 PLUMBING - FRONTRS

ProCarManuals.com

Page 2316 of 2399

(14) Remove the two screws that secure the expan-

sion valve to the evaporator tube tapping plate.

(15) Disconnect the HVAC wire harness connector

for the evaporator temperature sensor from the sen-

sor on the top of the expansion valve.

(16) Remove the expansion valve from the evapo-

rator inlet and outlet tube fittings.

(17) Remove the seals from the evaporator inlet

and outlet tube fittings and discard.

(18) Install plugs in, or tape over the opened evap-

orator inlet and outlet tube fittings and both expan-

sion valve ports.

INSTALLATION

(1) Remove the tape or plugs from the evaporator

inlet and outlet tube fittings and both ports on the

back of the expansion valve.

(2) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the evaporator

inlet and outlet tube fittings.

(3) Position the expansion valve onto the evapora-

tor inlet and outlet tube fittings.

(4) Install and tighten the two screws that secure

the expansion valve to the evaporator tube tapping

plate plate. Tighten the screws to 11 N´m (97 in.

lbs.).

(5) Reconnect the HVAC wire harness connector

for the evaporator temperature sensor to the sensor

connector receptacle on the top of the expansion

valve.

(6) Remove the tape or plugs from the front liquid

line rear section and suction line fittings for the

expansion valve and both ports on the front of the

expansion valve.

(7) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the front liquid

line rear section and suction line fittings for the

expansion valve.

(8) Reconnect the liquid line and suction line fit-

tings to the expansion valve.

(9) Install and tighten the nut that secures the

suction line and liquid line fittings to the stud on the

expansion valve. Tighten the nut to 23 N´m (17 ft.

lbs.).

(10) Remove the tape or plugs from the liquid line

rear section fitting for the filter-drier and the filter-

drier outlet port.

(11) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(12) Reconnect the liquid line fitting to the filter-

drier outlet port on the top of the filter-drier.

(13) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (18 in. lbs.).(14) Reconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer to the

transducer on the front liquid line rear section.

(15) Reconnect the drain tube to the wiper module

drain on the right side of the engine compartment.

(16) Reinstall the air cleaner housing into the

right side of the engine compartment.

(17) Reconnect the battery negative cable.

(18) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(19) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

HEATER CORE

DESCRIPTION

The heater core is located in the distribution hous-

ing of the heater-A/C unit, under the instrument

panel. It is a heat exchanger made of rows of tubes

and fins. One end of the core is fitted with a molded

plastic tank that includes integral heater core inlet

and outlet ports. The removable heater core tubes

are held in place these ports by a sealing plate

secured with a screw to the heater core tank. This

removable heater core tube arrangement allows the

heater core to be serviced without removing the heat-

er-A/C unit housing from the vehicle. The heater core

cannot be repaired and, if faulty or damaged, it must

be replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend air door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the heater-A/C unit housing is directed through the

heater core.

RSPLUMBING - FRONT24-73

EXPANSION VALVE (Continued)

ProCarManuals.com

Page 2317 of 2399

REMOVAL

REMOVAL- HEATER CORE EXTENSION TUBES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Disconnect and isolate the battery negative

cable.

(3) Disconnect the heater hoses from the heater

hose tubes. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/HEATER HOSE -

REMOVAL).

(4) Remove the silencer from beneath the driver

side end of the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL SILENCER - REMOVAL).

(5) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 15).

(6) Pull the heater core shield rearward far enough

to disengage the two location tabs that position the

front of the shield to the receptacles in the two lower

finger formations of the evaporator housing near the

dash panel.

(7) Remove the heater core shield from the distri-

bution housing.

(8) Take the proper precautions to protect the car-

peting below the heater core from spilled engine cool-

ant and have absorbent toweling readily available to

clean up any spills.

(9) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports (Fig. 16).(10) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.

(11) Install plugs in, or tape over the opened

heater core tube fittings and both heater core ports.

(12) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

(13) Pull both heater core tubes simultaneously

slightly away from the distribution housing and rear-

Fig. 15 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 16 Heater Core Tubes

1 - SEAL

2 - HEATER CORE TUBES

3 - SCREW

4 - HEATER CORE

5 - DISTRIBUTION HOUSING

6 - SEALING PLATE

24 - 74 PLUMBING - FRONTRS

HEATER CORE (Continued)

ProCarManuals.com

Page 2318 of 2399

ward far enough to disengage the engine compart-

ment ends of the tubes from the dash panel seal.

(14) Remove the heater core tubes and sealing

plate as a unit from beneath the instrument panel.

(15) Use absorbent toweling to clean up any

engine coolant spills from the preceding operation.

REMOVAL - HEATER CORE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Disconnect and isolate the battery negative

cable.

(3) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(4) Remove the brake lamp switch from its mount-

ing bracket. (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(5) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm.

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER - REMOV-

AL).

(6) Remove the three screws that secure the heater

core shield to the left end of the HVAC distribution

housing (Fig. 17).

(7) Pull the heater core shield rearward far enough

to disengage the two location tabs that position the

front of the shield to the receptacles in the two lower

finger formations of the evaporator housing near the

dash panel.(8) Remove the heater core shield from the distri-

bution housing.

(9) Take the proper precautions to protect the car-

peting below the heater core from spilled engine cool-

ant and have absorbent toweling readily available to

mop up any spills.

(10) Remove the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports (Fig. 18).

Fig. 17 Heater Core Shield

1 - HEATER/ AIR CONDITIONER HOUSING

2 - HEATER CORE SHIELD

3 - DISTRIBUTION HOUSING

4 - SCREWS (3)

5 - LOCATION TABS (2)

Fig. 18 Heater Core

1 - SEALING PLATE

2 - SCREW

3 - SCREWS (2)

4 - HEATER CORE

5 - HEATER CORE TUBES

RSPLUMBING - FRONT24-75

HEATER CORE (Continued)

ProCarManuals.com

Page 2319 of 2399

(11) Push both heater core tubes simultaneously

toward the dash panel far enough to disengage their

fittings from the heater core supply and return ports.

(12) Install plugs in, or tape over the opened

heater core tube fittings and both heater core ports.

(13) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation.

(14) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

(15) While pulling the accelerator pedal upward

(Fig. 19) and pushing the brake pedal downward

(Fig. 20) far enough for clearance, pull the heater

core out of the distribution housing.(16) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation. Also, if

the heater core was leaking, use absorbent toweling

and reach into the heater core opening to mop up

any residual engine coolant within the distribution

housing.

INSTALLATION

INSTALLATION- HEATER CORE EXTENSION

TUBES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the plugs or tape from both heater core

tube fittings and both heater core ports.

(2) Position the heater core tubes and sealing plate

as a unit beneath the instrument panel.

(3) Align the engine compartment ends of both

heater core tubes with the openings in the dash

panel seal and push them simultaneously forward

through the seal far enough to engage the heater

core ends of the tubes with the heater core supply

and return ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

(5) The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes as

required so that the sealing plate fits flush against

the heater core supply and return ports, which indi-

cates that the tubes are properly indexed.

Fig. 19 Accelerator Pedal

1 - SLIDE HEATER CORE PAST ACCELERATOR PEDAL

Fig. 20 Brake Pedal

1 - SLIDE HEATER CORE PAST BRAKE PEDAL

2 - DEPRESS BRAKE PEDAL

24 - 76 PLUMBING - FRONTRS

HEATER CORE (Continued)

ProCarManuals.com

Page 2322 of 2399

CAUTION:

When removing the heater hose from the heater

core or supply and return tube nipples, DO NOT

apply excessive pressure. Excessive pressure may

damage or deform the nipples and/or the heater

core causing an engine coolant leak.(3) After the clamp has been moved, grasp the end

of the hose firmly and carefully twist the hose back

and forth while pulling it away from the barbed end

of the nipple. Repeat this procedure at the opposite

end of the hose being removed. If this procedure is

not successful in removing the hose from the nipple,

carefully make a parallel cut through the hose where

it is engaged on the nipple and peel the hose off of

the nipple. This method of removal will require

heater hose replacement.

INSTALLATION

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines, while the

3.3L and 3.8L engines have unique heater return

plumbing on the engine for models with or without

an optional engine oil cooler. There are also unique

plumbing configurations at the heater core for mod-

els with or without the optional rear heater and air

conditioner. All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose toward the center of the hose being

installed. Release the clamp when it is near the cen-

ter of the hose.

(2) Grasp one end of the heater hose being

installed firmly and carefully twist the hose back and

forth while pushing it over from the barbed end of

the nipple. Repeat this procedure at the opposite end

of the hose being installed.

(3) Using spring tension clamp pliers, compress

and slide the clamps that secure each end of the

heater hose over the tube or nipple. Release the

clamp when it is over the tube or nipple.

(4) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

Fig. 24 Heater Return - 3.3/3.8L Engine w/o Oil

Cooler

1 - WATER PUMP RETURN NIPPLE

2 - HEATER RETURN TUBE & HOSE

3 - SCREW

4 - SCREW

Fig. 25 Heater Return - 3.3/3.8L Engine w/Oil Cooler

1 - ENGINE INLET NIPPLE

2 - HEATER RETURN TUBE & HOSE

3 - SCREW

4 - SCREW

5 - OIL COOLER

6 - HEATER RETURN HOSE

RSPLUMBING - FRONT24-79

HEATER HOSE (Continued)

ProCarManuals.com

Page 2323 of 2399

HEATER HOSES - DIESEL

SUPPLEMENTAL HEATER -

BUX

REMOVAL

(1) Elevate vehicle on a lift taking note of the

exhaust tube flexible section.

(2) Drain cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(3) Lower heater unit from vehicle(Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/HEATER UNIT - REMOVAL).

NOTE: Complete removal of cabin heater from vehi-

cle is not required, lowering unit allows easier

access to coolant line clamps.

(4) Remove clamps from both flexible coolant line

ends.

(5) Remove both lines from vehicle.

NOTE: If either line is damaged it is recommended

that both flexible lines be replaced.

INSTALLATION

(1) Install both flexible coolant lines to the heater

unit and install clamps.

(2) Install flexible coolant lines to the coolant pipes

and install clamps.

(3) Install heater unit into vehicle(Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/HEATER UNIT - INSTALLATION).

(4) Lower vehicle.

(5) Refill cooling system(Refer to 7 - COOLING -

STANDARD PROCEDURE).

(6) Verify operation of heater unit.

HEATER PIPES - DIESEL

SUPPLEMENTAL HEATER -

BUX

REMOVAL

CAUTION: Allow cooling system to cool completely

before removing radiator cap or draining cooling

system. Injury could result is system is opened

while system coolant is hot and under pressure.

NOTE: Steel heater lines from engine compartment

to heater unit are part of an assembly that includes

the air intake pipe. If the heater lines or air intake

pipe require removal or replacement the entire

assembly must be removed or replaced.

(1) Open hood.

(2) Drain the cooling system(Refer to 7 - COOL-

ING - STANDARD PROCEDURE).

(3) Remove clamps from both the EGR cooler and

the lower heater port. Separate hoses from the mat-

ing plumbing port. (Fig. 26).

(4) Remove retaining nut from heater line under

hood bracket.

(5) Elevate vehicle on a lift.

NOTE: When supporting vehicle care should be

taken not to damage the heater exhaust tube.

(6) Remove clamps from heater lines to the rubber

connection nearest the tubes. Separate the hoses

from the tube assembly leaving the rubber hose

attached to the supplemental heater.

(7) Remove heater unit intake pipe from heater-

(Refer to 24 - HEATING & AIR CONDITIONING/

CABIN HEATER/INLET HOSE - REMOVAL) (Fig.

27).

(8) Remove heater pipe assembly retaining screws

and remove assembly from vehicle.

24 - 80 PLUMBING - FRONTRS

ProCarManuals.com

Page 2344 of 2399

INSTALLATION

(1) Remove the tape or plugs from the evaporator

tube fittings and both expansion valve ports.

(2) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them on the evaporator

tube fittings.

(3) Position the expansion valve onto the evapora-

tor tubes.

(4) Install and tighten the two screws that secure

the expansion valve to the evaporator tube sealing

plate. Tighten the screws to 11 N´m (97 in. lbs.).

(5) Reinstall the rear evaporator line extension

onto the expansion valve. (Refer to 24 - HEATING &

AIR CONDITIONING/PLUMBING - REAR/EVAPO-

RATOR - INSTALLATION - EVAPORATOR LINE

EXTENSION).

(6) Install the foam insulator wrap over the rear

expansion valve.

(7) Reinstall the rear heater-A/C unit housing into

the vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - REAR/REAR HEATER-

A/C HOUSING - INSTALLATION).

(8) Run the HVAC Cooldown Test to verify proper

operation.

HEATER CORE

DESCRIPTION

The rear heater core is located near the front of

the rear heater-A/C unit housing, behind the right

rear wheel house. It is a heat exchanger made of

rows of tubes and fins. One end of the core is fitted

with a molded plastic tank that includes integral

heater core inlet and outlet nipples. The heater core

can be serviced without removing the rear heater-A/C

unit housing from the vehicle. The heater core cannot

be repaired and, if faulty or damaged, it must be

replaced.

OPERATION

Engine coolant is circulated through heater hoses

to the heater core at all times. As the coolant flows

through the heater core, heat removed from the

engine is transferred to the heater core fins and

tubes. Air directed through the heater core picks up

the heat from the heater core fins. The blend air door

allows control of the heater output air temperature

by controlling how much of the air flowing through

the rear heater-A/C unit housing is directed through

the heater core.

STANDARD PROCEDURE - HEATER CORE

FILLING

In its final installed position, the rear heater core

is positioned higher than the radiator fill cap. There-fore, when the cooling system is drained and refilled,

gravity will not refill the heater core with coolant to

the proper level. This may result in two problems:1.

Insufficient coolant level in the engine cooling sys-

tem, which may result in engine overheating.2.Air

entrapped within the rear heater core, which may

result in insufficient rear heater performance. There

are two methods that may be employed to prevent

these problems:1.Pre-filling of the rear heater core.

2.Thermal cycling of the engine cooling system. Fol-

lowing are descriptions of both prevention methods,

as well as a method to verify rear heater perfor-

mance.

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

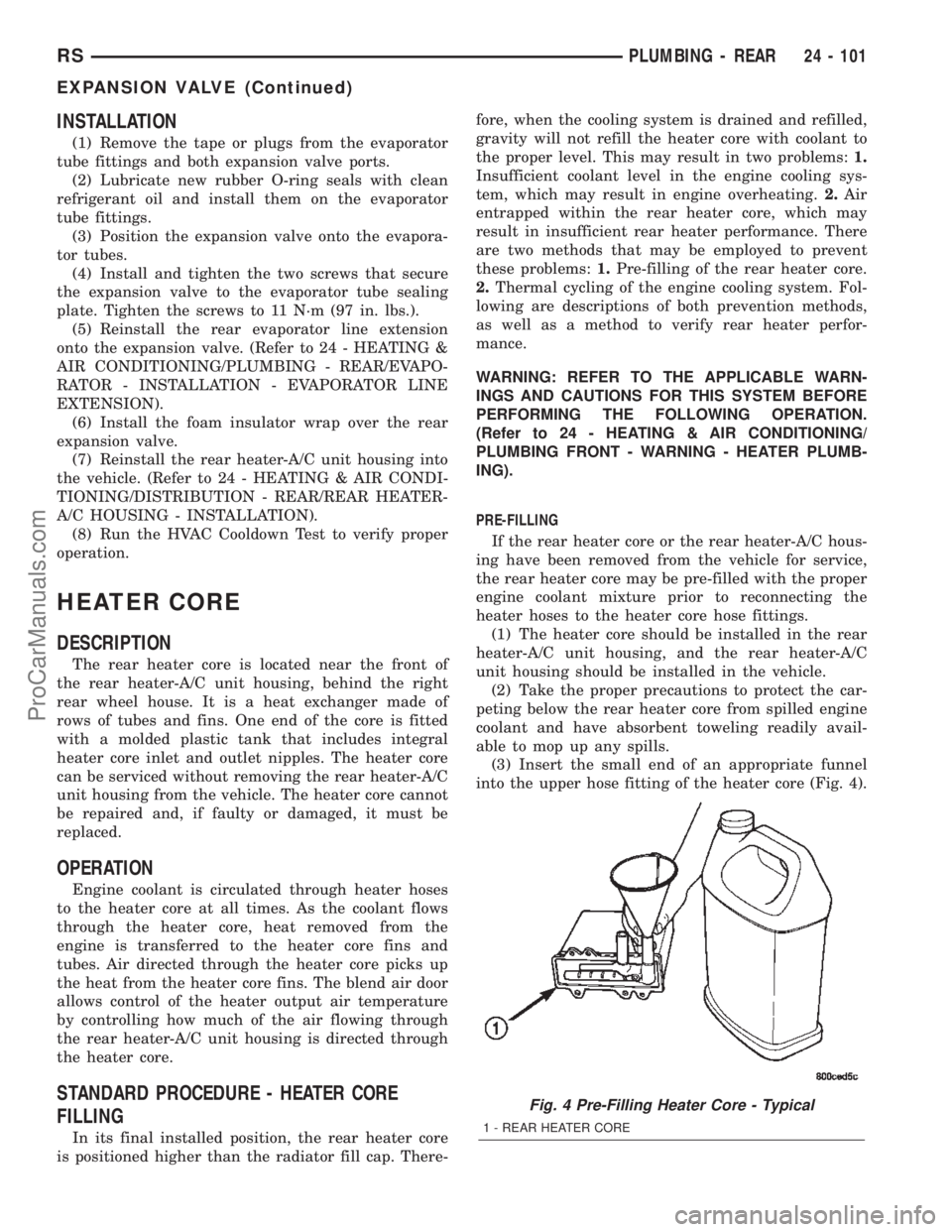

PRE-FILLING

If the rear heater core or the rear heater-A/C hous-

ing have been removed from the vehicle for service,

the rear heater core may be pre-filled with the proper

engine coolant mixture prior to reconnecting the

heater hoses to the heater core hose fittings.

(1) The heater core should be installed in the rear

heater-A/C unit housing, and the rear heater-A/C

unit housing should be installed in the vehicle.

(2) Take the proper precautions to protect the car-

peting below the rear heater core from spilled engine

coolant and have absorbent toweling readily avail-

able to mop up any spills.

(3) Insert the small end of an appropriate funnel

into the upper hose fitting of the heater core (Fig. 4).

Fig. 4 Pre-Filling Heater Core - Typical

1 - REAR HEATER CORE

RSPLUMBING - REAR24 - 101

EXPANSION VALVE (Continued)

ProCarManuals.com

Page 2345 of 2399

(4) Carefully pour the proper pre-mixed engine

coolant solution into the rear heater core through a

funnel until coolant begins to appear at the lower

hose fitting of the heater core.

(5) Use absorbent toweling to clean up any engine

coolant spills from the preceding operation.

(6) Reconnect the heater hoses to the rear heater

core. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE - INSTAL-

LATION).

(7) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

THERMAL CYCLING

If the rear heater core was emptied and was not

pre-filled, it will be necessary to thermal cycle the

vehicle at least two times to ensure that the rear

heater core is properly filled.

(1) Refill the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(2) Start the engine and allow it to operate until

the thermostat opens.

(3) Turn the engine off and allow it to cool.

(4) With the engine cold and not running, check

and top off the engine coolant level as necessary.

(Refer to 7 - COOLING - STANDARD PROCEDURE

- COOLANT LEVEL CHECK) and (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLANT

- ADDING).

(5) Start the engine and allow it to operate until

the thermostat opens again.

(6) Turn the engine off and allow it to cool down

again.

(7) With the engine cold and not running, check

and top off the engine coolant level as necessary.

(Refer to 7 - COOLING - STANDARD PROCEDURE

- COOLANT LEVEL CHECK) and (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLANT

- ADDING).

(8) Check the performance of the rear heater.

Refer to REAR HEATER PERFORMANCE CHECK .

REAR HEATER PERFORMANCE CHECK

Successful completion of the rear heater perfor-

mance check will confirm that the rear heater core is

properly filled with engine coolant. If the check is not

successful, either there is still air trapped in the rear

heater core or the rear heater plumbing is restricted.

This check should be performed with the vehicle in a

shop where the ambient temperature is about 21É C

(70É F).

(1) Start the engine and allow it to idle until it

warms up to normal operating temperature.(2) Adjust the heater-A/C controls so that the front

heater is turned Off, the rear heater is set for full

Heat, and the rear blower motor is at its highest

speed setting.

(3) Use an accurate test thermometer to measure

the temperature of the air being discharged from the

rear heater outlet located at the base of the right

C-pillar.

(4) Proper discharge air temperature readings

should be from 57É to 63É C (135É to 145É F).

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING FRONT - WARNING - HEATER PLUMB-

ING).

(1) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

(2) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - REMOVAL).

(3) Remove the rear heater distribution duct from

the right quarter inner panel. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/DISTRIBUTION -

REAR/REAR HEATER DISTRIBUTION DUCT -

REMOVAL).

(4) Remove the screw that secures the back of the

rear heater-A/C unit housing to the right D-pillar.

(5) Remove the screw that secures the front of the

rear heater-A/C unit housing to the right quarter

inner panel.

(6) Take the proper precautions to protect the car-

peting below the rear heater core from spilled engine

coolant and have absorbent toweling readily avail-

able to mop up any spills.

(7) Disconnect the heater hoses at the rear heater

core. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE - REMOV-

AL).

(8) Install plugs in, or tape over the opened heater

core fittings and both heater hoses (Fig. 5).

(9) Use absorbent toweling to clean up any engine

coolant spills from the preceding operation.

(10) Release the four latch tabs that secure the

heater core in the rear heater-A/C unit housing.

(11) Carefully pull the heater core straight out of

the rear heater-A/C unit housing.

(12) Use absorbent toweling to clean up any

engine coolant spills from the preceding operation.

24 - 102 PLUMBING - REARRS

HEATER CORE (Continued)

ProCarManuals.com

Page 2346 of 2399

INSTALLATION

NOTE: If the rear heater core or the rear heater-A/C

housing have been removed from the vehicle for

service, the rear heater core may be pre-filled with

the proper engine coolant mixture prior to recon-

necting the heater hoses to the heater core hose fit-

tings. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - REAR/HEATER CORE - STANDARD

PROCEDURE - HEATER CORE FILLING).

(1) Carefully slide the heater core into the rear

heater-A/C unit housing.

(2) Using hand pressure, press firmly and evenly

on the heater core end plate until the four latch tabs

that secure the heater core in the rear heater-A/C

unit housing are fully engaged (Fig. 5).

(3) Remove the plugs or tape from the heater core

fittings and both heater hoses.

(4) Reconnect the heater hoses to the rear heater

core. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - REAR/HEATER HOSE - INSTAL-

LATION).

(5) Install and tighten the screw that secures the

front of the rear heater-A/C unit housing to the right

quarter inner panel. Tighten the screw to 11 N´m (97

in. lbs.).

(6) Install and tighten the screw that secures the

back of the rear heater-A/C unit housing to the right

D-pillar. Tighten the screw to 11 N´m (97 in. lbs.).

(7) Reinstall the rear heater distribution duct onto

the right quarter inner panel. (Refer to 24 - HEAT-ING & AIR CONDITIONING/DISTRIBUTION -

REAR/REAR HEATER DISTRIBUTION DUCT -

INSTALLATION).

(8) Remove the right quarter trim panel and right

D-pillar trim panel from the quarter inner panel.

(Refer to 23 - BODY/INTERIOR/QUARTER TRIM

PANEL - INSTALLATION).

(9) Drain the engine cooling system. (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

HEATER HOSE

REMOVAL

REFER TO THE APPLICABLE WARNINGS AND

CAUTIONS FOR THIS SYSTEM BEFORE PER-

FORMING THE FOLLOWING OPERATION. (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMB-

ING FRONT - WARNING - HEATER PLUMBING).

(1) Partially drain engine cooling system. Refer to

Group 7, Engine Cooling.

(2) Loosen clamp at the front end of the hose

located at the right, outboard side of the underbody,

rearward of the front crossmember. (Fig. 9)

(3) Carefully rotate hose back and forth while tug-

ging slightly away from connector nipple. If the hose

will not come off, slice the hose at the connector nip-

ple and peel off heater hose. This method will require

heater hose replacement.

CAUTION:

When removing hoses from outlet nipples, do not

use excessive force. Outlet nipples may become

damaged and leak engine coolant.

(4) Compress insert in rear heater hose quick con-

nection and pull downward on hose. (Fig. 11)

(5) Remove (3) straps securing underbody lines.

(Fig. 8)

(6) Separate and remove rear heater lines from

vehicle.

INSTALLATION

There are several heater core plumbing configura-

tions used on this model, depending upon the engine

size and other optional equipment. One plumbing

configuration is used for all 2.4L engines, while the

3.3L and 3.8L engines have unique heater return

plumbing on the engine for models with or without

an optional engine oil cooler. There are also unique

plumbing configurations at the heater core for mod-

els with or without the optional rear heater and air

conditioner. All models use a combination of formed

steel tubing and rubber hoses. In most cases, the

rubber hose is secured to the steel tubing with a

spring tension clamp.

Fig. 5 Heater Core

1 - REAR HEATER-A/C HOUSING OUTLET

2 - REAR HEATER-A/C UNIT HOUSING

3 - LATCH (4)

4 - HEATER CORE

5 - RIGHT REAR WHEEL HOUSE

6 - HEATER HOSES

RSPLUMBING - REAR24 - 103

HEATER CORE (Continued)

ProCarManuals.com