clutch CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1737 of 2399

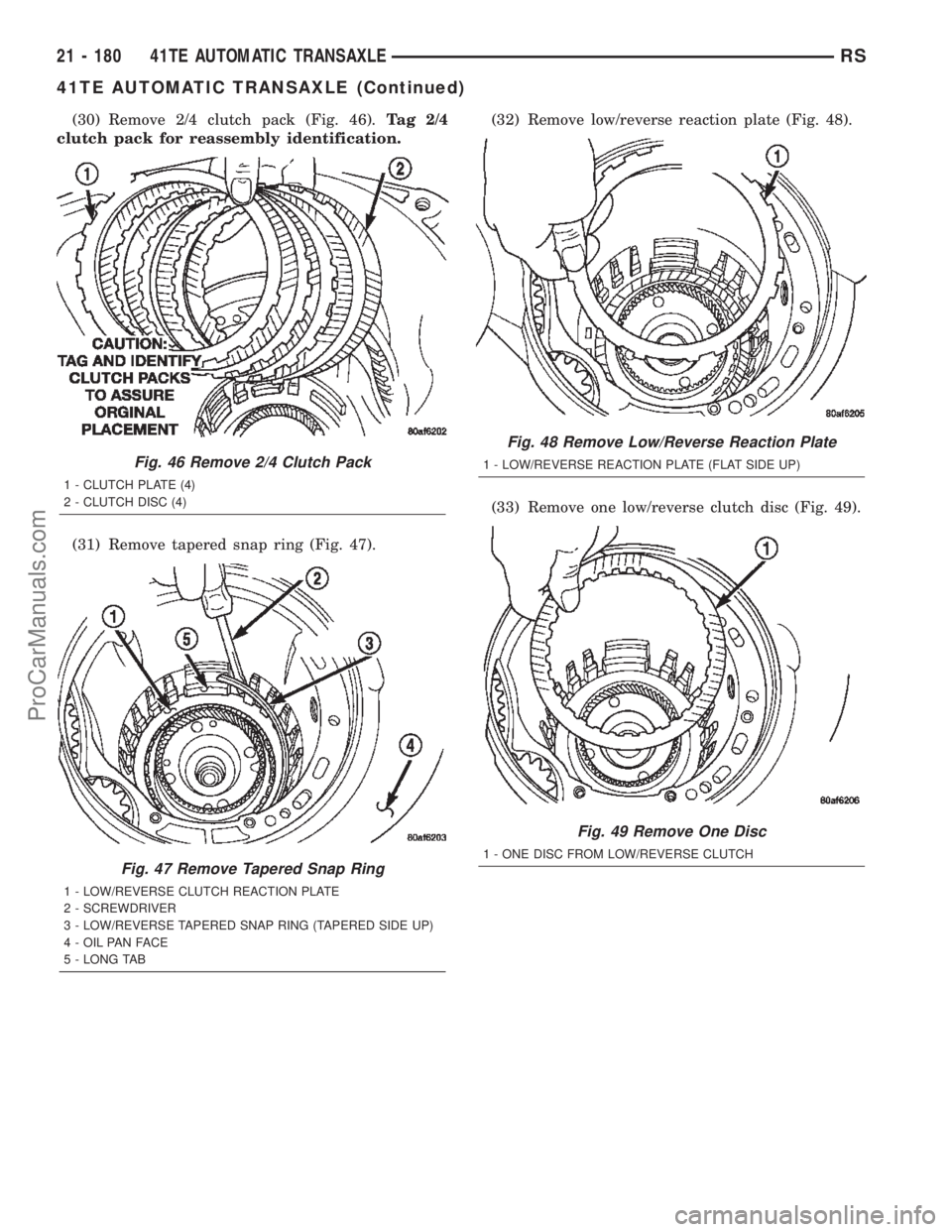

(30) Remove 2/4 clutch pack (Fig. 46).Tag 2/4

clutch pack for reassembly identification.

(31) Remove tapered snap ring (Fig. 47).(32) Remove low/reverse reaction plate (Fig. 48).

(33) Remove one low/reverse clutch disc (Fig. 49).

Fig. 46 Remove 2/4 Clutch Pack

1 - CLUTCH PLATE (4)

2 - CLUTCH DISC (4)

Fig. 47 Remove Tapered Snap Ring

1 - LOW/REVERSE CLUTCH REACTION PLATE

2 - SCREWDRIVER

3 - LOW/REVERSE TAPERED SNAP RING (TAPERED SIDE UP)

4 - OIL PAN FACE

5 - LONG TAB

Fig. 48 Remove Low/Reverse Reaction Plate

1 - LOW/REVERSE REACTION PLATE (FLAT SIDE UP)

Fig. 49 Remove One Disc

1 - ONE DISC FROM LOW/REVERSE CLUTCH

21 - 180 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1738 of 2399

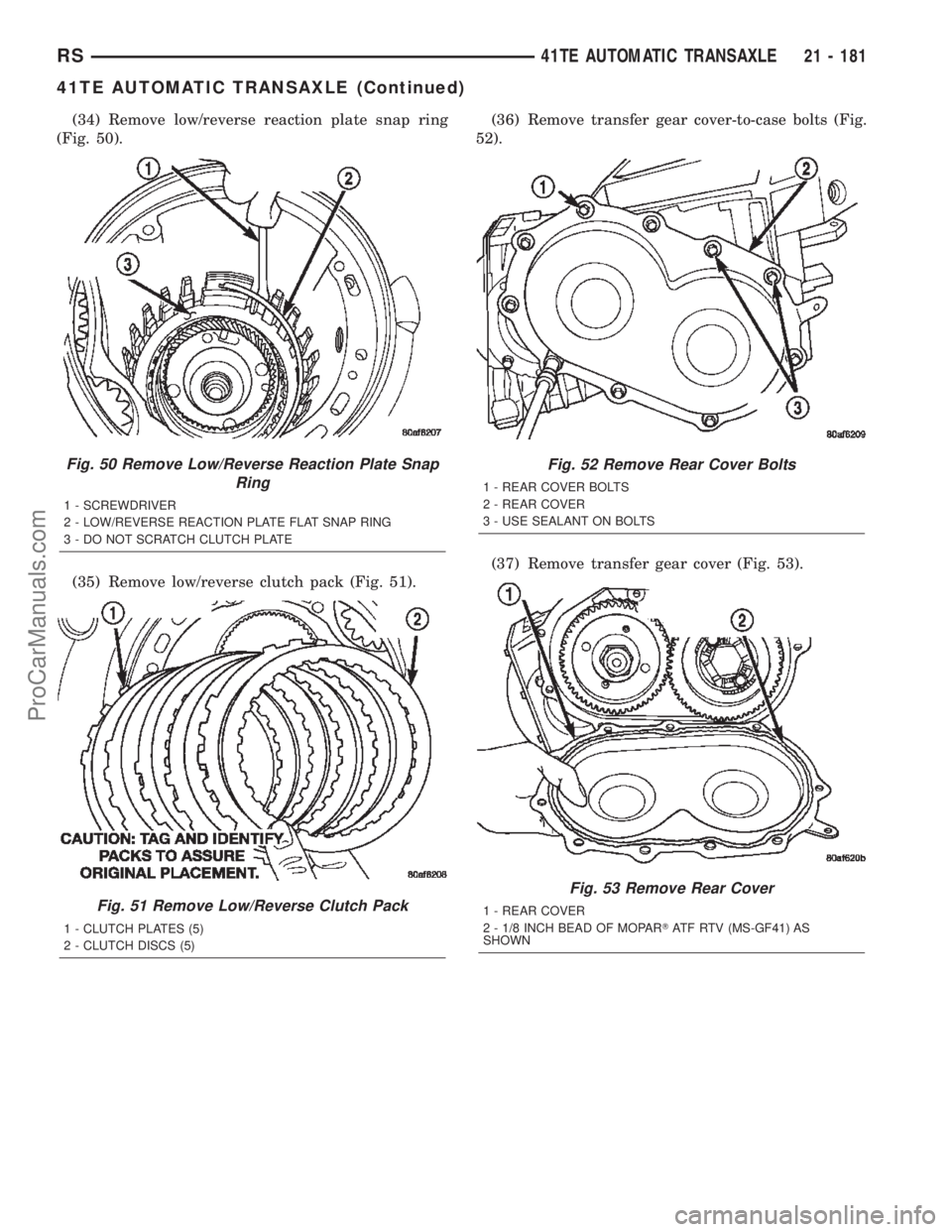

(34) Remove low/reverse reaction plate snap ring

(Fig. 50).

(35) Remove low/reverse clutch pack (Fig. 51).(36) Remove transfer gear cover-to-case bolts (Fig.

52).

(37) Remove transfer gear cover (Fig. 53).

Fig. 50 Remove Low/Reverse Reaction Plate Snap

Ring

1 - SCREWDRIVER

2 - LOW/REVERSE REACTION PLATE FLAT SNAP RING

3 - DO NOT SCRATCH CLUTCH PLATE

Fig. 51 Remove Low/Reverse Clutch Pack

1 - CLUTCH PLATES (5)

2 - CLUTCH DISCS (5)

Fig. 52 Remove Rear Cover Bolts

1 - REAR COVER BOLTS

2 - REAR COVER

3 - USE SEALANT ON BOLTS

Fig. 53 Remove Rear Cover

1 - REAR COVER

2 - 1/8 INCH BEAD OF MOPARTATF RTV (MS-GF41) AS

SHOWN

RS41TE AUTOMATIC TRANSAXLE21 - 181

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1744 of 2399

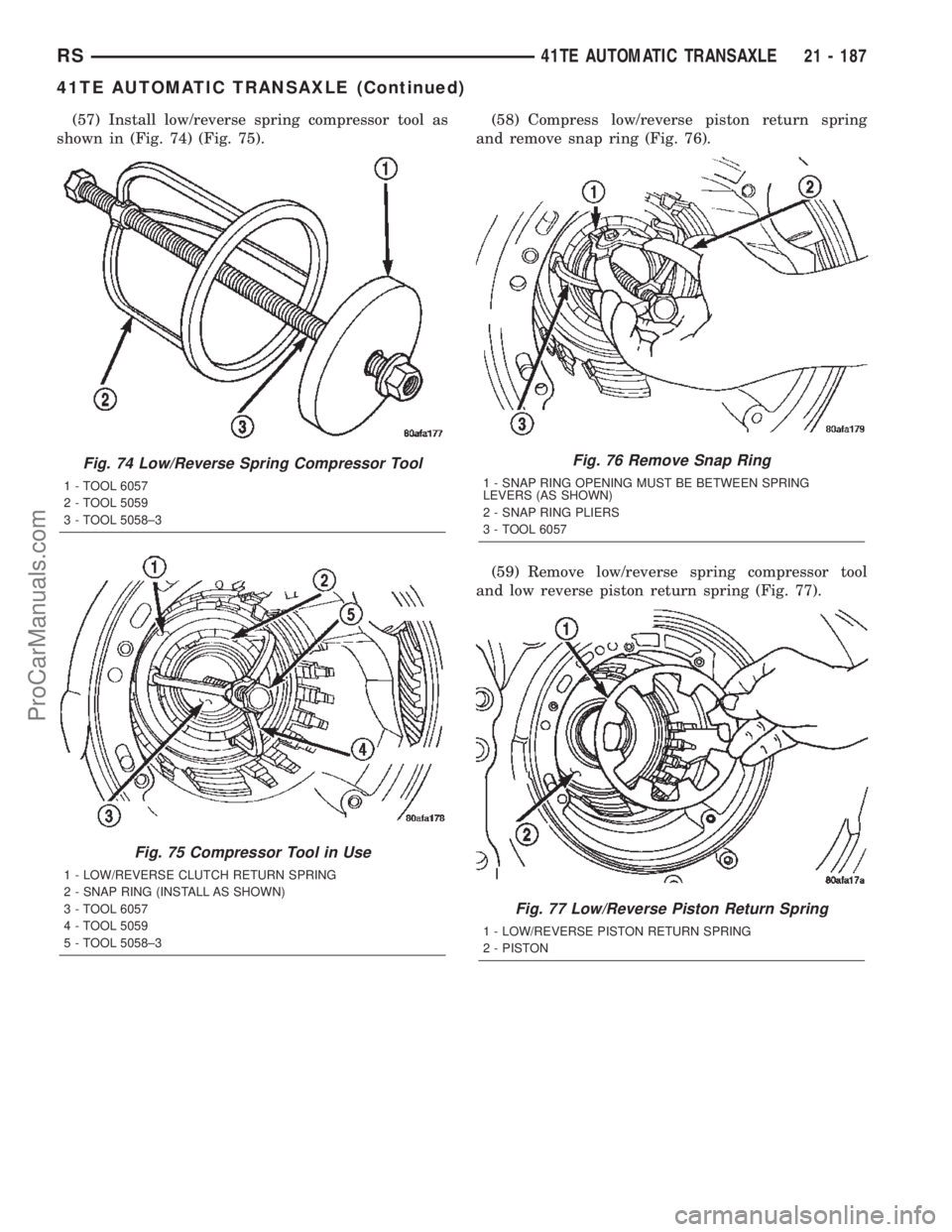

(57) Install low/reverse spring compressor tool as

shown in (Fig. 74) (Fig. 75).(58) Compress low/reverse piston return spring

and remove snap ring (Fig. 76).

(59) Remove low/reverse spring compressor tool

and low reverse piston return spring (Fig. 77).

Fig. 74 Low/Reverse Spring Compressor Tool

1 - TOOL 6057

2 - TOOL 5059

3 - TOOL 5058±3

Fig. 75 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 76 Remove Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING

LEVERS (AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 77 Low/Reverse Piston Return Spring

1 - LOW/REVERSE PISTON RETURN SPRING

2 - PISTON

RS41TE AUTOMATIC TRANSAXLE21 - 187

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1745 of 2399

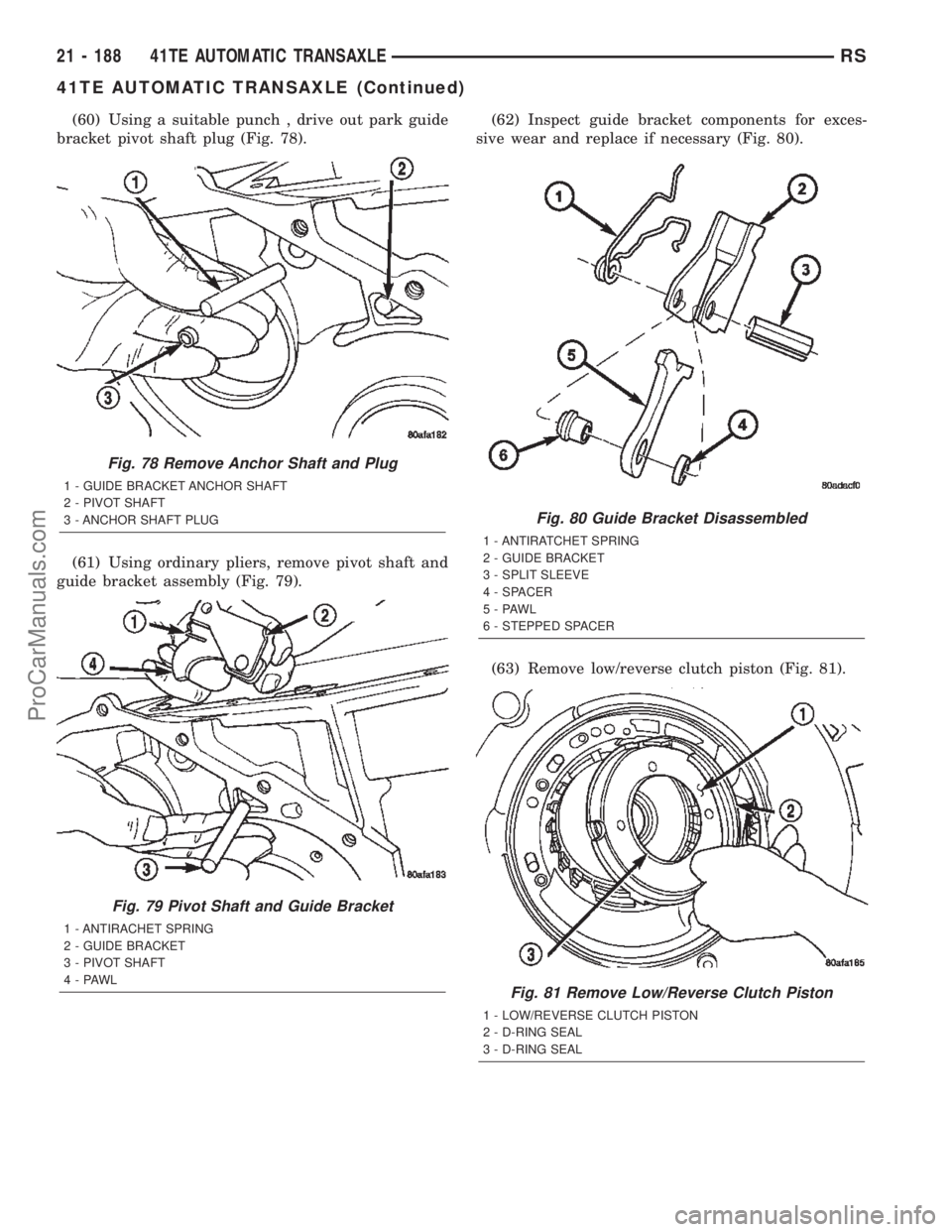

(60) Using a suitable punch , drive out park guide

bracket pivot shaft plug (Fig. 78).

(61) Using ordinary pliers, remove pivot shaft and

guide bracket assembly (Fig. 79).(62) Inspect guide bracket components for exces-

sive wear and replace if necessary (Fig. 80).

(63) Remove low/reverse clutch piston (Fig. 81).

Fig. 78 Remove Anchor Shaft and Plug

1 - GUIDE BRACKET ANCHOR SHAFT

2 - PIVOT SHAFT

3 - ANCHOR SHAFT PLUG

Fig. 79 Pivot Shaft and Guide Bracket

1 - ANTIRACHET SPRING

2 - GUIDE BRACKET

3 - PIVOT SHAFT

4-PAWL

Fig. 80 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

Fig. 81 Remove Low/Reverse Clutch Piston

1 - LOW/REVERSE CLUTCH PISTON

2 - D-RING SEAL

3 - D-RING SEAL

21 - 188 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1746 of 2399

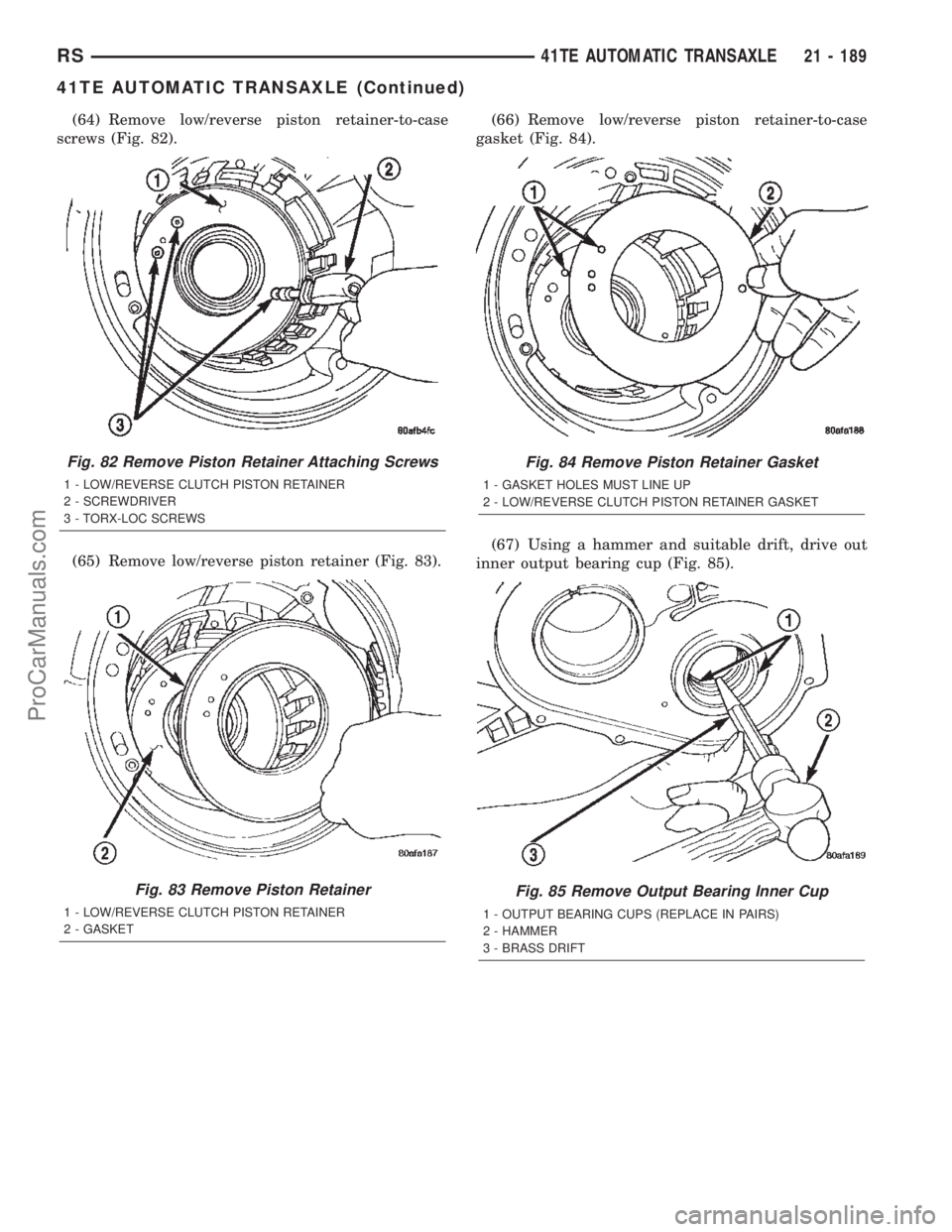

(64) Remove low/reverse piston retainer-to-case

screws (Fig. 82).

(65) Remove low/reverse piston retainer (Fig. 83).(66) Remove low/reverse piston retainer-to-case

gasket (Fig. 84).

(67) Using a hammer and suitable drift, drive out

inner output bearing cup (Fig. 85).

Fig. 82 Remove Piston Retainer Attaching Screws

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - SCREWDRIVER

3 - TORX-LOC SCREWS

Fig. 83 Remove Piston Retainer

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - GASKET

Fig. 84 Remove Piston Retainer Gasket

1 - GASKET HOLES MUST LINE UP

2 - LOW/REVERSE CLUTCH PISTON RETAINER GASKET

Fig. 85 Remove Output Bearing Inner Cup

1 - OUTPUT BEARING CUPS (REPLACE IN PAIRS)

2 - HAMMER

3 - BRASS DRIFT

RS41TE AUTOMATIC TRANSAXLE21 - 189

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1747 of 2399

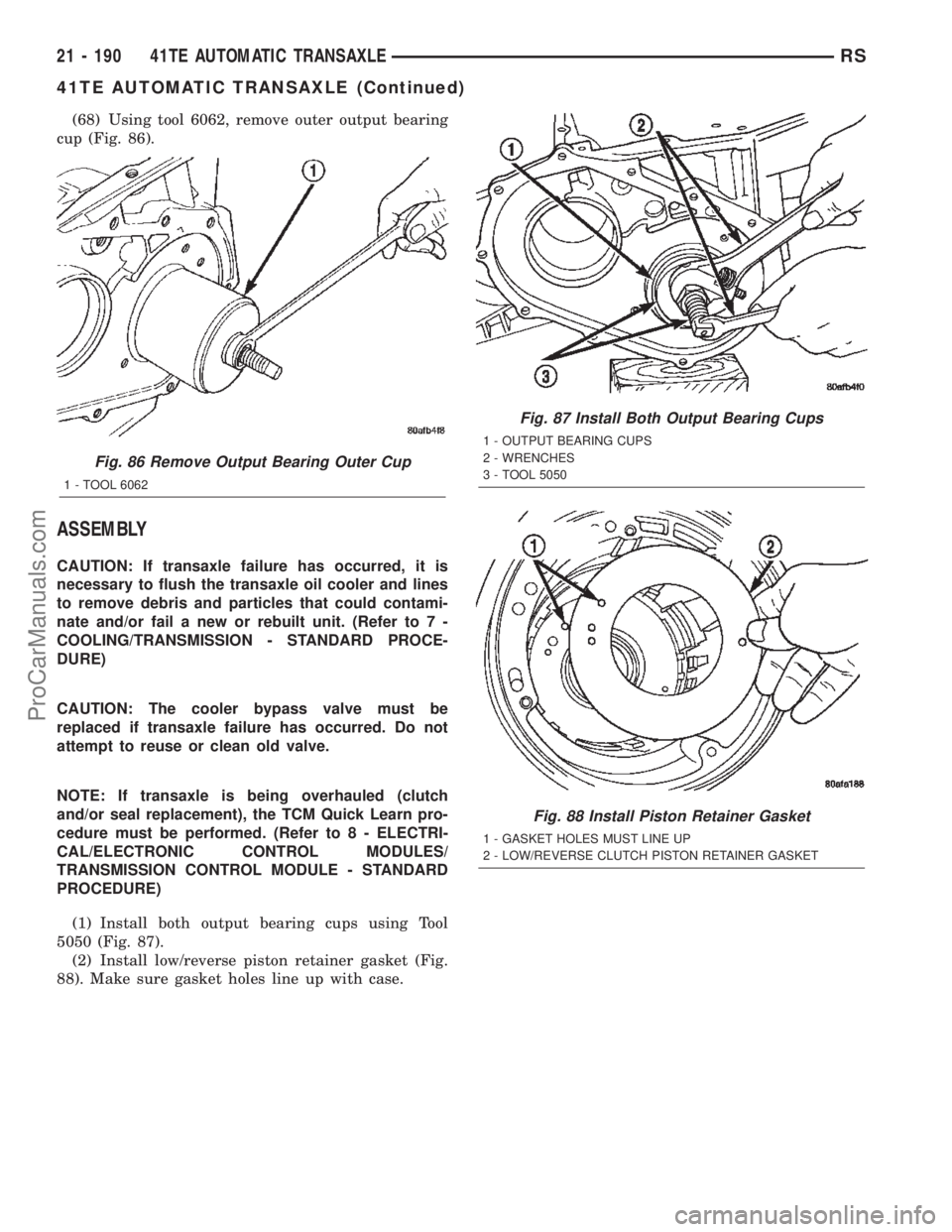

(68) Using tool 6062, remove outer output bearing

cup (Fig. 86).

ASSEMBLY

CAUTION: If transaxle failure has occurred, it is

necessary to flush the transaxle oil cooler and lines

to remove debris and particles that could contami-

nate and/or fail a new or rebuilt unit. (Refer to 7 -

COOLING/TRANSMISSION - STANDARD PROCE-

DURE)

CAUTION: The cooler bypass valve must be

replaced if transaxle failure has occurred. Do not

attempt to reuse or clean old valve.

NOTE: If transaxle is being overhauled (clutch

and/or seal replacement), the TCM Quick Learn pro-

cedure must be performed. (Refer to 8 - ELECTRI-

CAL/ELECTRONIC CONTROL MODULES/

TRANSMISSION CONTROL MODULE - STANDARD

PROCEDURE)

(1) Install both output bearing cups using Tool

5050 (Fig. 87).

(2) Install low/reverse piston retainer gasket (Fig.

88). Make sure gasket holes line up with case.

Fig. 86 Remove Output Bearing Outer Cup

1 - TOOL 6062

Fig. 87 Install Both Output Bearing Cups

1 - OUTPUT BEARING CUPS

2 - WRENCHES

3 - TOOL 5050

Fig. 88 Install Piston Retainer Gasket

1 - GASKET HOLES MUST LINE UP

2 - LOW/REVERSE CLUTCH PISTON RETAINER GASKET

21 - 190 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1748 of 2399

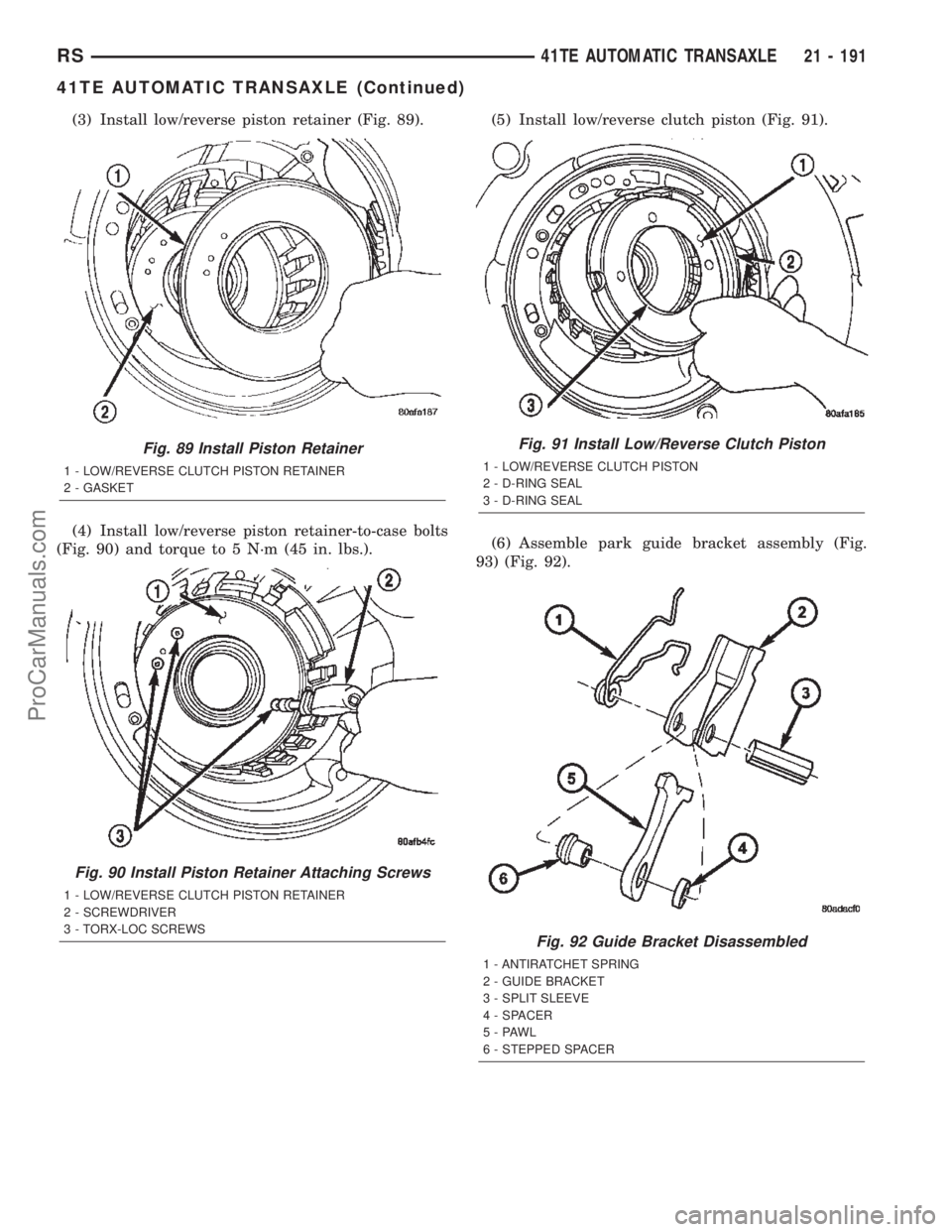

(3) Install low/reverse piston retainer (Fig. 89).

(4) Install low/reverse piston retainer-to-case bolts

(Fig. 90) and torque to 5 N´m (45 in. lbs.).(5) Install low/reverse clutch piston (Fig. 91).

(6) Assemble park guide bracket assembly (Fig.

93) (Fig. 92).

Fig. 89 Install Piston Retainer

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - GASKET

Fig. 90 Install Piston Retainer Attaching Screws

1 - LOW/REVERSE CLUTCH PISTON RETAINER

2 - SCREWDRIVER

3 - TORX-LOC SCREWS

Fig. 91 Install Low/Reverse Clutch Piston

1 - LOW/REVERSE CLUTCH PISTON

2 - D-RING SEAL

3 - D-RING SEAL

Fig. 92 Guide Bracket Disassembled

1 - ANTIRATCHET SPRING

2 - GUIDE BRACKET

3 - SPLIT SLEEVE

4 - SPACER

5-PAWL

6 - STEPPED SPACER

RS41TE AUTOMATIC TRANSAXLE21 - 191

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1750 of 2399

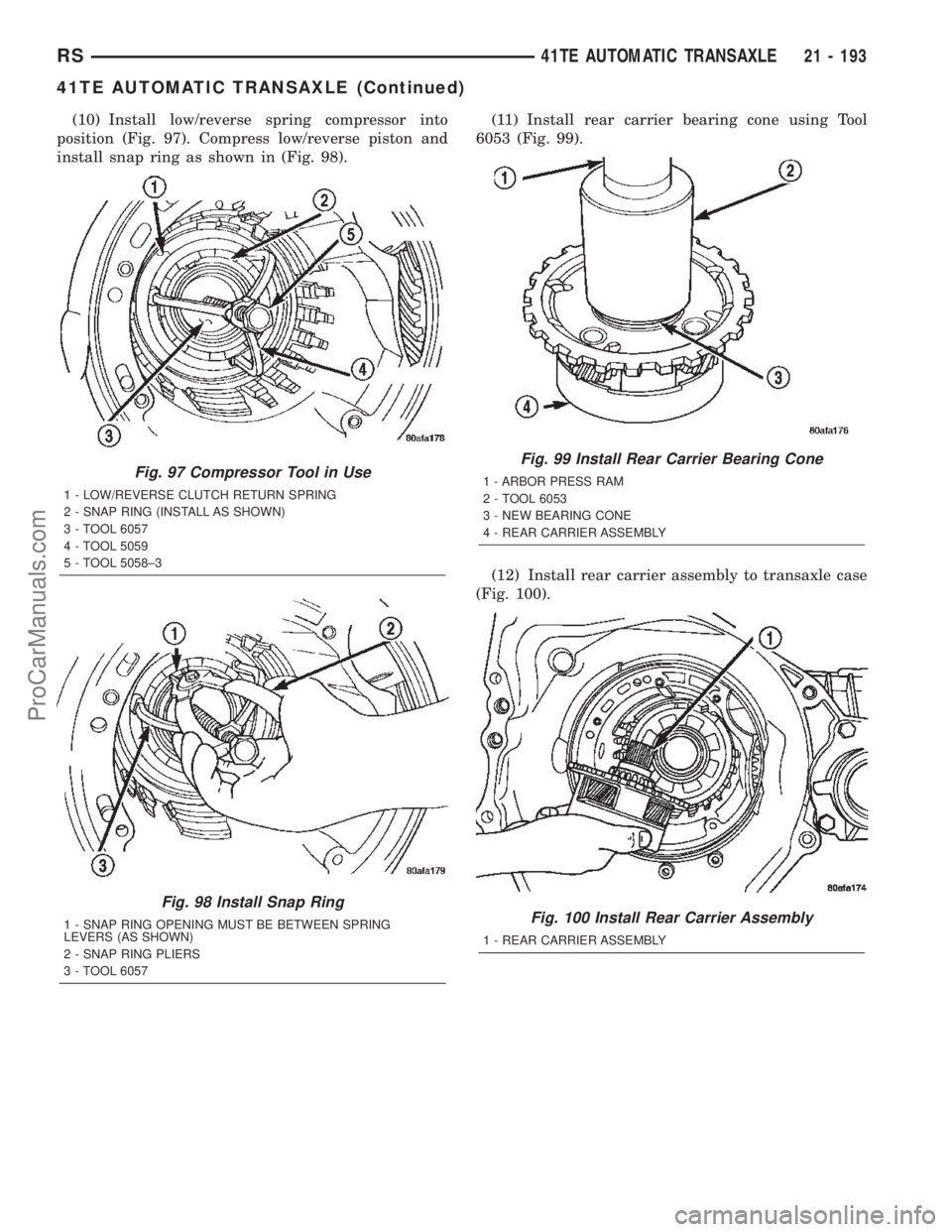

(10) Install low/reverse spring compressor into

position (Fig. 97). Compress low/reverse piston and

install snap ring as shown in (Fig. 98).(11) Install rear carrier bearing cone using Tool

6053 (Fig. 99).

(12) Install rear carrier assembly to transaxle case

(Fig. 100).

Fig. 97 Compressor Tool in Use

1 - LOW/REVERSE CLUTCH RETURN SPRING

2 - SNAP RING (INSTALL AS SHOWN)

3 - TOOL 6057

4 - TOOL 5059

5 - TOOL 5058±3

Fig. 98 Install Snap Ring

1 - SNAP RING OPENING MUST BE BETWEEN SPRING

LEVERS (AS SHOWN)

2 - SNAP RING PLIERS

3 - TOOL 6057

Fig. 99 Install Rear Carrier Bearing Cone

1 - ARBOR PRESS RAM

2 - TOOL 6053

3 - NEW BEARING CONE

4 - REAR CARRIER ASSEMBLY

Fig. 100 Install Rear Carrier Assembly

1 - REAR CARRIER ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 193

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1760 of 2399

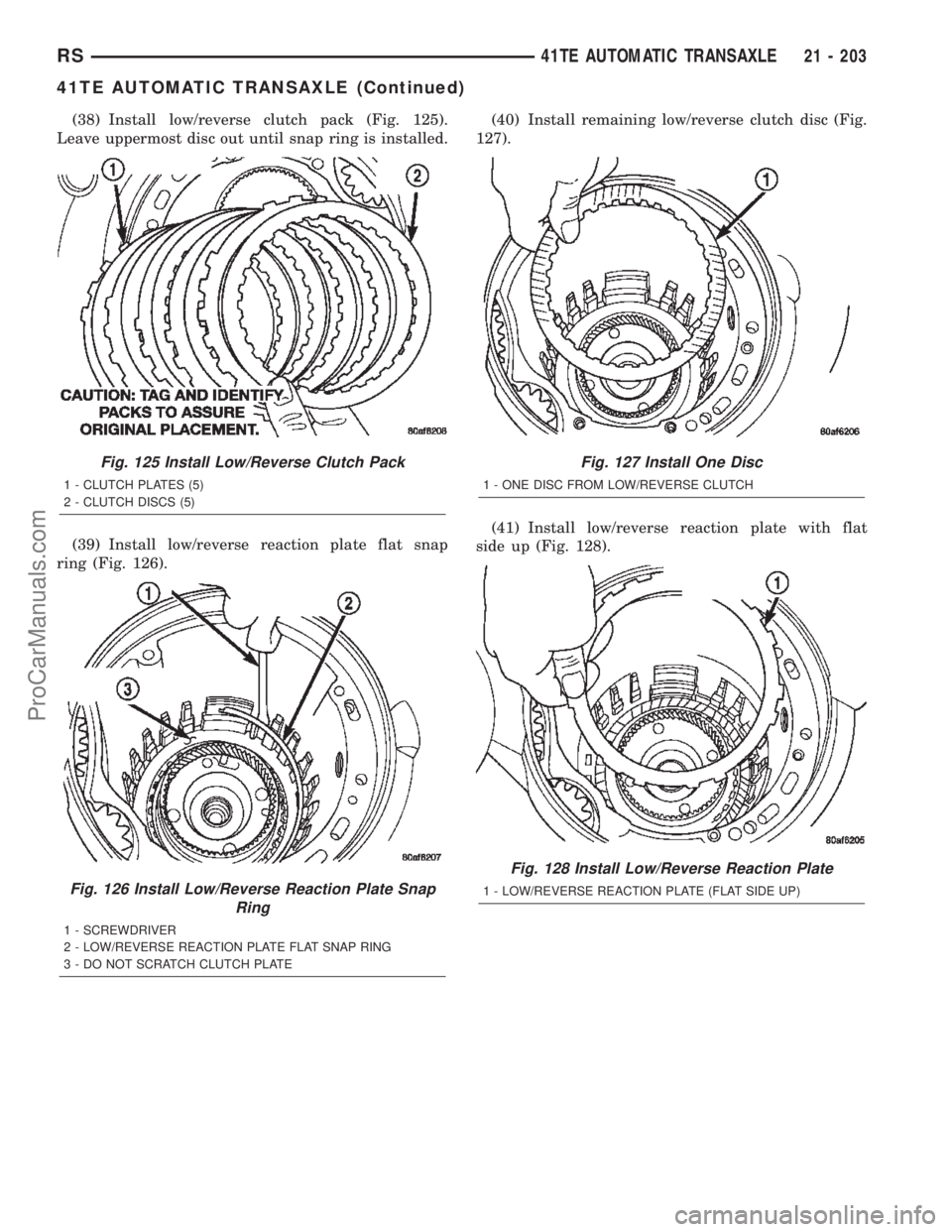

(38) Install low/reverse clutch pack (Fig. 125).

Leave uppermost disc out until snap ring is installed.

(39) Install low/reverse reaction plate flat snap

ring (Fig. 126).(40) Install remaining low/reverse clutch disc (Fig.

127).

(41) Install low/reverse reaction plate with flat

side up (Fig. 128).

Fig. 125 Install Low/Reverse Clutch Pack

1 - CLUTCH PLATES (5)

2 - CLUTCH DISCS (5)

Fig. 126 Install Low/Reverse Reaction Plate Snap

Ring

1 - SCREWDRIVER

2 - LOW/REVERSE REACTION PLATE FLAT SNAP RING

3 - DO NOT SCRATCH CLUTCH PLATE

Fig. 127 Install One Disc

1 - ONE DISC FROM LOW/REVERSE CLUTCH

Fig. 128 Install Low/Reverse Reaction Plate

1 - LOW/REVERSE REACTION PLATE (FLAT SIDE UP)

RS41TE AUTOMATIC TRANSAXLE21 - 203

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com

Page 1761 of 2399

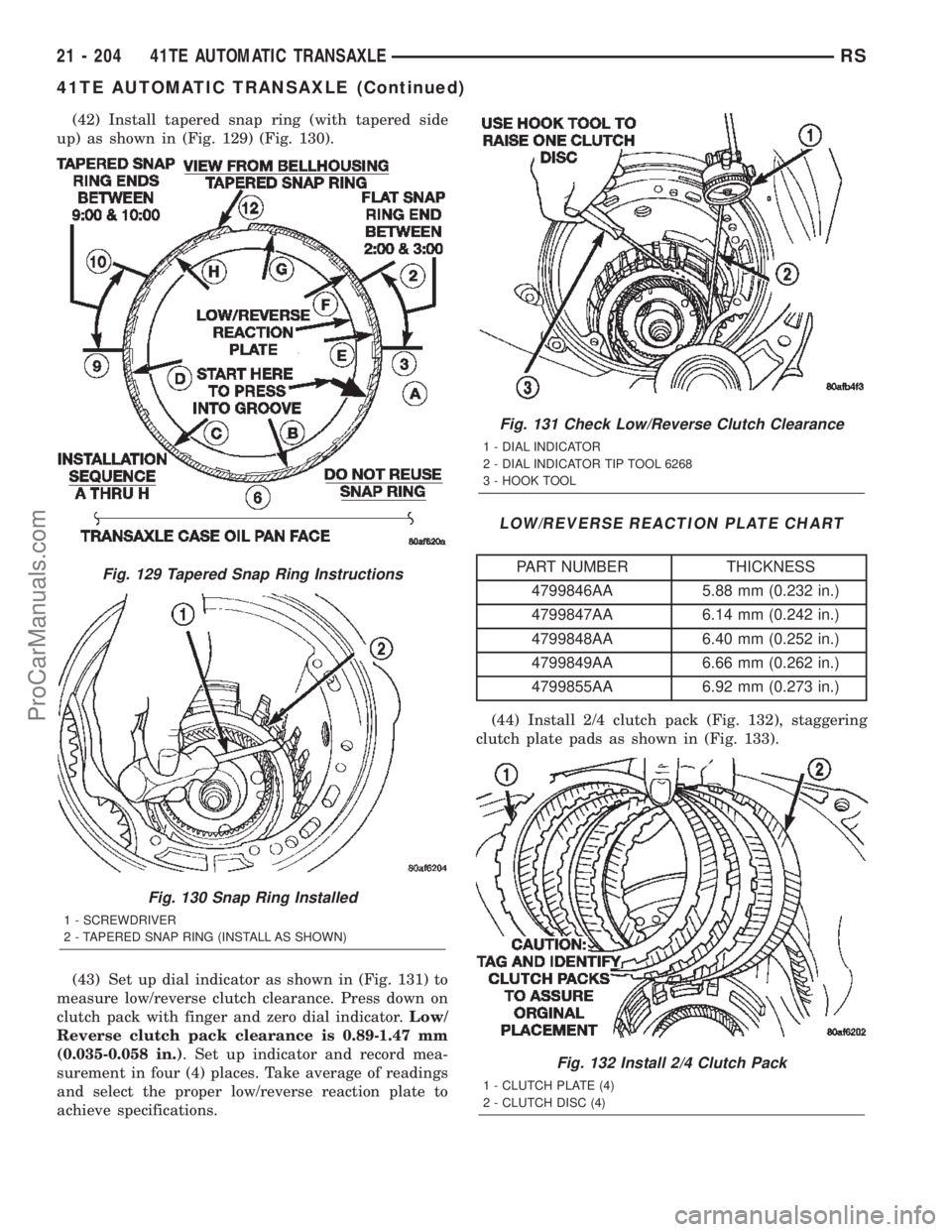

(42) Install tapered snap ring (with tapered side

up) as shown in (Fig. 129) (Fig. 130).

(43) Set up dial indicator as shown in (Fig. 131) to

measure low/reverse clutch clearance. Press down on

clutch pack with finger and zero dial indicator.Low/

Reverse clutch pack clearance is 0.89-1.47 mm

(0.035-0.058 in.). Set up indicator and record mea-

surement in four (4) places. Take average of readings

and select the proper low/reverse reaction plate to

achieve specifications.

LOW/REVERSE REACTION PLATE CHART

PART NUMBER THICKNESS

4799846AA 5.88 mm (0.232 in.)

4799847AA 6.14 mm (0.242 in.)

4799848AA 6.40 mm (0.252 in.)

4799849AA 6.66 mm (0.262 in.)

4799855AA 6.92 mm (0.273 in.)

(44) Install 2/4 clutch pack (Fig. 132), staggering

clutch plate pads as shown in (Fig. 133).Fig. 129 Tapered Snap Ring Instructions

Fig. 130 Snap Ring Installed

1 - SCREWDRIVER

2 - TAPERED SNAP RING (INSTALL AS SHOWN)

Fig. 131 Check Low/Reverse Clutch Clearance

1 - DIAL INDICATOR

2 - DIAL INDICATOR TIP TOOL 6268

3 - HOOK TOOL

Fig. 132 Install 2/4 Clutch Pack

1 - CLUTCH PLATE (4)

2 - CLUTCH DISC (4)

21 - 204 41TE AUTOMATIC TRANSAXLERS

41TE AUTOMATIC TRANSAXLE (Continued)

ProCarManuals.com