maintenance CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 22 of 2399

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end of

the vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

TOWING ± FRONT WHEEL LIFT

If the vehicle is being towed from the front, when-

ever possible ensure at least 10 inches road clearance

to the tires.

TOWING ± REAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²On AWD vehicles, all four wheels must be free to

rotate. Use towing dollies at unlifted end of vehicle.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

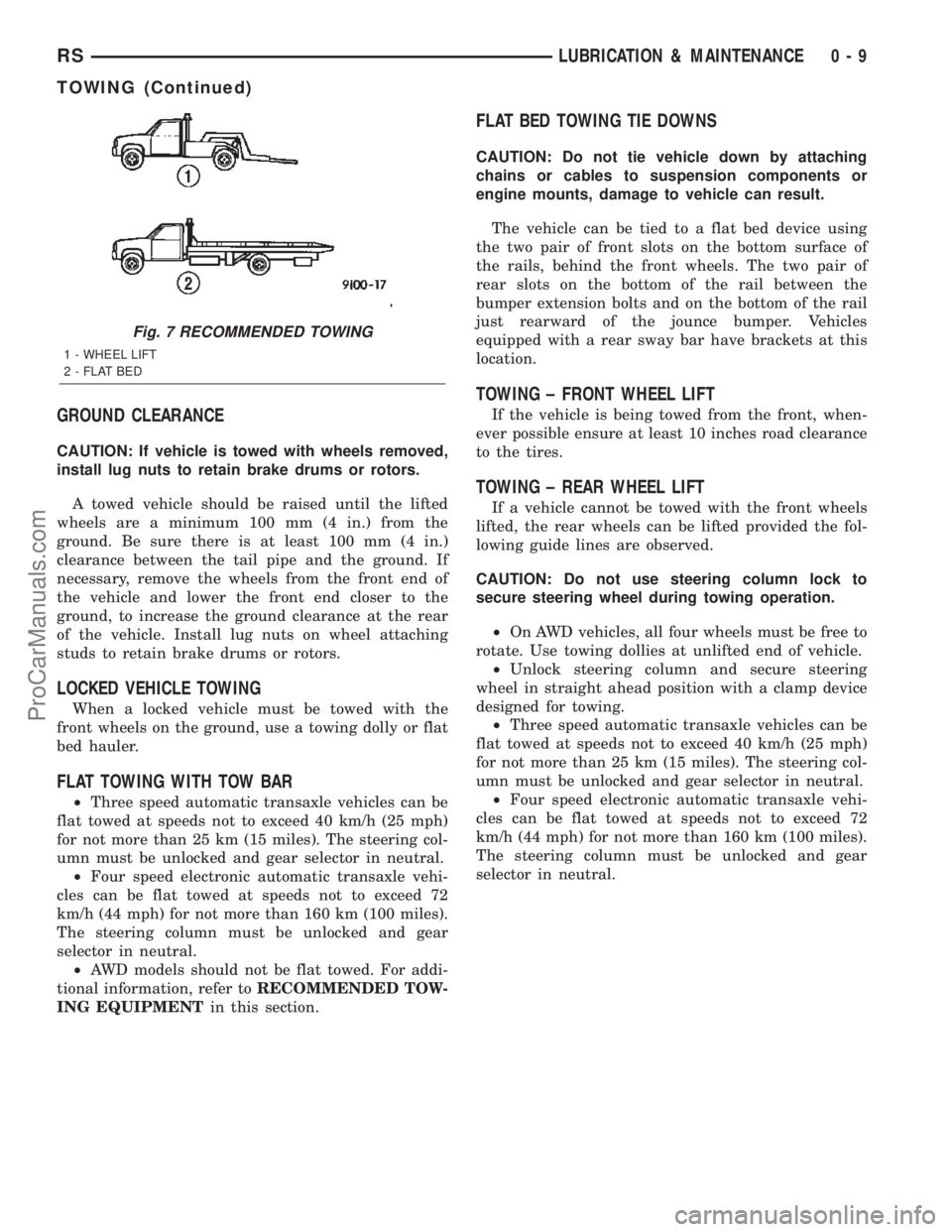

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-9

TOWING (Continued)

ProCarManuals.com

Page 25 of 2399

FRONT SUSPENSION

DESCRIPTION - FRONT SUSPENSION

This vehicle has a MacPherson Strut type front

suspension (Fig. 1).

OPERATION - FRONT SUSPENSION

The front suspension allows each wheel on a vehi-

cle to adapt to different road surfaces and conditions

without greatly affecting the opposite wheel and the

ability to control the vehicle. Each side of the front

suspension is allowed to pivot so the vehicle can be

steered in the direction preferred.

A strut assembly is used in place of the front sus-

pension upper control arm and upper ball joint.

When a vehicle strikes a bump, the force is trans-

ferred through the hub, bearing, and knuckle, into

the strut assembly to absorb the force and dampen it.

The top of the strut is mounted directly to the strut

tower of the vehicle. During steering maneuvers, thestrut assembly (through a pivot bearing in the upper

strut mount) and steering knuckle (through the lower

ball joint) turn as an assembly.

STANDARD PROCEDURE - LUBRICATION

There are no serviceable lubrication points on the

front suspension. The ball joints are sealed-for-life

and require no maintenance. The lower ball joints

have special grease fitting caps that prevent normal

grease gun attachment. This has been done to elimi-

nate the possibility of over-filling, damaging the non-

vented seal. Do not attempt to remove the special

grease fitting cap and replace it with a normal grease

zirc fitting.

CAUTION: No attempt should be made to replace

the ball joint grease fitting cap with a normal zirc

fitting or fill the ball joint with grease. Damage to

the grease seal can result.

Fig. 1 Front Suspension

1 - TOWER

2 - CROSSMEMBER TAPPING PLATES

3 - LEFT STRUT ASSEMBLY

4 - LEFT STEERING KNUCKLE (WITH HUB AND BEARING)

5 - STABILIZER BAR LINK

6 - STABILIZER BAR

7 - LEFT LOWER CONTROL ARM

8 - CRADLE/CROSSMEMBER9 - CRADLE/CROSSMEMBER REINFORCEMENT

10 - BALL JOINT

11 - ISOLATOR BUSHING

12 - STEERING GEAR TIE ROD

13 - RIGHT STEERING KNUCKLE

14 - RIGHT HUB AND BEARING

15 - RIGHT STRUT ASSEMBLY

2 - 2 FRONT SUSPENSIONRS

ProCarManuals.com

Page 27 of 2399

BUSHINGS

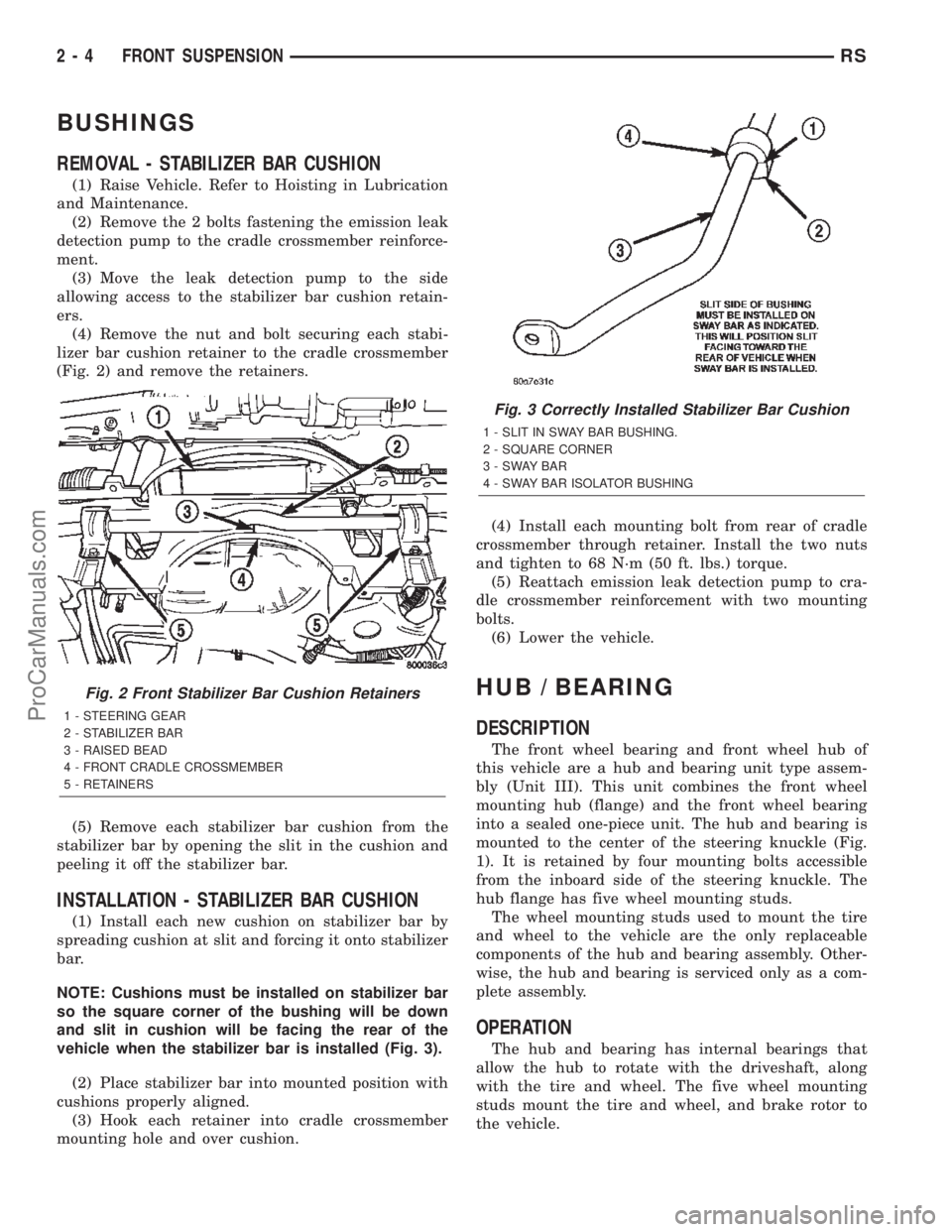

REMOVAL - STABILIZER BAR CUSHION

(1) Raise Vehicle. Refer to Hoisting in Lubrication

and Maintenance.

(2) Remove the 2 bolts fastening the emission leak

detection pump to the cradle crossmember reinforce-

ment.

(3) Move the leak detection pump to the side

allowing access to the stabilizer bar cushion retain-

ers.

(4) Remove the nut and bolt securing each stabi-

lizer bar cushion retainer to the cradle crossmember

(Fig. 2) and remove the retainers.

(5) Remove each stabilizer bar cushion from the

stabilizer bar by opening the slit in the cushion and

peeling it off the stabilizer bar.

INSTALLATION - STABILIZER BAR CUSHION

(1) Install each new cushion on stabilizer bar by

spreading cushion at slit and forcing it onto stabilizer

bar.

NOTE: Cushions must be installed on stabilizer bar

so the square corner of the bushing will be down

and slit in cushion will be facing the rear of the

vehicle when the stabilizer bar is installed (Fig. 3).

(2) Place stabilizer bar into mounted position with

cushions properly aligned.

(3) Hook each retainer into cradle crossmember

mounting hole and over cushion.(4) Install each mounting bolt from rear of cradle

crossmember through retainer. Install the two nuts

and tighten to 68 N´m (50 ft. lbs.) torque.

(5) Reattach emission leak detection pump to cra-

dle crossmember reinforcement with two mounting

bolts.

(6) Lower the vehicle.

HUB / BEARING

DESCRIPTION

The front wheel bearing and front wheel hub of

this vehicle are a hub and bearing unit type assem-

bly (Unit III). This unit combines the front wheel

mounting hub (flange) and the front wheel bearing

into a sealed one-piece unit. The hub and bearing is

mounted to the center of the steering knuckle (Fig.

1). It is retained by four mounting bolts accessible

from the inboard side of the steering knuckle. The

hub flange has five wheel mounting studs.

The wheel mounting studs used to mount the tire

and wheel to the vehicle are the only replaceable

components of the hub and bearing assembly. Other-

wise, the hub and bearing is serviced only as a com-

plete assembly.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the driveshaft, along

with the tire and wheel. The five wheel mounting

studs mount the tire and wheel, and brake rotor to

the vehicle.

Fig. 2 Front Stabilizer Bar Cushion Retainers

1 - STEERING GEAR

2 - STABILIZER BAR

3 - RAISED BEAD

4 - FRONT CRADLE CROSSMEMBER

5 - RETAINERS

Fig. 3 Correctly Installed Stabilizer Bar Cushion

1 - SLIT IN SWAY BAR BUSHING.

2 - SQUARE CORNER

3-SWAYBAR

4 - SWAY BAR ISOLATOR BUSHING

2 - 4 FRONT SUSPENSIONRS

ProCarManuals.com

Page 28 of 2399

DIAGNOSIS AND TESTING - HUB AND

BEARING

The condition of the front hub and bearing assem-

bly is diagnosed using the inspection and testing pro-

cedure detailed below.

The bearing contained in the Unit III front hub/

bearing assembly will produce noise and vibration

when worn or damaged. The noise will generally

change when the bearings are loaded. A road test of

the vehicle is normally required to determine the

location of a worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

unload the bearings and change the noise level.

When bearing damage is slight, the noise is some-

times noticeable at lower speeds and at other times

is more noticeable at speeds above 105 km/h (65

mph).

REMOVAL

NOTE: Replacement of the Unit III front hub/bearing

assembly can be normally done without having to

remove the steering knuckle from the vehicle. In the

event that the hub/bearing is frozen in the steering

knuckle and cannot be removed by hand, it will

have to be pressed out of the steering knuckle. The

steering knuckle will require removal from the vehi-

cle to allow the hub/bearing assembly to be

pressed out of the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove wheel lug nuts, and front tire and

wheel assembly.

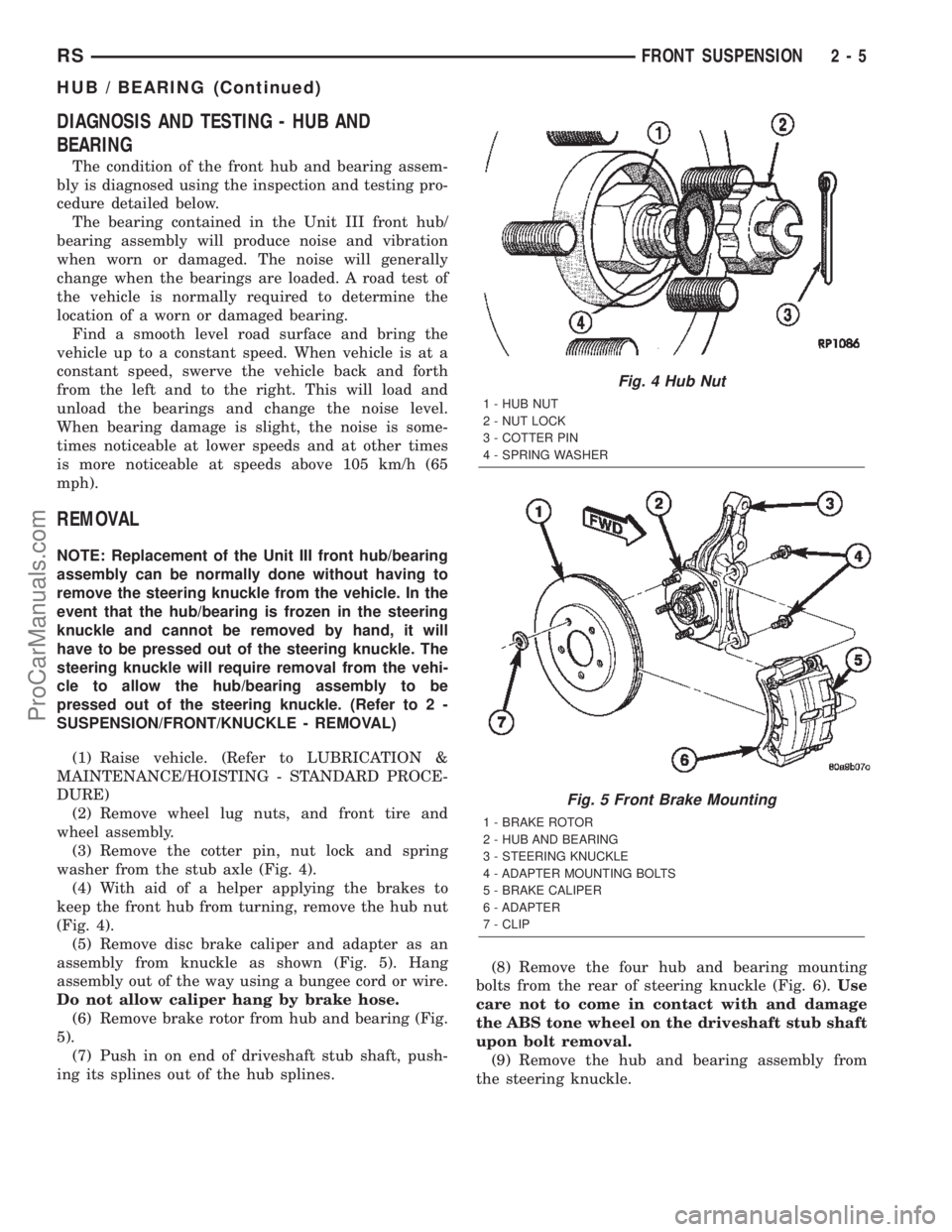

(3) Remove the cotter pin, nut lock and spring

washer from the stub axle (Fig. 4).

(4) With aid of a helper applying the brakes to

keep the front hub from turning, remove the hub nut

(Fig. 4).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 5). Hang

assembly out of the way using a bungee cord or wire.

Do not allow caliper hang by brake hose.

(6) Remove brake rotor from hub and bearing (Fig.

5).

(7) Push in on end of driveshaft stub shaft, push-

ing its splines out of the hub splines.(8) Remove the four hub and bearing mounting

bolts from the rear of steering knuckle (Fig. 6).Use

care not to come in contact with and damage

the ABS tone wheel on the driveshaft stub shaft

upon bolt removal.

(9) Remove the hub and bearing assembly from

the steering knuckle.

Fig. 4 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - SPRING WASHER

Fig. 5 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

RSFRONT SUSPENSION2-5

HUB / BEARING (Continued)

ProCarManuals.com

Page 30 of 2399

The center of the knuckle supports the hub and

bearing and axle shaft.

REMOVAL - STEERING KNUCKLE

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove the wheel and tire assembly from the

vehicle.

(3) Remove the cotter pin, nut lock and spring

washer from the end of the stub axle and hub nut

(Fig. 8).

(4) Have a helper apply the vehicle's brakes to

keep hub from turning,loosen and removethe hub

nut (Fig. 8).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 9). Hang

assembly out of the way using a bungee cord or wire

(Fig. 10).Do not allow caliper to hang by brake

hose.

(6) Remove nut attaching outer tie rod end to

steering knuckle by holding the tie rod end stud

while loosening and removing nut with a wrench

(Fig. 11).

(7) Remove tie rod end from steering knuckle

using Remover, Special Tool C-3894±A (Fig. 12).

(8) If equipped with antilock brakes, remove the

front wheel speed sensor from the steering knuckle

(Fig. 13).

(9) Remove the two steering knuckle-to-strut clevis

bracket attaching bolts.

(10) Tip the knuckle outward and remove the

driveshaft stub axle from the hub and bearing. Sus-

pend driveshaft straight outward using a bungee

cord or wire (Fig. 10).Do not allow driveshaft to

hang by inner joint.

Fig. 8 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - SPRING WASHER

Fig. 9 Front Brake Mounting

1 - BRAKE ROTOR

2 - HUB AND BEARING

3 - STEERING KNUCKLE

4 - ADAPTER MOUNTING BOLTS

5 - BRAKE CALIPER

6 - ADAPTER

7 - CLIP

Fig. 10 Caliper And Driveshaft Suspended

1 - HANGER SUSPENDING CALIPER

2 - HANGER SUSPENDING DRIVESHAFT

3 - DRIVESHAFT

4 - BRAKE CALIPER

RSFRONT SUSPENSION2-7

KNUCKLE (Continued)

ProCarManuals.com

Page 33 of 2399

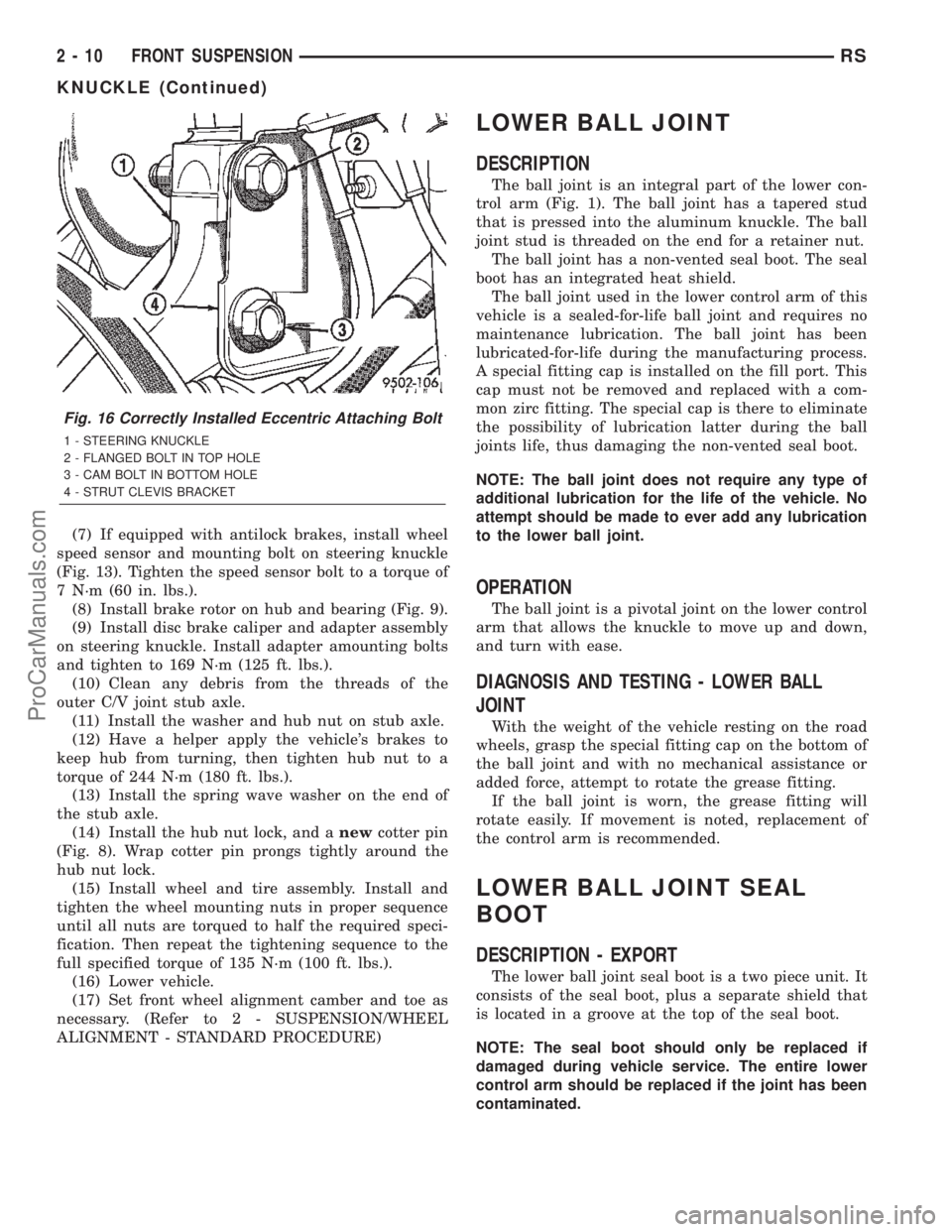

(7) If equipped with antilock brakes, install wheel

speed sensor and mounting bolt on steering knuckle

(Fig. 13). Tighten the speed sensor bolt to a torque of

7 N´m (60 in. lbs.).

(8) Install brake rotor on hub and bearing (Fig. 9).

(9) Install disc brake caliper and adapter assembly

on steering knuckle. Install adapter amounting bolts

and tighten to 169 N´m (125 ft. lbs.).

(10) Clean any debris from the threads of the

outer C/V joint stub axle.

(11) Install the washer and hub nut on stub axle.

(12) Have a helper apply the vehicle's brakes to

keep hub from turning, then tighten hub nut to a

torque of 244 N´m (180 ft. lbs.).

(13) Install the spring wave washer on the end of

the stub axle.

(14) Install the hub nut lock, and anewcotter pin

(Fig. 8). Wrap cotter pin prongs tightly around the

hub nut lock.

(15) Install wheel and tire assembly. Install and

tighten the wheel mounting nuts in proper sequence

until all nuts are torqued to half the required speci-

fication. Then repeat the tightening sequence to the

full specified torque of 135 N´m (100 ft. lbs.).

(16) Lower vehicle.

(17) Set front wheel alignment camber and toe as

necessary. (Refer to 2 - SUSPENSION/WHEEL

ALIGNMENT - STANDARD PROCEDURE)

LOWER BALL JOINT

DESCRIPTION

The ball joint is an integral part of the lower con-

trol arm (Fig. 1). The ball joint has a tapered stud

that is pressed into the aluminum knuckle. The ball

joint stud is threaded on the end for a retainer nut.

The ball joint has a non-vented seal boot. The seal

boot has an integrated heat shield.

The ball joint used in the lower control arm of this

vehicle is a sealed-for-life ball joint and requires no

maintenance lubrication. The ball joint has been

lubricated-for-life during the manufacturing process.

A special fitting cap is installed on the fill port. This

cap must not be removed and replaced with a com-

mon zirc fitting. The special cap is there to eliminate

the possibility of lubrication latter during the ball

joints life, thus damaging the non-vented seal boot.

NOTE: The ball joint does not require any type of

additional lubrication for the life of the vehicle. No

attempt should be made to ever add any lubrication

to the lower ball joint.

OPERATION

The ball joint is a pivotal joint on the lower control

arm that allows the knuckle to move up and down,

and turn with ease.

DIAGNOSIS AND TESTING - LOWER BALL

JOINT

With the weight of the vehicle resting on the road

wheels, grasp the special fitting cap on the bottom of

the ball joint and with no mechanical assistance or

added force, attempt to rotate the grease fitting.

If the ball joint is worn, the grease fitting will

rotate easily. If movement is noted, replacement of

the control arm is recommended.

LOWER BALL JOINT SEAL

BOOT

DESCRIPTION - EXPORT

The lower ball joint seal boot is a two piece unit. It

consists of the seal boot, plus a separate shield that

is located in a groove at the top of the seal boot.

NOTE: The seal boot should only be replaced if

damaged during vehicle service. The entire lower

control arm should be replaced if the joint has been

contaminated.

Fig. 16 Correctly Installed Eccentric Attaching Bolt

1 - STEERING KNUCKLE

2 - FLANGED BOLT IN TOP HOLE

3 - CAM BOLT IN BOTTOM HOLE

4 - STRUT CLEVIS BRACKET

2 - 10 FRONT SUSPENSIONRS

KNUCKLE (Continued)

ProCarManuals.com

Page 35 of 2399

(4) Wipe any grease off the ball joint stem using a

clean shop towel with MopartBrake Parts Cleaner

applied to it.

CAUTION: Do not attempt to install a normal grease

zirc in the ball joint an lubricate the joint through

the zirc fitting.

(5) Reinstall steering knuckle on vehicle. (Refer to

2 - SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

INSTALLATION - EXPORT

(1) Place a liberal dab of MopartWheel Bearing

Grease around the base of the ball joint stem at the

socket.

(2) Install aNEWseal boot by hand as far as pos-

sible on the ball joint.

CAUTION: Do not use an arbor press to install the

sealing boot on the ball joint. Damage to the seal-

ing boot will occur if excessive pressure is applied

to the sealing boot when it is being installed.

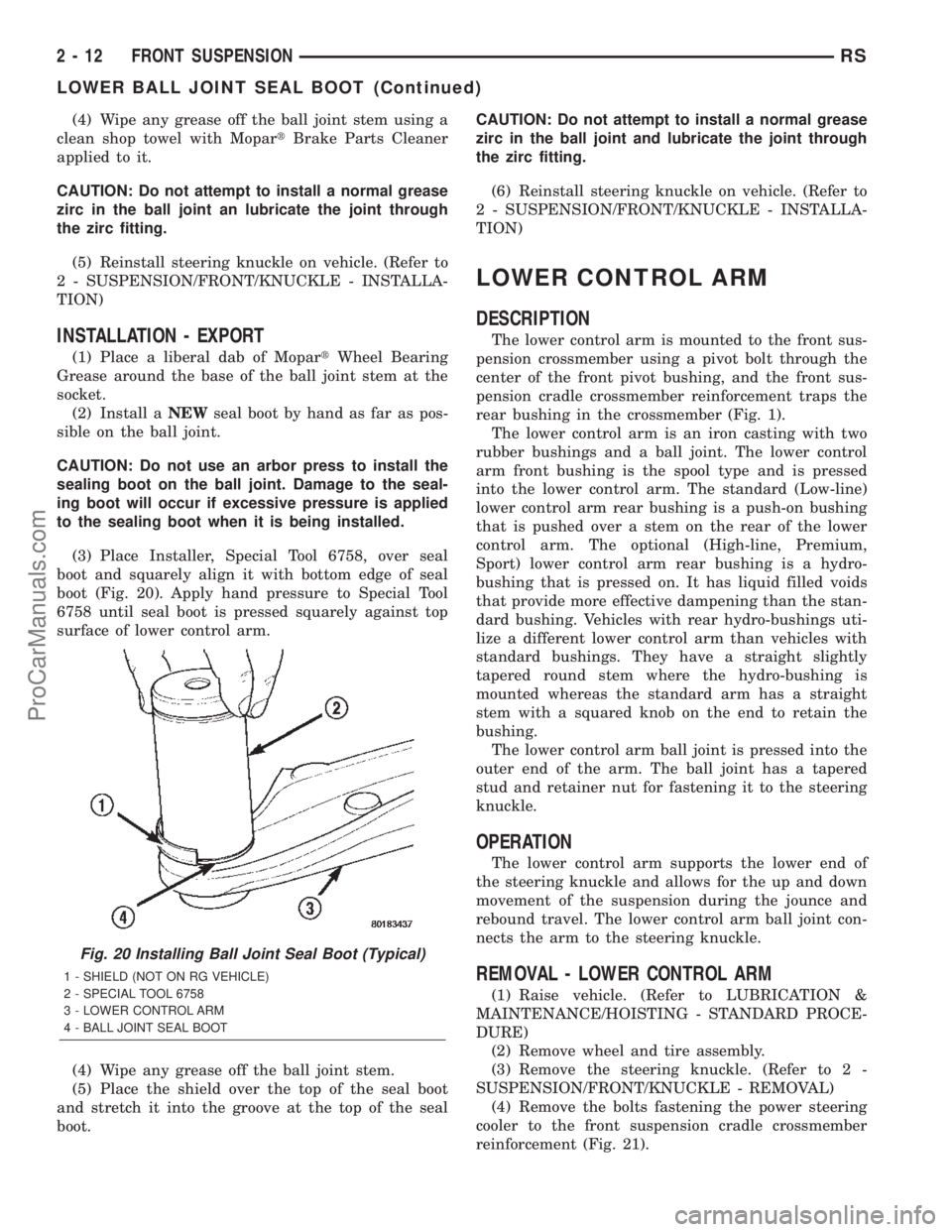

(3) Place Installer, Special Tool 6758, over seal

boot and squarely align it with bottom edge of seal

boot (Fig. 20). Apply hand pressure to Special Tool

6758 until seal boot is pressed squarely against top

surface of lower control arm.

(4) Wipe any grease off the ball joint stem.

(5) Place the shield over the top of the seal boot

and stretch it into the groove at the top of the seal

boot.CAUTION: Do not attempt to install a normal grease

zirc in the ball joint and lubricate the joint through

the zirc fitting.

(6) Reinstall steering knuckle on vehicle. (Refer to

2 - SUSPENSION/FRONT/KNUCKLE - INSTALLA-

TION)

LOWER CONTROL ARM

DESCRIPTION

The lower control arm is mounted to the front sus-

pension crossmember using a pivot bolt through the

center of the front pivot bushing, and the front sus-

pension cradle crossmember reinforcement traps the

rear bushing in the crossmember (Fig. 1).

The lower control arm is an iron casting with two

rubber bushings and a ball joint. The lower control

arm front bushing is the spool type and is pressed

into the lower control arm. The standard (Low-line)

lower control arm rear bushing is a push-on bushing

that is pushed over a stem on the rear of the lower

control arm. The optional (High-line, Premium,

Sport) lower control arm rear bushing is a hydro-

bushing that is pressed on. It has liquid filled voids

that provide more effective dampening than the stan-

dard bushing. Vehicles with rear hydro-bushings uti-

lize a different lower control arm than vehicles with

standard bushings. They have a straight slightly

tapered round stem where the hydro-bushing is

mounted whereas the standard arm has a straight

stem with a squared knob on the end to retain the

bushing.

The lower control arm ball joint is pressed into the

outer end of the arm. The ball joint has a tapered

stud and retainer nut for fastening it to the steering

knuckle.

OPERATION

The lower control arm supports the lower end of

the steering knuckle and allows for the up and down

movement of the suspension during the jounce and

rebound travel. The lower control arm ball joint con-

nects the arm to the steering knuckle.

REMOVAL - LOWER CONTROL ARM

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove wheel and tire assembly.

(3) Remove the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(4) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 21).

Fig. 20 Installing Ball Joint Seal Boot (Typical)

1 - SHIELD (NOT ON RG VEHICLE)

2 - SPECIAL TOOL 6758

3 - LOWER CONTROL ARM

4 - BALL JOINT SEAL BOOT

2 - 12 FRONT SUSPENSIONRS

LOWER BALL JOINT SEAL BOOT (Continued)

ProCarManuals.com

Page 40 of 2399

to minimize the body roll of the vehicle during sus-

pension movement.

Connecting the stabilizer bar links to the strut

assemblies helps reduce the fore-and-aft rate of the

stabilizer bar from the rest of the front suspension.

REMOVAL

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

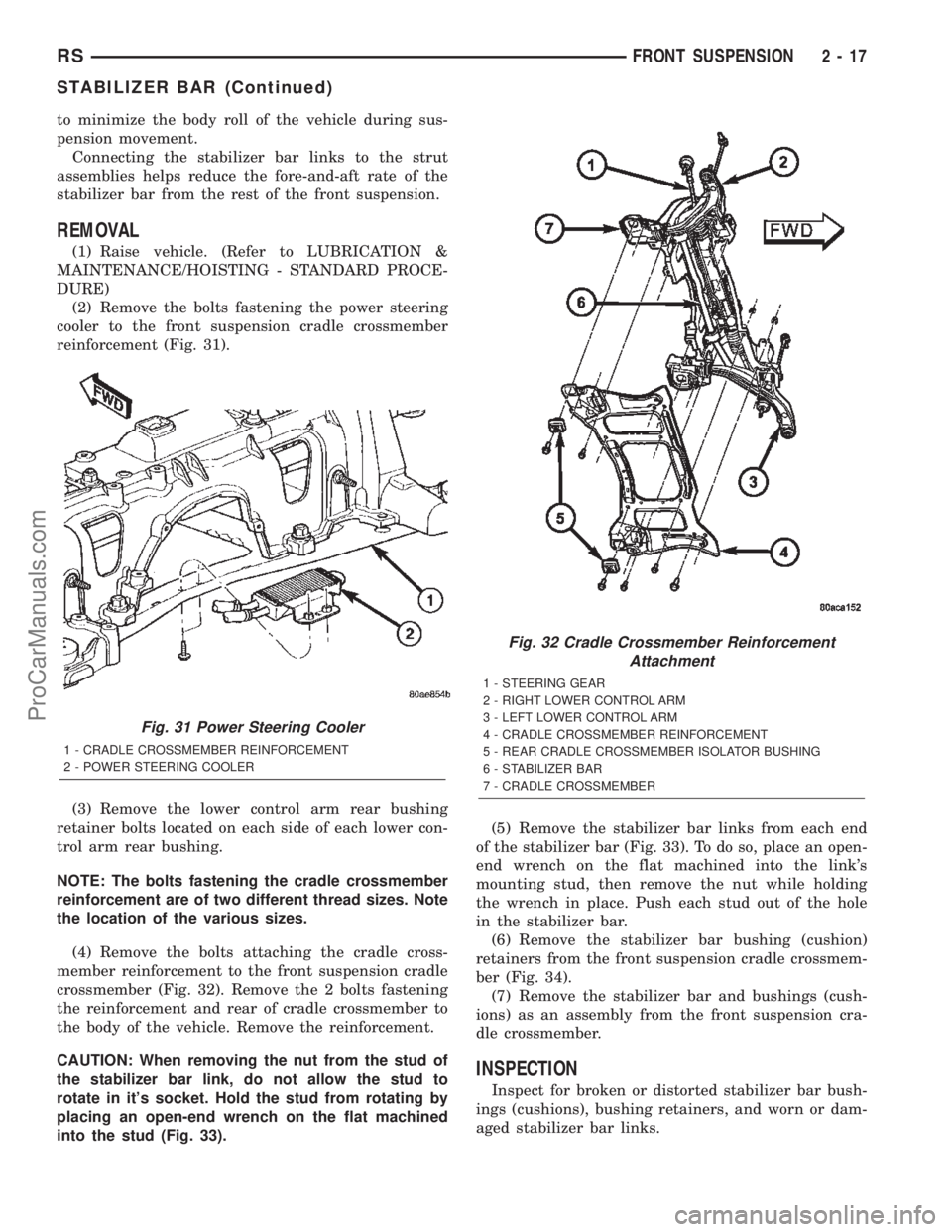

(2) Remove the bolts fastening the power steering

cooler to the front suspension cradle crossmember

reinforcement (Fig. 31).

(3) Remove the lower control arm rear bushing

retainer bolts located on each side of each lower con-

trol arm rear bushing.

NOTE: The bolts fastening the cradle crossmember

reinforcement are of two different thread sizes. Note

the location of the various sizes.

(4) Remove the bolts attaching the cradle cross-

member reinforcement to the front suspension cradle

crossmember (Fig. 32). Remove the 2 bolts fastening

the reinforcement and rear of cradle crossmember to

the body of the vehicle. Remove the reinforcement.

CAUTION: When removing the nut from the stud of

the stabilizer bar link, do not allow the stud to

rotate in it's socket. Hold the stud from rotating by

placing an open-end wrench on the flat machined

into the stud (Fig. 33).(5) Remove the stabilizer bar links from each end

of the stabilizer bar (Fig. 33). To do so, place an open-

end wrench on the flat machined into the link's

mounting stud, then remove the nut while holding

the wrench in place. Push each stud out of the hole

in the stabilizer bar.

(6) Remove the stabilizer bar bushing (cushion)

retainers from the front suspension cradle crossmem-

ber (Fig. 34).

(7) Remove the stabilizer bar and bushings (cush-

ions) as an assembly from the front suspension cra-

dle crossmember.

INSPECTION

Inspect for broken or distorted stabilizer bar bush-

ings (cushions), bushing retainers, and worn or dam-

aged stabilizer bar links.

Fig. 31 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

Fig. 32 Cradle Crossmember Reinforcement

Attachment

1 - STEERING GEAR

2 - RIGHT LOWER CONTROL ARM

3 - LEFT LOWER CONTROL ARM

4 - CRADLE CROSSMEMBER REINFORCEMENT

5 - REAR CRADLE CROSSMEMBER ISOLATOR BUSHING

6 - STABILIZER BAR

7 - CRADLE CROSSMEMBER

RSFRONT SUSPENSION2-17

STABILIZER BAR (Continued)

ProCarManuals.com

Page 43 of 2399

The coil spring controls ride quality and maintains

proper ride height.

The spring isolators isolate the coil spring at the

top and bottom from coming into metal-to-metal con-

tact with the upper seat and strut.

The jounce bumper limits suspension travel and

metal-to-metal contact under full jounce condition.

The strut dampens jounce and rebound motions of

the coil spring and suspension.

During steering maneuvers, the strut assembly

(through a pivot bearing in the upper strut mount)

and steering knuckle (through the lower ball joint)

turn as an assembly.

DIAGNOSIS AND TESTING - STRUT ASSEMBLY

(1) Inspect for damaged or broken coil springs

(Fig. 38).

(2) Inspect for torn or damaged strut assembly

dust boots (Fig. 38).

(3) Inspect the coil spring isolator on the lower

spring seat for any signs of damage or deterioration.

(4) Lift dust boot (Fig. 39) and inspect strut

assembly for evidence of fluid running from the

upper end of fluid reservoir. (Actual leakage will be astream of fluid running down the side and dripping

off lower end of unit). A slight amount of seepage

between the strut rod and strut shaft seal is not

unusual and does not affect performance of the strut

assembly (Fig. 39). Also inspect jounce bumpers for

signs of damage or deterioration.

REMOVAL - STRUT ASSEMBLY

WARNING: DO NOT REMOVE THE NUT FROM THE

STRUT ROD WHILE STRUT ASSEMBLY IS

INSTALLED IN VEHICLE, OR BEFORE STRUT

ASSEMBLY SPRING IS COMPRESSED.

(1) Raise the vehicle. See Hoisting in Lubrication

and Maintenance.

(2) Remove the wheel and tire assembly from loca-

tion on front of vehicle requiring strut removal.

(3) If both strut assemblies are to be removed,

mark the strut assemblies right or left according to

which side of the vehicle they were removed from.

(4) Remove the hydraulic brake hose routing

bracket and the speed sensor cable routing bracket

from the strut damper brackets (Fig. 40).

Fig. 38 STRUT ASSEMBLY

1 - NUT 6 - COIL SPRING

2 - UPPER MOUNT 7 - DUST SHIELD

3 - PIVOT BEARING 8 - JOUNCE BUMPER

4 - UPPER SPRING SEAT 9 - LOWER SPRING ISOLATOR

5 - UPPER SPRING ISOLATOR 10 - STRUT (DAMPER)

2 - 20 FRONT SUSPENSIONRS

STRUT (Continued)

ProCarManuals.com

Page 52 of 2399

BUSHINGS

REMOVAL - LEAF SPRING FRONT BUSHING

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 3).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

bushing replacement. Jack pad should just contact

axle.

(3) Remove shock absorber lower mounting bolt.

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(4) Remove four bolts securing leaf spring front

mounting bracket to the body (Fig. 3).

(5) Using jack,slowlylower rear axle, permitting

the forward end of rear spring to hang down. Lowerit enough to allow access to spring pivot bolt. It may

be necessary to place a wooden block between the

spring and vehicle to hold forward end of the spring

in place.

(6) Remove leaf spring forward pivot bolt, then

remove mounting bracket.

(7) Straighten the retainer tabs on the bushing

(Fig. 4).

(8) Place Remover/Installer, Special Tool 8459 on

leaf spring and bushing as shown (Fig. 5) and tighten

Set Screw securing Remover Plate to tool threaded

shaft.

(9) Tighten nut (Fig. 5), removing bushing from

spring eye.

(10) Remove the tool from spring, then remove

bushing from tool.

INSTALLATION - LEAF SPRING FRONT

BUSHING

(1) Install by hand NEW bushing in left side of

leaf spring eye.

(2) Place Remover/Installer, Special Tool 8459 on

leaf spring and bushing as shown (Fig. 6) and tighten

Set Screw securing Installer Plate (8459±3) to tool

threaded shaft.

(3) Tighten nut (Fig. 6), installing bushing in

spring eye. Tighten nut until there is approximately

a 1 mm gap between the bushing flange and the

spring eye.Do not bottom the flange against the

spring eye.

(4) Remove Remover/Installer from the bushing

and leaf spring.

(5) Bend the retainer tabs on bushing outward

against spring eye.

Fig. 3 LIFTING POINT AND SPRING MOUNT

1 - BODY SILL AREA

2 - MOUNTING BOLTS

3 - SPRING MOUNTING BRACKET

4 - LEAF SPRING

5 - HOIST LIFT ARM

6 - WOODEN BLOCK

Fig. 4 STRAIGHTENED RETAINING TABS

1 - SPRING EYE

2 - RETAINING TABS

RSREAR SUSPENSION2-29

ProCarManuals.com