manual radio set CHRYSLER CARAVAN 2002 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 388 of 2399

CONVENTIONAL BATTERY CHARGING TIME TABLE

Charging

Amperage5 Amps10

Amps20 Amps

Open Circuit

VoltageHours Charging @ 21É C (70É

F)

12.25 to 12.49 6 hours 3 hours 1.5

hours

12.00 to 12.24 10 hours 5 hours 2.5

hours

10.00 to 11.99 14 hours 7 hours 3.5

hours

Below 10.00 18 hours 9 hours 4.5

hours

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used if no other battery tester is

available.

Before proceeding with this test, completely charge

the battery. Refer to Standard Procedures for the

proper battery charging procedures.

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

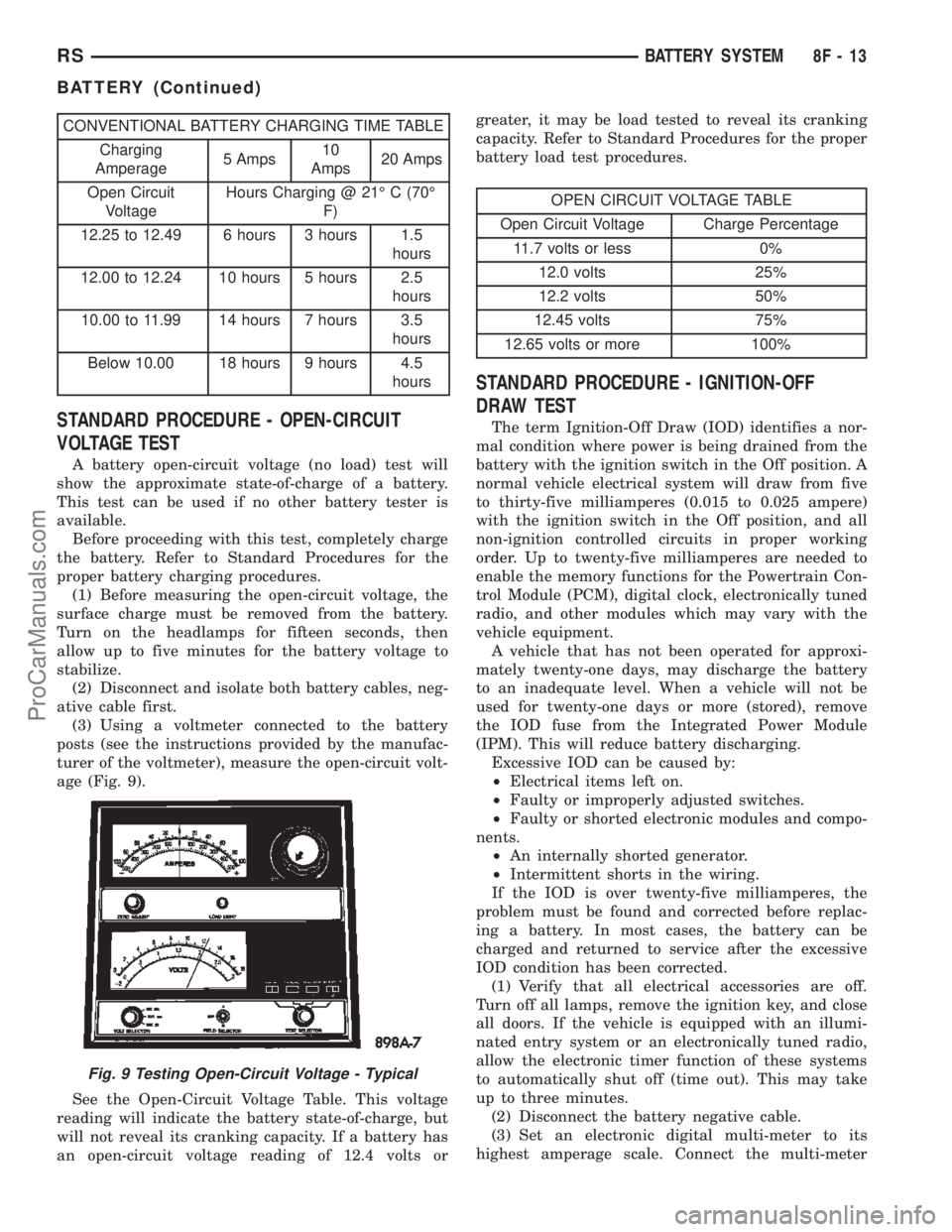

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts orgreater, it may be load tested to reveal its cranking

capacity. Refer to Standard Procedures for the proper

battery load test procedures.

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.45 volts 75%

12.65 volts or more 100%

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from five

to thirty-five milliamperes (0.015 to 0.025 ampere)

with the ignition switch in the Off position, and all

non-ignition controlled circuits in proper working

order. Up to twenty-five milliamperes are needed to

enable the memory functions for the Powertrain Con-

trol Module (PCM), digital clock, electronically tuned

radio, and other modules which may vary with the

vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty-one days, may discharge the battery

to an inadequate level. When a vehicle will not be

used for twenty-one days or more (stored), remove

the IOD fuse from the Integrated Power Module

(IPM). This will reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over twenty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes.

(2) Disconnect the battery negative cable.

(3) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

Fig. 9 Testing Open-Circuit Voltage - Typical

RSBATTERY SYSTEM8F-13

BATTERY (Continued)

ProCarManuals.com

Page 425 of 2399

²Intermittent shorts in the wiring.

If the IOD is over twenty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to three minutes.

(2) Disconnect the battery negative cable.

(3) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

between the disconnected battery negative cable ter-

minal clamp and the battery negative terminal post.

Make sure that the doors remain closed so that the

illuminated entry system is not activated. The multi-

meter amperage reading may remain high for up to

three minutes, or may not give any reading at all

while set in the highest amperage scale, depending

upon the electrical equipment in the vehicle. The

multi-meter leads must be securely clamped to the

battery negative cable terminal clamp and the bat-

tery negative terminal post. If continuity between the

battery negative terminal post and the negative cable

terminal clamp is lost during any part of the IOD

test, the electronic timer function will be activated

and all of the tests will have to be repeated.

(4) After about three minutes, the high-amperage

IOD reading on the multi-meter should become very

low or nonexistent, depending upon the electrical

equipment in the vehicle. If the amperage reading

remains high, remove and replace each fuse or circuit

breaker in the Integrated Power Module (IPM), one

at a time until the amperage reading becomes very

low, or nonexistent. Refer to the appropriate wiring

information in this service manual for complete Inte-

grated Power Module fuse, circuit breaker, and cir-

cuit identification. This will isolate each circuit and

identify the circuit that is the source of the high-am-

perage IOD. If the amperage reading remains high

after removing and replacing each fuse and circuit

breaker, disconnect the wire harness from the gener-

ator. If the amperage reading now becomes very low

or nonexistent, refer to Charging System for the

proper charging system diagnosis and testing proce-

dures. After the high-amperage IOD has been cor-

rected, switch the multi-meter to progressively lower

amperage scales and, if necessary, repeat the fuse

and circuit breaker remove-and-replace process to

identify and correct all sources of excessive IOD. It is

now safe to select the lowest milliampere scale of the

multi-meter to check the low-amperage IOD.CAUTION: Do not open any doors, or turn on any

electrical accessories with the lowest milliampere

scale selected, or the multi-meter may be damaged.

(5) Allow twenty minutes for the IOD to stabilize

and observe the multi-meter reading. The low-amper-

age IOD should not exceed twenty-five milliamperes

(0.025 ampere). If the current draw exceeds twenty-

five milliamperes, isolate each circuit using the fuse

and circuit breaker remove-and-replace process in

Step 4. The multi-meter reading will drop to within

the acceptable limit when the source of the excessive

current draw is disconnected. Repair this circuit as

required; whether a wiring short, incorrect switch

adjustment, or a component failure is at fault.

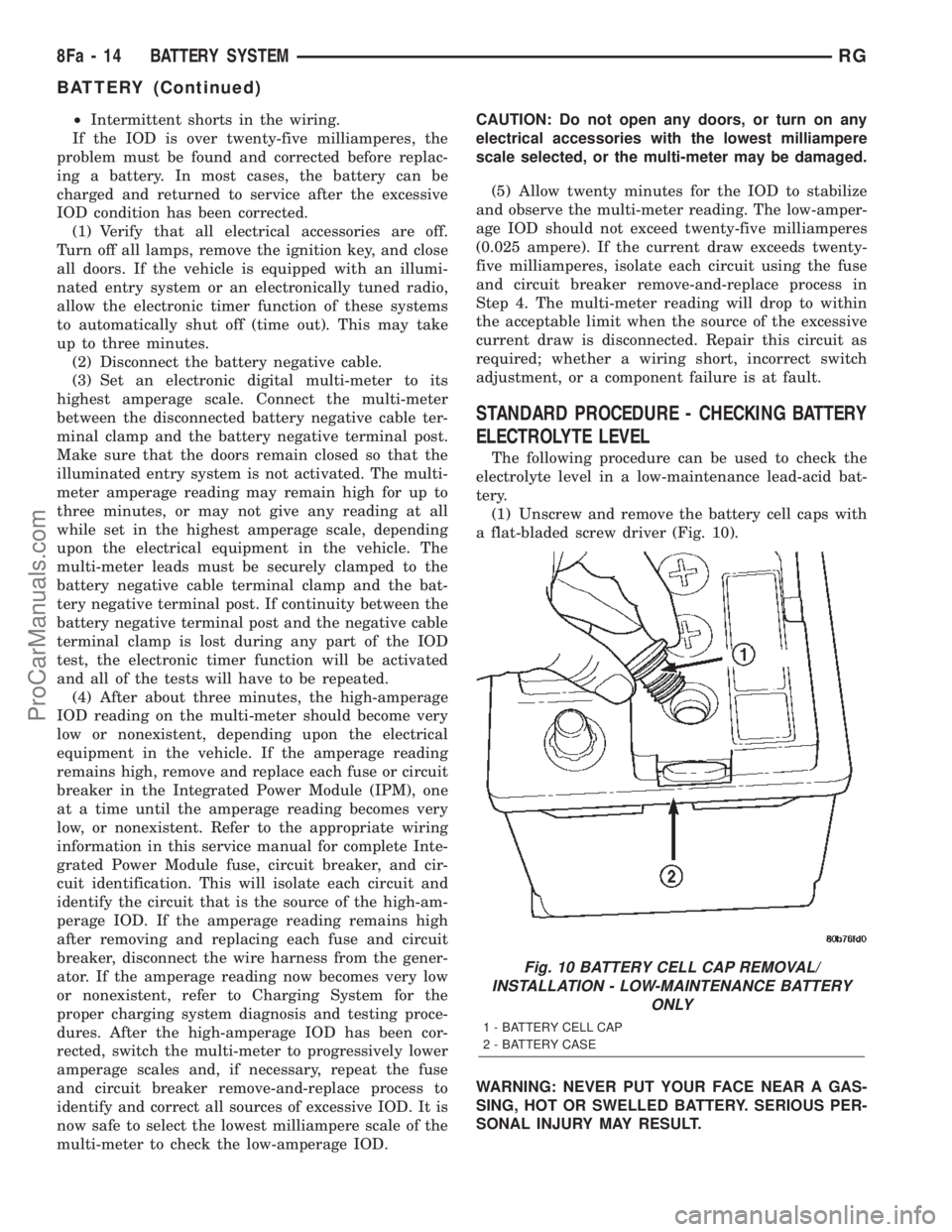

STANDARD PROCEDURE - CHECKING BATTERY

ELECTROLYTE LEVEL

The following procedure can be used to check the

electrolyte level in a low-maintenance lead-acid bat-

tery.

(1) Unscrew and remove the battery cell caps with

a flat-bladed screw driver (Fig. 10).

WARNING: NEVER PUT YOUR FACE NEAR A GAS-

SING, HOT OR SWELLED BATTERY. SERIOUS PER-

SONAL INJURY MAY RESULT.

Fig. 10 BATTERY CELL CAP REMOVAL/

INSTALLATION - LOW-MAINTENANCE BATTERY

ONLY

1 - BATTERY CELL CAP

2 - BATTERY CASE

8Fa - 14 BATTERY SYSTEMRG

BATTERY (Continued)

ProCarManuals.com

Page 485 of 2399

INSTALLATION

When replacing the spark plugs and spark plug

cables, route the cables correctly and secure them in

the appropriate retainers. Failure to route the cables

properly can cause the radio to reproduce ignition

noise, cross ignition of the spark plugs orshort cir-

cuit the cables to ground.

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 17.5 N´m (13 ft. lbs.)

torque.

(3) Install spark plug cables over spark plugs. A

click will be heard and felt when the cable properly

attaches to the spark plug.

SPARK PLUG CABLE

DESCRIPTION

Spark Plug cables are sometimes referred to as

secondary ignition wires. The wires transfer electri-

cal current from the ignition coil pack to individual

spark plugs at each cylinder. The resistive spark plug

cables are of nonmetallic construction. The cables

provide suppression of radio frequency emissions

from the ignition system.

Check the spark plug cable connections for good

contact at the coil, and spark plugs. Terminals should

be fully seated. The insulators should be in good con-

dition and should fit tightly on the coil, and spark

plugs. Spark plug cables with insulators that are

cracked or torn must be replaced.

Clean Spark Plug cables with a cloth moistened

with a non-flammable solvent. Wipe the cables dry.

Check for brittle or cracked insulation. The spark

plug cables and spark plug boots are made from high

temperature silicone materials. All spark plug cable

leads are properly identified with cylinder numbers.

The inside of most the spark plug boot is coated with

a special high temperature silicone grease for greater

sealing and to minimize boot bonding to the spark

plug insulator.

REMOVAL

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

Remove spark plug cable from coil first.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

INSTALLATION

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube, then connect the

other end to coil pack.

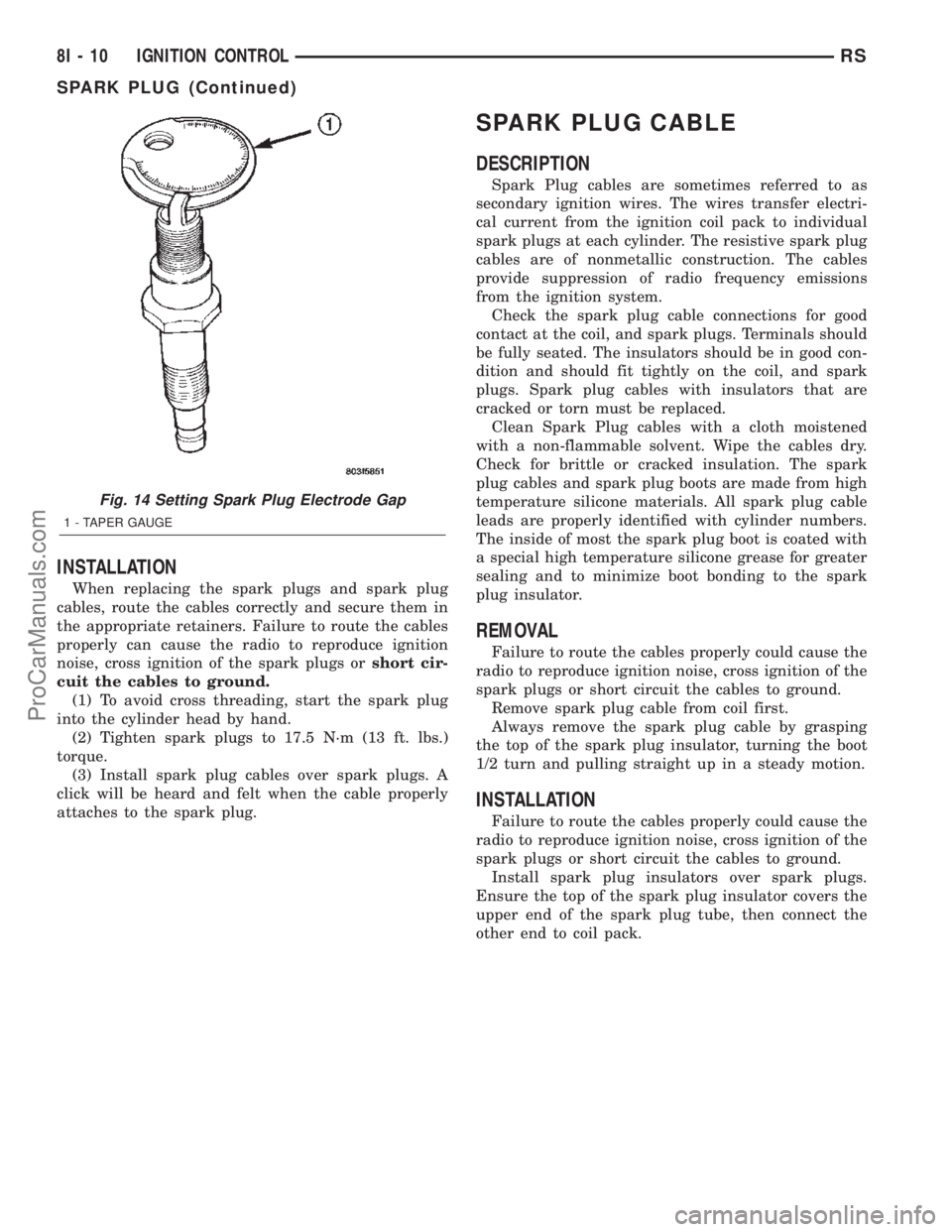

Fig. 14 Setting Spark Plug Electrode Gap

1 - TAPER GAUGE

8I - 10 IGNITION CONTROLRS

SPARK PLUG (Continued)

ProCarManuals.com

Page 593 of 2399

The eight-way power seat is also available with the

heated seat and memory seat system that automati-

cally positions the power seat for two different driv-

ers. Refer toHeated Seatsfor more information on

the heated seat option. Refer toDescription Mem-

ory Seat Systemin this section for more informa-

tion on the memory seat system.

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

²Programmable Communications Interface (PCI)

data bus network

Refer to Wiring Diagrams for complete circuit dia-

grams. Following are general descriptions and opera-

tions for the major components in the power seat

system and memory seat system.

DESCRIPTION - MEMORY SYSTEM

An electronic memory system is available on some

models. The memory system is able to store and

recall the driver side power seat positions (including

the power recliner position) and both outside side

view mirrors positions for two drivers. On vehicles

equipped with a factory radio, the memory system is

also able to store and recall radio station presets for

two drivers. The memory system also will store and

recall the last station listened to for each driver, even

if it is not one of the preset stations.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

EVIC module, which is located in the overhead con-

sole.

A Memory Seat Mirror Module (MSMM) is used on

some models to control and integrate the many elec-

tronic functions and features included in the memory

seat and mirror systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on both outside side

view mirrors

²Position potentiometers on the driver side power

seat track and power seat recliner motors.

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable).

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) J1850 data bus network. The PCI

data bus network allows the sharing of sensor infor-

mation. This helps to reduce wire harness complexity,

internal controller hardware, and component sensor

current loads. At the same time, this system provides

increased reliability, enhanced diagnostics, and

allows the addition of many new feature capabilities.

Initial diagnosis of these electronic modules or the

PCI data bus network requires the use of a DRB IIIt

scan tool and the proper Diagnostic Procedures man-

ual. If this method does not prove conclusive, the use

of a automotive meter such as the Fluket, the proper

wiring schematics and the service manual diagnostic

routines are required.

The other electronic modules that may affect mem-

ory system operation are as follows:

Fig. 1 Identifying a Side Airbag Equipped Seat

1 - Airbag Label

8N - 52 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

ProCarManuals.com

Page 902 of 2399

8W-45 BODY CONTROL MODULE

Component Page

A/C- Heater Control.............. 8W-45-16, 19

Auto Temp Control............... 8W-45-16, 19

Automatic Day/Night Mirror........... 8W-45-11

Body Control Module . . . 8W-45-2, 3, 4, 5, 6, 7, 8, 9,

10, 11, 12, 13, 15, 16, 17, 18, 19, 20

Center Dome Lamp................ 8W-45-9, 13

Clockspring........................ 8W-45-17

Controller Antilock Brake............. 8W-45-13

Diagnostic Junction Port.............. 8W-45-12

Driver Door Courtesy Lamp........... 8W-45-15

Driver Door Lock Switch........... 8W-45-12, 15

Driver Heated Seat Module............ 8W-45-11

Floor Console Lamp................. 8W-45-13

Front Cigar Lighter................. 8W-45-17

Front Control Module................. 8W-45-3

Front Reading Lamps/Switch........ 8W-45-8, 13

Fuel Pump Module.................. 8W-45-15

Fuse 14............................ 8W-45-3

Fuse 19............................ 8W-45-2

Fuse 20............................ 8W-45-2

Fuse 24............................ 8W-45-2

G301.......................... 8W-45-5, 6, 8

Glove Box Lamp.................... 8W-45-19

Halo Lamp........................ 8W-45-19

Headlamp Switch.............. 8W-45-11, 16, 20

Hood Ajar Switch................... 8W-45-12

Ignition Switch...................... 8W-45-3

Instrument Cluster............ 8W-45-16, 18, 19

Instrument Panel Switch

Bank.................. 8W-45-10, 11, 17, 19

Integrated Power Module..... 8W-45-2, 3, 5, 6, 13

Left B-Pillar Switch.................. 8W-45-9

Left Cylinder Lock Switch............. 8W-45-10

Left Front Door Lock Motor/Ajar

Switch......................... 8W-45-4, 7

Left Liftgate Flood Lamp............. 8W-45-12

Left Mid Reading Lamp............ 8W-45-9, 14

Left Power Mirror................... 8W-45-20

Left Rear Lamp Assembly............ 8W-45-5, 6

Left Rear Reading Lamp............ 8W-45-9, 14

Left Remote Radio Switch............. 8W-45-17

Left Repeater Lamp................. 8W-45-20

Left Sliding Door Control Module..... 8W-45-8, 10

Left Sliding Door Lock Motor........... 8W-45-7

Left Sliding Door Lock Motor/Ajar

Switch......................... 8W-45-7, 8Component Page

Left Stop/Turn Signal Relay............ 8W-45-5

Left Visor/Vanity Lamp............... 8W-45-13

License Lamp....................... 8W-45-8

Liftgate Ajar Switch................. 8W-45-12

Liftgate Cinch/Release Motor.......... 8W-45-12

Liftgate Cylinder Lock Switch.......... 8W-45-9

Memory Set Switch................... 8W-45-4

Message Center..................... 8W-45-18

Multi- Function Switch............... 8W-45-16

Name Brand Speaker Relay............ 8W-45-3

Overhead Console................. 8W-45-4, 11

Passenger Door Courtesy Lamp........ 8W-45-15

Passenger Door Lock Switch........ 8W-45-12, 15

Passenger Folding Mirror Relay........ 8W-45-20

Passenger Heated Seat Module......... 8W-45-11

Power Folding Mirror Switch.......... 8W-45-20

Power Liftgate Module................ 8W-45-8

Power Mirror Switch................. 8W-45-16

Radio............................. 8W-45-17

Rear Auto Temp Control Switch..... 8W-45-10, 19

Rear Blower Rear Control Switch....... 8W-45-10

Rear Dome Lamp.................... 8W-45-9

Rear Wiper Motor.................... 8W-45-8

Remote Keyless Entry Module....... 8W-45-4, 16

Right B-Pillar Switch................. 8W-45-9

Right Combination Relay.............. 8W-45-5

Right Cylinder Lock Switch........... 8W-45-10

Right Front Door Lock Motor/Ajar

Switch......................... 8W-45-7, 9

Right Liftgate Flood Lamp............ 8W-45-12

Right Mid Reading Lamp........... 8W-45-9, 14

Right Power Mirror.................. 8W-45-20

Right Rear Lamp Assembly........... 8W-45-5, 6

Right Rear Reading Lamp........... 8W-45-9, 14

Right Remote Radio Switch........... 8W-45-17

Right Repeater Lamp................ 8W-45-20

Right Sliding Door Control Module.... 8W-45-8, 10

Right Sliding Door Lock Motor.......... 8W-45-7

Right Sliding Door Lock Motor/Ajar

Switch......................... 8W-45-7, 8

Right Visor/Vanity Lamp.............. 8W-45-13

Thatcham Alarm Module............. 8W-45-10

Traction Control Switch.............. 8W-45-17

RS8W-45 BODY CONTROL MODULE8W-45-1

ProCarManuals.com

Page 1035 of 2399

Component Page

Memory Set Switch.................. 8W-80-84

Message Center (High Line)........... 8W-80-85

Mode Door Actuator (ATC)............ 8W-80-85

Mode Door Actuator (MTC)............ 8W-80-85

Multi-Function Switch............... 8W-80-85

Output Speed Sensor (EATX).......... 8W-80-86

Overhead Console (Except Base)........ 8W-80-86

Oxygen Sensor 1/1 Upstream (Gas)...... 8W-80-86

Oxygen Sensor 1/2 Downstream (Gas) . . . 8W-80-87

Park/Neutral Position Switch (ATX)..... 8W-80-87

Passenger Airbag................... 8W-80-87

Passenger Blend Door Actuator (ATC) . . . 8W-80-87

Passenger Blend Door Actuator (MTC) . . . 8W-80-87

Passenger Door Courtesy Lamp........ 8W-80-88

Passenger Door Lock Switch........... 8W-80-88

Passenger Folding Mirror Relay

(Built-Up-Export)................. 8W-80-88

Passenger Heated Seat Back........... 8W-80-88

Passenger Heated Seat Cushion........ 8W-80-88

Passenger Heated Seat Module C1...... 8W-80-89

Passenger Heated Seat Module C2...... 8W-80-89

Passenger Heated Seat Module C3...... 8W-80-89

Passenger Power Seat Front Riser Motor . 8W-80-89

Passenger Power Seat Horizontal Motor . . 8W-80-90

Passenger Power Seat Rear Riser Motor . . 8W-80-90

Passenger Power Seat Recliner Motor.... 8W-80-90

Passenger Power Seat Switch.......... 8W-80-90

Passenger Power Window Motor........ 8W-80-90

Passenger Power Window Switch....... 8W-80-91

Passenger Seat Belt Switch........... 8W-80-91

Passenger Seat Belt Tensioner......... 8W-80-91

Power Folding Mirror Switch

(Built-Up-Export)................. 8W-80-91

Power Liftgate Module C1............ 8W-80-92

Power Liftgate Module C2............ 8W-80-92

Power Liftgate Motor................ 8W-80-92

Power Mirror Switch................. 8W-80-93

Power Outlet....................... 8W-80-93

Power Seat Circuit Breaker (30A)....... 8W-80-93

Power Window Circuit Breaker (25A).... 8W-80-93

Power Window Switch (Lowline)........ 8W-80-94

Powertrain Control Module C1 (Gas).... 8W-80-94

Powertrain Control Module C2 (Gas).... 8W-80-95

Radiator Fan No. 1 (Diesel)........... 8W-80-96

Radiator Fan No. 1 (Gas)............. 8W-80-96

Radiator Fan No. 2 (Diesel)........... 8W-80-96

Radiator Fan No. 2 (Gas)............. 8W-80-96

Radiator Fan Relay (Gas)............. 8W-80-96

Radiator Fan Relay No. 1 (Diesel)....... 8W-80-97

Radiator Fan Relay No. 2 (Diesel)....... 8W-80-97

Radiator Fan Relay No. 3 (Diesel)....... 8W-80-97

Radio C1.......................... 8W-80-98

Radio C2.......................... 8W-80-98

Radio Choke....................... 8W-80-99Component Page

Rear A/C-Heater Unit (3 Zone HVAC).... 8W-80-99

Rear Auto Temp Control Switch (ATC) . . . 8W-80-99

Rear Blower Front Control Switch

(3 Zone HVAC)................... 8W-80-99

Rear Blower Motor Power Module

C1(ATC) ....................... 8W-80-100

Rear Blower Motor Power Module C2

(ATC).......................... 8W-80-100

Rear Blower Rear Control Switch C1

(3 Zone HVAC).................. 8W-80-100

Rear Blower Rear Control Switch C2

(3 Zone HVAC).................. 8W-80-100

Rear Dome Lamp (Except Luxury)..... 8W-80-100

Rear Mode Motor (ATC)............. 8W-80-101

Rear Power Outlet................. 8W-80-101

Rear Temperature Motor (ATC)........ 8W-80-101

Rear Washer Pump Motor............ 8W-80-101

Rear Wiper Motor.................. 8W-80-101

Recirculation Door Actuator (ATC)..... 8W-80-102

Recirculation Door Actuator (MTC)..... 8W-80-102

Remote Keyless Entry Antenna

(Japan)........................ 8W-80-102

Remote Keyless Entry Module........ 8W-80-102

Right B-Pillar Switch

(Power Sliding Door).............. 8W-80-102

Right Cinch/Release Motor

(Power Sliding Door).............. 8W-80-103

Right Combination Relay (Trailer Tow) . . 8W-80-103

Right Cylinder Lock Switch.......... 8W-80-103

Right Door Speaker................. 8W-80-103

Right Fog Lamp (Built-Up-Export)..... 8W-80-103

Right Fog Lamp (Except

Built-Up-Export)................. 8W-80-104

Right Front Door Ajar Switch (Base).... 8W-80-104

Right Front Door Lock Motor/Ajar

Switch (Except Base).............. 8W-80-104

Right Front Park/Turn Signal Lamp

(Except Built-Up-Export).......... 8W-80-104

Right Front Wheel Speed Sensor...... 8W-80-104

Right Full Open Switch

(Power Sliding Door).............. 8W-80-105

Right Headlamp (Except

Built-Up-Export)................. 8W-80-105

Right Headlamp Leveling Motor

(Built-Up-Export)................ 8W-80-105

Right High Beam Lamp

(Built-Up-Export)................ 8W-80-105

Right Instrument Panel Speaker...... 8W-80-105

Right Liftgate Flood Lamp........... 8W-80-106

Right Low Beam Lamp

(Built-Up-Export)................ 8W-80-106

Right Mid Reading Lamp

(Premium/Luxury)................ 8W-80-106

Right Park Lamp (Built-Up-Export).... 8W-80-106

Right Power Mirror................. 8W-80-106

8W - 80 - 4 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com

Page 1970 of 2399

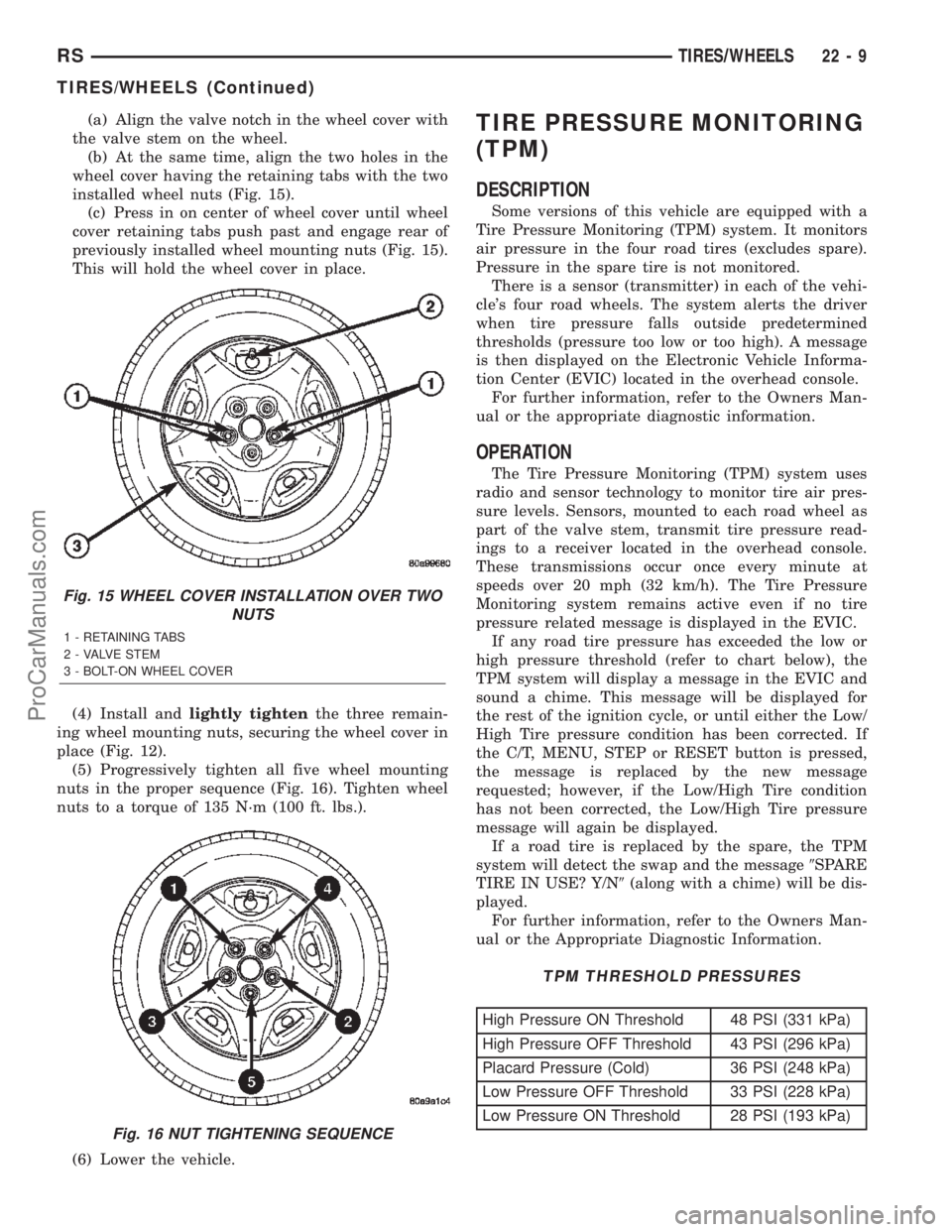

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.

(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.TIRE PRESSURE MONITORING

(TPM)

DESCRIPTION

Some versions of this vehicle are equipped with a

Tire Pressure Monitoring (TPM) system. It monitors

air pressure in the four road tires (excludes spare).

Pressure in the spare tire is not monitored.

There is a sensor (transmitter) in each of the vehi-

cle's four road wheels. The system alerts the driver

when tire pressure falls outside predetermined

thresholds (pressure too low or too high). A message

is then displayed on the Electronic Vehicle Informa-

tion Center (EVIC) located in the overhead console.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit tire pressure read-

ings to a receiver located in the overhead console.

These transmissions occur once every minute at

speeds over 20 mph (32 km/h). The Tire Pressure

Monitoring system remains active even if no tire

pressure related message is displayed in the EVIC.

If any road tire pressure has exceeded the low or

high pressure threshold (refer to chart below), the

TPM system will display a message in the EVIC and

sound a chime. This message will be displayed for

the rest of the ignition cycle, or until either the Low/

High Tire pressure condition has been corrected. If

the C/T, MENU, STEP or RESET button is pressed,

the message is replaced by the new message

requested; however, if the Low/High Tire condition

has not been corrected, the Low/High Tire pressure

message will again be displayed.

If a road tire is replaced by the spare, the TPM

system will detect the swap and the message9SPARE

TIRE IN USE? Y/N9(along with a chime) will be dis-

played.

For further information, refer to the Owners Man-

ual or the Appropriate Diagnostic Information.

TPM THRESHOLD PRESSURES

High Pressure ON Threshold 48 PSI (331 kPa)

High Pressure OFF Threshold 43 PSI (296 kPa)

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

ProCarManuals.com