shaft CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 1957 of 2399

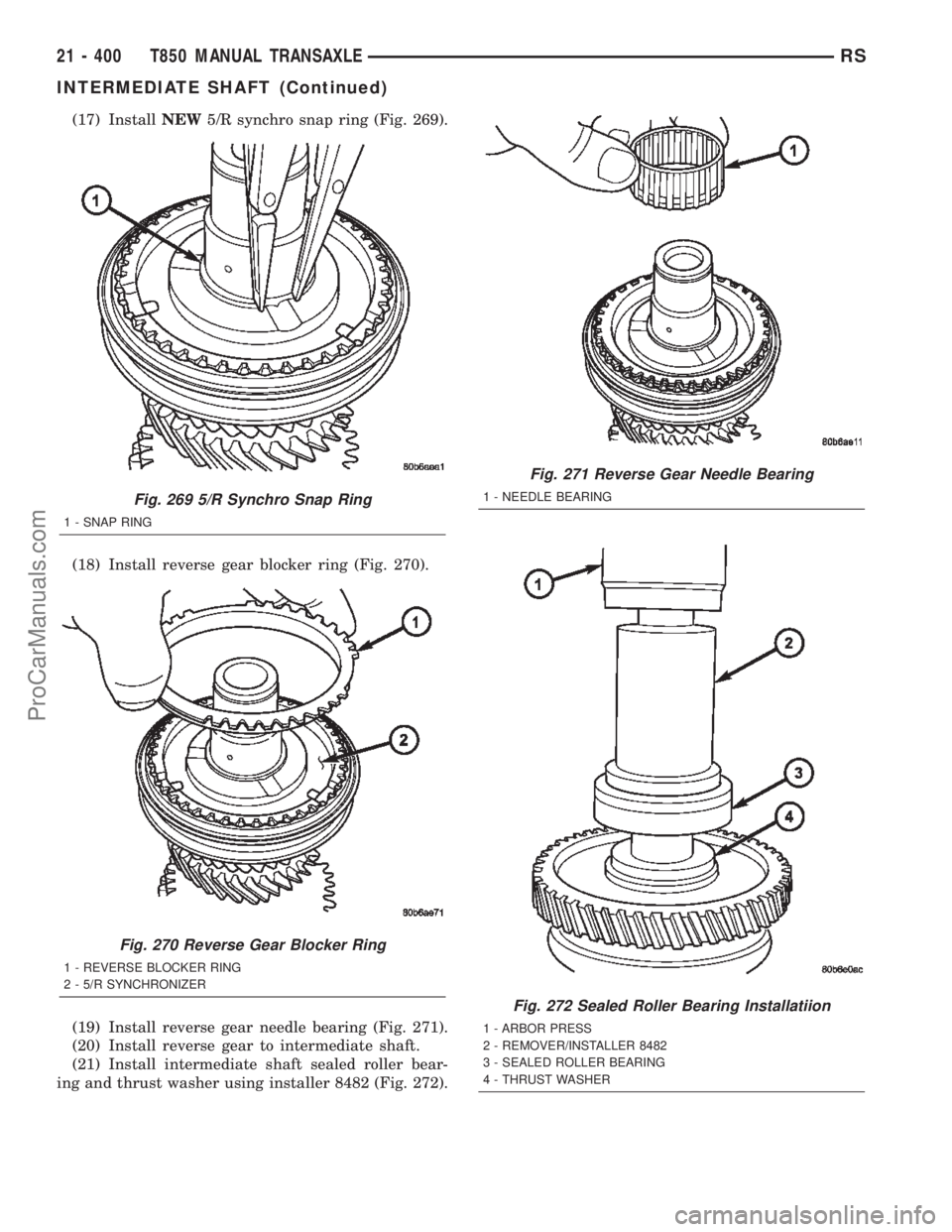

(17) InstallNEW5/R synchro snap ring (Fig. 269).

(18) Install reverse gear blocker ring (Fig. 270).

(19) Install reverse gear needle bearing (Fig. 271).

(20) Install reverse gear to intermediate shaft.

(21) Install intermediate shaft sealed roller bear-

ing and thrust washer using installer 8482 (Fig. 272).

Fig. 269 5/R Synchro Snap Ring

1 - SNAP RING

Fig. 270 Reverse Gear Blocker Ring

1 - REVERSE BLOCKER RING

2 - 5/R SYNCHRONIZER

Fig. 271 Reverse Gear Needle Bearing

1 - NEEDLE BEARING

Fig. 272 Sealed Roller Bearing Installatiion

1 - ARBOR PRESS

2 - REMOVER/INSTALLER 8482

3 - SEALED ROLLER BEARING

4 - THRUST WASHER

21 - 400 T850 MANUAL TRANSAXLERS

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1958 of 2399

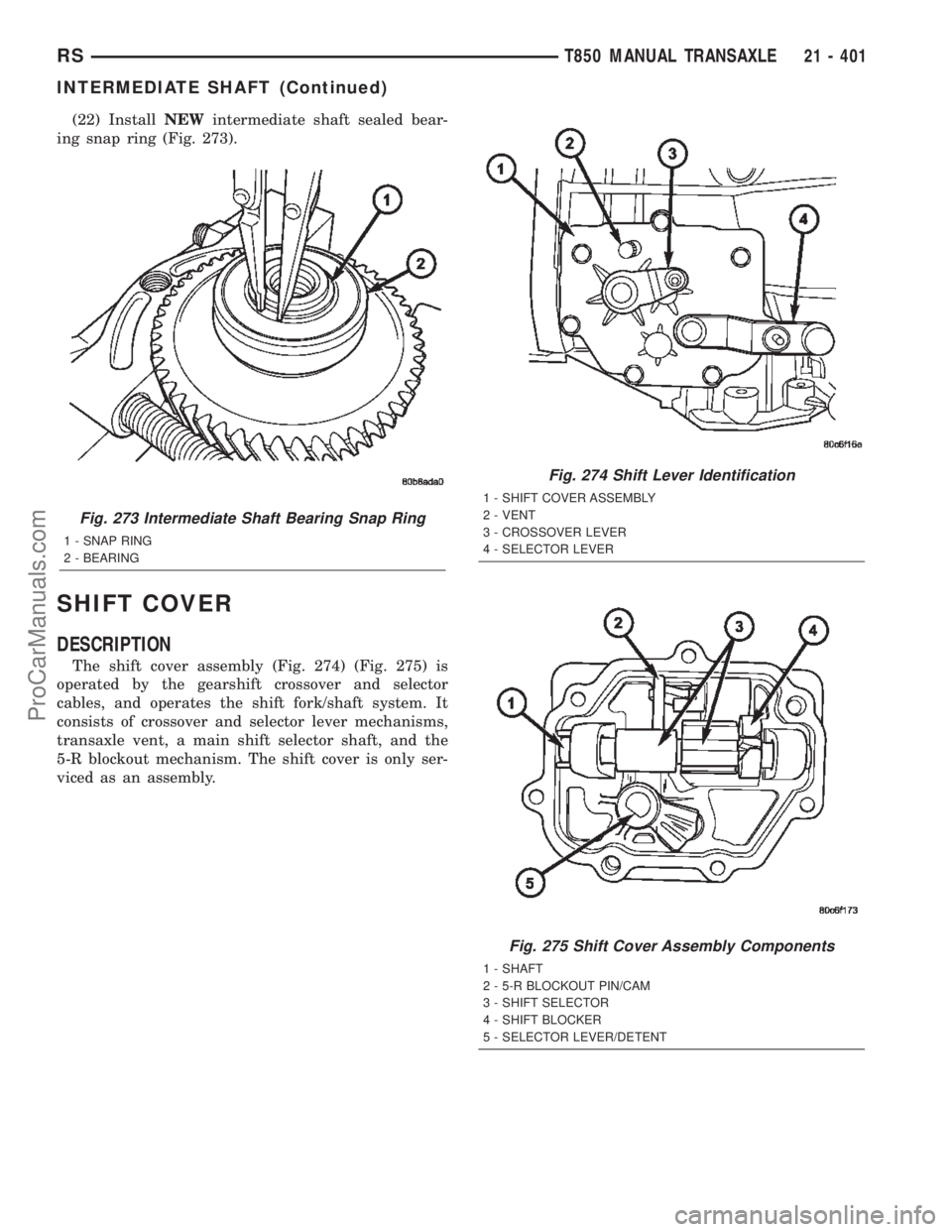

(22) InstallNEWintermediate shaft sealed bear-

ing snap ring (Fig. 273).

SHIFT COVER

DESCRIPTION

The shift cover assembly (Fig. 274) (Fig. 275) is

operated by the gearshift crossover and selector

cables, and operates the shift fork/shaft system. It

consists of crossover and selector lever mechanisms,

transaxle vent, a main shift selector shaft, and the

5-R blockout mechanism. The shift cover is only ser-

viced as an assembly.

Fig. 274 Shift Lever Identification

1 - SHIFT COVER ASSEMBLY

2 - VENT

3 - CROSSOVER LEVER

4 - SELECTOR LEVER

Fig. 273 Intermediate Shaft Bearing Snap Ring

1 - SNAP RING

2 - BEARING

Fig. 275 Shift Cover Assembly Components

1 - SHAFT

2 - 5-R BLOCKOUT PIN/CAM

3 - SHIFT SELECTOR

4 - SHIFT BLOCKER

5 - SELECTOR LEVER/DETENT

RST850 MANUAL TRANSAXLE21 - 401

INTERMEDIATE SHAFT (Continued)

ProCarManuals.com

Page 1959 of 2399

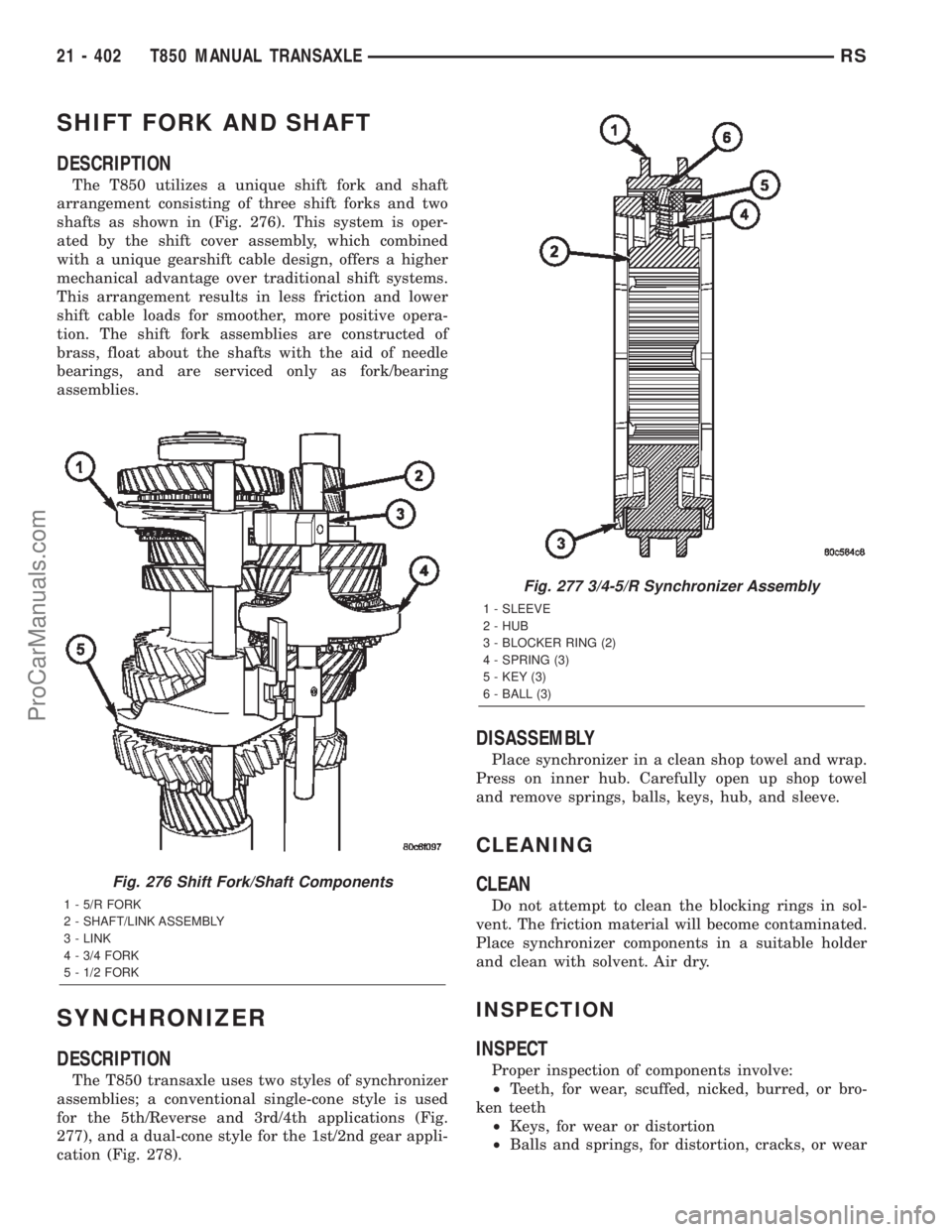

SHIFT FORK AND SHAFT

DESCRIPTION

The T850 utilizes a unique shift fork and shaft

arrangement consisting of three shift forks and two

shafts as shown in (Fig. 276). This system is oper-

ated by the shift cover assembly, which combined

with a unique gearshift cable design, offers a higher

mechanical advantage over traditional shift systems.

This arrangement results in less friction and lower

shift cable loads for smoother, more positive opera-

tion. The shift fork assemblies are constructed of

brass, float about the shafts with the aid of needle

bearings, and are serviced only as fork/bearing

assemblies.

SYNCHRONIZER

DESCRIPTION

The T850 transaxle uses two styles of synchronizer

assemblies; a conventional single-cone style is used

for the 5th/Reverse and 3rd/4th applications (Fig.

277), and a dual-cone style for the 1st/2nd gear appli-

cation (Fig. 278).

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

CLEANING

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECTION

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

Fig. 276 Shift Fork/Shaft Components

1 - 5/R FORK

2 - SHAFT/LINK ASSEMBLY

3 - LINK

4 - 3/4 FORK

5 - 1/2 FORK

Fig. 277 3/4-5/R Synchronizer Assembly

1 - SLEEVE

2 - HUB

3 - BLOCKER RING (2)

4 - SPRING (3)

5 - KEY (3)

6 - BALL (3)

21 - 402 T850 MANUAL TRANSAXLERS

ProCarManuals.com

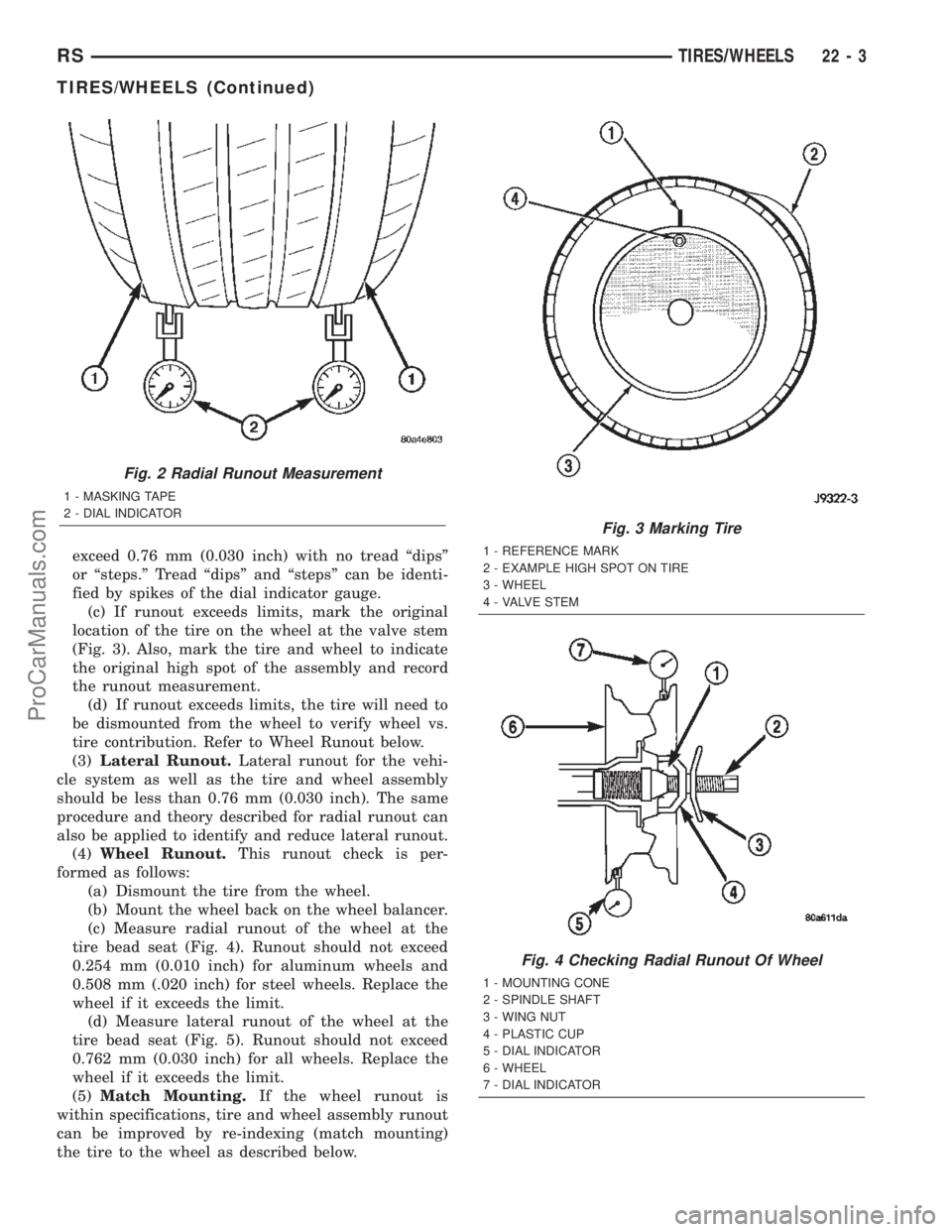

Page 1964 of 2399

exceed 0.76 mm (0.030 inch) with no tread ªdipsº

or ªsteps.º Tread ªdipsº and ªstepsº can be identi-

fied by spikes of the dial indicator gauge.

(c) If runout exceeds limits, mark the original

location of the tire on the wheel at the valve stem

(Fig. 3). Also, mark the tire and wheel to indicate

the original high spot of the assembly and record

the runout measurement.

(d) If runout exceeds limits, the tire will need to

be dismounted from the wheel to verify wheel vs.

tire contribution. Refer to Wheel Runout below.

(3)Lateral Runout.Lateral runout for the vehi-

cle system as well as the tire and wheel assembly

should be less than 0.76 mm (0.030 inch). The same

procedure and theory described for radial runout can

also be applied to identify and reduce lateral runout.

(4)Wheel Runout.This runout check is per-

formed as follows:

(a) Dismount the tire from the wheel.

(b) Mount the wheel back on the wheel balancer.

(c) Measure radial runout of the wheel at the

tire bead seat (Fig. 4). Runout should not exceed

0.254 mm (0.010 inch) for aluminum wheels and

0.508 mm (.020 inch) for steel wheels. Replace the

wheel if it exceeds the limit.

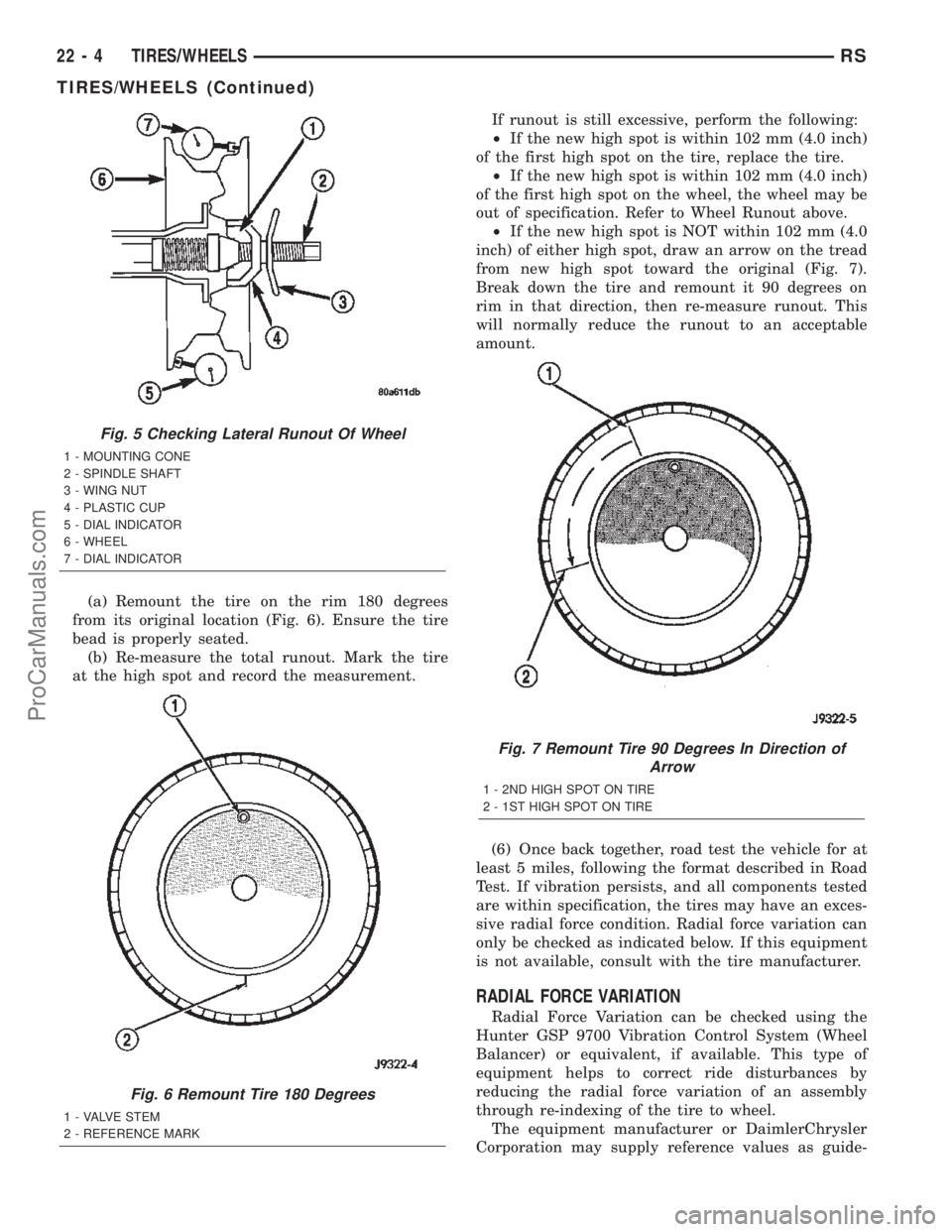

(d) Measure lateral runout of the wheel at the

tire bead seat (Fig. 5). Runout should not exceed

0.762 mm (0.030 inch) for all wheels. Replace the

wheel if it exceeds the limit.

(5)Match Mounting.If the wheel runout is

within specifications, tire and wheel assembly runout

can be improved by re-indexing (match mounting)

the tire to the wheel as described below.

Fig. 2 Radial Runout Measurement

1 - MASKING TAPE

2 - DIAL INDICATOR

Fig. 3 Marking Tire

1 - REFERENCE MARK

2 - EXAMPLE HIGH SPOT ON TIRE

3 - WHEEL

4 - VALVE STEM

Fig. 4 Checking Radial Runout Of Wheel

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

RSTIRES/WHEELS22-3

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 1965 of 2399

(a) Remount the tire on the rim 180 degrees

from its original location (Fig. 6). Ensure the tire

bead is properly seated.

(b) Re-measure the total runout. Mark the tire

at the high spot and record the measurement.If runout is still excessive, perform the following:

²If the new high spot is within 102 mm (4.0 inch)

of the first high spot on the tire, replace the tire.

²If the new high spot is within 102 mm (4.0 inch)

of the first high spot on the wheel, the wheel may be

out of specification. Refer to Wheel Runout above.

²If the new high spot is NOT within 102 mm (4.0

inch) of either high spot, draw an arrow on the tread

from new high spot toward the original (Fig. 7).

Break down the tire and remount it 90 degrees on

rim in that direction, then re-measure runout. This

will normally reduce the runout to an acceptable

amount.

(6) Once back together, road test the vehicle for at

least 5 miles, following the format described in Road

Test. If vibration persists, and all components tested

are within specification, the tires may have an exces-

sive radial force condition. Radial force variation can

only be checked as indicated below. If this equipment

is not available, consult with the tire manufacturer.

RADIAL FORCE VARIATION

Radial Force Variation can be checked using the

Hunter GSP 9700 Vibration Control System (Wheel

Balancer) or equivalent, if available. This type of

equipment helps to correct ride disturbances by

reducing the radial force variation of an assembly

through re-indexing of the tire to wheel.

The equipment manufacturer or DaimlerChrysler

Corporation may supply reference values as guide-

Fig. 5 Checking Lateral Runout Of Wheel

1 - MOUNTING CONE

2 - SPINDLE SHAFT

3 - WING NUT

4 - PLASTIC CUP

5 - DIAL INDICATOR

6 - WHEEL

7 - DIAL INDICATOR

Fig. 6 Remount Tire 180 Degrees

1 - VALVE STEM

2 - REFERENCE MARK

Fig. 7 Remount Tire 90 Degrees In Direction of

Arrow

1 - 2ND HIGH SPOT ON TIRE

2 - 1ST HIGH SPOT ON TIRE

22 - 4 TIRES/WHEELSRS

TIRES/WHEELS (Continued)

ProCarManuals.com

Page 2004 of 2399

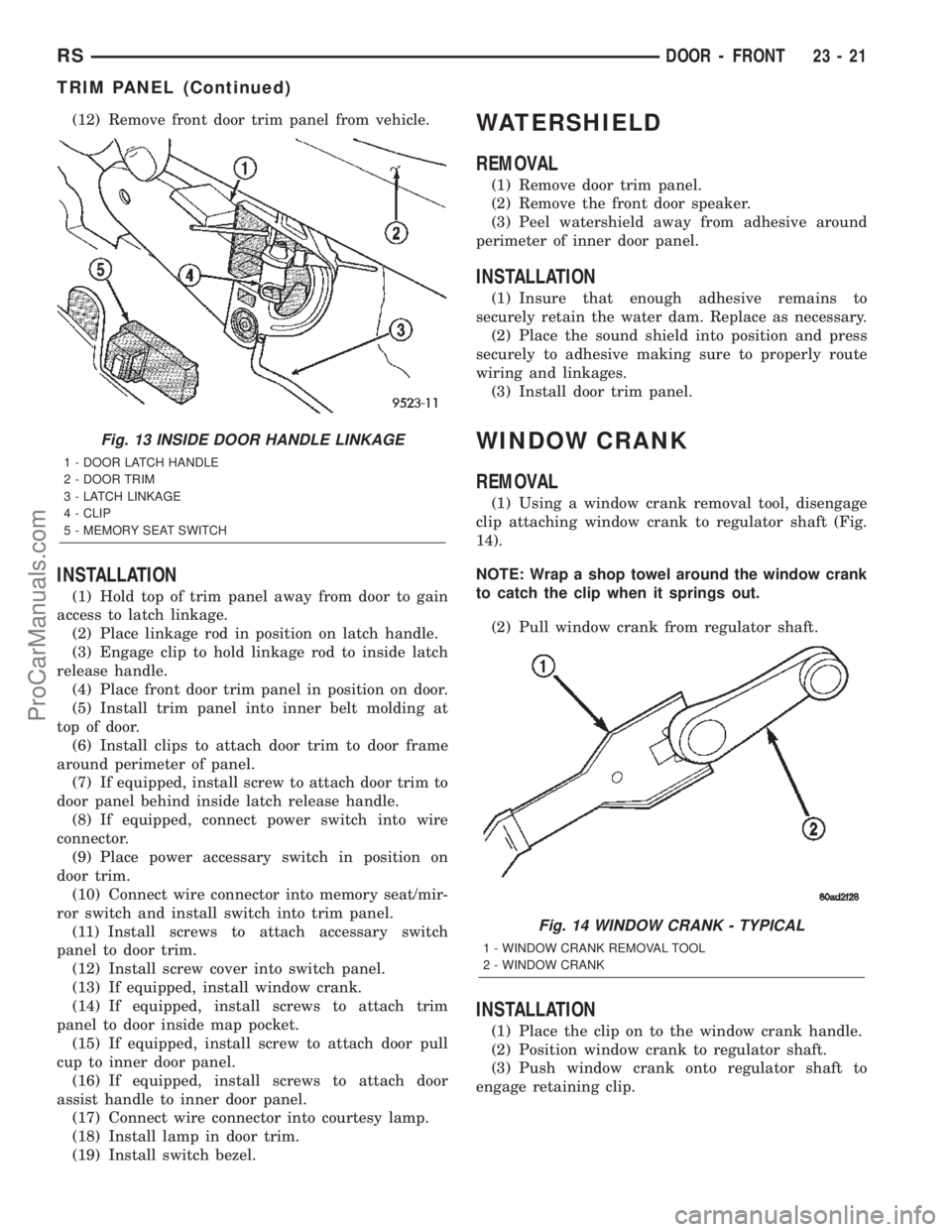

(12) Remove front door trim panel from vehicle.

INSTALLATION

(1) Hold top of trim panel away from door to gain

access to latch linkage.

(2) Place linkage rod in position on latch handle.

(3) Engage clip to hold linkage rod to inside latch

release handle.

(4) Place front door trim panel in position on door.

(5) Install trim panel into inner belt molding at

top of door.

(6) Install clips to attach door trim to door frame

around perimeter of panel.

(7) If equipped, install screw to attach door trim to

door panel behind inside latch release handle.

(8) If equipped, connect power switch into wire

connector.

(9) Place power accessary switch in position on

door trim.

(10) Connect wire connector into memory seat/mir-

ror switch and install switch into trim panel.

(11) Install screws to attach accessary switch

panel to door trim.

(12) Install screw cover into switch panel.

(13) If equipped, install window crank.

(14) If equipped, install screws to attach trim

panel to door inside map pocket.

(15) If equipped, install screw to attach door pull

cup to inner door panel.

(16) If equipped, install screws to attach door

assist handle to inner door panel.

(17) Connect wire connector into courtesy lamp.

(18) Install lamp in door trim.

(19) Install switch bezel.

WATERSHIELD

REMOVAL

(1) Remove door trim panel.

(2) Remove the front door speaker.

(3) Peel watershield away from adhesive around

perimeter of inner door panel.

INSTALLATION

(1) Insure that enough adhesive remains to

securely retain the water dam. Replace as necessary.

(2) Place the sound shield into position and press

securely to adhesive making sure to properly route

wiring and linkages.

(3) Install door trim panel.

WINDOW CRANK

REMOVAL

(1) Using a window crank removal tool, disengage

clip attaching window crank to regulator shaft (Fig.

14).

NOTE: Wrap a shop towel around the window crank

to catch the clip when it springs out.

(2) Pull window crank from regulator shaft.

INSTALLATION

(1) Place the clip on to the window crank handle.

(2) Position window crank to regulator shaft.

(3) Push window crank onto regulator shaft to

engage retaining clip.

Fig. 13 INSIDE DOOR HANDLE LINKAGE

1 - DOOR LATCH HANDLE

2 - DOOR TRIM

3 - LATCH LINKAGE

4 - CLIP

5 - MEMORY SEAT SWITCH

Fig. 14 WINDOW CRANK - TYPICAL

1 - WINDOW CRANK REMOVAL TOOL

2 - WINDOW CRANK

RSDOOR - FRONT23-21

TRIM PANEL (Continued)

ProCarManuals.com

Page 2025 of 2399

LOCK CYLINDER

REMOVAL

(1) Remove the liftgate trim panel. (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - REMOVAL)

(2) Disconnect the electrical connector.

(3) Disconnect the latch rod.

(4) Rotate plastic lock cylinder nut one quarter

turn and remove nut and spring washer.

(5) Remove the lock cylinder from the liftgate.

INSTALLATION

(1) Install lock cylinder into liftgate.

(2) Install the plastic lock cylinder lock nut, spring

washer and rotate one quarter turn.

(3) Connect the electrical connector.

(4) Connect the latch rod.

(5) Install the trim panel. (Refer to 23 - BODY/

DECKLID/HATCH/LIFTGATE/TAILGATE/TRIM

PANEL - INSTALLATION)

(6) Verify lock cylinder operation.

SUPPORT CYLINDER

REMOVAL

(1) Release liftgate latch and open liftgate.

(2) Support liftgate on a suitable lifting device in

the full open position.

(3) Pull liftgate opening weatherstrip from D-pillar

flange next to prop assembly end pivot.

(4) Remove bolt attaching end pivot to D-pillar

(Fig. 6).

(5) Remove bolt attaching prop assembly to lift-

gate.

(6) Remove prop assembly from vehicle.

INSTALLATION

Ensure that the cylinder end is attached to the

D-pillar and the shaft end is attached to the liftgate.

(1) Place prop assembly in position.

(2) Install bolt attaching prop assembly to liftgate.

(3) Install bolt attaching end pivot to D-pillar.

Tighten bolts to 28 N´m (21 ft. lbs.) torque.

(4) Install liftgate opening weatherstrip to D-pillar

flange next to prop assembly end pivot.

(5) Close liftgate. Check liftgate operation.

TRIM PANEL

REMOVAL

(1) Remove the bolt attaching the lift motor link, if

equipped (Fig. 7).

(2) Remove liftgate upper frame molding (Fig. 8).

(3) Remove assist handle screws.

(4) Disengage hidden clips holding trim panel to

liftgate from around perimeter or liftgate (Fig. 8).

(5) Disconnect wire connector from lamps.

(6) Remove liftgate trim panel from vehicle.

Fig. 6 LIFTGATE PROP ASSEMBLY

1 - LIFTGATE

2 - PROP ASSEMBLY

Fig. 7 LIFTGATE MOTOR

1 - LIFTGATE MOTOR LINK BOLT

2 - LIFTGATE MOTOR

3 - LIFTGATE

23 - 42 DECKLID/HATCH/LIFTGATE/TAILGATERS

ProCarManuals.com

Page 2033 of 2399

COWL GRILLE

REMOVAL

(1) Remove wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS -

REMOVAL)

(2) Remove four (4) screws securing cowl cover to

wiper module (Fig. 6).

(3) Disengage quarter turn fasteners at outboard

ends of cowl grill from body.

(4) Release hood latch and open hood.

CAUTION: To prevent hood scratching of cowl grille

before removal, cover outboard exterior ends of

cowl grille with masking tape or equivalent method.

NOTE: Do not over bend cowl grille during removal.

Bend cowl grille just enough to clear top of wiper

pivot shaft and bottom rear corner of hood.

(5) Remove cowl grill by raising above driver side

wiper pivot shaft and swinging away towards engine

compartment. The cowl grille will need to be bent on

outboard end to clear simultaneously top of wiper

pivot shaft and bottom corner of hood.

(6) Close hood. Do not latch. Remove outboard

screws. (Fig. 7).

(7) Disconnect washer hose in line connector.

(8) Disconnect washer hose and grommet from

hole in wiper module and pull out.

(9) Remove cowl grille by raising over opposite

wiper pivot shaft and removing away from vehicle.

(10) Remove cowl cover from vehicle.

INSTALLATION

(1) Reverse removal procedure.

(2) When installing cowl cover over wiper module,

make sure fore aft locator on the underside of cowl

grill seat into the locator grooves on top of wiper

module.

(3) Star all cowl grille mounting screws by hand

before torquing to specifications.

(4) Assure washer hose is properly routed and not

pinched.

(5) Center cowl grille to body and windshield.

(6) Assure ªarrowº indicator head of quarter turn

fasteners is pointing toward windshield.

(7) Tighten screw to 1.2 N´m (11 in. lbs.) torque.

(8) Install the wiper arms. (Refer to 8 - ELECTRI-

CAL/WIPERS/WASHERS/WIPER ARMS - INSTAL-

LATION)

(9) Check for proper spray pattern from washer

nozzles.

EXTERIOR NAME PLATES -

TAPE ATTACHED

REMOVAL

(1) Mark reference points before removing.

(2) Using a heat gun gently apply heat in a circu-

lar motion to loosen the adhesive bond.

(3) Using a nonmetallic prying device, such as a

plastic or wood trim stick gently pry up at corners

and remove.Fig. 6 COWL COVER

1 - COWL COVER

2 - WIPER PIVOT

3 - WASHER HOSES

4 - HOOD

Fig. 7 COWL COVER RETAINERS

1 - SCREW

2 - WINDSHIELD

3 - COWL COVER

4 - FRONT FENDER

23 - 50 EXTERIORRS

ProCarManuals.com

Page 2072 of 2399

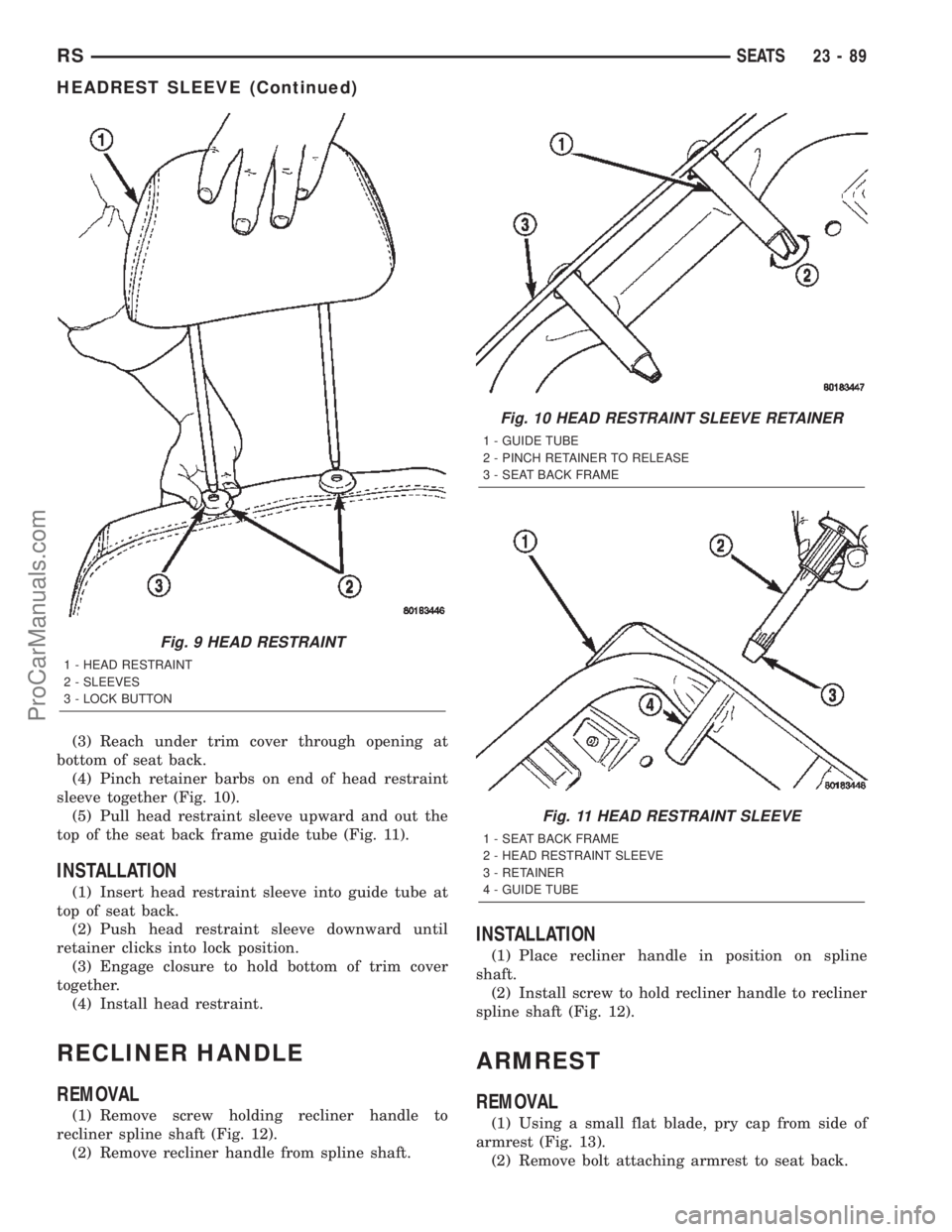

(3) Reach under trim cover through opening at

bottom of seat back.

(4) Pinch retainer barbs on end of head restraint

sleeve together (Fig. 10).

(5) Pull head restraint sleeve upward and out the

top of the seat back frame guide tube (Fig. 11).

INSTALLATION

(1) Insert head restraint sleeve into guide tube at

top of seat back.

(2) Push head restraint sleeve downward until

retainer clicks into lock position.

(3) Engage closure to hold bottom of trim cover

together.

(4) Install head restraint.

RECLINER HANDLE

REMOVAL

(1) Remove screw holding recliner handle to

recliner spline shaft (Fig. 12).

(2) Remove recliner handle from spline shaft.

INSTALLATION

(1) Place recliner handle in position on spline

shaft.

(2) Install screw to hold recliner handle to recliner

spline shaft (Fig. 12).

ARMREST

REMOVAL

(1) Using a small flat blade, pry cap from side of

armrest (Fig. 13).

(2) Remove bolt attaching armrest to seat back.

Fig. 9 HEAD RESTRAINT

1 - HEAD RESTRAINT

2 - SLEEVES

3 - LOCK BUTTON

Fig. 10 HEAD RESTRAINT SLEEVE RETAINER

1 - GUIDE TUBE

2 - PINCH RETAINER TO RELEASE

3 - SEAT BACK FRAME

Fig. 11 HEAD RESTRAINT SLEEVE

1 - SEAT BACK FRAME

2 - HEAD RESTRAINT SLEEVE

3 - RETAINER

4 - GUIDE TUBE

RSSEATS23-89

HEADREST SLEEVE (Continued)

ProCarManuals.com

Page 2254 of 2399

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Disconnect the headlamp and dash wire har-

ness connector for the A/C pressure transducer from

the transducer connector receptacle (Fig. 3).

(3) Using an open end wrench, unscrew the A/C

pressure transducer from the fitting on the liquid

line between the filter-drier and the expansion valve.

(4) Remove the seal from the A/C pressure trans-

ducer fitting and discard.

INSTALLATION

(1) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the A/C pressure

transducer fitting.

(2) Using an open end wrench, install and tighten

the A/C pressure transducer onto the fitting on the

liquid line between the filter-drier and the expansion

valve.

(3) Reconnect the headlamp and dash wire harness

connector for the A/C pressure transducer to the

transducer connector receptacle.

(4) Reconnect the battery negative cable.

BLEND DOOR ACTUATOR

DESCRIPTION

The blend door actuators are reversible, 12-volt

Direct Current (DC), servo motors. Models with the

single zone heater and air conditioner system have a

single blend air door, which is controlled by a singleblend door actuator. Models with the optional dual

zone front heater and air conditioner system have

dual blend air doors, which are controlled by two

blend door actuators. The single zone blend door

actuator is located on the driver side end of the heat-

er-A/C housing unit, close to the dash panel. In the

dual zone system, the same blend door actuator used

for the single zone system becomes the passenger

blend door actuator, and is mechanically connected to

only the passenger side blend air door. In the dual

zone system, a second separate blend door actuator is

also located on the driver side end of the heater-A/C

housing unit close to the instrument panel, and is

mechanically connected to only the driver side blend

air door.

The blend door actuators are interchangeable with

each other, as well as with the actuators for the

mode door and the recirculation air door. Each actua-

tor is contained within an identical black molded

plastic housing with an integral wire connector

receptacle. Two integral mounting tabs allow the

actuator to be secured with two screws to the heater-

A/C unit housing. Each actuator also has an identical

output shaft with splines that connects it to the link-

age that drives the proper blend air door. The blend

door actuators do not require mechanical indexing to

the blend door linkage, as they are electronically cal-

ibrated by the heater-A/C control module. The blend

door actuators cannot be adjusted or repaired and, if

damaged or faulty, they must be replaced.

OPERATION

Each blend door actuator is connected to the heat-

er-A/C control module through the vehicle electrical

system by a dedicated two-wire take out and connec-

tor of the HVAC wire harness. The blend door actua-

tor can move the blend air door in two directions.

When the heater-A/C control module pulls the volt-

age on one side of the motor connection high and the

other connection low, the blend air door will move in

one direction. When the module reverses the polarity

of the voltage to the motor, the blend air door moves

in the opposite direction. When the module makes

the voltage to both connections high or both connec-

tions low, the blend air door stops and will not move.

These same motor connections also provide a feed-

back signal to the heater-A/C control module. This

feedback signal allows the module to monitor the

operation and relative positions of the blend door

actuator and the blend air door. The heater-A/C con-

trol module learns the blend air door stop positions

during the calibration procedure and will store a

Diagnostic Trouble Code (DTC) for any problems it

detects in the blend door actuator circuits. The blend

door actuator can be diagnosed using a DRBIIItscan

tool. Refer to the appropriate diagnostic information.

Fig. 3 A/C Pressure Transducer

1 - RIGHT FRONT STRUT TOWER

2 - CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - RIGHT WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

RSCONTROLS - FRONT24-11

A/C PRESSURE TRANSDUCER (Continued)

ProCarManuals.com