airbag off CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 172 of 2399

ing pedal adjustment, the APM will monitor pedal

position sensor voltage. If the APM does not detect

expected voltage change within 3 seconds, it will cut

power to the adjustable pedal motor.

An optional memory feature is available. This

allows storing of one or two preferred pedal positions

in the APS. A preferred position can be stored and

recalled using the door-mounted switches. A stored

pedal position can be recalled (but not stored) using

the Remote Keyless Entry (RKE) if equipped with

the memory feature.

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL SYSTEM

Refer to Appropriate Diagnostic Information.

REMOVAL

NOTE: Before proceeding, review all Steering Col-

umn and Airbag Warnings and Cautions. (Refer to

19 - STEERING/COLUMN - WARNING)(Refer to 8 -

ELECTRICAL/RESTRAINTS - WARNING)

(1) Remove battery ground cable terminal from

battery negative post and isolate.

(2) Under instrument panel, remove silencer panel

below lower steering column cover.

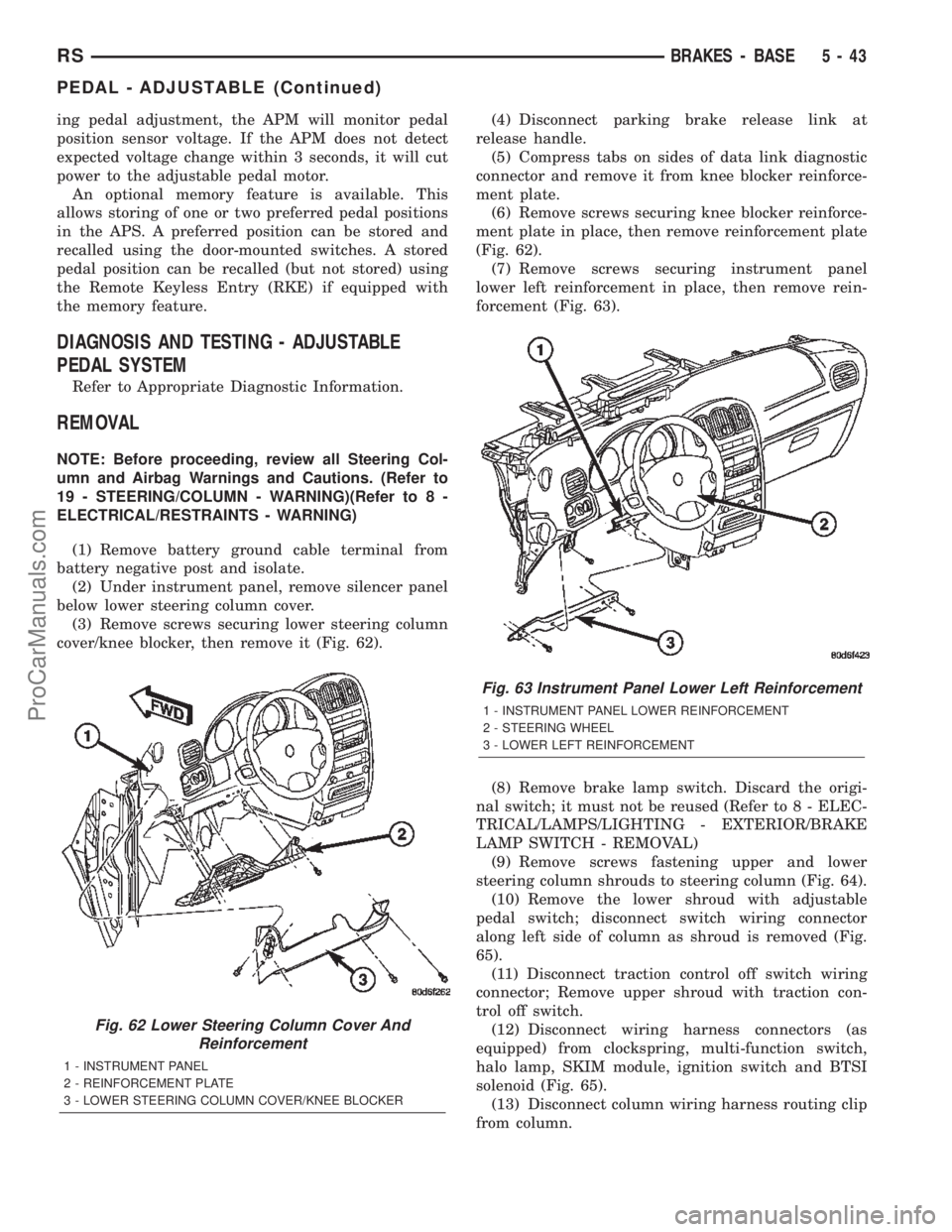

(3) Remove screws securing lower steering column

cover/knee blocker, then remove it (Fig. 62).(4) Disconnect parking brake release link at

release handle.

(5) Compress tabs on sides of data link diagnostic

connector and remove it from knee blocker reinforce-

ment plate.

(6) Remove screws securing knee blocker reinforce-

ment plate in place, then remove reinforcement plate

(Fig. 62).

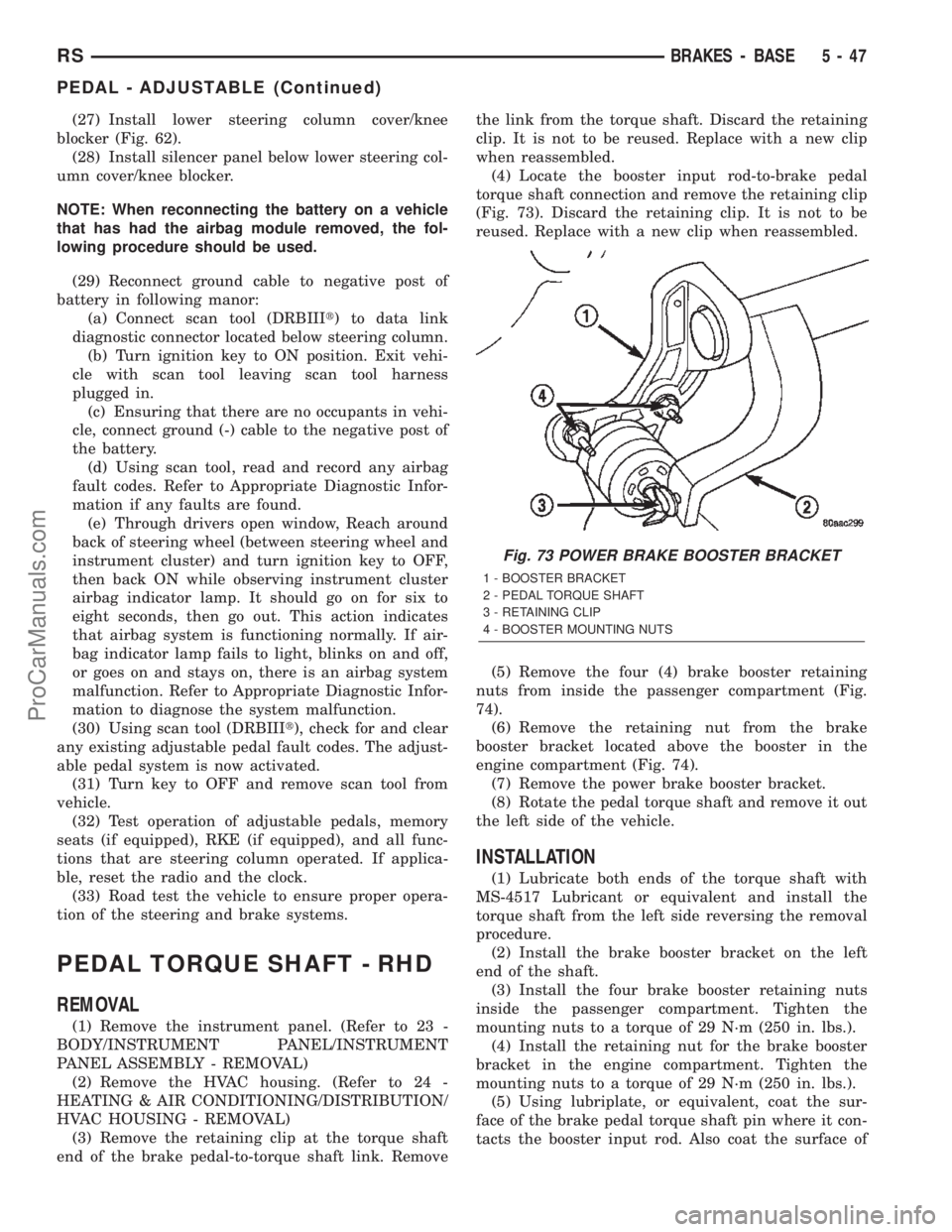

(7) Remove screws securing instrument panel

lower left reinforcement in place, then remove rein-

forcement (Fig. 63).

(8) Remove brake lamp switch. Discard the origi-

nal switch; it must not be reused (Refer to 8 - ELEC-

TRICAL/LAMPS/LIGHTING - EXTERIOR/BRAKE

LAMP SWITCH - REMOVAL)

(9) Remove screws fastening upper and lower

steering column shrouds to steering column (Fig. 64).

(10) Remove the lower shroud with adjustable

pedal switch; disconnect switch wiring connector

along left side of column as shroud is removed (Fig.

65).

(11) Disconnect traction control off switch wiring

connector; Remove upper shroud with traction con-

trol off switch.

(12) Disconnect wiring harness connectors (as

equipped) from clockspring, multi-function switch,

halo lamp, SKIM module, ignition switch and BTSI

solenoid (Fig. 65).

(13) Disconnect column wiring harness routing clip

from column.

Fig. 62 Lower Steering Column Cover And

Reinforcement

1 - INSTRUMENT PANEL

2 - REINFORCEMENT PLATE

3 - LOWER STEERING COLUMN COVER/KNEE BLOCKER

Fig. 63 Instrument Panel Lower Left Reinforcement

1 - INSTRUMENT PANEL LOWER REINFORCEMENT

2 - STEERING WHEEL

3 - LOWER LEFT REINFORCEMENT

RSBRAKES - BASE5-43

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 176 of 2399

(27) Install lower steering column cover/knee

blocker (Fig. 62).

(28) Install silencer panel below lower steering col-

umn cover/knee blocker.

NOTE: When reconnecting the battery on a vehicle

that has had the airbag module removed, the fol-

lowing procedure should be used.

(29) Reconnect ground cable to negative post of

battery in following manor:

(a) Connect scan tool (DRBIIIt) to data link

diagnostic connector located below steering column.

(b) Turn ignition key to ON position. Exit vehi-

cle with scan tool leaving scan tool harness

plugged in.

(c) Ensuring that there are no occupants in vehi-

cle, connect ground (-) cable to the negative post of

the battery.

(d) Using scan tool, read and record any airbag

fault codes. Refer to Appropriate Diagnostic Infor-

mation if any faults are found.

(e) Through drivers open window, Reach around

back of steering wheel (between steering wheel and

instrument cluster) and turn ignition key to OFF,

then back ON while observing instrument cluster

airbag indicator lamp. It should go on for six to

eight seconds, then go out. This action indicates

that airbag system is functioning normally. If air-

bag indicator lamp fails to light, blinks on and off,

or goes on and stays on, there is an airbag system

malfunction. Refer to Appropriate Diagnostic Infor-

mation to diagnose the system malfunction.

(30) Using scan tool (DRBIIIt), check for and clear

any existing adjustable pedal fault codes. The adjust-

able pedal system is now activated.

(31) Turn key to OFF and remove scan tool from

vehicle.

(32) Test operation of adjustable pedals, memory

seats (if equipped), RKE (if equipped), and all func-

tions that are steering column operated. If applica-

ble, reset the radio and the clock.

(33) Road test the vehicle to ensure proper opera-

tion of the steering and brake systems.

PEDAL TORQUE SHAFT - RHD

REMOVAL

(1) Remove the instrument panel. (Refer to 23 -

BODY/INSTRUMENT PANEL/INSTRUMENT

PANEL ASSEMBLY - REMOVAL)

(2) Remove the HVAC housing. (Refer to 24 -

HEATING & AIR CONDITIONING/DISTRIBUTION/

HVAC HOUSING - REMOVAL)

(3) Remove the retaining clip at the torque shaft

end of the brake pedal-to-torque shaft link. Removethe link from the torque shaft. Discard the retaining

clip. It is not to be reused. Replace with a new clip

when reassembled.

(4) Locate the booster input rod-to-brake pedal

torque shaft connection and remove the retaining clip

(Fig. 73). Discard the retaining clip. It is not to be

reused. Replace with a new clip when reassembled.

(5) Remove the four (4) brake booster retaining

nuts from inside the passenger compartment (Fig.

74).

(6) Remove the retaining nut from the brake

booster bracket located above the booster in the

engine compartment (Fig. 74).

(7) Remove the power brake booster bracket.

(8) Rotate the pedal torque shaft and remove it out

the left side of the vehicle.

INSTALLATION

(1) Lubricate both ends of the torque shaft with

MS-4517 Lubricant or equivalent and install the

torque shaft from the left side reversing the removal

procedure.

(2) Install the brake booster bracket on the left

end of the shaft.

(3) Install the four brake booster retaining nuts

inside the passenger compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(4) Install the retaining nut for the brake booster

bracket in the engine compartment. Tighten the

mounting nuts to a torque of 29 N´m (250 in. lbs.).

(5) Using lubriplate, or equivalent, coat the sur-

face of the brake pedal torque shaft pin where it con-

tacts the booster input rod. Also coat the surface of

Fig. 73 POWER BRAKE BOOSTER BRACKET

1 - BOOSTER BRACKET

2 - PEDAL TORQUE SHAFT

3 - RETAINING CLIP

4 - BOOSTER MOUNTING NUTS

RSBRAKES - BASE5-47

PEDAL - ADJUSTABLE (Continued)

ProCarManuals.com

Page 321 of 2399

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

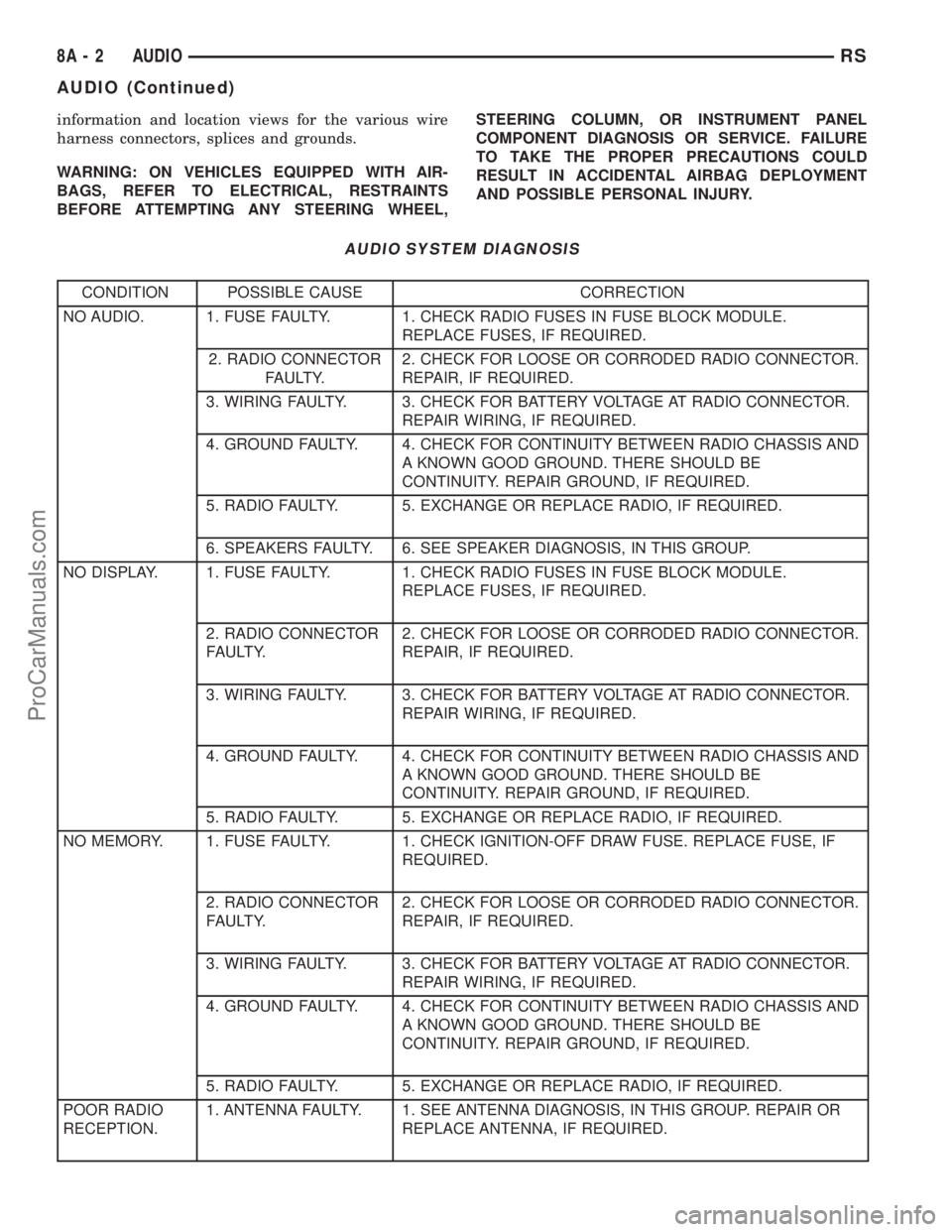

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO MEMORY. 1. FUSE FAULTY. 1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

POOR RADIO

RECEPTION.1. ANTENNA FAULTY. 1. SEE ANTENNA DIAGNOSIS, IN THIS GROUP. REPAIR OR

REPLACE ANTENNA, IF REQUIRED.

8A - 2 AUDIORS

AUDIO (Continued)

ProCarManuals.com

Page 328 of 2399

RADIO

DIAGNOSIS AND TESTING - RADIO

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

If the vehicle is equipped with remote radio

switches located on the back of the steering wheel

spokes, and the problem being diagnosed is related to

one of the symptoms listed below, be certain to check

the remote radio switches and circuits as described

in this group, prior to attempting radio diagnosis or

repair.

²Stations changing with no remote radio switch

input

²Radio memory presets not working properly

²Volume changes with no remote radio switch

input

²Remote radio switch buttons taking on other

functions

²CD player skipping tracks

²Remote radio switch inoperative.

CAUTION: The speaker output of the radio is a

ªfloating groundº system. Do not allow any speaker

lead to short to ground, as damage to the radio

may result.

(1) Check the fuse(s) in the junction block and the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse(s).

(2) Check for battery voltage at the fuse in the

(IPM). If OK, go to Step 3. If not OK, repair the open

circuit to the battery as required.

(3) Turn the ignition switch to the ON position.

Check for battery voltage at the fuse in the junction

block. If OK, go to Step 4. If not OK, repair the open

circuit to the ignition switch as required.(4) Turn the ignition switch to the OFF position.

Remove the radio, but do not unplug the wire har-

ness connectors. Check for continuity between the

radio chassis and a good ground. There should be

continuity. If OK, go to Step 5. If not OK, repair the

open radio chassis ground circuit as required.

(5) Connect the battery negative cable. Turn the

ignition switch to the ON position. Check for battery

voltage at the fused ignition switch output circuit

cavity of the radio wire harness connector. If OK, go

to Step 6. If not OK, repair the open circuit as

required.

(6) Turn the ignition switch to the OFF position.

Check for battery voltage at the fused B(+) circuit

cavity of the radio wire harness connector. If OK,

replace the faulty radio. If not OK, repair the open

circuit to the Ignition-Off Draw (IOD) fuse as

required.

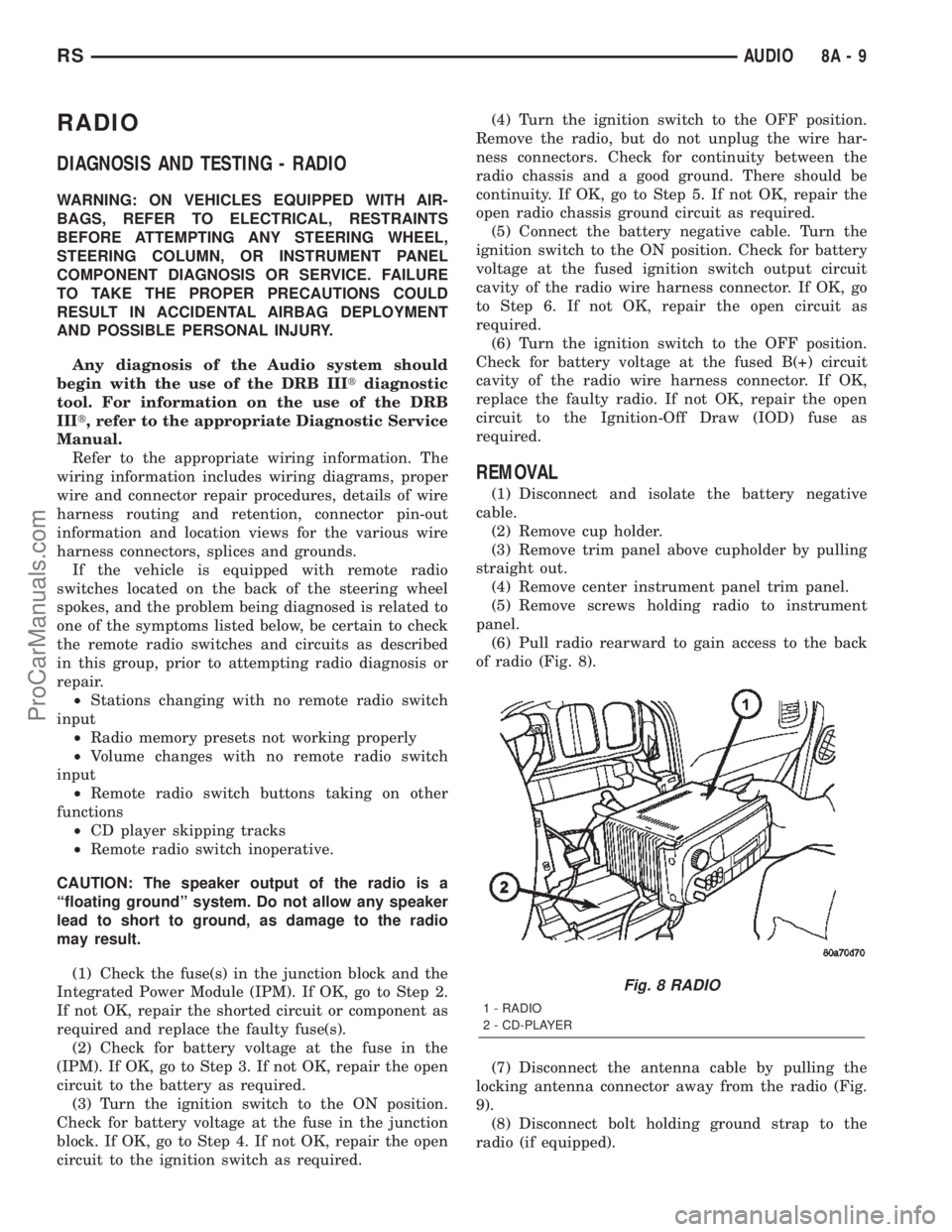

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove cup holder.

(3) Remove trim panel above cupholder by pulling

straight out.

(4) Remove center instrument panel trim panel.

(5) Remove screws holding radio to instrument

panel.

(6) Pull radio rearward to gain access to the back

of radio (Fig. 8).

(7) Disconnect the antenna cable by pulling the

locking antenna connector away from the radio (Fig.

9).

(8) Disconnect bolt holding ground strap to the

radio (if equipped).

Fig. 8 RADIO

1 - RADIO

2 - CD-PLAYER

RSAUDIO8A-9

ProCarManuals.com

Page 340 of 2399

(5) Obtain ignition keys to be programmed from

customer (8 keys maximum).

(6) Using the DRB III, erase all ignition keys by

selecting MISCELLANEOUS and ERASE ALL CUR-

RENT IGN. KEYS.

(7) Program all ignition keys.

Learned Key In Ignition - Ignition key transponder

ID is currently programmed in SKIM memory.

ADJUSTABLE PEDAL MODULE

DIAGNOSIS AND TESTING - ADJUSTABLE

PEDAL MODULE

Refer to Appropriate Diagnostic Information.

REMOVAL

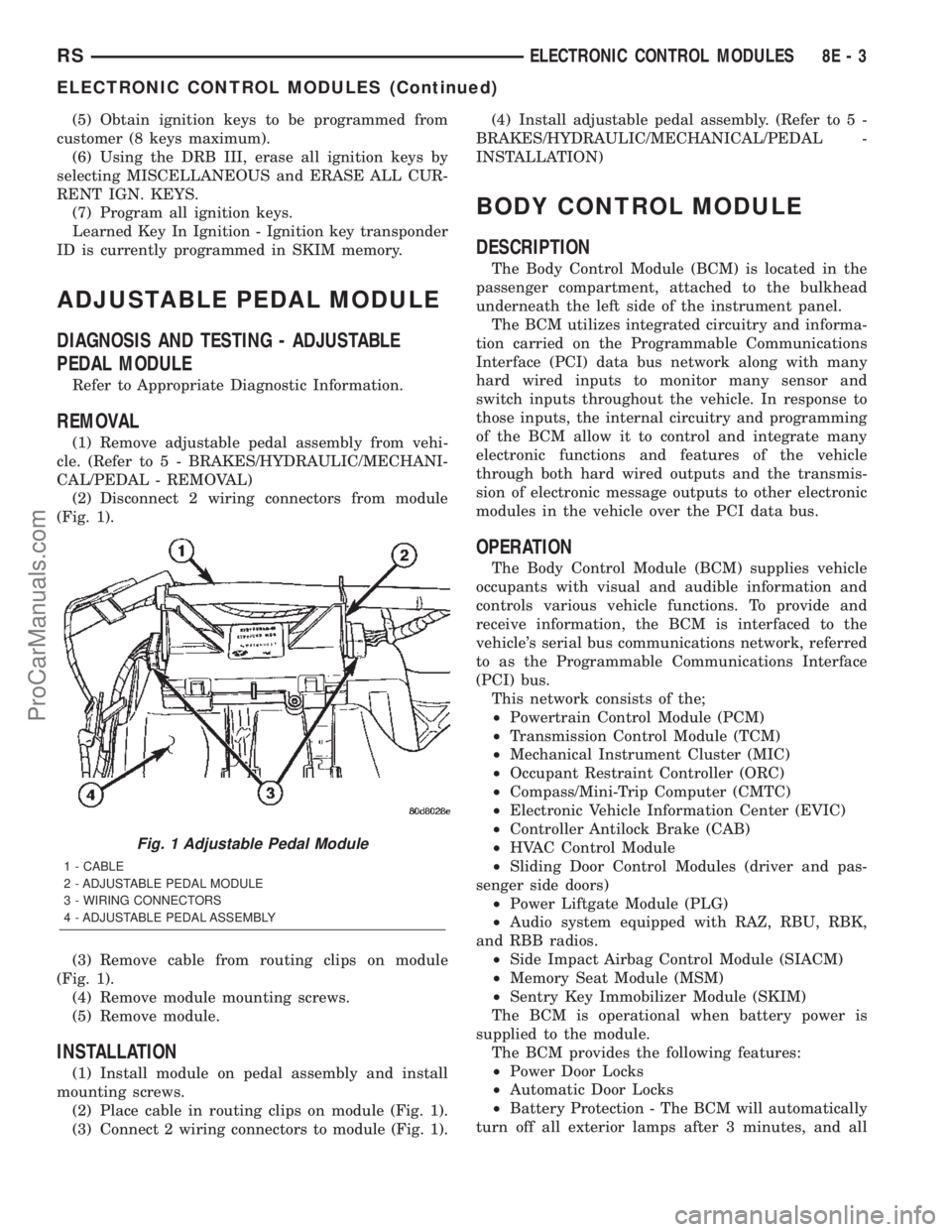

(1) Remove adjustable pedal assembly from vehi-

cle. (Refer to 5 - BRAKES/HYDRAULIC/MECHANI-

CAL/PEDAL - REMOVAL)

(2) Disconnect 2 wiring connectors from module

(Fig. 1).

(3) Remove cable from routing clips on module

(Fig. 1).

(4) Remove module mounting screws.

(5) Remove module.

INSTALLATION

(1) Install module on pedal assembly and install

mounting screws.

(2) Place cable in routing clips on module (Fig. 1).

(3) Connect 2 wiring connectors to module (Fig. 1).(4) Install adjustable pedal assembly. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/PEDAL -

INSTALLATION)

BODY CONTROL MODULE

DESCRIPTION

The Body Control Module (BCM) is located in the

passenger compartment, attached to the bulkhead

underneath the left side of the instrument panel.

The BCM utilizes integrated circuitry and informa-

tion carried on the Programmable Communications

Interface (PCI) data bus network along with many

hard wired inputs to monitor many sensor and

switch inputs throughout the vehicle. In response to

those inputs, the internal circuitry and programming

of the BCM allow it to control and integrate many

electronic functions and features of the vehicle

through both hard wired outputs and the transmis-

sion of electronic message outputs to other electronic

modules in the vehicle over the PCI data bus.

OPERATION

The Body Control Module (BCM) supplies vehicle

occupants with visual and audible information and

controls various vehicle functions. To provide and

receive information, the BCM is interfaced to the

vehicle's serial bus communications network, referred

to as the Programmable Communications Interface

(PCI) bus.

This network consists of the;

²Powertrain Control Module (PCM)

²Transmission Control Module (TCM)

²Mechanical Instrument Cluster (MIC)

²Occupant Restraint Controller (ORC)

²Compass/Mini-Trip Computer (CMTC)

²Electronic Vehicle Information Center (EVIC)

²Controller Antilock Brake (CAB)

²HVAC Control Module

²Sliding Door Control Modules (driver and pas-

senger side doors)

²Power Liftgate Module (PLG)

²Audio system equipped with RAZ, RBU, RBK,

and RBB radios.

²Side Impact Airbag Control Module (SIACM)

²Memory Seat Module (MSM)

²Sentry Key Immobilizer Module (SKIM)

The BCM is operational when battery power is

supplied to the module.

The BCM provides the following features:

²Power Door Locks

²Automatic Door Locks

²Battery Protection - The BCM will automatically

turn off all exterior lamps after 3 minutes, and all

Fig. 1 Adjustable Pedal Module

1 - CABLE

2 - ADJUSTABLE PEDAL MODULE

3 - WIRING CONNECTORS

4 - ADJUSTABLE PEDAL ASSEMBLY

RSELECTRONIC CONTROL MODULES8E-3

ELECTRONIC CONTROL MODULES (Continued)

ProCarManuals.com

Page 489 of 2399

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS

²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

²MECHANICAL TRANSMISSION RANGE

INDICATOR (PRND21) DIAGNOSIS

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

ProCarManuals.com

Page 526 of 2399

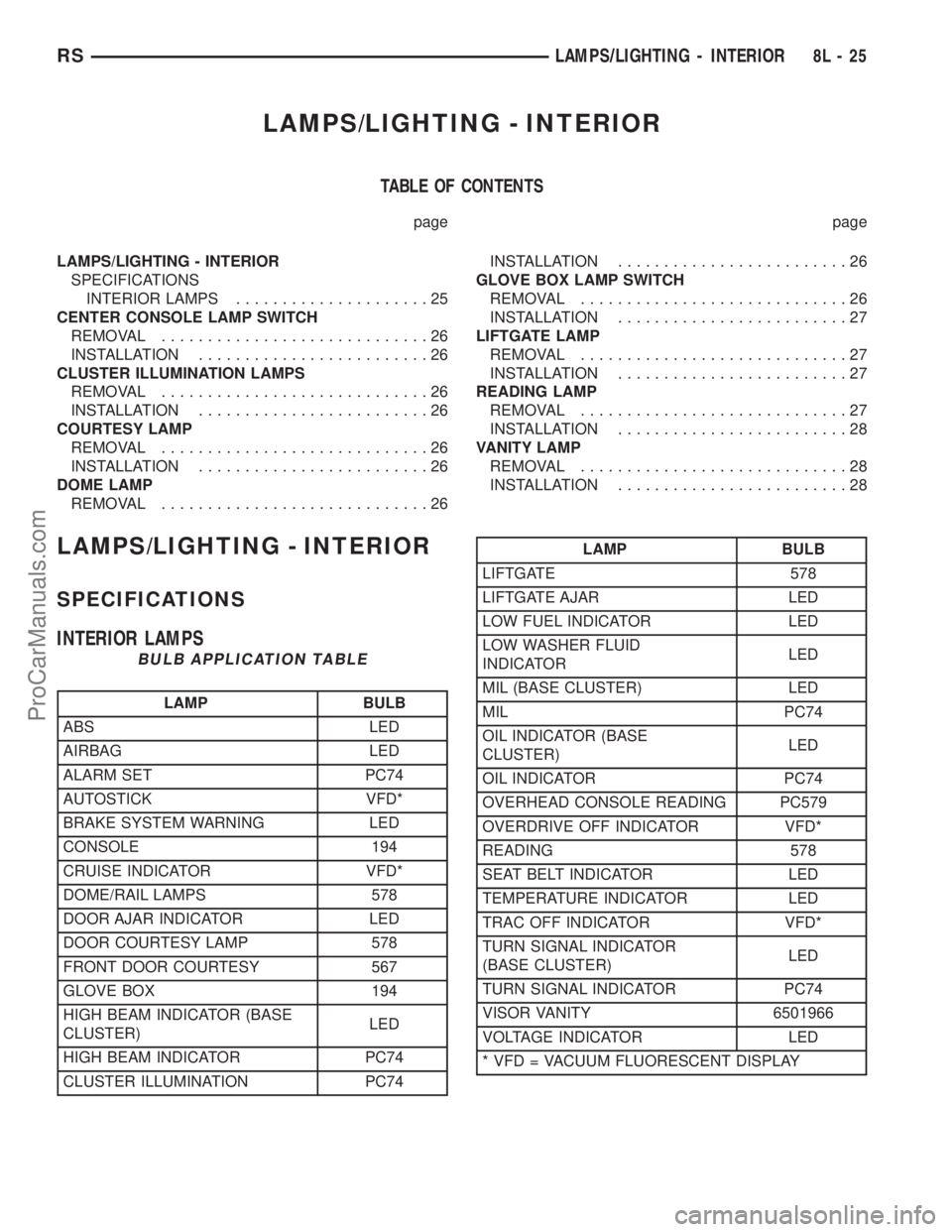

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................25

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................26

INSTALLATION.........................26

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................26

INSTALLATION.........................26

COURTESY LAMP

REMOVAL.............................26

INSTALLATION.........................26

DOME LAMP

REMOVAL.............................26INSTALLATION.........................26

GLOVE BOX LAMP SWITCH

REMOVAL.............................26

INSTALLATION.........................27

LIFTGATE LAMP

REMOVAL.............................27

INSTALLATION.........................27

READING LAMP

REMOVAL.............................27

INSTALLATION.........................28

VANITY LAMP

REMOVAL.............................28

INSTALLATION.........................28

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET PC74

AUTOSTICK VFD*

BRAKE SYSTEM WARNING LED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY LAMP 578

FRONT DOOR COURTESY 567

GLOVE BOX 194

HIGH BEAM INDICATOR (BASE

CLUSTER)LED

HIGH BEAM INDICATOR PC74

CLUSTER ILLUMINATION PC74

LAMP BULB

LIFTGATE 578

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL (BASE CLUSTER) LED

MIL PC74

OIL INDICATOR (BASE

CLUSTER)LED

OIL INDICATOR PC74

OVERHEAD CONSOLE READING PC579

OVERDRIVE OFF INDICATOR VFD*

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE INDICATOR LED

TRAC OFF INDICATOR VFD*

TURN SIGNAL INDICATOR

(BASE CLUSTER)LED

TURN SIGNAL INDICATOR PC74

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VFD = VACUUM FLUORESCENT DISPLAY

RSLAMPS/LIGHTING - INTERIOR8L-25

ProCarManuals.com

Page 626 of 2399

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................5

SWITCH

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 25 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral. The speed

control can be disengaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

ProCarManuals.com

Page 630 of 2399

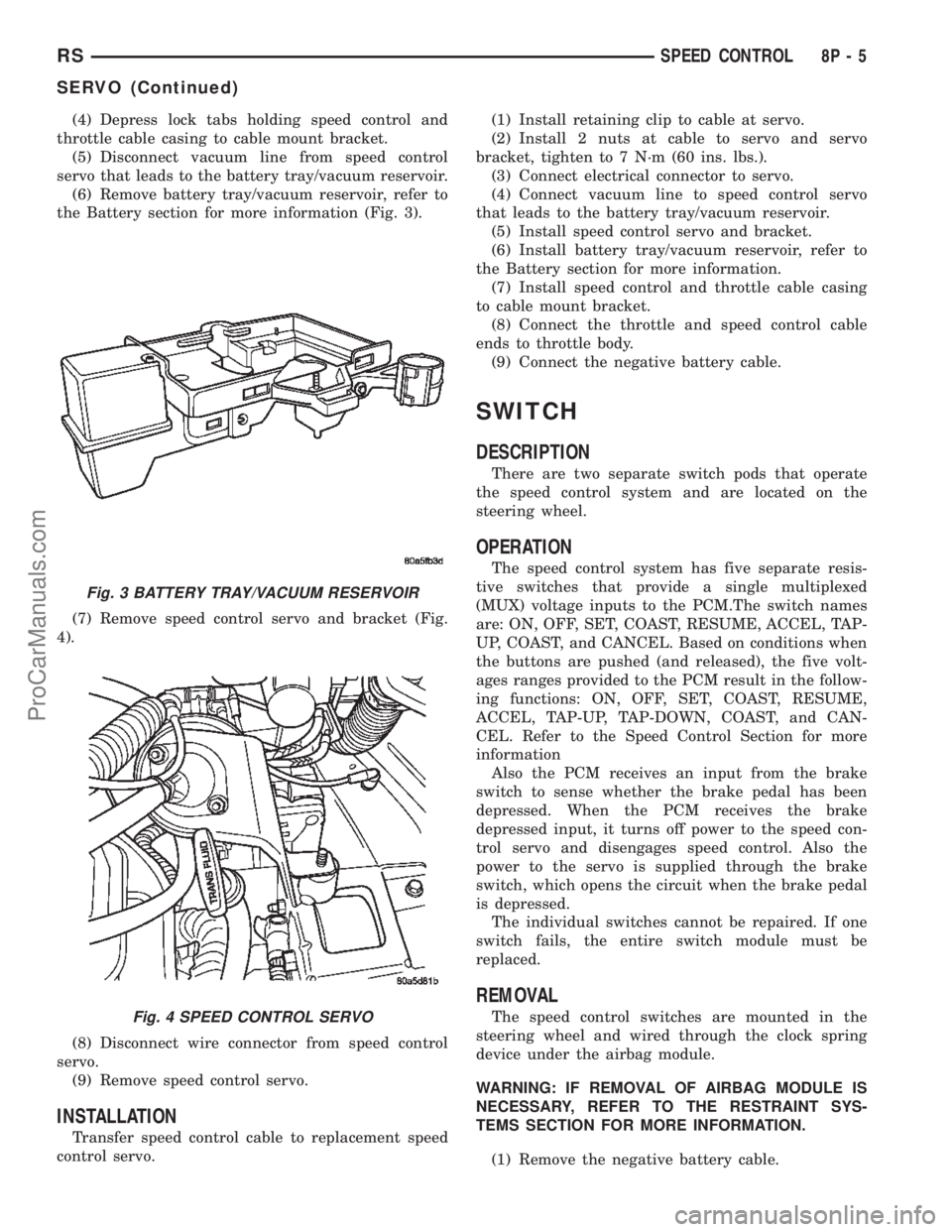

(4) Depress lock tabs holding speed control and

throttle cable casing to cable mount bracket.

(5) Disconnect vacuum line from speed control

servo that leads to the battery tray/vacuum reservoir.

(6) Remove battery tray/vacuum reservoir, refer to

the Battery section for more information (Fig. 3).

(7) Remove speed control servo and bracket (Fig.

4).

(8) Disconnect wire connector from speed control

servo.

(9) Remove speed control servo.

INSTALLATION

Transfer speed control cable to replacement speed

control servo.(1) Install retaining clip to cable at servo.

(2) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(3) Connect electrical connector to servo.

(4) Connect vacuum line to speed control servo

that leads to the battery tray/vacuum reservoir.

(5) Install speed control servo and bracket.

(6) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(7) Install speed control and throttle cable casing

to cable mount bracket.

(8) Connect the throttle and speed control cable

ends to throttle body.

(9) Connect the negative battery cable.

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

ages ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, TAP-DOWN, COAST, and CAN-

CEL. Refer to the Speed Control Section for more

information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control. Also the

power to the servo is supplied through the brake

switch, which opens the circuit when the brake pedal

is depressed.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

Fig. 3 BATTERY TRAY/VACUUM RESERVOIR

Fig. 4 SPEED CONTROL SERVO

RSSPEED CONTROL8P-5

SERVO (Continued)

ProCarManuals.com

Page 631 of 2399

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove the screw from bottom of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

(3) Install screw for the switch.

(4) Repeat for the other switch.

(5) Install the air bag, refer to the restraint section

for more information.

(6) Install the negative battery cable.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is located in the engine com-

partment. It is made of plastic.

OPERATION

The reservoir stores engine vacuum. Manifold vac-

uum is supplied from the brake booster check valve.

The speed control vacuum supply hose has a check

valve at the source (brake booster) to maintain the

highest available vacuum level in the servo, reservoir

and vacuum hoses. When engine vacuum drops, as in

climbing a grade while driving, the reservoir supplies

the vacuum needed to maintain proper speed control

operation. The vacuum reservoir cannot be repaired

and must be replaced if faulty.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect the negative battery cable.

(3) Disconnect the vacuum line to the battery tray/

vacuum reservoir.

(4) Remove battery tray/vacuum reservoir, refer to

the Battery section for more information.

INSTALLATION

(1) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(2) Connect vacuum line that leads to the battery

tray/vacuum reservoir.

(3) Connect the negative battery cable.

8P - 6 SPEED CONTROLRS

SWITCH (Continued)

ProCarManuals.com