automatic transmission fluid CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 14 of 2399

LUBRICATION & MAINTENANCE

TABLE OF CONTENTS

page page

LUBRICATION & MAINTENANCE

SPECIFICATIONS - FLUID CAPACITIES.......1

INTERNATIONAL SYMBOLS

DESCRIPTION..........................2

FLUID TYPES

DESCRIPTION

DESCRIPTION - ENGINE OIL AND

LUBRICANTS.........................2

DESCRIPTION - ENGINE COOLANT........3

DESCRIPTION - FLEXIBLE FUEL ENGINE

OIL .................................3

DESCRIPTION - AUTOMATIC

TRANSMISSION FLUID..................4

DESCRIPTION - FUEL REQUIREMENTS.....4

DESCRIPTION - FUEL REQUIREMENTS -

DIESEL ENGINE.......................6DESCRIPTION - ENGINE OIL - DIESEL

ENGINES............................6

FLUID FILL/CHECK LOCATIONS

DESCRIPTION..........................6

LUBRICATION POINTS

DESCRIPTION..........................6

MAINTENANCE SCHEDULES

DESCRIPTION..........................6

HOISTING

STANDARD PROCEDURE - HOISTING........6

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING . . 7

TOWING

STANDARD PROCEDURE - TOWING.........8

LUBRICATION &

MAINTENANCE

SPECIFICATIONS - FLUID CAPACITIES

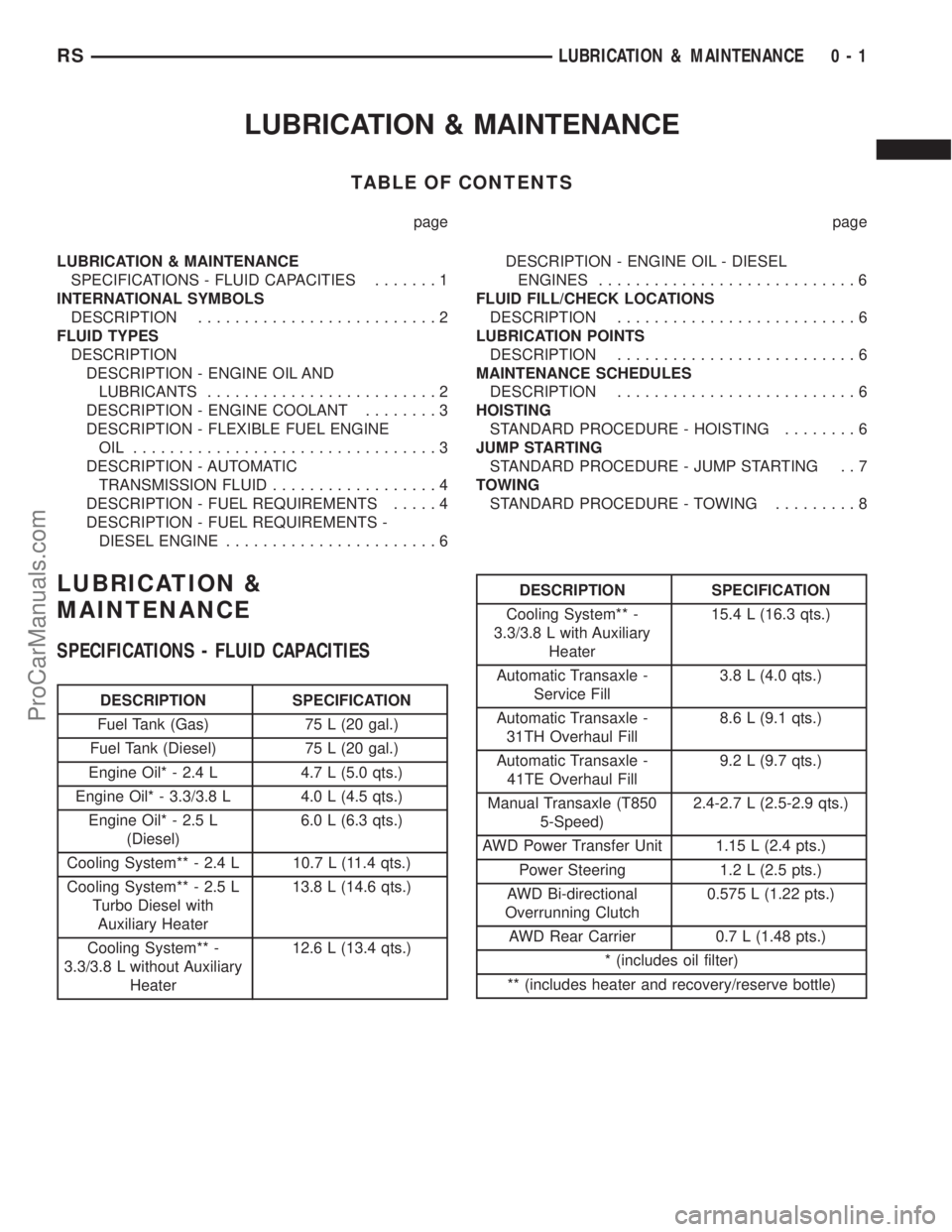

DESCRIPTION SPECIFICATION

Fuel Tank (Gas) 75 L (20 gal.)

Fuel Tank (Diesel) 75 L (20 gal.)

Engine Oil* - 2.4 L 4.7 L (5.0 qts.)

Engine Oil* - 3.3/3.8 L 4.0 L (4.5 qts.)

Engine Oil* - 2.5 L

(Diesel)6.0 L (6.3 qts.)

Cooling System** - 2.4 L 10.7 L (11.4 qts.)

Cooling System** - 2.5 L

Turbo Diesel with

Auxiliary Heater13.8 L (14.6 qts.)

Cooling System** -

3.3/3.8 L without Auxiliary

Heater12.6 L (13.4 qts.)

DESCRIPTION SPECIFICATION

Cooling System** -

3.3/3.8 L with Auxiliary

Heater15.4 L (16.3 qts.)

Automatic Transaxle -

Service Fill3.8 L (4.0 qts.)

Automatic Transaxle -

31TH Overhaul Fill8.6 L (9.1 qts.)

Automatic Transaxle -

41TE Overhaul Fill9.2 L (9.7 qts.)

Manual Transaxle (T850

5-Speed)2.4-2.7 L (2.5-2.9 qts.)

AWD Power Transfer Unit 1.15 L (2.4 pts.)

Power Steering 1.2 L (2.5 pts.)

AWD Bi-directional

Overrunning Clutch0.575 L (1.22 pts.)

AWD Rear Carrier 0.7 L (1.48 pts.)

* (includes oil filter)

** (includes heater and recovery/reserve bottle)

RSLUBRICATION & MAINTENANCE0-1

ProCarManuals.com

Page 17 of 2399

WARNING: Ethanol vapors are extremely flammable

and could cause serious personal injury. Never

have any smoking materials lit in or near the vehi-

cle when removing the fuel filler tube cap (gas cap)

or filling the tank. Do not use E-85 as a cleaning

agent and never use it near an open flame.

FUEL REQUIREMENTS

The vehicle will operate on both unleaded gasoline

with an octane rating of 87, or E-85 fuel, or any mix-

ture of these two.

For best results, a refueling pattern that alternates

between E-85 and unleaded gasoline should be

avoided. When you do switch fuels, it is recom-

mended that

²you do not switch when the fuel gauge indicates

less than 1/4 full

²you do not add less than 5 gallons when refuel-

ing

²you operate the vehicle immediately after refuel-

ing for a period of at least 5 minutes

Observing these precautions will avoid possible

hard starting and/or significant deterioration in

driveability during warm up.

FFV STARTING

The characteristics of E-85 fuel make it unsuitable

for use when ambient temperatures fall below 0ÉF. In

the range of 0ÉF to 32ÉF, you may experience an

increase in the time it takes for your engine to start,

and a deterioration in driveability (sags and/or hesi-

tations) until the engine is fully warmed up.

Engine Operating on E-85 Fuel

If vehicle operates on E-85 fuel either full or part-

time, use only MopartFlexible Fuel 5W-30 engine oil

or an equivalent that meets DaimlerChrysler Stan-

dard MS-9214. Equivalent commercial Flexible Fuel

engine oils may be labeled as Multi-Fuel, Variable

Fuel, Flexible Fuel, etc. These engine oils may be

satisfactory if they meet the DaimlerChrysler Stan-

dard.

SAE 5W-30 engine oil is preferred for use in Flex-

ible Fuel engines.

CAUTION: If Flexible Fuel engine oil is not used

when using E-85 fuel, engine wear or damage may

result.

CRUISING RANGE

Because E-85 fuel contains less energy per gallon

than gasoline, you will experience an increase in fuel

consumption. You can expect your MPG and your

driving range to decrease by about 30% compared to

gasoline operation.

DESCRIPTION - AUTOMATIC TRANSMISSION

FLUID

NOTE: Refer to the maintenance schedules for the

recommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: All transaxles have a common transmission

and differential sump. Filling the transaxle accom-

modates the differential as well.

TRANSMISSION FLUID

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) is required in the 41TE automatic and

T850 manual transaxles. Substitute fluids can induce

torque converter clutch shudder.

MopartATF+4 (Automatic Transmission Fluid-

Type 9602) when new is red in color. The ATF is dyed

red so it can be identified from other fluids used in

the vehicle such as engine oil or antifreeze. The red

color is not permanent and is not an indicator of fluid

condition. As the vehicle is driven, the ATF will begin

to look darker in color and may eventually become

brown.This is normal.ATF+4 also has a unique

odor that may change with age. Consequently,odor

and color cannot be used to indicate the fluid

condition or the need for a fluid change.

FLUID ADDITIVES

DaimlerChrysler strongly recommends against the

addition of any fluids to the transmission, other than

those automatic transmission fluids listed above.

Exceptions to this policy are the use of special dyes

to aid in detecting fluid leaks.

Various ªspecialº additives and supplements exist

that claim to improve shift feel and/or quality. These

additives and others also claim to improve converter

clutch operation and inhibit overheating, oxidation,

varnish, and sludge. These claims have not been sup-

ported to the satisfaction of DaimlerChrysler and

these additivesmust not be used.The use of trans-

mission ªsealersº should also be avoided, since they

may adversely affect the integrity of transmission

seals.

DESCRIPTION - FUEL REQUIREMENTS

Your engine is designed to meet all emissions reg-

ulations and provide excellent fuel economy and per-

formance when using high quality unleaded gasoline

having an octane rating of 87. The use of premium

gasoline is not recommended. The use of premium

gasoline will provide no benefit over high quality reg-

ular gasoline, and in some circumstances may result

in poorer performance.

0 - 4 LUBRICATION & MAINTENANCERS

FLUID TYPES (Continued)

ProCarManuals.com

Page 84 of 2399

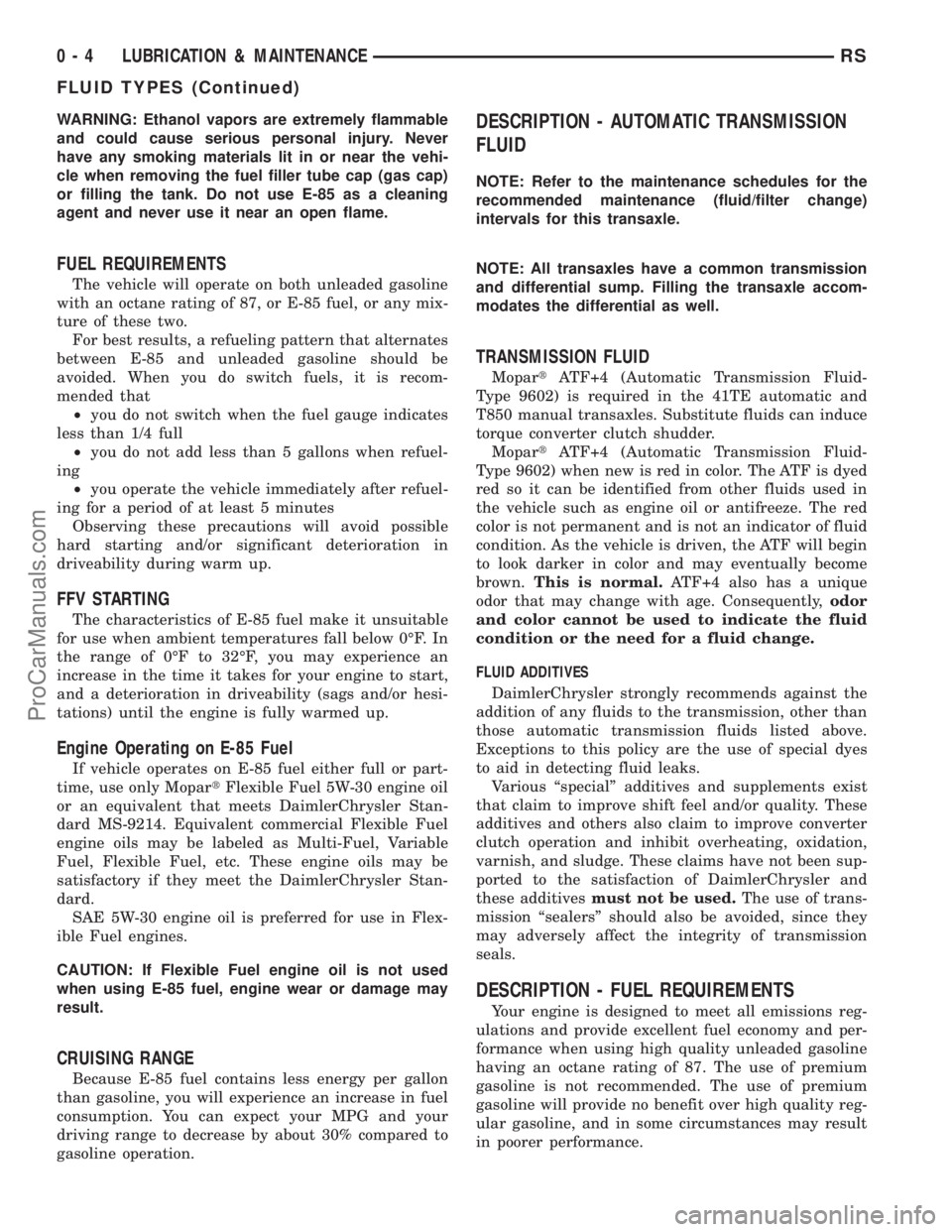

CAUTION: If the vehicle being serviced is equipped

with eccentric strut assembly attaching bolts, the

eccentric bolt must be installed in the bottom (slot-

ted) hole on the strut clevis bracket (Fig. 10).

(7) Install steering knuckle in clevis bracket of

strut damper assembly. Install the strut damper to

steering knuckle attaching bolts. Tighten both bolts

to a torque of 81 N´m (60 ft. lbs.) plus an additional

1/4 turn.

(8) Install braking disc on hub and bearing assem-

bly.(9) Install disc brake caliper assembly on steering

knuckle. Caliper is installed by first sliding bottom of

caliper assembly under abutment on steering

knuckle, and then rotating top of caliper against top

abutment.

(10) Install disc brake caliper adapter to steering

knuckle attaching bolts (Fig. 4). Tighten the disc

brake caliper adapter attaching bolts to a torque of

169 N´m (125 ft. lbs.).

(11) Clean all foreign matter from the threads of

the outer CV joint. Install the washer and half shaft

to hub/bearing assembly nut on half shaft and

securely tighten nut.

(12) Install front wheel and tire assembly. Install

and tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half the

required specification. Then repeat the tightening

sequence to the full specified torque of 135 N´m (100

ft. lbs.).

(13) Lower vehicle.

(14) With the vehicle's brakes applied to keep hub

from turning, tighten the hub nut to a torque of 244

N´m (180 ft. lbs.) (Fig. 11).

(15) Install the spring wave washer on the end of

the half shaft.

(16) Install the hub nut lock, and anewcotter pin

(Fig. 2). Wrap cotter pin prongs tightly around the

hub nut lock as shown in (Fig. 2).

(17) Check for correct fluid level in transaxle

assembly. (Refer to 21 - TRANSMISSION/TRANS-

AXLE/AUTOMATIC - 41TE/FLUID - STANDARD

PROCEDURE)

Fig. 9 Outer CV Joint Inspection

1 - OUTER C/V JOINT

2 - THIS AREA OF OUTER C/V JOINT MUST BE FREE OF ALL

DEBRIS AND MOISTURE, BEFORE INSTALLATION INTO

STEERING KNUCKLE.

Fig. 10 Correctly Installed Eccentric Attaching Bolt

1 - STEERING KNUCKLE

2 - FLANGED BOLT IN TOP HOLE

3 - CAM BOLT IN BOTTOM HOLE

4 - STRUT CLEVIS BRACKET

Fig. 11 Torquing Front Half Shaft To Hub Nut

1 - TORQUE WRENCH

RSHALF SHAFT - FRONT3-5

HALF SHAFT - FRONT (Continued)

ProCarManuals.com

Page 103 of 2399

REAR DRIVELINE MODULE

TABLE OF CONTENTS

page page

REAR DRIVELINE MODULE

DESCRIPTION.........................24

OPERATION...........................24

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE NOISE.............25

DIAGNOSIS AND TESTING - REAR

DRIVELINE MODULE OPERATION........27

REMOVAL.............................27

DISASSEMBLY.........................28

ASSEMBLY............................30

INSTALLATION.........................34

SPECIFICATIONS - REAR DRIVELINE

MODULE............................35

SPECIAL TOOLS.......................35

BI-DIRECTIONAL OVERRUNNING CLUTCH

DESCRIPTION.........................36

OPERATION...........................38

DIFFERENTIAL ASSEMBLY

DESCRIPTION.........................41OPERATION...........................41

FLUID - DIFFERENTIAL ASSEMBLY

STANDARD PROCEDURE - DIFFERENTIAL

ASSEMBLY FLUID DRAIN AND FILL.......42

FLUID

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE.......43

VISCOUS COUPLER

DESCRIPTION.........................44

OPERATION...........................44

TORQUE ARM

REMOVAL.............................46

INSTALLATION.........................46

INPUT FLANGE SEAL

REMOVAL.............................46

INSTALLATION.........................47

OUTPUT FLANGE SEAL

REMOVAL.............................48

INSTALLATION.........................49

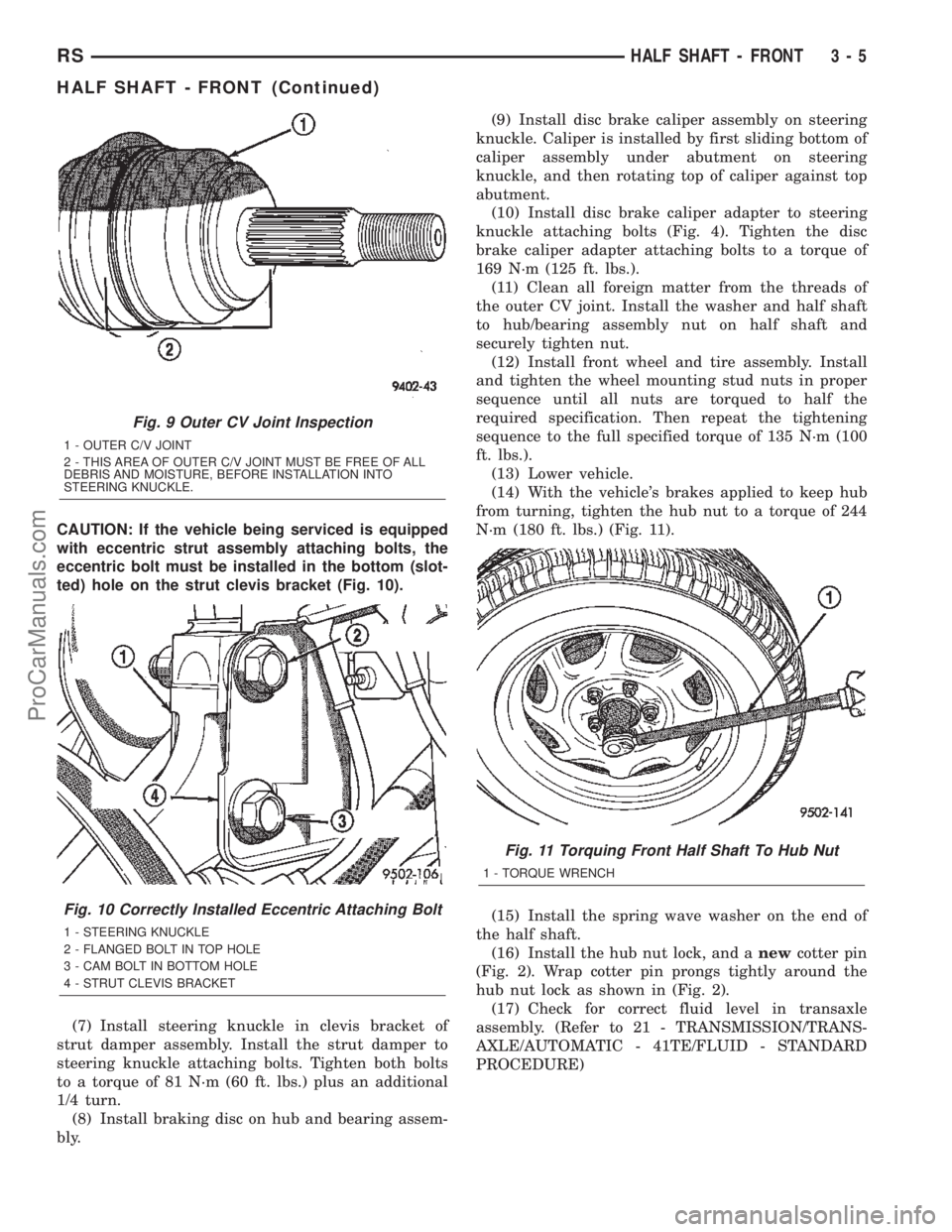

REAR DRIVELINE MODULE

DESCRIPTION

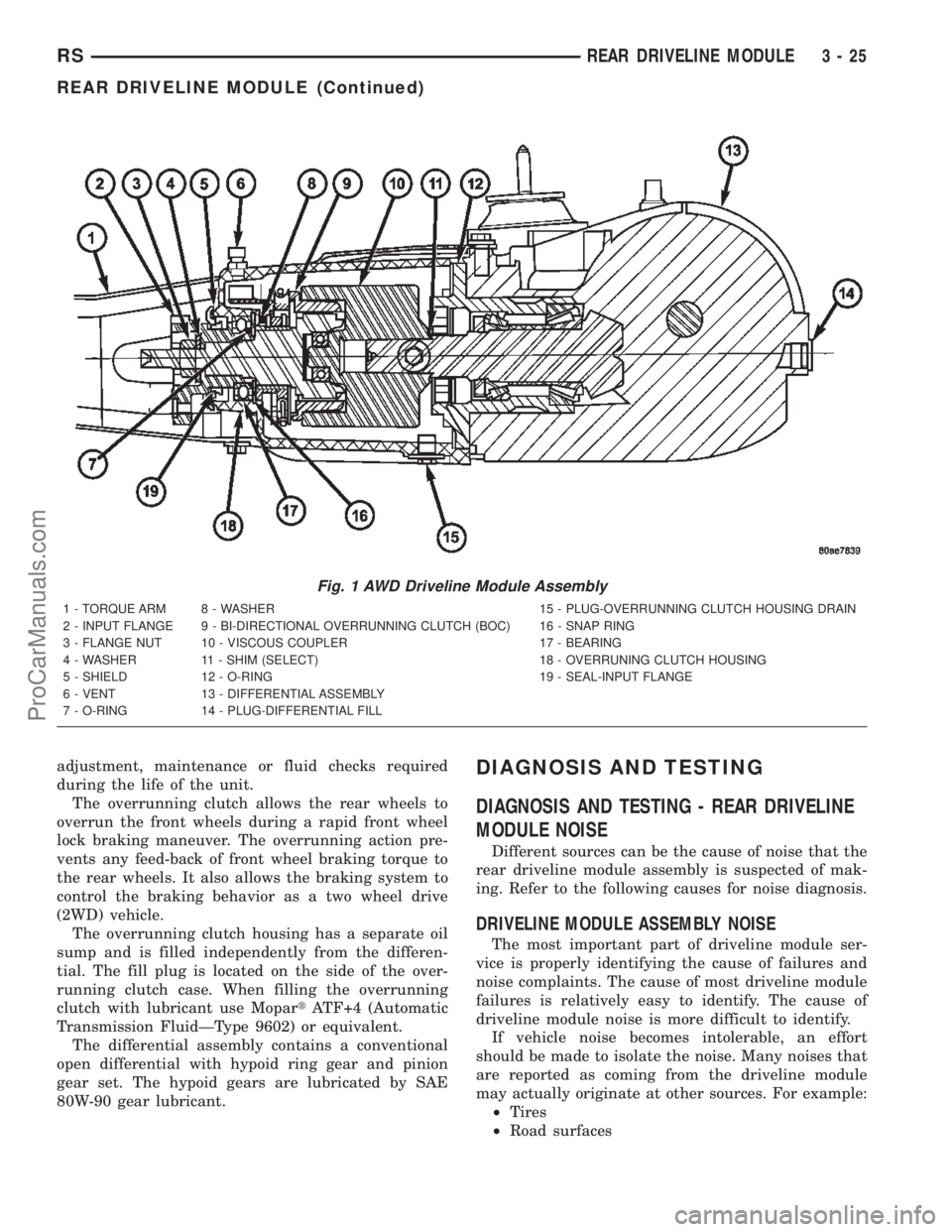

The rear driveline module assembly (Fig. 1) con-

sists of four main components:

²Bi-Directional Overrunning Clutch (BOC)

²Viscous Coupling

²Differential Assembly

²Torque Arm

The viscous coupling and bi-directional overrun-

ning clutch are contained within an overrunning

clutch housing, which fastens to the differential

assembly. The overrunning clutch housing and differ-

ential assembly have unique fluid sumps, each

requiring their own type and capacity of fluid. The

overrunning clutch housing requires MopartATF+4

(Automatic Transmission FluidÐType 9602) or equiv-

alent. The differential assembly requires

Driveline module service is limited to the following

components:

²Differential Assembly (serviced only as assem-

bly)

²Viscous Coupling

²Bi-Directional Overrunning Clutch (BOC)

²Overrunning Clutch Housing

²Seals (Input Flange, Output Flange, Overrun-

ning Clutch Housing O-rings)²Input Flange/Shield

²Torque Arm

²Vents

²Fasteners

OPERATION

The primary benefits of All Wheel Drive are:

²Superior straight line acceleration, and corner-

ing on all surfaces

²Better traction and handling under adverse con-

ditions, resulting in improved hill climbing ability

and safer driving.

The heart of the system is an inter-axle viscous

coupling. The vehicle retains predominantly front-

wheel drive characteristics, but the All Wheel Drive

capability takes effect when the front wheels start to

slip. Under normal level road, straight line driving,

100% of the torque is allocated to the front wheels.

The viscous coupling controls and distributes torque/

power to the rear wheels. The viscous coupling trans-

mits torque to the rear wheels in proportion of the

amount of the slippage at the front wheels. Thais

variable torque distribution is automatic with no

driver inputs required. The coupling is similar to a

multi-plate clutch. It consists of a series of closely

spaced discs, which are alternately connected to the

front and rear drive units. The unit is totally sealed

and partially filled with silicone fluid. There is no

3 - 24 REAR DRIVELINE MODULERS

ProCarManuals.com

Page 104 of 2399

adjustment, maintenance or fluid checks required

during the life of the unit.

The overrunning clutch allows the rear wheels to

overrun the front wheels during a rapid front wheel

lock braking maneuver. The overrunning action pre-

vents any feed-back of front wheel braking torque to

the rear wheels. It also allows the braking system to

control the braking behavior as a two wheel drive

(2WD) vehicle.

The overrunning clutch housing has a separate oil

sump and is filled independently from the differen-

tial. The fill plug is located on the side of the over-

running clutch case. When filling the overrunning

clutch with lubricant use MopartATF+4 (Automatic

Transmission FluidÐType 9602) or equivalent.

The differential assembly contains a conventional

open differential with hypoid ring gear and pinion

gear set. The hypoid gears are lubricated by SAE

80W-90 gear lubricant.DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REAR DRIVELINE

MODULE NOISE

Different sources can be the cause of noise that the

rear driveline module assembly is suspected of mak-

ing. Refer to the following causes for noise diagnosis.

DRIVELINE MODULE ASSEMBLY NOISE

The most important part of driveline module ser-

vice is properly identifying the cause of failures and

noise complaints. The cause of most driveline module

failures is relatively easy to identify. The cause of

driveline module noise is more difficult to identify.

If vehicle noise becomes intolerable, an effort

should be made to isolate the noise. Many noises that

are reported as coming from the driveline module

may actually originate at other sources. For example:

²Tires

²Road surfaces

Fig. 1 AWD Driveline Module Assembly

1 - TORQUE ARM 8 - WASHER 15 - PLUG-OVERRUNNING CLUTCH HOUSING DRAIN

2 - INPUT FLANGE 9 - BI-DIRECTIONAL OVERRUNNING CLUTCH (BOC) 16 - SNAP RING

3 - FLANGE NUT 10 - VISCOUS COUPLER 17 - BEARING

4 - WASHER 11 - SHIM (SELECT) 18 - OVERRUNING CLUTCH HOUSING

5 - SHIELD 12 - O-RING 19 - SEAL-INPUT FLANGE

6 - VENT 13 - DIFFERENTIAL ASSEMBLY

7 - O-RING 14 - PLUG-DIFFERENTIAL FILL

RSREAR DRIVELINE MODULE3-25

REAR DRIVELINE MODULE (Continued)

ProCarManuals.com

Page 122 of 2399

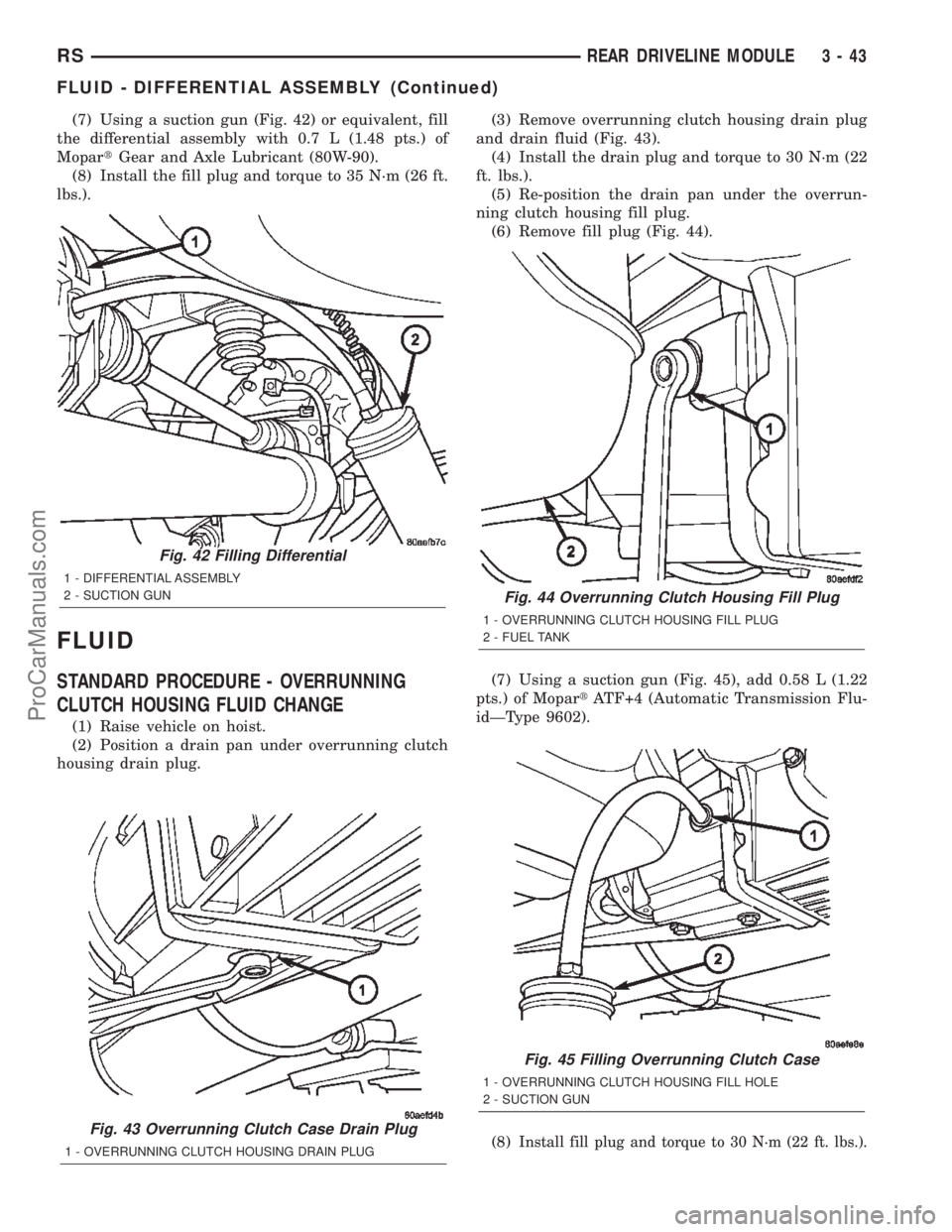

(7) Using a suction gun (Fig. 42) or equivalent, fill

the differential assembly with 0.7 L (1.48 pts.) of

MopartGear and Axle Lubricant (80W-90).

(8) Install the fill plug and torque to 35 N´m (26 ft.

lbs.).

FLUID

STANDARD PROCEDURE - OVERRUNNING

CLUTCH HOUSING FLUID CHANGE

(1) Raise vehicle on hoist.

(2) Position a drain pan under overrunning clutch

housing drain plug.(3) Remove overrunning clutch housing drain plug

and drain fluid (Fig. 43).

(4) Install the drain plug and torque to 30 N´m (22

ft. lbs.).

(5) Re-position the drain pan under the overrun-

ning clutch housing fill plug.

(6) Remove fill plug (Fig. 44).

(7) Using a suction gun (Fig. 45), add 0.58 L (1.22

pts.) of MopartATF+4 (Automatic Transmission Flu-

idÐType 9602).

(8)

Install fill plug and torque to 30 N´m (22 ft. lbs.).Fig. 43 Overrunning Clutch Case Drain Plug

1 - OVERRUNNING CLUTCH HOUSING DRAIN PLUG

Fig. 42 Filling Differential

1 - DIFFERENTIAL ASSEMBLY

2 - SUCTION GUN

Fig. 44 Overrunning Clutch Housing Fill Plug

1 - OVERRUNNING CLUTCH HOUSING FILL PLUG

2 - FUEL TANK

Fig. 45 Filling Overrunning Clutch Case

1 - OVERRUNNING CLUTCH HOUSING FILL HOLE

2 - SUCTION GUN

RSREAR DRIVELINE MODULE3-43

FLUID - DIFFERENTIAL ASSEMBLY (Continued)

ProCarManuals.com

Page 287 of 2399

TRANSMISSION

TABLE OF CONTENTS

page page

TRANSMISSION

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES.................38

TRANSMISSION OIL COOLER

DESCRIPTION.........................38

REMOVAL.............................38CLEANING............................39

INSPECTION..........................39

INSTALLATION.........................39

TRANSMISSION OIL COOLER LINES

REMOVAL.............................39

INSTALLATION.........................40

TRANSMISSION

STANDARD PROCEDURE - FLUSHING

COOLERS AND TUBES

The recommended procedure for cooler flushing is

to use Tool 6906 Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES. KEEP LIT CIGARETTES, SPARKS,

FLAMES, AND OTHER IGNITION SOURCES AWAY

FROM THE AREA TO PREVENT THE IGNITION OF

COMBUSTIBLE LIQUIDS AND GASES. KEEP A

CLASS (B) FIRE EXTINGUISHER IN THE AREA

WHERE THE FLUSHER WILL BE USED.

WARNING: KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

(1) Remove cover plate filler plug on Tool 6906.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Use MopartTransmission Cooler Flush (MS-552) or

equivalent solution conforming to MS-552. Flushing

solvents are petroleum based solutions generally

used to clean automatic transmission components.

DO NOTuse solvents containing acids, water, gaso-

line, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.(4) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(5) Connect the CLEAR return line to the INLET

(To) cooler line

(6) Turn pump ON for two to three minutes to

flush cooler and lines.

(7) Turn pump OFF.

(8) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(9) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(10) Place CLEAR suction line into a one quart

container of MopartATF+4 (Automatic Transmission

FluidÐType 9602).

(11) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(12) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

TRANSMISSION OIL COOLER

DESCRIPTION

The transmission oil cooler is an oil-to-air type

cooler that is mounted between the front of the radi-

ator and back side of the A/C condenser (Fig. 2). Use

only approved transmission oil cooler hoses that are

molded to fit the space available.

REMOVAL

(1) Remove the radiator. (Refer to 7 - COOLING/

ENGINE/RADIATOR - REMOVAL)

(2) Disconnect lines from oil cooler (Fig. 1).

(3) Remove oil cooler attaching screws (Fig. 2).

(4) Remove the oil cooler.

7 - 38 TRANSMISSIONRS

ProCarManuals.com

Page 746 of 2399

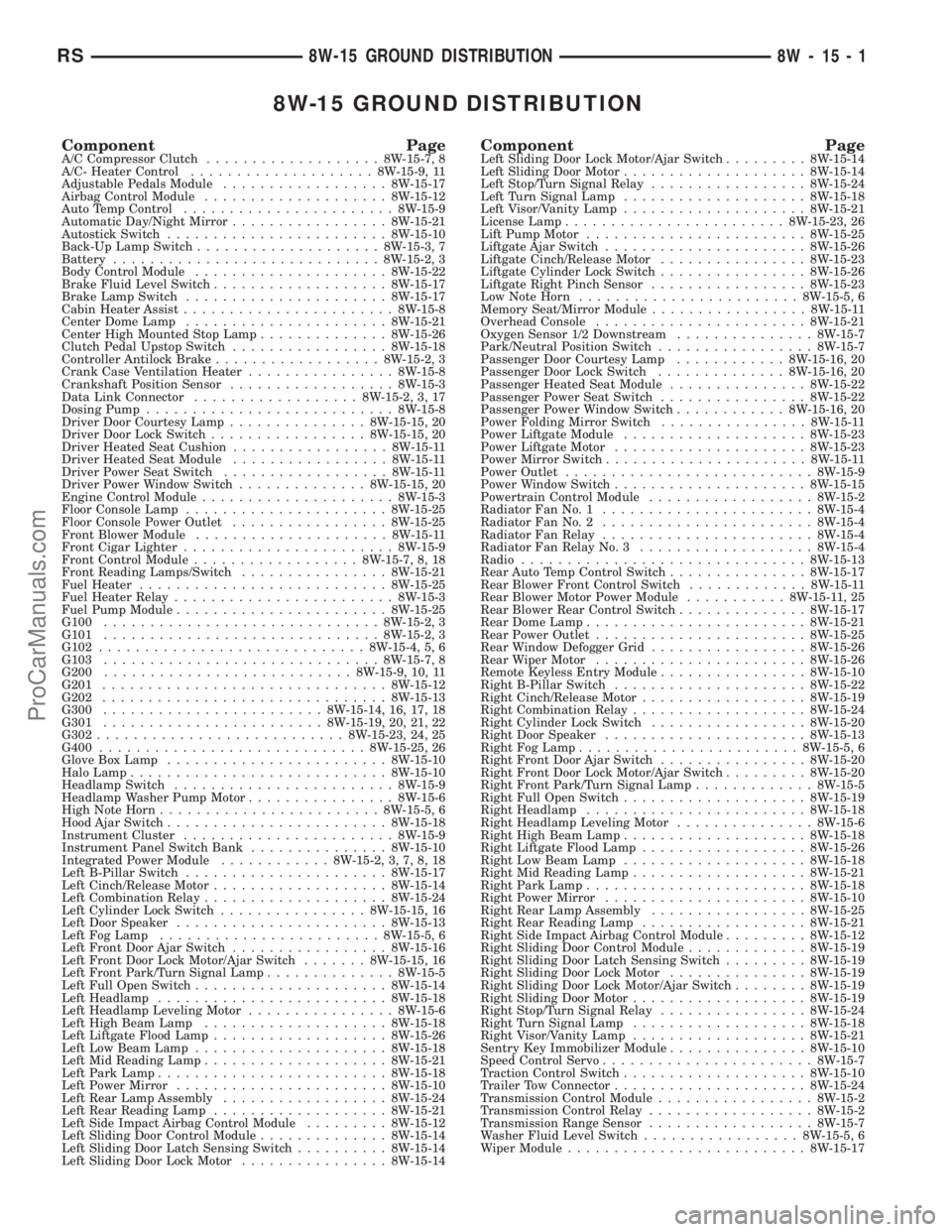

8W-15 GROUND DISTRIBUTION

Component PageA/C Compressor Clutch...................8W-15-7, 8

A/C- Heater Control....................8W-15-9, 11

Adjustable Pedals Module..................8W-15-17

Airbag Control Module....................8W-15-12

Auto Temp Control.......................8W-15-9

Automatic Day/Night Mirror.................8W-15-21

Autostick Switch........................8W-15-10

Back-Up Lamp Switch....................8W-15-3, 7

Battery.............................8W-15-2, 3

Body Control Module.....................8W-15-22

Brake Fluid Level Switch...................8W-15-17

Brake Lamp Switch......................8W-15-17

Cabin Heater Assist.......................8W-15-8

Center Dome Lamp......................8W-15-21

Center High Mounted Stop Lamp..............8W-15-26

Clutch Pedal Upstop Switch.................8W-15-18

Controller Antilock Brake..................8W-15-2, 3

Crank Case Ventilation Heater................8W-15-8

Crankshaft Position Sensor..................8W-15-3

Data Link Connector..................8W-15-2, 3, 17

Dosing Pump...........................8W-15-8

Driver Door Courtesy Lamp...............8W-15-15, 20

Driver Door Lock Switch.................8W-15-15, 20

Driver Heated Seat Cushion.................8W-15-11

Driver Heated Seat Module.................8W-15-11

Driver Power Seat Switch..................8W-15-11

Driver Power Window Switch..............8W-15-15, 20

Engine Control Module.....................8W-15-3

Floor Console Lamp......................8W-15-25

Floor Console Power Outlet.................8W-15-25

Front Blower Module.....................8W-15-11

Front Cigar Lighter.......................8W-15-9

Front Control Module..................8W-15-7, 8, 18

Front Reading Lamps/Switch................8W-15-21

Fuel Heater...........................8W-15-25

Fuel Heater Relay........................8W-15-3

Fuel Pump Module.......................8W-15-25

G100..............................8W-15-2, 3

G101..............................8W-15-2, 3

G102.............................8W-15-4, 5, 6

G103..............................8W-15-7, 8

G200...........................8W-15-9, 10, 11

G201...............................8W-15-12

G202...............................8W-15-13

G300........................8W-15-14, 16, 17, 18

G301........................8W-15-19, 20, 21, 22

G302...........................8W-15-23, 24, 25

G400.............................8W-15-25, 26

Glove Box Lamp........................8W-15-10

Halo Lamp............................8W-15-10

Headlamp Switch........................8W-15-9

Headlamp Washer Pump Motor................8W-15-6

High Note Horn........................8W-15-5, 6

Hood Ajar Switch........................8W-15-18

Instrument Cluster.......................8W-15-9

Instrument Panel Switch Bank...............8W-15-10

Integrated Power Module............8W-15-2, 3, 7, 8, 18

Left B-Pillar Switch......................8W-15-17

Left Cinch/Release Motor...................8W-15-14

Left Combination Relay....................8W-15-24

Left Cylinder Lock Switch................8W-15-15, 16

Left Door Speaker.......................8W-15-13

Left Fog Lamp........................8W-15-5, 6

Left Front Door Ajar Switch.................8W-15-16

Left Front Door Lock Motor/Ajar Switch.......8W-15-15, 16

Left Front Park/Turn Signal Lamp..............8W-15-5

Left Full Open Switch.....................8W-15-14

Left Headlamp.........................8W-15-18

Left Headlamp Leveling Motor................8W-15-6

Left High Beam Lamp....................8W-15-18

Left Liftgate Flood Lamp...................8W-15-26

Left Low Beam Lamp.....................8W-15-18

Left Mid Reading Lamp....................8W-15-21

Left Park Lamp.........................8W-15-18

Left Power Mirror.......................8W-15-10

Left Rear Lamp Assembly..................8W-15-24

Left Rear Reading Lamp...................8W-15-21

Left Side Impact Airbag Control Module.........8W-15-12

Left Sliding Door Control Module..............8W-15-14

Left Sliding Door Latch Sensing Switch..........8W-15-14

Left Sliding Door Lock Motor................8W-15-14Component PageLeft Sliding Door Lock Motor/Ajar Switch.........8W-15-14

Left Sliding Door Motor....................8W-15-14

Left Stop/Turn Signal Relay.................8W-15-24

Left Turn Signal Lamp....................8W-15-18

Left Visor/Vanity Lamp....................8W-15-21

License Lamp........................8W-15-23, 26

Lift Pump Motor........................8W-15-25

Liftgate Ajar Switch......................8W-15-26

Liftgate Cinch/Release Motor................8W-15-23

Liftgate Cylinder Lock Switch................8W-15-26

Liftgate Right Pinch Sensor.................8W-15-23

Low Note Horn........................8W-15-5, 6

Memory Seat/Mirror Module.................8W-15-11

Overhead Console.......................8W-15-21

Oxygen Sensor 1/2 Downstream...............8W-15-7

Park/Neutral Position Switch.................8W-15-7

Passenger Door Courtesy Lamp............8W-15-16, 20

Passenger Door Lock Switch..............8W-15-16, 20

Passenger Heated Seat Module...............8W-15-22

Passenger Power Seat Switch................8W-15-22

Passenger Power Window Switch............8W-15-16, 20

Power Folding Mirror Switch................8W-15-11

Power Liftgate Module....................8W-15-23

Power Liftgate Motor.....................8W-15-23

Power Mirror Switch......................8W-15-11

Power Outlet...........................8W-15-9

Power Window Switch.....................8W-15-15

Powertrain Control Module..................8W-15-2

Radiator Fan No. 1.......................8W-15-4

Radiator Fan No. 2.......................8W-15-4

Radiator Fan Relay.......................8W-15-4

Radiator Fan Relay No. 3...................8W-15-4

Radio...............................8W-15-13

Rear Auto Temp Control Switch...............8W-15-17

Rear Blower Front Control Switch.............8W-15-11

Rear Blower Motor Power Module...........8W-15-11, 25

Rear Blower Rear Control Switch..............8W-15-17

Rear Dome Lamp........................8W-15-21

Rear Power Outlet.......................8W-15-25

Rear Window Defogger Grid.................8W-15-26

Rear Wiper Motor.......................8W-15-26

Remote Keyless Entry Module................8W-15-10

Right B-Pillar Switch.....................8W-15-22

Right Cinch/Release Motor..................8W-15-19

Right Combination Relay...................8W-15-24

Right Cylinder Lock Switch.................8W-15-20

Right Door Speaker......................8W-15-13

Right Fog Lamp........................8W-15-5, 6

Right Front Door Ajar Switch................8W-15-20

Right Front Door Lock Motor/Ajar Switch.........8W-15-20

Right Front Park/Turn Signal Lamp.............8W-15-5

Right Full Open Switch....................8W-15-19

Right Headlamp........................8W-15-18

Right Headlamp Leveling Motor...............8W-15-6

Right High Beam Lamp....................8W-15-18

Right Liftgate Flood Lamp..................8W-15-26

Right Low Beam Lamp....................8W-15-18

Right Mid Reading Lamp...................8W-15-21

Right Park Lamp........................8W-15-18

Right Power Mirror......................8W-15-10

Right Rear Lamp Assembly.................8W-15-25

Right Rear Reading Lamp..................8W-15-21

Right Side Impact Airbag Control Module.........8W-15-12

Right Sliding Door Control Module.............8W-15-19

Right Sliding Door Latch Sensing Switch.........8W-15-19

Right Sliding Door Lock Motor...............8W-15-19

Right Sliding Door Lock Motor/Ajar Switch........8W-15-19

Right Sliding Door Motor...................8W-15-19

Right Stop/Turn Signal Relay................8W-15-24

Right Turn Signal Lamp...................8W-15-18

Right Visor/Vanity Lamp...................8W-15-21

Sentry Key Immobilizer Module...............8W-15-10

Speed Control Servo.......................8W-15-7

Traction Control Switch....................8W-15-10

Trailer Tow Connector.....................8W-15-24

Transmission Control Module.................8W-15-2

Transmission Control Relay..................8W-15-2

Transmission Range Sensor..................8W-15-7

Washer Fluid Level Switch.................8W-15-5, 6

Wiper Module..........................8W-15-17

RS8W-15 GROUND DISTRIBUTION8W-15-1

ProCarManuals.com

Page 1032 of 2399

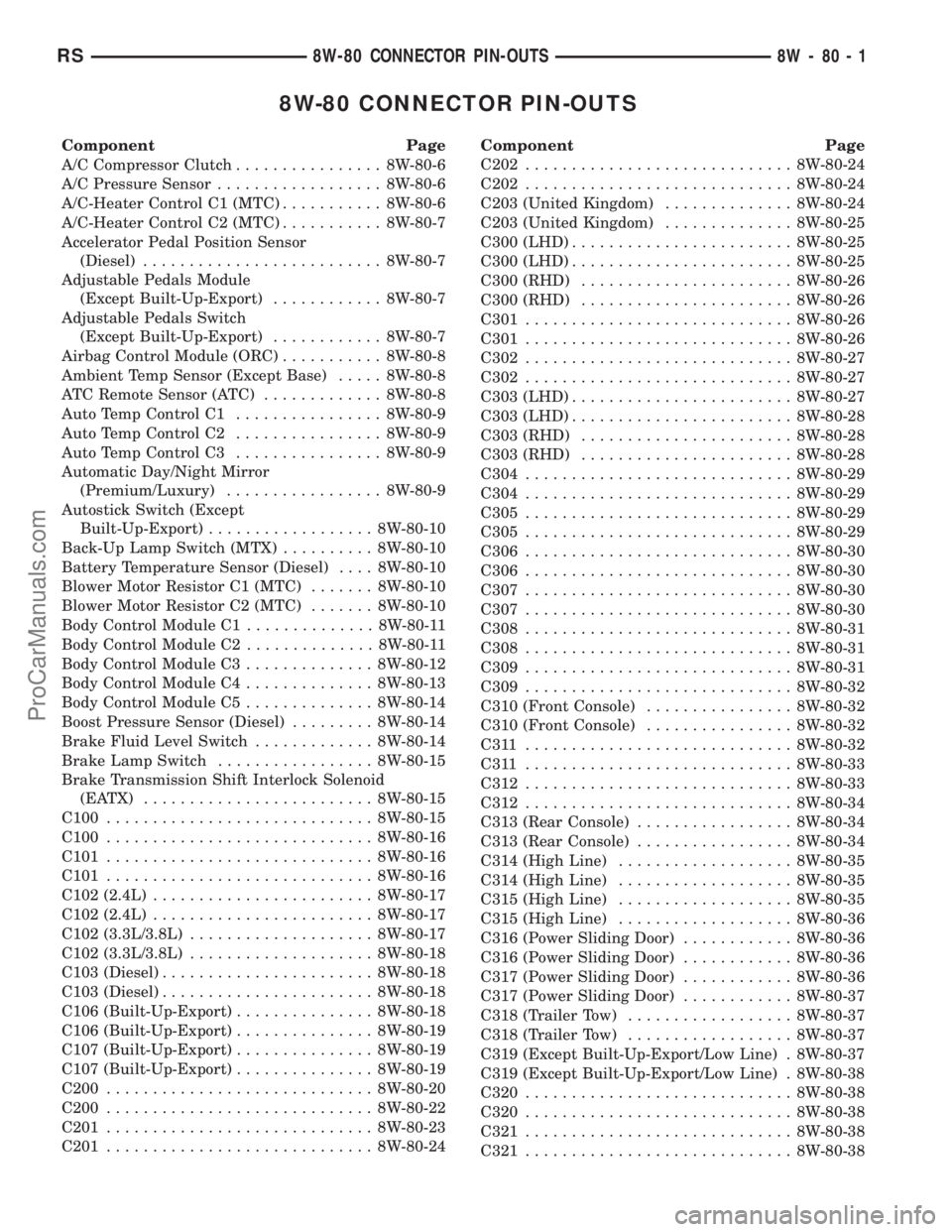

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch................ 8W-80-6

A/C Pressure Sensor.................. 8W-80-6

A/C-Heater Control C1 (MTC)........... 8W-80-6

A/C-Heater Control C2 (MTC)........... 8W-80-7

Accelerator Pedal Position Sensor

(Diesel).......................... 8W-80-7

Adjustable Pedals Module

(Except Built-Up-Export)............ 8W-80-7

Adjustable Pedals Switch

(Except Built-Up-Export)............ 8W-80-7

Airbag Control Module (ORC)........... 8W-80-8

Ambient Temp Sensor (Except Base)..... 8W-80-8

ATC Remote Sensor (ATC)............. 8W-80-8

Auto Temp Control C1................ 8W-80-9

Auto Temp Control C2................ 8W-80-9

Auto Temp Control C3................ 8W-80-9

Automatic Day/Night Mirror

(Premium/Luxury)................. 8W-80-9

Autostick Switch (Except

Built-Up-Export).................. 8W-80-10

Back-Up Lamp Switch (MTX).......... 8W-80-10

Battery Temperature Sensor (Diesel).... 8W-80-10

Blower Motor Resistor C1 (MTC)....... 8W-80-10

Blower Motor Resistor C2 (MTC)....... 8W-80-10

Body Control Module C1.............. 8W-80-11

Body Control Module C2.............. 8W-80-11

Body Control Module C3.............. 8W-80-12

Body Control Module C4.............. 8W-80-13

Body Control Module C5.............. 8W-80-14

Boost Pressure Sensor (Diesel)......... 8W-80-14

Brake Fluid Level Switch............. 8W-80-14

Brake Lamp Switch................. 8W-80-15

Brake Transmission Shift Interlock Solenoid

(EATX) ......................... 8W-80-15

C100............................. 8W-80-15

C100............................. 8W-80-16

C101............................. 8W-80-16

C101............................. 8W-80-16

C102 (2.4L)........................ 8W-80-17

C102 (2.4L)........................ 8W-80-17

C102 (3.3L/3.8L).................... 8W-80-17

C102 (3.3L/3.8L).................... 8W-80-18

C103 (Diesel)....................... 8W-80-18

C103 (Diesel)....................... 8W-80-18

C106 (Built-Up-Export)............... 8W-80-18

C106 (Built-Up-Export)............... 8W-80-19

C107 (Built-Up-Export)............... 8W-80-19

C107 (Built-Up-Export)............... 8W-80-19

C200............................. 8W-80-20

C200............................. 8W-80-22

C201............................. 8W-80-23

C201............................. 8W-80-24Component Page

C202............................. 8W-80-24

C202............................. 8W-80-24

C203 (United Kingdom).............. 8W-80-24

C203 (United Kingdom).............. 8W-80-25

C300 (LHD)........................ 8W-80-25

C300 (LHD)........................ 8W-80-25

C300 (RHD)....................... 8W-80-26

C300 (RHD)....................... 8W-80-26

C301............................. 8W-80-26

C301............................. 8W-80-26

C302............................. 8W-80-27

C302............................. 8W-80-27

C303 (LHD)........................ 8W-80-27

C303 (LHD)........................ 8W-80-28

C303 (RHD)....................... 8W-80-28

C303 (RHD)....................... 8W-80-28

C304............................. 8W-80-29

C304............................. 8W-80-29

C305............................. 8W-80-29

C305............................. 8W-80-29

C306............................. 8W-80-30

C306............................. 8W-80-30

C307............................. 8W-80-30

C307............................. 8W-80-30

C308............................. 8W-80-31

C308............................. 8W-80-31

C309............................. 8W-80-31

C309............................. 8W-80-32

C310 (Front Console)................ 8W-80-32

C310 (Front Console)................ 8W-80-32

C311 ............................. 8W-80-32

C311 ............................. 8W-80-33

C312............................. 8W-80-33

C312............................. 8W-80-34

C313 (Rear Console)................. 8W-80-34

C313 (Rear Console)................. 8W-80-34

C314 (High Line)................... 8W-80-35

C314 (High Line)................... 8W-80-35

C315 (High Line)................... 8W-80-35

C315 (High Line)................... 8W-80-36

C316 (Power Sliding Door)............ 8W-80-36

C316 (Power Sliding Door)............ 8W-80-36

C317 (Power Sliding Door)............ 8W-80-36

C317 (Power Sliding Door)............ 8W-80-37

C318 (Trailer Tow).................. 8W-80-37

C318 (Trailer Tow).................. 8W-80-37

C319 (Except Built-Up-Export/Low Line) . 8W-80-37

C319 (Except Built-Up-Export/Low Line) . 8W-80-38

C320............................. 8W-80-38

C320............................. 8W-80-38

C321............................. 8W-80-38

C321............................. 8W-80-38

RS8W-80 CONNECTOR PIN-OUTS8W-80-1

ProCarManuals.com

Page 1101 of 2399

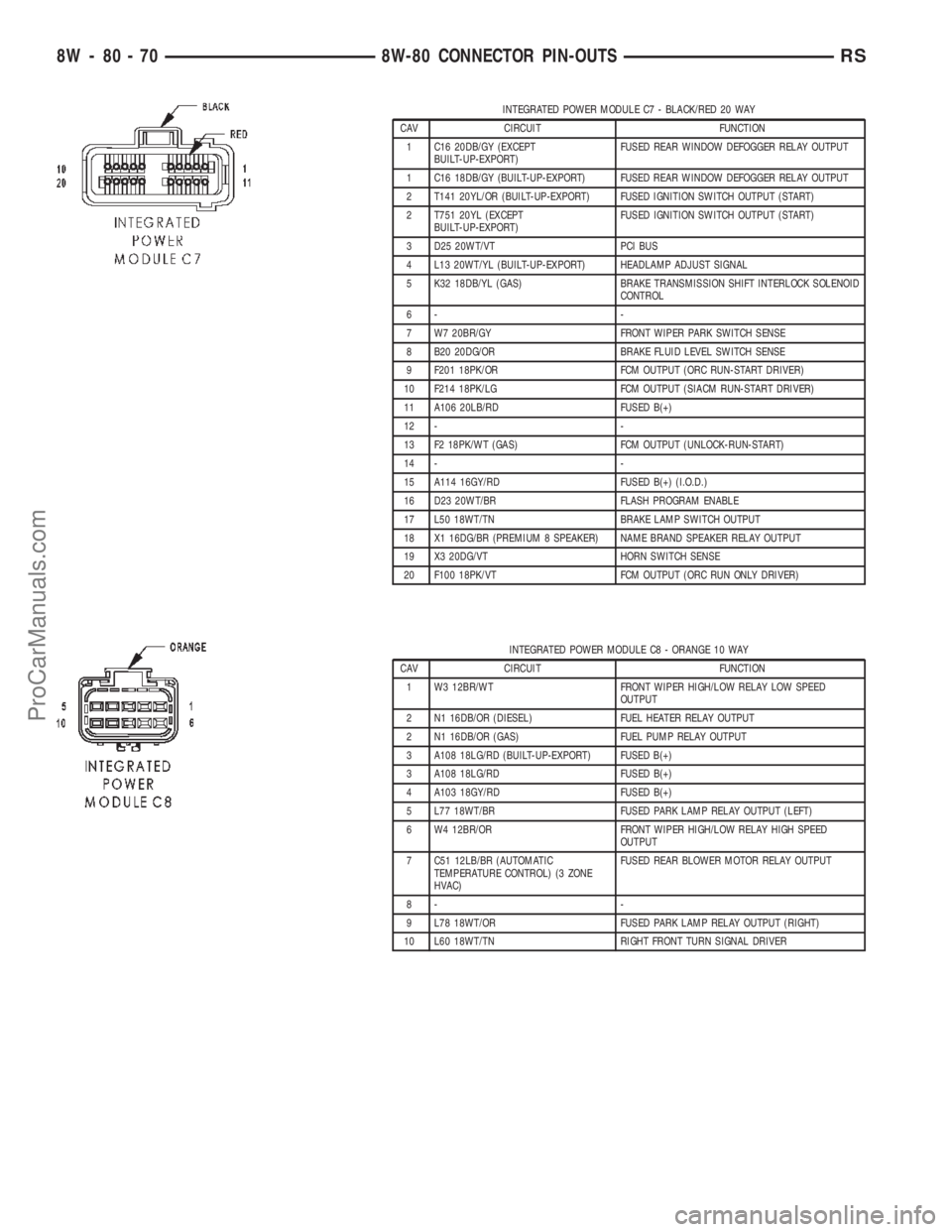

INTEGRATED POWER MODULE C7 - BLACK/RED 20 WAY

CAV CIRCUIT FUNCTION

1 C16 20DB/GY (EXCEPT

BUILT-UP-EXPORT)FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

1 C16 18DB/GY (BUILT-UP-EXPORT) FUSED REAR WINDOW DEFOGGER RELAY OUTPUT

2 T141 20YL/OR (BUILT-UP-EXPORT) FUSED IGNITION SWITCH OUTPUT (START)

2 T751 20YL (EXCEPT

BUILT-UP-EXPORT)FUSED IGNITION SWITCH OUTPUT (START)

3 D25 20WT/VT PCI BUS

4 L13 20WT/YL (BUILT-UP-EXPORT) HEADLAMP ADJUST SIGNAL

5 K32 18DB/YL (GAS) BRAKE TRANSMISSION SHIFT INTERLOCK SOLENOID

CONTROL

6- -

7 W7 20BR/GY FRONT WIPER PARK SWITCH SENSE

8 B20 20DG/OR BRAKE FLUID LEVEL SWITCH SENSE

9 F201 18PK/OR FCM OUTPUT (ORC RUN-START DRIVER)

10 F214 18PK/LG FCM OUTPUT (SIACM RUN-START DRIVER)

11 A106 20LB/RD FUSED B(+)

12 - -

13 F2 18PK/WT (GAS) FCM OUTPUT (UNLOCK-RUN-START)

14 - -

15 A114 16GY/RD FUSED B(+) (I.O.D.)

16 D23 20WT/BR FLASH PROGRAM ENABLE

17 L50 18WT/TN BRAKE LAMP SWITCH OUTPUT

18 X1 16DG/BR (PREMIUM 8 SPEAKER) NAME BRAND SPEAKER RELAY OUTPUT

19 X3 20DG/VT HORN SWITCH SENSE

20 F100 18PK/VT FCM OUTPUT (ORC RUN ONLY DRIVER)

INTEGRATED POWER MODULE C8 - ORANGE 10 WAY

CAV CIRCUIT FUNCTION

1 W3 12BR/WT FRONT WIPER HIGH/LOW RELAY LOW SPEED

OUTPUT

2 N1 16DB/OR (DIESEL) FUEL HEATER RELAY OUTPUT

2 N1 16DB/OR (GAS) FUEL PUMP RELAY OUTPUT

3 A108 18LG/RD (BUILT-UP-EXPORT) FUSED B(+)

3 A108 18LG/RD FUSED B(+)

4 A103 18GY/RD FUSED B(+)

5 L77 18WT/BR FUSED PARK LAMP RELAY OUTPUT (LEFT)

6 W4 12BR/OR FRONT WIPER HIGH/LOW RELAY HIGH SPEED

OUTPUT

7 C51 12LB/BR (AUTOMATIC

TEMPERATURE CONTROL) (3 ZONE

HVAC)FUSED REAR BLOWER MOTOR RELAY OUTPUT

8- -

9 L78 18WT/OR FUSED PARK LAMP RELAY OUTPUT (RIGHT)

10 L60 18WT/TN RIGHT FRONT TURN SIGNAL DRIVER

8W - 80 - 70 8W-80 CONNECTOR PIN-OUTSRS

ProCarManuals.com