refrigerant type CHRYSLER CARAVAN 2002 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2002, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2002Pages: 2399, PDF Size: 57.96 MB

Page 2253 of 2399

A/C PRESSURE TRANSDUCER

DESCRIPTION - A/C PRESSURE TRANSDUCER

The A/C pressure transducer (Fig. 2) is a switch

that is installed on a fitting located on the refriger-

ant liquid line between the filter-drier and the

expansion valve in the right rear corner of the engine

compartment. An internally threaded hex fitting on

the transducer connects it to the externally threaded

Schrader-type fitting on the liquid line. A rubber

O-ring seals the connection between the transducer

and the liquid line fitting. Three terminals within a

molded plastic connector receptacle on the top of the

transducer connect it to the vehicle electrical system

through a take out and connector of the headlamp

and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it musty be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the liquid line.

The transducer will change its internal resistance in

response to the pressures it monitors. The Power-

train Control Module (PCM) provides a five volt ref-

erence signal and a sensor ground to the transducer,

then monitors the output voltage of the transducer

on a sensor return circuit to determine refrigerant

pressure. The PCM is programmed to respond to thisand other sensor inputs by controlling the operation

of the air conditioning compressor clutch and the

radiator cooling fan to help optimize air conditioning

system performance and to protect the system com-

ponents from damage. The A/C pressure transducer

input to the PCM will also prevent the air condition-

ing compressor clutch from engaging when ambient

temperatures are below about 10É C (50É F) due to

the pressure/temperature relationship of the refriger-

ant. The Schrader-type valve in the liquid line fitting

permits the A/C pressure transducer to be removed

or installed without disturbing the refrigerant in the

system. The A/C pressure transducer is diagnosed

using a DRBIIItscan tool. Refer to the appropriate

diagnostic information.

DIAGNOSIS AND TESTING - A/C PRESSURE

TRANSDUCER

The A/C pressure transducer is tested using a

DRBIIItscan tool. Refer to the appropriate diagnos-

tic information. Before testing the A/C pressure

transducer, be certain that the transducer wire har-

ness connection is clean of corrosion and properly

connected. For the air conditioning system to operate,

an A/C pressure transducer voltage reading between

0.451 and 4.519 volts is required. Voltages outside

this range indicate a low or high refrigerant system

pressure condition to the Powertrain Control Module

(PCM). The PCM is programmed to respond to a low

or high refrigerant system pressure by suppressing

operation of the compressor. Refer to the A/C Pres-

sure Transducer Voltage table for the possible condi-

tion indicated by the transducer voltage readings.

A/C PRESSURE TRANSDUCER VOLTAGE

VOLTAGE POSSIBLE INDICATION

0.0 1. NO SENSOR SUPPLY

VOLTAGE FROM PCM.

2. SHORTED SENSOR CIRCUIT.

3. FAULTY TRANSDUCER.

0.150 TO 0.450 1. AMBIENT TEMPERATURE

BELOW 10É C (50É F).

2. LOW REFRIGERANT

SYSTEM PRESSURE.

0.451 TO 4.519 1. NORMAL REFRIGERANT

SYSTEM PRESSURE.

4.520 TO 4.850 1. HIGH REFRIGERANT

SYSTEM PRESSURE.

5.0 1. OPEN SENSOR CIRCUIT.

2. FAULTY TRANSDUCER.

Fig. 2 A/C Pressure Transducer

1 - RIGHT FRONT STRUT TOWER

2 - CONNECTOR

3 - A/C PRESSURE TRANSDUCER

4 - RIGHT WIPER MODULE DRAIN TUBE

5 - HIGH SIDE SERVICE PORT

6 - LIQUID LINE

24 - 10 CONTROLS - FRONTRS

ProCarManuals.com

Page 2263 of 2399

NOTE: A new snap ring must be used to secure the

clutch pulley to the compressor. The bevel side of

the snap ring must face outward.

(5) Using snap ring pliers (Special Tool C-4574 or

equivalent), install the external snap ring (bevel side

facing outward) that secures the clutch pulley to the

front cover of the compressor. Be certain that the

snap ring is fully and properly seated in the groove.

(6) If the original clutch plate and clutch pulley

are to be reused, reinstall the original shim(s) on the

compressor shaft against the shoulder. If a new

clutch plate and/or clutch pulley are being used,

install a trial stack of shims 1.0 mm (0.040 in.) thick

on the compressor shaft against the shoulder.

(7) Install the clutch plate onto the compressor

shaft.

(8) Install and tighten the compressor shaft nut. If

necessary, a band-type oil filter wrench or a strap

wrench can be placed around the clutch plate to aid

in bolt tightening. Tighten the bolt to 17.5 N´m (155

in. lbs.).

(9) If a new clutch plate and/or clutch pulley are

being installed, the air gap between the clutch plate

and clutch pulley must be checked. (Refer to 24 -

HEATING & AIR CONDITIONING/CONTROLS -

FRONT/COMPRESSOR CLUTCH - STANDARD

PROCEDURE - COMPRESSOR CLUTCH AIR GAP).

(10) On models with the 2.4L engine only, loosely

install the four screws that secure the compressor tothe mounting bracket on the engine. Tighten the

screws to 28 N´m (21 ft. lbs.).

(11) On models with the 3.3L and 3.8L engines

only, loosely install the three screws and one nut that

secure the compressor to the engine. Tighten each of

the fasteners using the following sequence to 54 N´m

(40 ft. lbs.).

²The upper screw at the rear of the compressor.

²The lower screw at the rear of the compressor.

²The lower screw at the front of the compressor.

²The upper nut at the front of the compressor.

(12) On models with the 3.3L and 3.8L engines

only, engage the retainer on the engine wire harness

compressor clutch coil take out with the bracket on

the top of the compressor.

(13) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(14) Reinstall the serpentine accessory drive belt

onto the front of the engine. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - 2.4L -

INSTALLATION) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3L/3.8L - INSTAL-

LATION).

(15) Lower the vehicle.

(16) Reconnect the battery negative cable.

(17) If a new clutch plate and/or clutch pulley are

being installed, the new clutch components must be

burnished. (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/COMPRESSOR

CLUTCH - STANDARD PROCEDURE - COMPRES-

SOR CLUTCH BREAK-IN).

COMPRESSOR CLUTCH COIL

DIAGNOSIS AND TESTING - COMPRESSOR

CLUTCH COIL

The air conditioning compressor clutch coil electri-

cal circuit is controlled by the Powertrain Control

Module (PCM) through the compressor clutch relay,

which is located in the Intelligent Power Module

(IPM) in the engine compartment near the battery.

Begin testing of a suspected compressor clutch coil

problem by performing the preliminary checks.

PRELIMINARY CHECKS

(1) If the compressor clutch will not engage, verify

the refrigerant charge level. (Refer to 24 - HEATING

& AIR CONDITIONING/PLUMBING - FRONT/RE-

FRIGERANT - DIAGNOSIS AND TESTING -

REFRIGERANT CHARGE LEVEL). If the refriger-

ant charge level is OK, go to Step 2. If the refriger-

ant charge level is not OK, adjust the refrigerant

charge as required.

Fig. 16 Install Clutch Pulley

1 - PULLEY ASSEMBLY

2 - WOOD BLOCK

24 - 20 CONTROLS - FRONTRS

COMPRESSOR CLUTCH (Continued)

ProCarManuals.com

Page 2307 of 2399

(17) Remove the compressor from the engine com-

partment.

NOTE: If a replacement compressor is being

installed, be certain to drain and measure the refrig-

erant oil contained in the removed compressor.

This will determine how much oil the replacement

compressor must contain before it is installed.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT OIL - STAN-

DARD PROCEDURE - REFRIGERANT OIL LEVEL).

REMOVAL - COMPRESSOR MOUNTING

BRACKET - 2.4L ENGINE

(1) Remove the compressor from the mounting

bracket. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING/COMPRESSOR - REMOVAL).

(2) Remove the four screws that secure the com-

pressor mounting bracket to the engine (Fig. 3).

(3) Remove the compressor mounting bracket from

the engine.

INSTALLATION

INSTALLATION - COMPRESSOR

NOTE: If a replacement compressor is being

installed, be certain to check the refrigerant oil

level. (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT/REFRIGERANT OIL - STAN-

DARD PROCEDURE - REFRIGERANT OIL LEVEL).

Use only refrigerant oil of the type recommended

for the compressor in the vehicle.(1) Position the compressor into the engine com-

partment.

(2) On models with the 2.4L engine, loosely install

the four screws that secure the compressor to the

mounting bracket on the engine. Tighten the screws

to 28 N´m (21 ft. lbs.).

(3) On models with the 3.3L and 3.8L engines,

loosely install the three screws and one nut that

secure the compressor to the engine. Tighten each of

the fasteners using the following sequence to 54 N´m

(40 ft. lbs.).

²The upper screw at the rear of the compressor.

²The lower screw at the rear of the compressor.

²The lower screw at the front of the compressor.

²The upper nut at the front of the compressor.

(4) On models with the 3.3L and 3.8L engines only,

engage the retainer on the engine wire harness com-

pressor clutch coil take out with the bracket on the

top of the compressor.

(5) Reconnect the engine wire harness connector

for the compressor clutch coil to the coil pigtail wire

connector on the top of the compressor.

(6) Reinstall the serpentine accessory drive belt

onto the front of the engine. (Refer to 7 - COOLING/

ACCESSORY DRIVE/DRIVE BELTS - 2.4L -

INSTALLATION) or (Refer to 7 - COOLING/ACCES-

SORY DRIVE/DRIVE BELTS - 3.3L/3.8L - INSTAL-

LATION).

(7) Lower the vehicle.

(8) Remove the tape or plugs from the compressor

discharge port and the discharge line fitting.

(9) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the discharge line fit-

ting.

(10) Reconnect the discharge line fitting to the

compressor discharge port.

(11) Install and tighten the nut that secures the

discharge line fitting to the compressor. Tighten the

nut to 23 N´m (17 ft. lbs.).

(12) Remove the tape or plugs from the compressor

suction port and the suction line fitting.

(13) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the suction line fit-

ting.

(14) Reconnect the suction line fitting to the com-

pressor suction port.

(15) Install and tighten the nut that secures the

suction line fitting to the compressor. Tighten the nut

to 23 N´m (17 ft. lbs.).

(16) Reconnect the battery negative cable.

(17) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(18) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

Fig. 3 Compressor Mounting Bracket - 2.4L Engine

1 - MOUNTING BRACKET

2 - SCREWS (4)

3 - ENGINE

24 - 64 PLUMBING - FRONTRS

COMPRESSOR (Continued)

ProCarManuals.com

Page 2309 of 2399

(8) Disconnect the discharge line fitting from the

condenser inlet port.

(9) Remove the seal from the discharge line fitting

and discard.

(10) Install plugs in, or tape over the opened dis-

charge line fitting and the condenser inlet port.

(11) Remove the nut that secures the liquid line

fitting to the condenser on the right side of the cool-

ing module.

(12) Disconnect the liquid line fitting from the con-

denser outlet port.

(13) Remove the seal from the liquid line fitting

and discard.

(14) Install plugs in, or tape over the opened liquid

line fitting and the condenser outlet port.

(15) Remove the screw that secures the top of the

mounting bracket on each side of the condenser to

the cooling module (Fig. 5).

(16) Lift the condenser, transmission oil cooler, and

mounting brackets as a unit far enough to disengage

the locating pin that secures the mounting brackets

in the lower mount rubber isolators on each side of

the cooling module.

(17) Remove the condenser, transmission oil cooler,

and mounting brackets from the vehicle as a unit.(18) Remove the two screws that secure each

mounting bracket to the sides of the condenser.

(19) Remove the one screw that secures the left

mounting bracket to the side of the transmission oil

cooler.

(20) Remove the left mounting bracket from the

side of the condenser and transmission oil cooler.

(21) Remove the condenser from the right mount-

ing bracket and transmission oil cooler unit.

INSTALLATION

NOTE: If the condenser is being replaced, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle.

NOTE: Be certain that each of the radiator and con-

denser air seals are reinstalled in their proper loca-

tions. These air seals are required in order for the

air conditioning and engine cooling systems to per-

form as designed.

(1) Position the condenser to the right mounting

bracket and transmission oil cooler unit.

(2) Position the left mounting bracket onto the side

of the condenser and transmission oil cooler.

(3) Install and tighten the one screw that secures

the left mounting bracket to the side of the transmis-

sion oil cooler. Tighten the screw to 5 N´m (45 in.

lbs.).

(4) Install and tighten the two screws that secure

each mounting bracket to the sides of the condenser.

Tighten the screws to 5 N´m (45 in. lbs.).

(5) Position the condenser, transmission oil cooler,

and mounting brackets into the vehicle as a unit. Be

certain that the locating pins that secure the mount-

ing brackets are engaged in the lower mount rubber

isolators on each side of the cooling module.

NOTE: Verify that the condensor isolators are all

installed and positioned correctly.

(6) Install and tighten the two screws that secure

the top of the mounting bracket on each side of the

condenser to the cooling module. Tighten the screws

to 5 N´m (45 in. lbs.).

(7) Remove the tape or plugs from the condenser

outlet port and the liquid line fitting.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the con-

denser outlet port on the right side of the cooling

module.

Fig. 5 Condenser Mounting

1 - SCREW (2)

2 - LOWER MOUNT ISOLATOR (2)

3 - CONDENSER

24 - 66 PLUMBING - FRONTRS

CONDENSER (Continued)

ProCarManuals.com

Page 2313 of 2399

(15) Carefully separate and remove the upper half

of the evaporator housing from the lower half. Be cer-

tain not to lose the rubber grommet for the HVAC

wire harness evaporator temperature sensor take

out. This grommet is located on the inboard side of

the flange around the expansion valve/evaporator

tube opening on the dash panel side of the unit,

where it is captured in a notched area between the

upper and lower housing halves (Fig. 13).(16) Carefully lift the evaporator and its foam

wrap out of the lower half of the evaporator housing

as a unit. Be certain not to lose the clam shell type

rubber seal that is fitted to the evaporator inlet and

outlet tubes where they exit the evaporator housing.

INSTALLATION

NOTE: If the evaporator is being replaced, add 60

milliliters (2 fluid ounces) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle.

(1) Carefully lower the evaporator and its foam

wrap into the lower half of the evaporator housing as

a unit. Be certain that the clam shell type rubber

seal is fitted to the evaporator inlet and outlet tubes

where they exit the evaporator housing.

(2) Position the upper half of the evaporator hous-

ing onto the lower half. Be certain that the rubber

grommet and the HVAC wire harness take out for

the evaporator temperature sensor are captured in

the notched area between the upper and lower hous-

ing halves.

(3) Install and tighten the twelve screws around

the perimeter of the evaporator housing that secure

the upper housing half to the lower half. Tighten the

screws to 2 N´m (18 in. lbs.).

(4) Position the upper half of the recirculation air

door onto the lower half of the door.

(5) Install and tighten the two screws that secure

the upper half of the recirculation air door to the

Fig. 11 Upper Intake Air Housing

1 - EVAPORATOR HOUSING

2- UPPER INTAKE AIR HOUSING

3 - RECIRCULATION AIR DOOR

4 - BLOWER WHEEL

Fig. 12 Recirculation Air Door

1 - EVAPORATOR HOUSING

2 - UPPER RECIRCULATION AIR DOOR

3 - LOWER INTAKE AIR HOUSING

Fig. 13 Evaporator Housing

1 - LOWER EVAPORATOR HOUSING

2 - UPPER EVAPORATOR HOUSING

3 - BLOWER WHEEL

4 - EVAPORATOR

24 - 70 PLUMBING - FRONTRS

EVAPORATOR (Continued)

ProCarManuals.com

Page 2314 of 2399

lower half of the door. Tighten the screws to 2 N´m

(18 in. lbs.).

(6) Position the upper intake air housing onto the

top of the evaporator housing over the recirculation

air door and the blower wheel housing. Be certain

that the upper pivot of the recirculation air door is

captured in the pivot receptacle of the upper intake

air housing.

(7) Install and tighten the three screws that secure

the upper intake air housing to the top of the out-

board end of the evaporator housing. Be certain not

to miss the screw located just inside the inboard side

of the fresh air intake opening. Tighten the screws to

2 N´m (18 in. lbs.).

(8) Install and tighten the two screws that secure

the upper intake air housing to the lower intake air

housing. Tighten the screws to 2 N´m (18 in. lbs.).

(9) Engage the two hook formations on the bottom

of the distribution housing in the two receptacles on

the evaporator housing.

(10) Roll the top of the distribution housing up

into position against the evaporator housing.

(11) Install and tighten the three screws from the

dash panel side of the unit that secure the top of the

distribution housing to the inboard end of the evapo-

rator housing. Tighten the screws to 2 N´m (18 in.

lbs.).

(12) Engage the HVAC wire harness in the routing

clips molded into the outside of the HVAC housing

components.

(13) Reconnect the HVAC wire harness connector

for the blower motor with the motor connector recep-

tacle on the bottom of the outboard end of the evap-

orator housing.

(14) Reinstall the expansion valve onto the evapo-

rator inlet and outlet tube fittings. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/EXPANSION VALVE - INSTALLATION).

(15) Install a new foam seal onto the HVAC hous-

ing seal flange around the fresh air inlet opening and

the expansion valve/evaporator tube opening on the

dash panel side of the unit.

(16) Reinstall the heater core tubes into the heater

core. (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT/HEATER CORE -

INSTALLATION - HEATER CORE TUBES).

(17) Reinstall the HVAC unit housing into the

vehicle. (Refer to 24 - HEATING & AIR CONDI-

TIONING/DISTRIBUTION - FRONT/HVAC HOUS-

ING - INSTALLATION).

(18) Run the HVAC Control Actuator Calibration

procedure(Refer to 24 - HEATING & AIR CONDI-

TIONING - DIAGNOSIS AND TESTING)(Refer to 24

- HEATING & AIR CONDITIONING - DIAGNOSIS

AND TESTING).EXPANSION VALVE

DESCRIPTION

The front ªHº valve-type thermal expansion valve

(TXV) is located at the dash panel between the liquid

and suction lines, and the evaporator coil. The

assembly consists of an H-valve body and a thermal

sensor. High-pressure, low temperature liquid refrig-

erant from the liquid line passes through the expan-

sion valve orifice, converting it into a low-pressure,

low-temperature mixture of liquid and gas before it

enters the evaporator coil. The expansion valve is a

factory calibrated unit and cannot be adjusted or

repaired. If faulty or damaged, the expansion valve

must be replaced.

OPERATION

A mechanical sensor in the expansion valve control

head monitors the temperature and pressure of the

refrigerant leaving the evaporator coil through the

suction line, and adjusts the orifice size at the liquid

line to let the proper amount of refrigerant into the

evaporator coil to meet the vehicle cooling require-

ments. Controlling the refrigerant flow through the

evaporator ensures that none of the refrigerant leav-

ing the evaporator is still in a liquid state, which

could damage the compressor. The thermo sensor

measures refrigerant suction gas temperature which

is monitored by the a/c control assembly.

DIAGNOSIS AND TESTING - EXPANSION VALVE

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The expansion valve should only be tested

following testing of the compressor.

NOTE: Liquid CO is required to test the expansion

valve. This material is available from most welding

supply facilities. Liquid CO is also available from

companies which service and sell fire extinguish-

ers.

When testing the expansion valve, the work area

and the vehicle temperature must be 21É to 27É C

(70É to 85É F). To test the expansion valve:

(1) Connect a charging station or manifold gauge

set to the refrigerant system service ports. Verify the

refrigerant charge level.

RSPLUMBING - FRONT24-71

EVAPORATOR (Continued)

ProCarManuals.com

Page 2329 of 2399

(1) Recover the refrigerant from the refrigerant

system. (Refer to 24 - HEATING & AIR CONDI-

TIONING/PLUMBING - FRONT/REFRIGERANT -

STANDARD PROCEDURE - REFRIGERANT

RECOVERY).

(2) Remove the air cleaner housing from the right

side of the engine compartment.

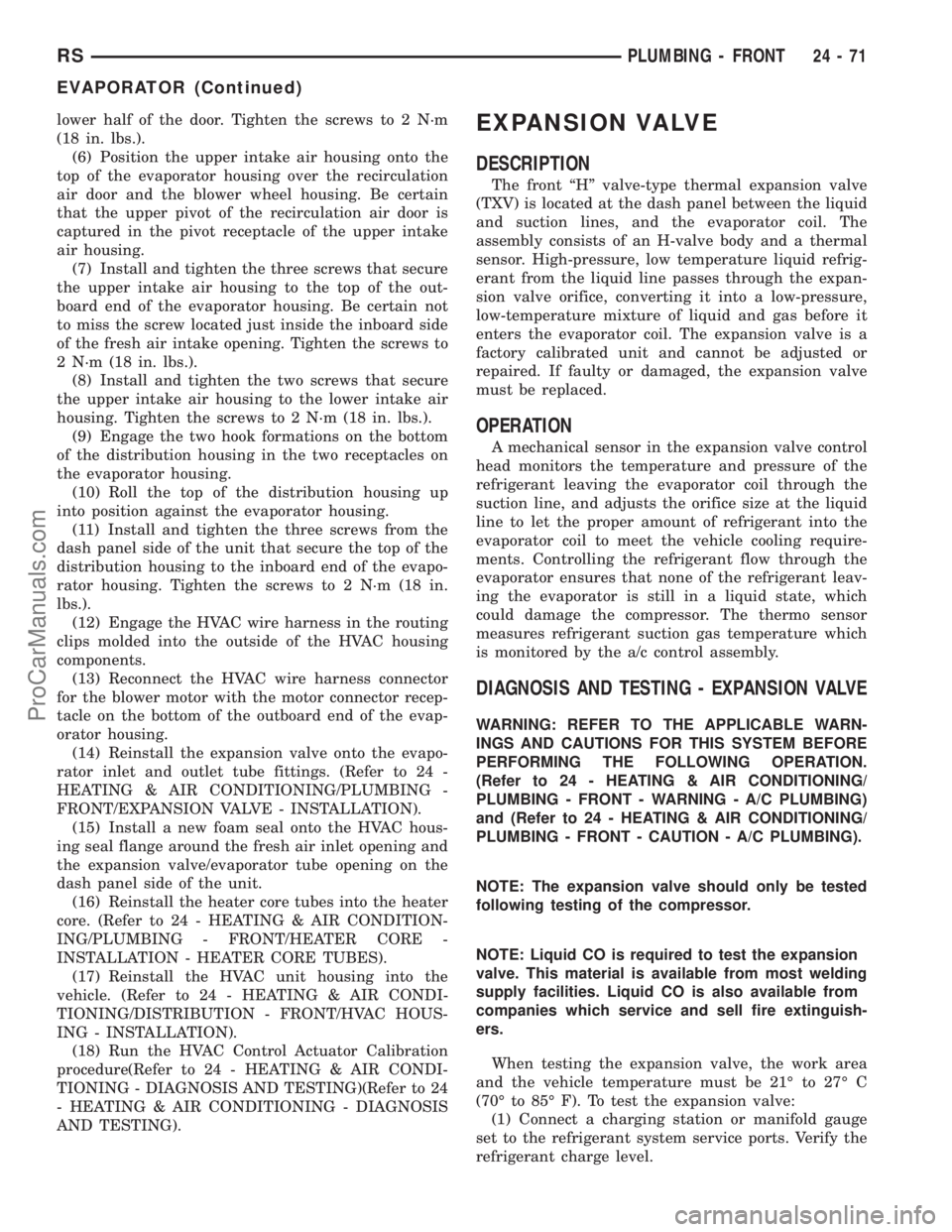

(3) Remove the screw that secures the liquid line

front section fitting to the top of the filter-drier (Fig.

32).

(4) Disconnect the liquid line fitting from the fil-

ter-drier inlet port.

(5) Remove the seal from the liquid line fitting and

discard.

(6) Install plugs in, or tape over the opened liquid

line fitting and the filter-drier inlet port.

(7) Remove the screw that secures the liquid line

rear section fitting to the top of the filter-drier.

(8) Disconnect the liquid line fitting from the fil-

ter-drier outlet port.(9) Remove the seal from the liquid line fitting and

discard.

(10) Install plugs in, or tape over the opened liquid

line fitting and the filter-drier outlet port.

(11) Remove the two nuts that secure the filter-

drier mounting bracket to the weld studs on the side

of the right front strut tower.

(12) Remove the filter-drier and mounting bracket

unit from the studs.

INSTALLATION

NOTE: If the filter-drier is being replaced, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system. Use only refrigerant oil of the

type recommended for the compressor in the vehi-

cle.

(1) Position the filter-drier and mounting bracket

unit onto the weld studs on the side of the right front

strut tower.

(2) Install and tighten the two nuts that secure

the filter-drier mounting bracket to the studs.

Tighten the nuts to 10 N´m (89 in. lbs.).

(3) Remove the tape or plugs from the liquid line

rear section fitting for the filter-drier and the filter-

drier outlet port.

(4) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(5) Reconnect the liquid line fitting to the filter-

drier outlet port on the top of the filter-drier.

(6) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (18 in. lbs.).

(7) Remove the tape or plugs from the liquid line

front section fitting for the filter-drier and the filter-

drier inlet port.

(8) Lubricate a new rubber O-ring seal with clean

refrigerant oil and install it on the liquid line fitting.

(9) Reconnect the liquid line fitting to the filter-

drier inlet port on the top of the filter-drier.

(10) Install and tighten the screw that secures the

liquid line fitting to the filter-drier. Tighten the screw

to 2 N´m (18 in. lbs.).

(11) Reinstall the air cleaner housing into the

right side of the engine compartment.

(12) Evacuate the refrigerant system. (Refer to 24

- HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(13) Charge the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM CHARGE).

Fig. 32 Front Liquid Lines

1 - A/C GROUND STRAP

2 - NUT

3 - WELD STUD

4 - A/C PRESSURE TRANSDUCER

5 - WELD STUD (2)

6 - EXPANSION VALVE

7 - FRONT LIQUID LINE REAR SECTION

8 - LIQUID LINE EXTENSION (REAR A/C ONLY)

9 - NUT (2)

10 - FILTER-DRIER

11 - ROUTING CLIP

12 - FRONT LIQUID LINE FRONT SECTION

24 - 86 PLUMBING - FRONTRS

RECEIVER/DRIER (Continued)

ProCarManuals.com

Page 2330 of 2399

REFRIGERANT

DESCRIPTION

The refrigerant used in this air conditioning sys-

tem is a HydroFluoroCarbon (HFC), type R-134a.

Unlike R-12, which is a ChloroFluoroCarbon (CFC),

R-134a refrigerant does not contain ozone-depleting

chlorine. R-134a refrigerant is a non-toxic, non-flam-

mable, clear, and colorless liquefied gas. Even though

R-134a does not contain chlorine, it must be

reclaimed and recycled just like CFC-type refriger-

ants. This is because R-134a is a greenhouse gas and

can contribute to global warming.

OPERATION

R-134a refrigerant is not compatible with R-12

refrigerant in an air conditioning system. Even a

small amount of R-12 added to an R-134a refrigerant

system will cause compressor failure, refrigerant oil

sludge or poor air conditioning system performance.

In addition, the PolyAlkylene Glycol (PAG) synthetic

refrigerant oils used in an R-134a refrigerant system

are not compatible with the mineral-based refriger-

ant oils used in an R-12 refrigerant system. R-134a

refrigerant system service ports, service tool couplers

and refrigerant dispensing bottles have all been

designed with unique fittings to ensure that an

R-134a system is not accidentally contaminated with

the wrong refrigerant (R-12). There are also labels

posted in the engine compartment of the vehicle and

on the compressor identifying to service technicians

that the air conditioning system is equipped with

R-134a.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM CHARGE LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The proper amount of R-134a refrigerant for

the refrigerant system in this model is:

²Single or Dual Zone (Front Unit Only) - 0.96

kilograms (2.13 pounds or 34 ounces)

²Three Zone (Front and Rear Units) - 1.31 kilo-

grams (2.88 pounds or 46 ounces)The procedure that follows should be used to deter-

mine whether the refrigerant system contains the

proper refrigerant charge. Symptoms of an improper

refrigerant charge (low) include: poor air conditioner

performance, fog emitted from the air conditioner

outlets, a hissing sound from the expansion valve/

evaporator area. There are two different methods

with which the refrigerant charge level may be

tested:

²Using a DRBIIItscan tool, a thermocouple and

the Charge Determination Chart (Fig. 33). Refer to

the appropriate diagnostic information.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Chart (Fig. 33).

A temperature probe is required to measure liquid

line temperature. The clamp-on, Type K thermocou-

ple temperature probe used in this procedure is

available through the DaimlerChrysler Professional

Service Equipment (PSE) program. This probe (PSE

#66-324-0014 or #80PK-1A) is compatible with tem-

perature-measuring instruments that accept Type K

thermocouples, and have a miniature connector

input. Other temperature probes are available

through aftermarket sources; however, all references

in this procedure will reflect the use of the probe

made available through the PSE program.

In order to use the temperature probe, a digital

thermometer will also be required. If a digital ther-

mometer is not available, an adapter is available

through the PSE program that will convert any stan-

dard digital multimeter into a digital thermometer.

This adapter is designed to accept any standard Type

K thermocouple. If a digital multimeter is not avail-

able, this tool is also available through the PSE pro-

gram.

NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set or a

R-134a refrigerant recovery/recycling/charging sta-

tion that meets SAE Standard J2210 to the refriger-

ant system.

(2) Attach a clamp-on thermocouple to the liquid

line. The thermocouple must be placed as close to the

A/C pressure transducer as possible to accurately

observe liquid line temperature.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run at idle under the following condi-

tions for five minutes.

(a) Front windows are open.

(b) Transaxle in Park.

RSPLUMBING - FRONT24-87

ProCarManuals.com

Page 2332 of 2399

location of a possible refrigerant leak, the exact leak

location should be confirmed with an electronic leak

detector prior to component repair or replacement.

An electronic leak detector designed for R-134a

refrigerant is recommended for locating and confirm-

ing refrigerant system leaks. See the operating

instructions supplied by the equipment manufacturer

for proper care and use of this equipment.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

results of the refrigerant system charge level test.

SYSTEM EMPTY

(1) Evacuate the refrigerant system. (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT/REFRIGERANT - STANDARD PROCE-

DURE - REFRIGERANT SYSTEM EVACUATE).

(2) Connect and dispense 0.283 kilograms (0.625

pounds or 10 ounces) of R-134a refrigerant into the

evacuated refrigerant system. (Refer to 24 - HEAT-

ING & AIR CONDITIONING/PLUMBING - FRONT/

REFRIGERANT - STANDARD PROCEDURE -

REFRIGERANT SYSTEM CHARGE).

(3) Proceed to the SYSTEM LOW procedures.

SYSTEM LOW

(1) Position the vehicle in a wind-free work area.

This will aid in detecting small leaks.

(2) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run at idle under the following condi-

tions for five minutes, then turning the engine off.

(a) Front windows are open.

(b) Rear air conditioner Off (if equipped).

(c) Transaxle in Park.

(d) Front heater-A/C controls set to outside air,

panel mode, blower high, and compressor engaged.

(3) Wait five to seven minutes and, with the

engine not running, use a electronic R-134a leak

detector and search for leaks. Because R-134a refrig-

erant is heavier than air, the leak detector probe

should be moved slowly along the bottom side of all

refrigerant lines, connector fittings and components.

(4) To inspect an evaporator for leaks, insert the

electronic leak detector probe into a floor outlet or

the recirculation air intake.

DIAGNOSIS AND TESTING - REFRIGERANT

SYSTEM CHARGE LEVEL 2.5L DIESEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

NOTE: The proper amount of R-134a refrigerant for

the refrigerant system in this model is:

²Single or Dual Zone (Front Unit Only - 2.5L Die-

sel) ± 0.91 kilograms (2.00 pounds or 32 ounces)

²Single or Dual Zone (Front Unit Only) - 0.96

kilograms (2.13 pounds or 34 ounces)

²Three Zone (Front and Rear Units) - 1.31 kilo-

grams (2.88 pounds or 46 ounces)

The procedure that follows should be used to deter-

mine whether the refrigerant system contains the

proper refrigerant charge. Symptoms of an improper

refrigerant charge (low) include: poor air conditioner

performance, fog emitted from the air conditioner

outlets, a hissing sound from the expansion valve/

evaporator area. There are two different methods

with which the refrigerant charge level may be

tested:

²Using a DRBIIItscan tool, a thermocouple and

the Charge Determination Chart (Fig. 34). Refer to

the appropriate diagnostic information.

²Using a manifold gauge set, a thermocouple and

the Charge Determination Chart (Fig. 34).

A temperature probe is required to measure liquid

line temperature. The clamp-on, Type K thermocou-

ple temperature probe used in this procedure is

available through the DaimlerChrysler Professional

Service Equipment (PSE) program. This probe (PSE

#66-324-0014 or #80PK-1A) is compatible with tem-

perature-measuring instruments that accept Type K

thermocouples, and have a miniature connector

input. Other temperature probes are available

through aftermarket sources; however, all references

in this procedure will reflect the use of the probe

made available through the PSE program.

In order to use the temperature probe, a digital

thermometer will also be required. If a digital ther-

mometer is not available, an adapter is available

through the PSE program that will convert any stan-

dard digital multimeter into a digital thermometer.

This adapter is designed to accept any standard Type

K thermocouple. If a digital multimeter is not avail-

able, this tool is also available through the PSE pro-

gram.

NOTE: When connecting the service equipment

couplings to the refrigerant system service ports,

be certain that the valve of each coupling is fully

closed. This will reduce the amount of effort

required to make the connection.

(1) Remove the caps from the refrigerant system

service ports and attach a manifold gauge set or a

R-134a refrigerant recovery/recycling/charging sta-

RSPLUMBING - FRONT24-89

REFRIGERANT (Continued)

ProCarManuals.com

Page 2336 of 2399

STANDARD PROCEDURE - REFRIGERANT

RECOVERY

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

A R-134a refrigerant recovery/recycling/charging

station that meets SAE Standard J2210 must be

used to recover the refrigerant from an R-134a refrig-

erant system, whenever the refrigerant system must

be opened for service. See the operating instructions

supplied by the equipment manufacturer for the

proper care and use of this equipment.

REFRIGERANT OIL

DESCRIPTION

The refrigerant oil used in R-134a refrigerant sys-

tems is a synthetic-based, PolyAlkylene Glycol (PAG),

wax-free lubricant. Mineral-based R-12 refrigerant

oils are not compatible with PAG oils, and should

never be introduced to an R-134a refrigerant system.

There are different PAG oils available, and each con-

tains a different additive package. The 10S20H com-

pressor used in this vehicle are designed to use an

ND-8 PAG refrigerant oil. Use only refrigerant oil of

this same type to service the refrigerant system.

OPERATION

After performing any refrigerant recovery or recy-

cling operation, always replenish the refrigerant sys-

tem with the same amount of the recommended

refrigerant oil as was removed. Too little refrigerant

oil can cause compressor damage, and too much can

reduce air conditioning system performance. PAG

refrigerant oil is much more hygroscopic than min-

eral oil, and will absorb any moisture it comes into

contact with, even moisture in the air. The PAG oil

container should always be kept tightly capped until

it is ready to be used. After use, recap the oil con-

tainer immediately to prevent moisture contamina-

tion.

STANDARD PROCEDURE - REFRIGERANT OIL

LEVEL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION.

(Refer to 24 - HEATING & AIR CONDITIONING/PLUMBING - FRONT - WARNING - A/C PLUMBING)

and (Refer to 24 - HEATING & AIR CONDITIONING/

PLUMBING - FRONT - CAUTION - A/C PLUMBING).

When an air conditioning system is assembled at

the factory, all components except the compressor are

refrigerant oil free. After the refrigerant system has

been charged and operated, the refrigerant oil in the

compressor is dispersed throughout the refrigerant

system. The receiver/drier, evaporator, condenser, and

compressor will each retain a significant amount of

the needed refrigerant oil.

It is important to have the correct amount of oil in

the refrigerant system. This ensures proper lubrica-

tion of the compressor. Too little oil will result in

damage to the compressor. Too much oil will reduce

the cooling capacity of the air conditioning system.

It will not be necessary to check the oil level in the

compressor or to add oil, unless there has been an oil

loss. An oil loss may occur due to a rupture or leak

from a refrigerant line, a connector fitting, a compo-

nent, or a component seal. If a leak occurs, add 30

milliliters (1 fluid ounce) of refrigerant oil to the

refrigerant system after the repair has been made.

Refrigerant oil loss will be evident at the leak point

by the presence of a wet, shiny surface around the

leak.

Refrigerant oil must be added when an receiver/

drier, evaporator or condenser is replaced. See the

Refrigerant Oil Capacities chart for the proper

amount of refrigerant oil to add. When a compressor

is replaced, the refrigerant oil must be drained from

the old compressor and measured. Drain all of the

refrigerant oil from the new compressor, then fill the

new compressor with the same amount of fresh new

refrigerant oil that was drained out of the old com-

pressor.

REFRIGERANT OIL CAPACITIES

Front A/C Front & Rear

A/C

COMPONENT ml fl oz ml fl oz

Compressor 150 5.0 220 7.4

Filter-Drier 30 1.0 30 1.0

Condenser 30 1.0 30 1.0

Front Evaporator 60 2.0 60 2.0

Rear Evap. (including

underbody lines)N/A N/A 60 2.0

Compressor Drain and measure the oil

from the old compressor -

See text above.

RSPLUMBING - FRONT24-93

REFRIGERANT (Continued)

ProCarManuals.com