wheel CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 239 of 2177

(2) Using a brake pedal depressor, move and lock

the brake pedal to a position past the first inch of

pedal travel.This will prevent brake fluid from

draining out of the master cylinder when the

brake tubes are removed from the HCU.

(3) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(4) Remove the routing clip attaching the ICU wir-

ing harness to the ICU mounting bracket (Fig. 17).

CAUTION: Do not apply a 12 volt power source to

any terminals of the HCU connector when discon-

nected.

(5) Remove the 24-way connector (Fig. 17) from

the CAB. The 24-way connector is removed from the

CAB using the following procedure. Grasp the lock

on the 24-way connector (Fig. 17) and pull it as far

out as possible (Fig. 18). This will raise and unlock

the 24-way connector from the socket on the CAB.

CAUTION: Before removing the brake tubes from

the HCU, the HCU must be thoroughly cleaned. This

must be done to prevent dirt particles from falling

into the ports of HCU or entering the brake tubes.(6) Thoroughly clean all surfaces of the HCU, and

all brake tube nuts located on the HCU. Use only a

solvent such as Mopar Brake Parts Cleaner or an

equivalent to clean the HCU.

(7) Remove the brake tubes (6) from the inlet and

outlet ports on the HCU. (Fig. 19).

Fig. 17 CAB 24-Way Connector

1 - CAB WIRING HARNESS

2 - 24±WAY CONNECTOR

3 - FLOOR PAN

4 - HCU

5 - CAB

6 - HCU MOUNTING BRACKET

7 - CONNECTOR LOCK

Fig. 18 Unlocked 24-Way CAB Connector

1 - HCU

2 - CAB

3 - 24±WAY CONNECTOR

4 - CONNECTOR LOCK (UNLOCKED)

Fig. 19 Brake Tube Connections To HCU

1 - LEFT REAR WHEEL BRAKE TUBE

2 - SECONDARY BRAKE TUBE FROM MASTER CYLINDER

3 - LEFT FRONT WHEEL BRAKE TUBE

4 - CAB

5 - RIGHT REAR WHEEL BRAKE TUBE

6 - HCU MOUNTING BRACKET

7 - BRAKE TUBE TO HCU CONNECTION LOCATION LEGEND

8 - RIGHT FRONT WHEEL BRAKE TUBE

9 - PRIMARY BRAKE TUBE FROM MASTER CYLINDER

5 - 92 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 241 of 2177

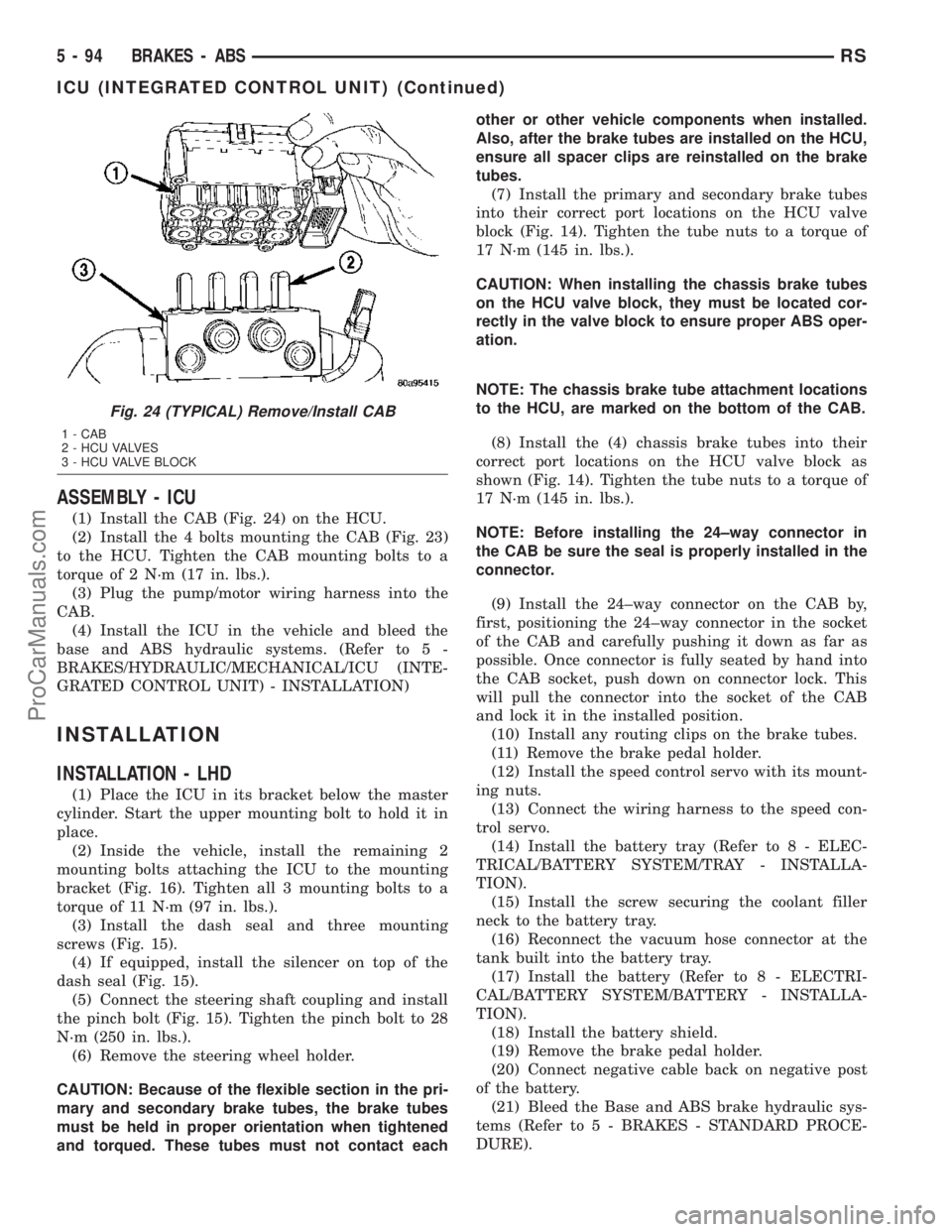

ASSEMBLY - ICU

(1) Install the CAB (Fig. 24) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 23)

to the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB.

(4) Install the ICU in the vehicle and bleed the

base and ABS hydraulic systems. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/ICU (INTE-

GRATED CONTROL UNIT) - INSTALLATION)

INSTALLATION

INSTALLATION - LHD

(1) Place the ICU in its bracket below the master

cylinder. Start the upper mounting bolt to hold it in

place.

(2) Inside the vehicle, install the remaining 2

mounting bolts attaching the ICU to the mounting

bracket (Fig. 16). Tighten all 3 mounting bolts to a

torque of 11 N´m (97 in. lbs.).

(3) Install the dash seal and three mounting

screws (Fig. 15).

(4) If equipped, install the silencer on top of the

dash seal (Fig. 15).

(5) Connect the steering shaft coupling and install

the pinch bolt (Fig. 15). Tighten the pinch bolt to 28

N´m (250 in. lbs.).

(6) Remove the steering wheel holder.

CAUTION: Because of the flexible section in the pri-

mary and secondary brake tubes, the brake tubes

must be held in proper orientation when tightened

and torqued. These tubes must not contact eachother or other vehicle components when installed.

Also, after the brake tubes are installed on the HCU,

ensure all spacer clips are reinstalled on the brake

tubes.

(7) Install the primary and secondary brake tubes

into their correct port locations on the HCU valve

block (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

CAUTION: When installing the chassis brake tubes

on the HCU valve block, they must be located cor-

rectly in the valve block to ensure proper ABS oper-

ation.

NOTE: The chassis brake tube attachment locations

to the HCU, are marked on the bottom of the CAB.

(8) Install the (4) chassis brake tubes into their

correct port locations on the HCU valve block as

shown (Fig. 14). Tighten the tube nuts to a torque of

17 N´m (145 in. lbs.).

NOTE: Before installing the 24±way connector in

the CAB be sure the seal is properly installed in the

connector.

(9) Install the 24±way connector on the CAB by,

first, positioning the 24±way connector in the socket

of the CAB and carefully pushing it down as far as

possible. Once connector is fully seated by hand into

the CAB socket, push down on connector lock. This

will pull the connector into the socket of the CAB

and lock it in the installed position.

(10) Install any routing clips on the brake tubes.

(11) Remove the brake pedal holder.

(12) Install the speed control servo with its mount-

ing nuts.

(13) Connect the wiring harness to the speed con-

trol servo.

(14) Install the battery tray (Refer to 8 - ELEC-

TRICAL/BATTERY SYSTEM/TRAY - INSTALLA-

TION).

(15) Install the screw securing the coolant filler

neck to the battery tray.

(16) Reconnect the vacuum hose connector at the

tank built into the battery tray.

(17) Install the battery (Refer to 8 - ELECTRI-

CAL/BATTERY SYSTEM/BATTERY - INSTALLA-

TION).

(18) Install the battery shield.

(19) Remove the brake pedal holder.

(20) Connect negative cable back on negative post

of the battery.

(21) Bleed the Base and ABS brake hydraulic sys-

tems (Refer to 5 - BRAKES - STANDARD PROCE-

DURE).

Fig. 24 (TYPICAL) Remove/Install CAB

1 - CAB

2 - HCU VALVES

3 - HCU VALVE BLOCK

5 - 94 BRAKES - ABSRS

ICU (INTEGRATED CONTROL UNIT) (Continued)

ProCarManuals.com

Page 244 of 2177

CLUTCH

TABLE OF CONTENTS

page page

CLUTCH

DESCRIPTION..........................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - CLUTCH

SYSTEM.............................3

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT.......................6

DIAGNOSIS AND TESTING - CLUTCH

COVER AND DISC RUNOUT..............6

DIAGNOSIS AND TESTING - CLUTCH

CHATTER COMPLAINTS.................6

SPECIAL TOOLS - T850 TRANSAXLE........6

CLUTCH RELEASE LEVER AND BEARING

REMOVAL.............................6

INSTALLATION..........................7

MASTER CYLINDER - RHD

REMOVAL.............................8

INSTALLATION..........................9

MASTER CYLINDER - LHD

REMOVAL.............................9INSTALLATION.........................10

MODULAR CLUTCH ASSY - 2.4L GAS

REMOVAL.............................11

INSTALLATION.........................11

SLAVE CYLINDER

REMOVAL.............................11

INSTALLATION.........................11

CLUTCH DISC AND PRESSURE PLATE - 2.5L TD

REMOVAL.............................11

INSTALLATION.........................12

FLYWHEEL

REMOVAL.............................12

INSTALLATION.........................12

CLUTCH PEDAL INTERLOCK SWITCH

REMOVAL.............................13

INSTALLATION.........................14

CLUTCH PEDAL UPSTOP SWITCH

REMOVAL.............................15

INSTALLATION.........................16

CLUTCH

DESCRIPTION

CLUTCH COMPONENTS

Models equipped with a 2.4L Gas engine utilize a

modular clutch assembly (Fig. 1). The modular clutch

consists of a single, dry-type clutch disc, a diaphragm

style clutch cover, and an integrated flywheel. The

clutch cover (pressure plate) is riveted to the fly-

wheel, and therefore can only be serviced as an

assembly.

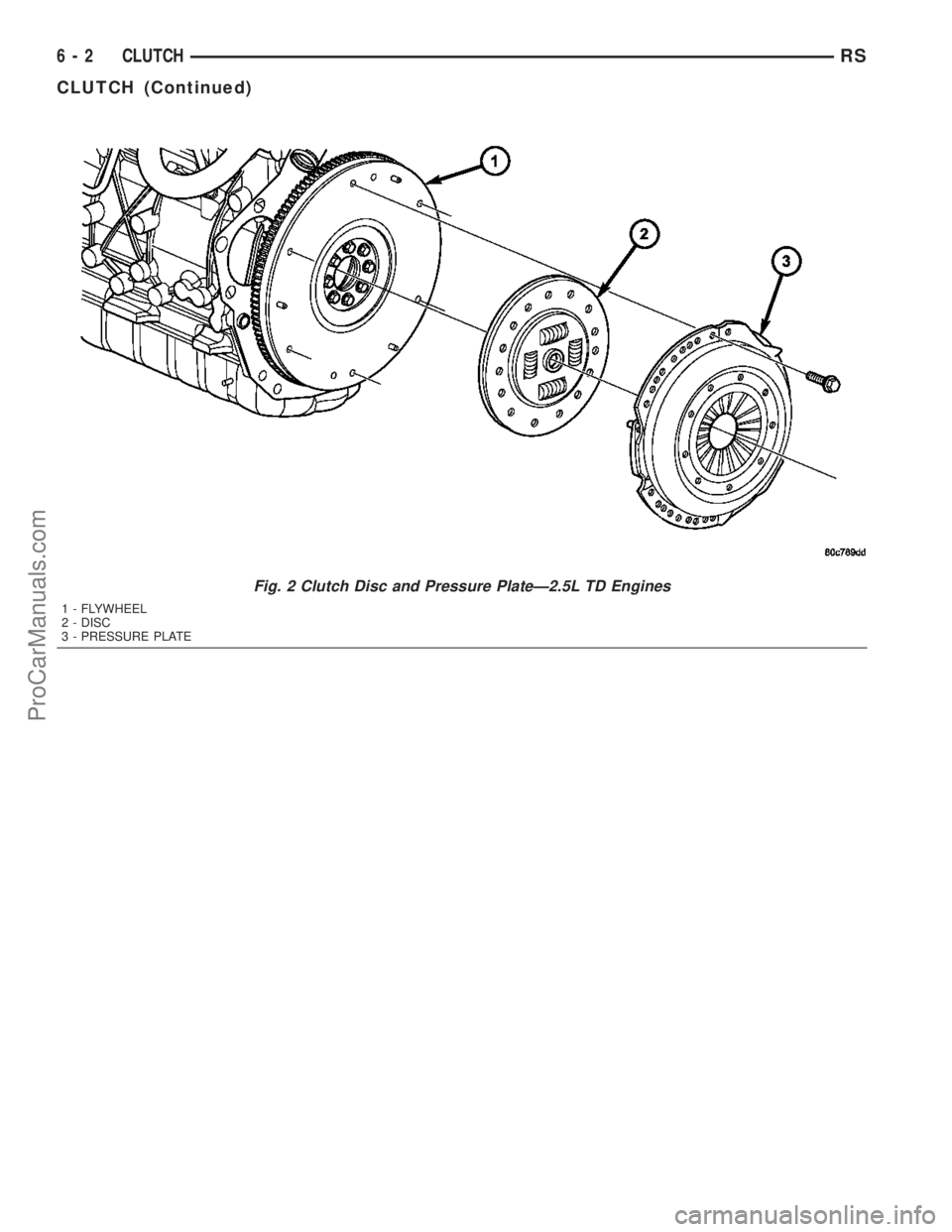

Models equipped with the 2.5L Turbo Diesel engine

utilize a conventional clutch system (Fig. 2). This

system consists of a flywheel, clutch disc, and clutch

cover (pressure plate), which is fastened to the fly-

wheel, capturing the clutch disc within. Each compo-

nent is individually serviceable, however it ishighly

recommended that the clutch cover and disc be

replaced as a set.

Fig. 1 Modular Clutch AssemblyÐ2.4L Gas Engines

1 - MODULAR CLUTCH ASSEMBLY

RSCLUTCH6-1

ProCarManuals.com

Page 245 of 2177

Fig. 2 Clutch Disc and Pressure PlateÐ2.5L TD Engines

1 - FLYWHEEL

2 - DISC

3 - PRESSURE PLATE

6 - 2 CLUTCHRS

CLUTCH (Continued)

ProCarManuals.com

Page 248 of 2177

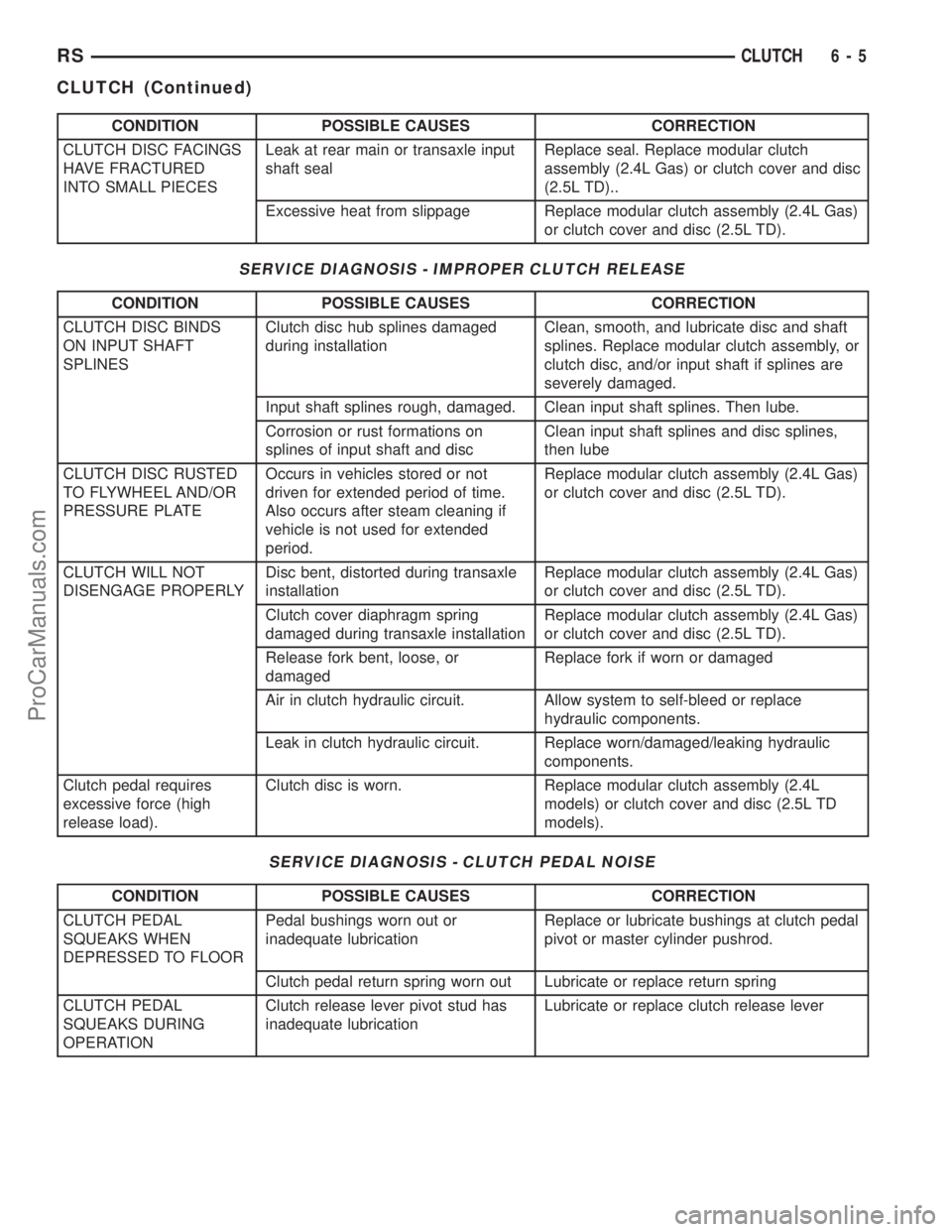

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC FACINGS

HAVE FRACTURED

INTO SMALL PIECESLeak at rear main or transaxle input

shaft sealReplace seal. Replace modular clutch

assembly (2.4L Gas) or clutch cover and disc

(2.5L TD)..

Excessive heat from slippage Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

SERVICE DIAGNOSIS - IMPROPER CLUTCH RELEASE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH DISC BINDS

ON INPUT SHAFT

SPLINESClutch disc hub splines damaged

during installationClean, smooth, and lubricate disc and shaft

splines. Replace modular clutch assembly, or

clutch disc, and/or input shaft if splines are

severely damaged.

Input shaft splines rough, damaged. Clean input shaft splines. Then lube.

Corrosion or rust formations on

splines of input shaft and discClean input shaft splines and disc splines,

then lube

CLUTCH DISC RUSTED

TO FLYWHEEL AND/OR

PRESSURE PLATEOccurs in vehicles stored or not

driven for extended period of time.

Also occurs after steam cleaning if

vehicle is not used for extended

period.Replace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

CLUTCH WILL NOT

DISENGAGE PROPERLYDisc bent, distorted during transaxle

installationReplace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Clutch cover diaphragm spring

damaged during transaxle installationReplace modular clutch assembly (2.4L Gas)

or clutch cover and disc (2.5L TD).

Release fork bent, loose, or

damagedReplace fork if worn or damaged

Air in clutch hydraulic circuit. Allow system to self-bleed or replace

hydraulic components.

Leak in clutch hydraulic circuit. Replace worn/damaged/leaking hydraulic

components.

Clutch pedal requires

excessive force (high

release load).Clutch disc is worn. Replace modular clutch assembly (2.4L

models) or clutch cover and disc (2.5L TD

models).

SERVICE DIAGNOSIS - CLUTCH PEDAL NOISE

CONDITION POSSIBLE CAUSES CORRECTION

CLUTCH PEDAL

SQUEAKS WHEN

DEPRESSED TO FLOORPedal bushings worn out or

inadequate lubricationReplace or lubricate bushings at clutch pedal

pivot or master cylinder pushrod.

Clutch pedal return spring worn out Lubricate or replace return spring

CLUTCH PEDAL

SQUEAKS DURING

OPERATIONClutch release lever pivot stud has

inadequate lubricationLubricate or replace clutch release lever

RSCLUTCH6-5

CLUTCH (Continued)

ProCarManuals.com

Page 249 of 2177

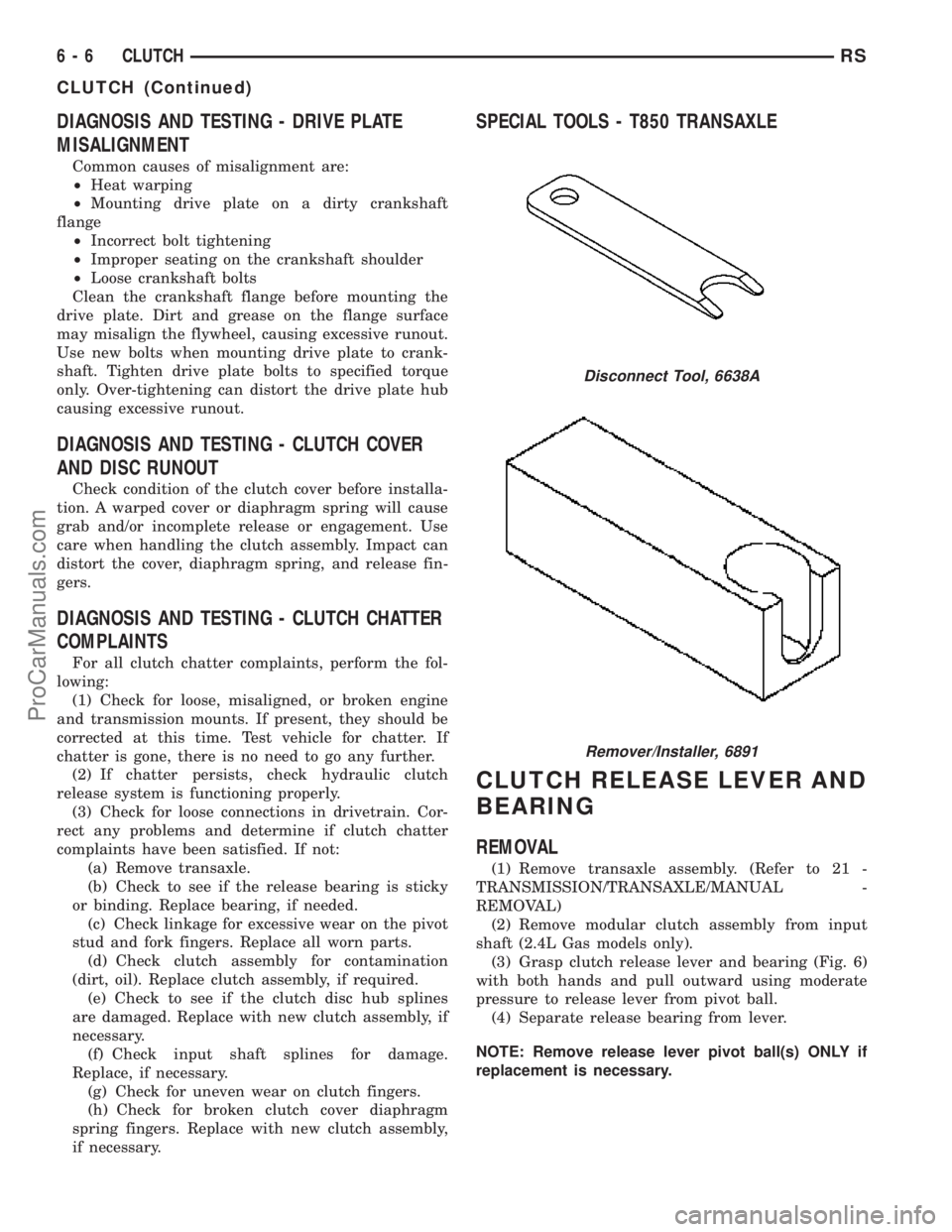

DIAGNOSIS AND TESTING - DRIVE PLATE

MISALIGNMENT

Common causes of misalignment are:

²Heat warping

²Mounting drive plate on a dirty crankshaft

flange

²Incorrect bolt tightening

²Improper seating on the crankshaft shoulder

²Loose crankshaft bolts

Clean the crankshaft flange before mounting the

drive plate. Dirt and grease on the flange surface

may misalign the flywheel, causing excessive runout.

Use new bolts when mounting drive plate to crank-

shaft. Tighten drive plate bolts to specified torque

only. Over-tightening can distort the drive plate hub

causing excessive runout.

DIAGNOSIS AND TESTING - CLUTCH COVER

AND DISC RUNOUT

Check condition of the clutch cover before installa-

tion. A warped cover or diaphragm spring will cause

grab and/or incomplete release or engagement. Use

care when handling the clutch assembly. Impact can

distort the cover, diaphragm spring, and release fin-

gers.

DIAGNOSIS AND TESTING - CLUTCH CHATTER

COMPLAINTS

For all clutch chatter complaints, perform the fol-

lowing:

(1) Check for loose, misaligned, or broken engine

and transmission mounts. If present, they should be

corrected at this time. Test vehicle for chatter. If

chatter is gone, there is no need to go any further.

(2) If chatter persists, check hydraulic clutch

release system is functioning properly.

(3) Check for loose connections in drivetrain. Cor-

rect any problems and determine if clutch chatter

complaints have been satisfied. If not:

(a) Remove transaxle.

(b) Check to see if the release bearing is sticky

or binding. Replace bearing, if needed.

(c) Check linkage for excessive wear on the pivot

stud and fork fingers. Replace all worn parts.

(d) Check clutch assembly for contamination

(dirt, oil). Replace clutch assembly, if required.

(e) Check to see if the clutch disc hub splines

are damaged. Replace with new clutch assembly, if

necessary.

(f) Check input shaft splines for damage.

Replace, if necessary.

(g) Check for uneven wear on clutch fingers.

(h) Check for broken clutch cover diaphragm

spring fingers. Replace with new clutch assembly,

if necessary.

SPECIAL TOOLS - T850 TRANSAXLE

CLUTCH RELEASE LEVER AND

BEARING

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove modular clutch assembly from input

shaft (2.4L Gas models only).

(3) Grasp clutch release lever and bearing (Fig. 6)

with both hands and pull outward using moderate

pressure to release lever from pivot ball.

(4) Separate release bearing from lever.

NOTE: Remove release lever pivot ball(s) ONLY if

replacement is necessary.

Disconnect Tool, 6638A

Remover/Installer, 6891

6 - 6 CLUTCHRS

CLUTCH (Continued)

ProCarManuals.com

Page 254 of 2177

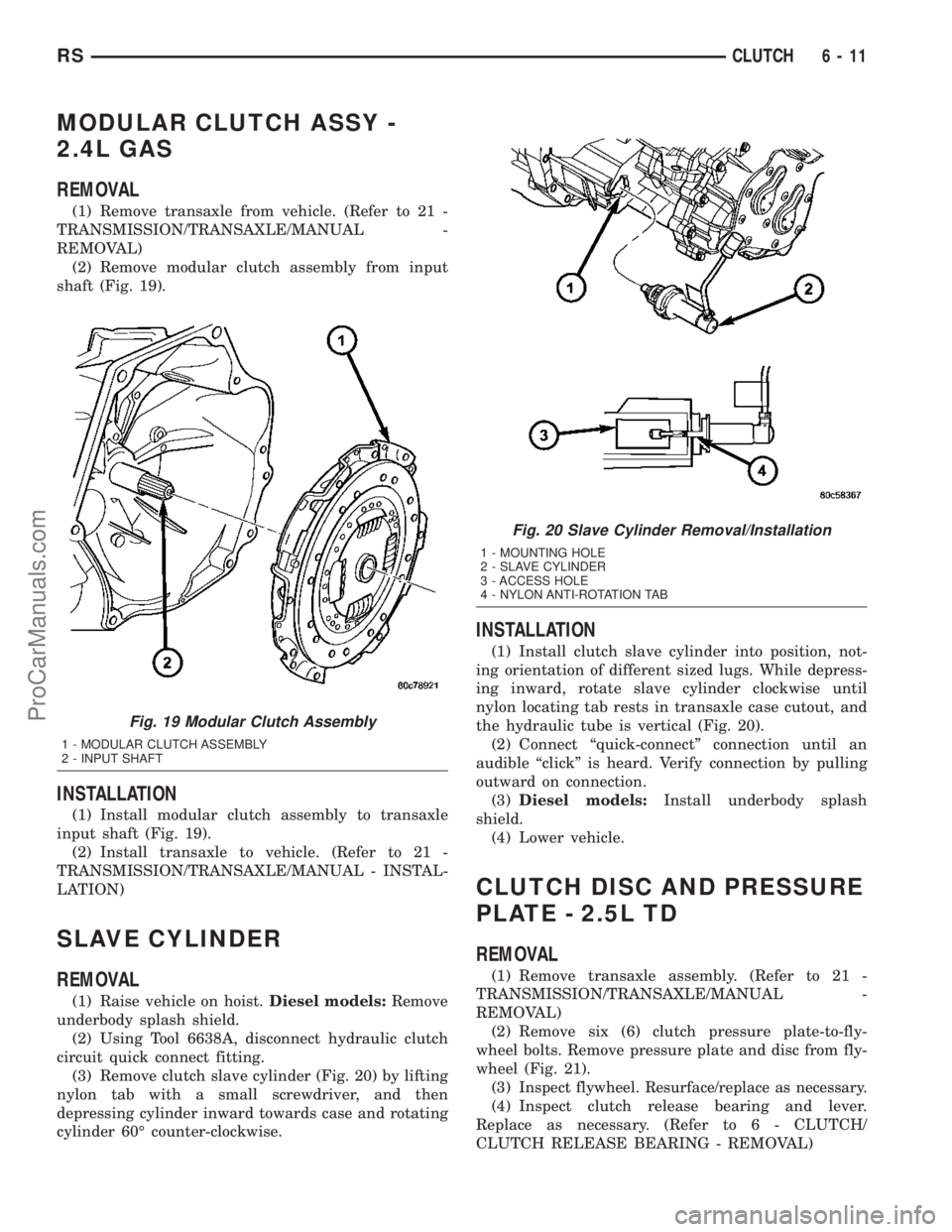

MODULAR CLUTCH ASSY -

2.4L GAS

REMOVAL

(1) Remove transaxle from vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove modular clutch assembly from input

shaft (Fig. 19).

INSTALLATION

(1) Install modular clutch assembly to transaxle

input shaft (Fig. 19).

(2) Install transaxle to vehicle. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

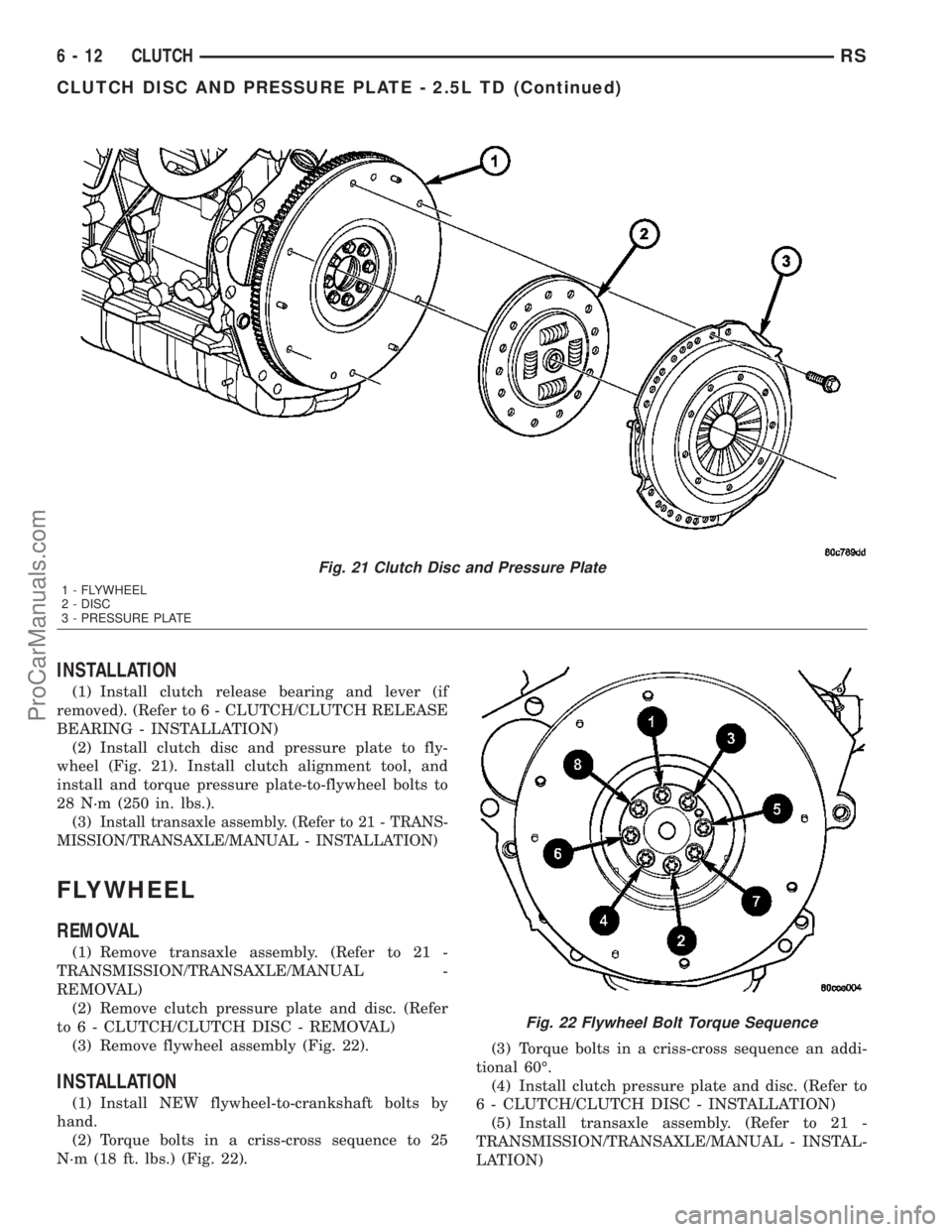

SLAVE CYLINDER

REMOVAL

(1) Raise vehicle on hoist.Diesel models:Remove

underbody splash shield.

(2) Using Tool 6638A, disconnect hydraulic clutch

circuit quick connect fitting.

(3) Remove clutch slave cylinder (Fig. 20) by lifting

nylon tab with a small screwdriver, and then

depressing cylinder inward towards case and rotating

cylinder 60É counter-clockwise.

INSTALLATION

(1) Install clutch slave cylinder into position, not-

ing orientation of different sized lugs. While depress-

ing inward, rotate slave cylinder clockwise until

nylon locating tab rests in transaxle case cutout, and

the hydraulic tube is vertical (Fig. 20).

(2) Connect ªquick-connectº connection until an

audible ªclickº is heard. Verify connection by pulling

outward on connection.

(3)Diesel models:Install underbody splash

shield.

(4) Lower vehicle.

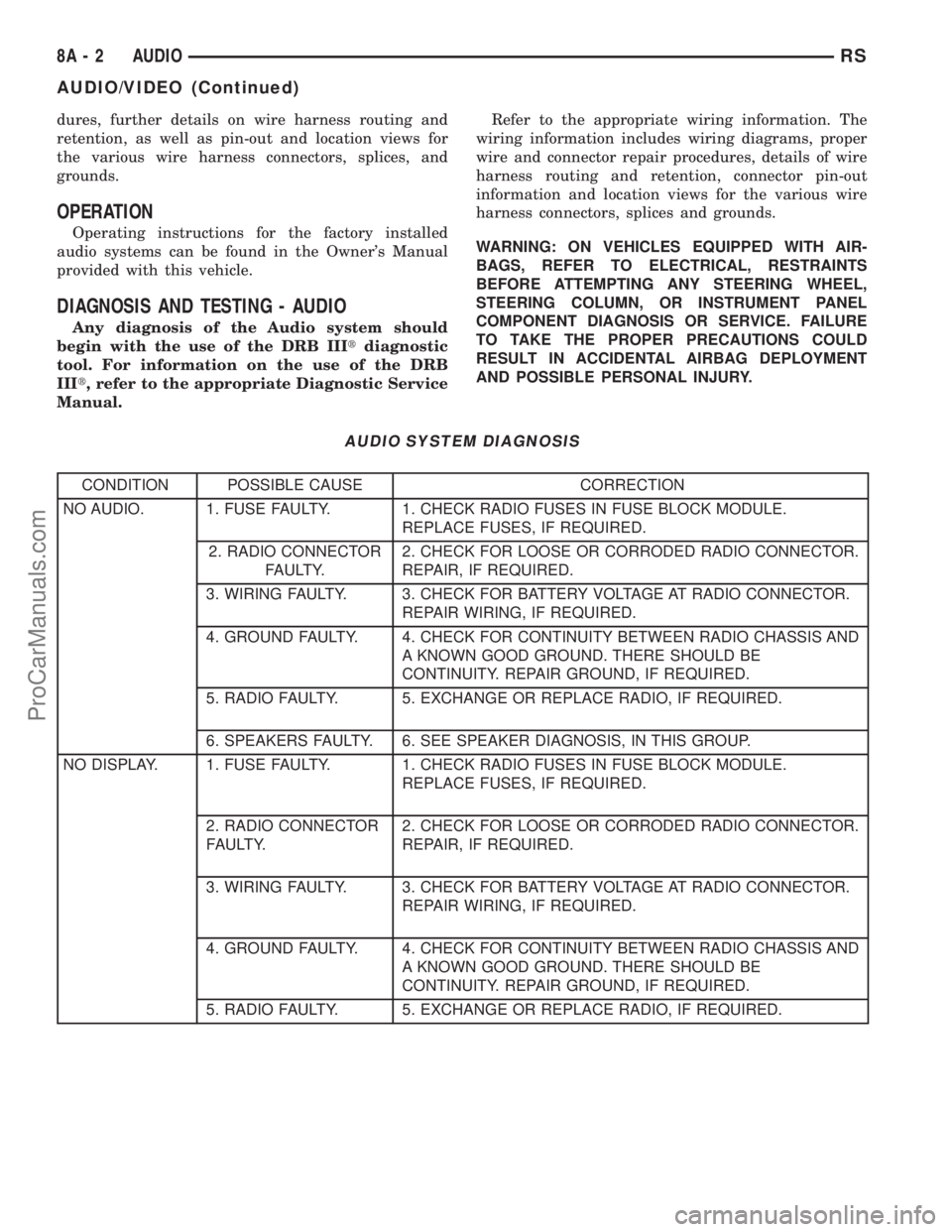

CLUTCH DISC AND PRESSURE

PLATE - 2.5L TD

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove six (6) clutch pressure plate-to-fly-

wheel bolts. Remove pressure plate and disc from fly-

wheel (Fig. 21).

(3)

Inspect flywheel. Resurface/replace as necessary.

(4) Inspect clutch release bearing and lever.

Replace as necessary. (Refer to 6 - CLUTCH/

CLUTCH RELEASE BEARING - REMOVAL)

Fig. 19 Modular Clutch Assembly

1 - MODULAR CLUTCH ASSEMBLY

2 - INPUT SHAFT

Fig. 20 Slave Cylinder Removal/Installation

1 - MOUNTING HOLE

2 - SLAVE CYLINDER

3 - ACCESS HOLE

4 - NYLON ANTI-ROTATION TAB

RSCLUTCH6-11

ProCarManuals.com

Page 255 of 2177

INSTALLATION

(1) Install clutch release bearing and lever (if

removed). (Refer to 6 - CLUTCH/CLUTCH RELEASE

BEARING - INSTALLATION)

(2) Install clutch disc and pressure plate to fly-

wheel (Fig. 21). Install clutch alignment tool, and

install and torque pressure plate-to-flywheel bolts to

28 N´m (250 in. lbs.).

(3)

Install transaxle assembly. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/MANUAL - INSTALLATION)

FLYWHEEL

REMOVAL

(1) Remove transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL -

REMOVAL)

(2) Remove clutch pressure plate and disc. (Refer

to 6 - CLUTCH/CLUTCH DISC - REMOVAL)

(3) Remove flywheel assembly (Fig. 22).

INSTALLATION

(1) Install NEW flywheel-to-crankshaft bolts by

hand.

(2) Torque bolts in a criss-cross sequence to 25

N´m (18 ft. lbs.) (Fig. 22).(3) Torque bolts in a criss-cross sequence an addi-

tional 60É.

(4) Install clutch pressure plate and disc. (Refer to

6 - CLUTCH/CLUTCH DISC - INSTALLATION)

(5) Install transaxle assembly. (Refer to 21 -

TRANSMISSION/TRANSAXLE/MANUAL - INSTAL-

LATION)

Fig. 21 Clutch Disc and Pressure Plate

1 - FLYWHEEL

2 - DISC

3 - PRESSURE PLATE

Fig. 22 Flywheel Bolt Torque Sequence

6 - 12 CLUTCHRS

CLUTCH DISC AND PRESSURE PLATE - 2.5L TD (Continued)

ProCarManuals.com

Page 299 of 2177

dures, further details on wire harness routing and

retention, as well as pin-out and location views for

the various wire harness connectors, splices, and

grounds.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8A - 2 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com

Page 301 of 2177

CONDITION POSSIBLE CAUSE CORRECTION

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FREE FROM THESE

CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

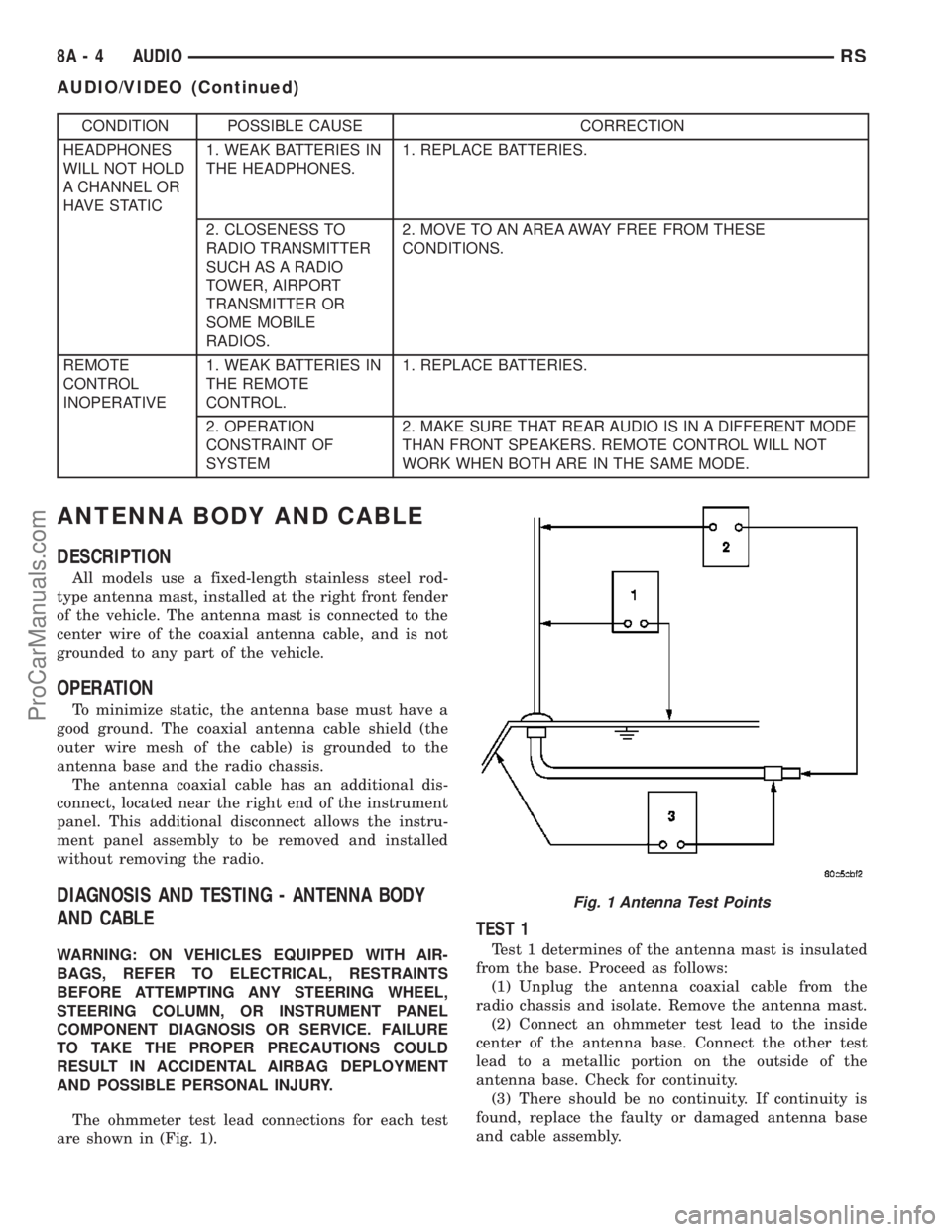

ANTENNA BODY AND CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 1 Antenna Test Points

8A - 4 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com