automatic transmission fluid CHRYSLER CARAVAN 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 588 of 2177

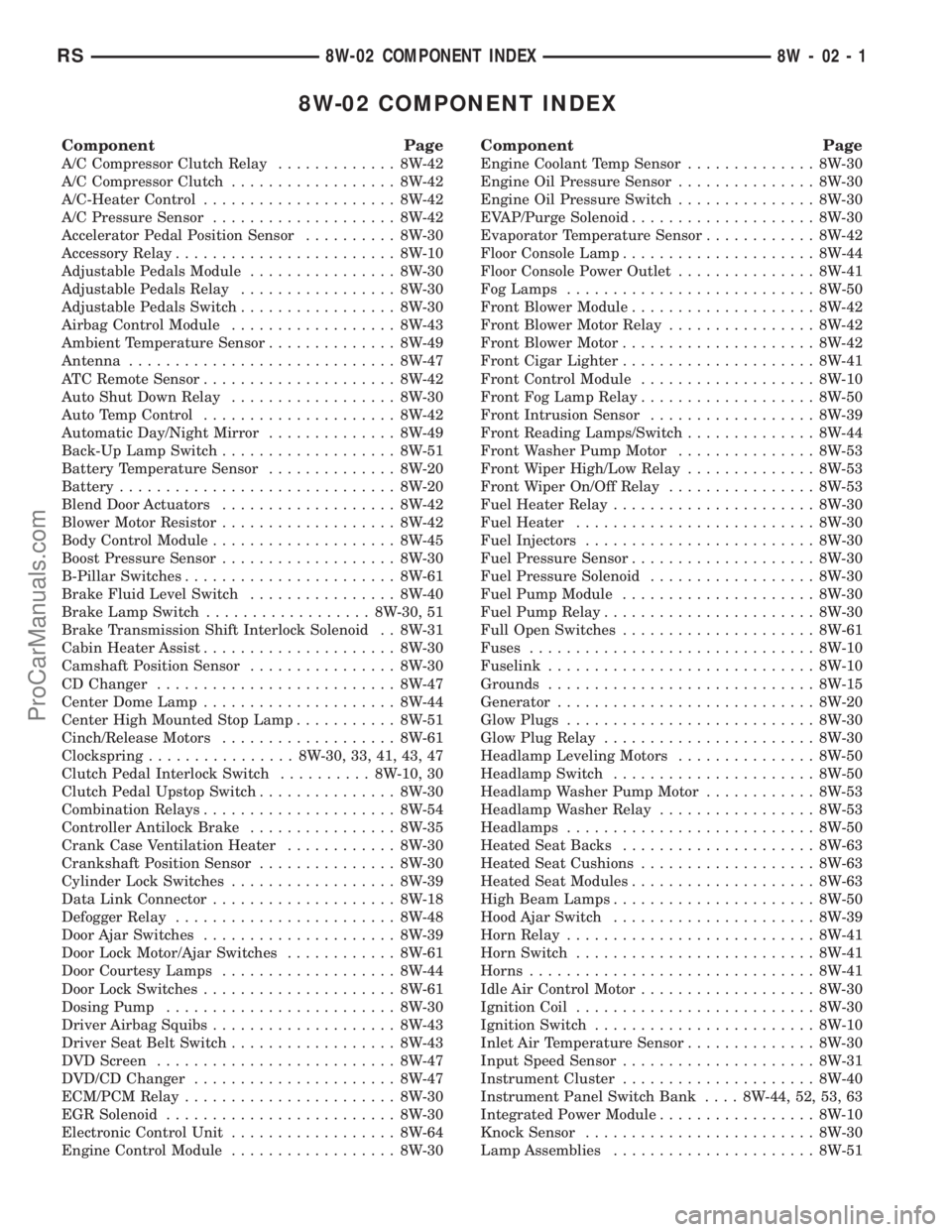

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch Relay............. 8W-42

A/C Compressor Clutch.................. 8W-42

A/C-Heater Control..................... 8W-42

A/C Pressure Sensor.................... 8W-42

Accelerator Pedal Position Sensor.......... 8W-30

Accessory Relay........................ 8W-10

Adjustable Pedals Module................ 8W-30

Adjustable Pedals Relay................. 8W-30

Adjustable Pedals Switch................. 8W-30

Airbag Control Module.................. 8W-43

Ambient Temperature Sensor.............. 8W-49

Antenna............................. 8W-47

ATC Remote Sensor..................... 8W-42

Auto Shut Down Relay.................. 8W-30

Auto Temp Control..................... 8W-42

Automatic Day/Night Mirror.............. 8W-49

Back-Up Lamp Switch................... 8W-51

Battery Temperature Sensor.............. 8W-20

Battery.............................. 8W-20

Blend Door Actuators................... 8W-42

Blower Motor Resistor................... 8W-42

Body Control Module.................... 8W-45

Boost Pressure Sensor................... 8W-30

B-Pillar Switches....................... 8W-61

Brake Fluid Level Switch................ 8W-40

Brake Lamp Switch.................. 8W-30, 51

Brake Transmission Shift Interlock Solenoid . . 8W-31

Cabin Heater Assist..................... 8W-30

Camshaft Position Sensor................ 8W-30

CD Changer.......................... 8W-47

Center Dome Lamp..................... 8W-44

Center High Mounted Stop Lamp........... 8W-51

Cinch/Release Motors................... 8W-61

Clockspring................ 8W-30, 33, 41, 43, 47

Clutch Pedal Interlock Switch.......... 8W-10, 30

Clutch Pedal Upstop Switch............... 8W-30

Combination Relays..................... 8W-54

Controller Antilock Brake................ 8W-35

Crank Case Ventilation Heater............ 8W-30

Crankshaft Position Sensor............... 8W-30

Cylinder Lock Switches.................. 8W-39

Data Link Connector.................... 8W-18

Defogger Relay........................ 8W-48

Door Ajar Switches..................... 8W-39

Door Lock Motor/Ajar Switches............ 8W-61

Door Courtesy Lamps................... 8W-44

Door Lock Switches..................... 8W-61

Dosing Pump......................... 8W-30

Driver Airbag Squibs.................... 8W-43

Driver Seat Belt Switch.................. 8W-43

DVD Screen.......................... 8W-47

DVD/CD Changer...................... 8W-47

ECM/PCM Relay....................... 8W-30

EGR Solenoid......................... 8W-30

Electronic Control Unit.................. 8W-64

Engine Control Module.................. 8W-30

Component Page

Engine Coolant Temp Sensor.............. 8W-30

Engine Oil Pressure Sensor............... 8W-30

Engine Oil Pressure Switch............... 8W-30

EVAP/Purge Solenoid.................... 8W-30

Evaporator Temperature Sensor............ 8W-42

Floor Console Lamp..................... 8W-44

Floor Console Power Outlet............... 8W-41

Fog Lamps........................... 8W-50

Front Blower Module.................... 8W-42

Front Blower Motor Relay................ 8W-42

Front Blower Motor..................... 8W-42

Front Cigar Lighter..................... 8W-41

Front Control Module................... 8W-10

Front Fog Lamp Relay................... 8W-50

Front Intrusion Sensor.................. 8W-39

Front Reading Lamps/Switch.............. 8W-44

Front Washer Pump Motor............... 8W-53

Front Wiper High/Low Relay.............. 8W-53

Front Wiper On/Off Relay................ 8W-53

Fuel Heater Relay...................... 8W-30

Fuel Heater.......................... 8W-30

Fuel Injectors......................... 8W-30

Fuel Pressure Sensor.................... 8W-30

Fuel Pressure Solenoid.................. 8W-30

Fuel Pump Module..................... 8W-30

Fuel Pump Relay....................... 8W-30

Full Open Switches..................... 8W-61

Fuses............................... 8W-10

Fuselink............................. 8W-10

Grounds............................. 8W-15

Generator............................ 8W-20

Glow Plugs........................... 8W-30

Glow Plug Relay....................... 8W-30

Headlamp Leveling Motors............... 8W-50

Headlamp Switch...................... 8W-50

Headlamp Washer Pump Motor............ 8W-53

Headlamp Washer Relay................. 8W-53

Headlamps........................... 8W-50

Heated Seat Backs..................... 8W-63

Heated Seat Cushions................... 8W-63

Heated Seat Modules.................... 8W-63

High Beam Lamps...................... 8W-50

Hood Ajar Switch...................... 8W-39

Horn Relay........................... 8W-41

Horn Switch.......................... 8W-41

Horns............................... 8W-41

Idle Air Control Motor................... 8W-30

Ignition Coil.......................... 8W-30

Ignition Switch........................ 8W-10

Inlet Air Temperature Sensor.............. 8W-30

Input Speed Sensor..................... 8W-31

Instrument Cluster..................... 8W-40

Instrument Panel Switch Bank.... 8W-44, 52, 53, 63

Integrated Power Module................. 8W-10

Knock Sensor......................... 8W-30

Lamp Assemblies...................... 8W-51

RS8W-02 COMPONENT INDEX8W-02-1

ProCarManuals.com

Page 662 of 2177

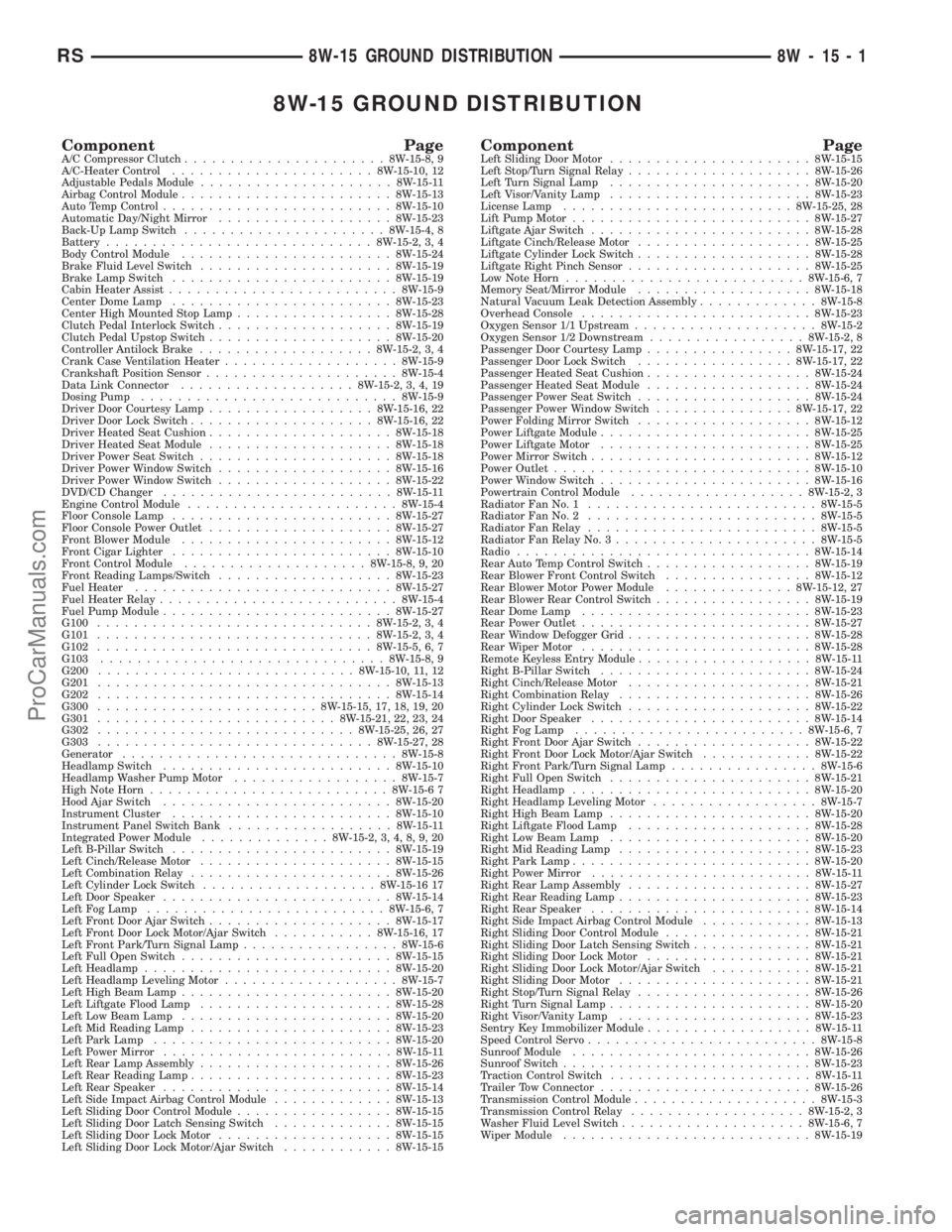

8W-15 GROUND DISTRIBUTION

Component PageA/C Compressor Clutch......................8W-15-8, 9

A/C-Heater Control......................8W-15-10, 12

Adjustable Pedals Module.....................8W-15-11

Airbag Control Module.......................8W-15-13

Auto Temp Control.........................8W-15-10

Automatic Day/Night Mirror...................8W-15-23

Back-Up Lamp Switch......................8W-15-4, 8

Battery.............................8W-15-2, 3, 4

Body Control Module.......................8W-15-24

Brake Fluid Level Switch.....................8W-15-19

Brake Lamp Switch........................8W-15-19

Cabin Heater Assist.........................8W-15-9

Center Dome Lamp........................8W-15-23

Center High Mounted Stop Lamp.................8W-15-28

Clutch Pedal Interlock Switch...................8W-15-19

Clutch Pedal Upstop Switch....................8W-15-20

Controller Antilock Brake...................8W-15-2, 3, 4

Crank Case Ventilation Heater...................8W-15-9

Crankshaft Position Sensor.....................8W-15-4

Data Link Connector...................8W-15-2, 3, 4, 19

Dosing Pump............................8W-15-9

Driver Door Courtesy Lamp..................8W-15-16, 22

Driver Door Lock Switch....................8W-15-16, 22

Driver Heated Seat Cushion....................8W-15-18

Driver Heated Seat Module....................8W-15-18

Driver Power Seat Switch.....................8W-15-18

Driver Power Window Switch...................8W-15-16

Driver Power Window Switch...................8W-15-22

DVD/CD Changer.........................8W-15-11

Engine Control Module.......................8W-15-4

Floor Console Lamp........................8W-15-27

Floor Console Power Outlet....................8W-15-27

Front Blower Module.......................8W-15-12

Front Cigar Lighter........................8W-15-10

Front Control Module....................8W-15-8, 9, 20

Front Reading Lamps/Switch...................8W-15-23

Fuel Heater............................8W-15-27

Fuel Heater Relay..........................8W-15-4

Fuel Pump Module.........................8W-15-27

G100..............................8W-15-2, 3, 4

G101..............................8W-15-2, 3, 4

G102..............................8W-15-5, 6, 7

G103...............................8W-15-8, 9

G200............................8W-15-10, 11, 12

G201................................8W-15-13

G202................................8W-15-14

G300........................8W-15-15, 17, 18, 19, 20

G301..........................8W-15-21, 22, 23, 24

G302............................8W-15-25, 26, 27

G303..............................8W-15-27, 28

Generator..............................8W-15-8

Headlamp Switch.........................8W-15-10

Headlamp Washer Pump Motor..................8W-15-7

High Note Horn..........................8W-15-6 7

Hood Ajar Switch.........................8W-15-20

Instrument Cluster........................8W-15-10

Instrument Panel Switch Bank..................8W-15-11

Integrated Power Module..............8W-15-2, 3, 4, 8, 9, 20

Left B-Pillar Switch........................8W-15-19

Left Cinch/Release Motor.....................8W-15-15

Left Combination Relay......................8W-15-26

Left Cylinder Lock Switch...................8W-15-16 17

Left Door Speaker.........................8W-15-14

Left Fog Lamp..........................8W-15-6, 7

Left Front Door Ajar Switch....................8W-15-17

Left Front Door Lock Motor/Ajar Switch...........8W-15-16, 17

Left Front Park/Turn Signal Lamp.................8W-15-6

Left Full Open Switch.......................8W-15-15

Left Headlamp...........................8W-15-20

Left Headlamp Leveling Motor...................8W-15-7

Left High Beam Lamp.......................8W-15-20

Left Liftgate Flood Lamp.....................8W-15-28

Left Low Beam Lamp.......................8W-15-20

Left Mid Reading Lamp......................8W-15-23

Left Park Lamp..........................8W-15-20

Left Power Mirror.........................8W-15-11

Left Rear Lamp Assembly.....................8W-15-26

Left Rear Reading Lamp......................8W-15-23

Left Rear Speaker.........................8W-15-14

Left Side Impact Airbag Control Module.............8W-15-13

Left Sliding Door Control Module.................8W-15-15

Left Sliding Door Latch Sensing Switch.............8W-15-15

Left Sliding Door Lock Motor...................8W-15-15

Left Sliding Door Lock Motor/Ajar Switch............8W-15-15Component PageLeft Sliding Door Motor......................8W-15-15

Left Stop/Turn Signal Relay....................8W-15-26

Left Turn Signal Lamp......................8W-15-20

Left Visor/Vanity Lamp......................8W-15-23

License Lamp.........................8W-15-25, 28

Lift Pump Motor..........................8W-15-27

Liftgate Ajar Switch........................8W-15-28

Liftgate Cinch/Release Motor...................8W-15-25

Liftgate Cylinder Lock Switch...................8W-15-28

Liftgate Right Pinch Sensor....................8W-15-25

Low Note Horn..........................8W-15-6, 7

Memory Seat/Mirror Module...................8W-15-18

Natural Vacuum Leak Detection Assembly.............8W-15-8

Overhead Console.........................8W-15-23

Oxygen Sensor 1/1 Upstream....................8W-15-2

Oxygen Sensor 1/2 Downstream.................8W-15-2, 8

Passenger Door Courtesy Lamp................8W-15-17, 22

Passenger Door Lock Switch.................8W-15-17, 22

Passenger Heated Seat Cushion..................8W-15-24

Passenger Heated Seat Module..................8W-15-24

Passenger Power Seat Switch...................8W-15-24

Passenger Power Window Switch...............8W-15-17, 22

Power Folding Mirror Switch...................8W-15-12

Power Liftgate Module.......................8W-15-25

Power Liftgate Motor.......................8W-15-25

Power Mirror Switch........................8W-15-12

Power Outlet............................8W-15-10

Power Window Switch.......................8W-15-16

Powertrain Control Module...................8W-15-2, 3

Radiator Fan No. 1.........................8W-15-5

Radiator Fan No. 2.........................8W-15-5

Radiator Fan Relay.........................8W-15-5

Radiator Fan Relay No. 3......................8W-15-5

Radio................................8W-15-14

Rear Auto Temp Control Switch..................8W-15-19

Rear Blower Front Control Switch................8W-15-12

Rear Blower Motor Power Module..............8W-15-12, 27

Rear Blower Rear Control Switch.................8W-15-19

Rear Dome Lamp.........................8W-15-23

Rear Power Outlet.........................8W-15-27

Rear Window Defogger Grid....................8W-15-28

Rear Wiper Motor.........................8W-15-28

Remote Keyless Entry Module...................8W-15-11

Right B-Pillar Switch.......................8W-15-24

Right Cinch/Release Motor....................8W-15-21

Right Combination Relay.....................8W-15-26

Right Cylinder Lock Switch....................8W-15-22

Right Door Speaker........................8W-15-14

Right Fog Lamp.........................8W-15-6, 7

Right Front Door Ajar Switch...................8W-15-22

Right Front Door Lock Motor/Ajar Switch............8W-15-22

Right Front Park/Turn Signal Lamp................8W-15-6

Right Full Open Switch......................8W-15-21

Right Headlamp..........................8W-15-20

Right Headlamp Leveling Motor..................8W-15-7

Right High Beam Lamp......................8W-15-20

Right Liftgate Flood Lamp....................8W-15-28

Right Low Beam Lamp......................8W-15-20

Right Mid Reading Lamp.....................8W-15-23

Right Park Lamp..........................8W-15-20

Right Power Mirror........................8W-15-11

Right Rear Lamp Assembly....................8W-15-27

Right Rear Reading Lamp.....................8W-15-23

Right Rear Speaker........................8W-15-14

Right Side Impact Airbag Control Module............8W-15-13

Right Sliding Door Control Module................8W-15-21

Right Sliding Door Latch Sensing Switch.............8W-15-21

Right Sliding Door Lock Motor..................8W-15-21

Right Sliding Door Lock Motor/Ajar Switch...........8W-15-21

Right Sliding Door Motor.....................8W-15-21

Right Stop/Turn Signal Relay...................8W-15-26

Right Turn Signal Lamp......................8W-15-20

Right Visor/Vanity Lamp.....................8W-15-23

Sentry Key Immobilizer Module..................8W-15-11

Speed Control Servo.........................8W-15-8

Sunroof Module..........................8W-15-26

Sunroof Switch...........................8W-15-23

Traction Control Switch......................8W-15-11

Trailer Tow Connector.......................8W-15-26

Transmission Control Module....................8W-15-3

Transmission Control Relay...................8W-15-2, 3

Washer Fluid Level Switch....................8W-15-6, 7

Wiper Module...........................8W-15-19

RS8W-15 GROUND DISTRIBUTION8W-15-1

ProCarManuals.com

Page 982 of 2177

8W-80 CONNECTOR PIN-OUTS

Component Page

A/C Compressor Clutch............... 8W-80-6

A/C Pressure Sensor.................. 8W-80-6

A/C-Heater Control C1 (MTC).......... 8W-80-6

A/C-Heater Control C2 (MTC).......... 8W-80-7

Accelerator Pedal Position Sensor

(Diesel).......................... 8W-80-7

Adjustable Pedals Module

(Except Export)................... 8W-80-7

Adjustable Pedals Relay

(Except Export)................... 8W-80-8

Adjustable Pedals Switch

(Except Export)................... 8W-80-8

Airbag Control Module (ORC).......... 8W-80-8

Ambient Temperature Sensor (Except

Base)........................... 8W-80-9

ATC Remote Sensor (ATC)............. 8W-80-9

Auto Temp Control C1................ 8W-80-9

Auto Temp Control C2................ 8W-80-9

Auto Temp Control C3............... 8W-80-10

Automatic Day/Night Mirror (Premium/

Luxury)........................ 8W-80-10

Autostick Switch (Except Export)....... 8W-80-10

Back-Up Lamp Switch (MTX).......... 8W-80-10

Battery Temperature Sensor (2.4L/

Diesel)......................... 8W-80-11

Blower Motor Resistor C1 (MTC)....... 8W-80-11

Blower Motor Resistor C2 (MTC)....... 8W-80-11

Body Control Module C1.............. 8W-80-11

Body Control Module C2.............. 8W-80-12

Body Control Module C3.............. 8W-80-13

Body Control Module C4.............. 8W-80-14

Body Control Module C5.............. 8W-80-15

Boost Pressure Sensor (Diesel)......... 8W-80-15

Brake Fluid Level Switch............. 8W-80-16

Brake Lamp Switch................. 8W-80-16

Brake Transmission Shift Interlock Solenoid

(EATX) ......................... 8W-80-16

C100............................. 8W-80-16

C100............................. 8W-80-17

C101............................. 8W-80-17

C101............................. 8W-80-18

C102 (2.4L)........................ 8W-80-18

C102 (2.4L)........................ 8W-80-18

C102 (3.3L/3.8L).................... 8W-80-19

C102 (3.3L/3.8L).................... 8W-80-19

C103 (Diesel)...................... 8W-80-19

C103 (Diesel)...................... 8W-80-20

C106 (Export)...................... 8W-80-20

C106 (Export)...................... 8W-80-20

C107 (Export)...................... 8W-80-20

C107 (Export)...................... 8W-80-21

C110 (2.4L)........................ 8W-80-21Component Page

C110 (2.4L)........................ 8W-80-21

C111 (2.4L)........................ 8W-80-21

C111 (2.4L)........................ 8W-80-22

C200............................. 8W-80-22

C200............................. 8W-80-24

C201............................. 8W-80-26

C201............................. 8W-80-26

C202............................. 8W-80-26

C202............................. 8W-80-26

C203 (United Kingdom).............. 8W-80-27

C203 (United Kingdom).............. 8W-80-27

C204 (Premium).................... 8W-80-27

C204 (Premium).................... 8W-80-27

C300 (LHD)....................... 8W-80-28

C300 (LHD)....................... 8W-80-28

C300 (RHD Except Lowline)........... 8W-80-29

C300 (RHD Lowline)................ 8W-80-29

C300 (RHD)....................... 8W-80-29

C301 (Base/Power Locks)............. 8W-80-30

C301 (Base/Power Locks)............. 8W-80-30

C301 (LHD Premium/Memory)......... 8W-80-30

C301 (LHD Premium/Memory)......... 8W-80-30

C301 (RHD/LHD Premium Except

Memory)........................ 8W-80-31

C301 (RHD/LHD Premium Except

Memory)........................ 8W-80-31

C302 (Except RHD Memory).......... 8W-80-31

C302 (Except RHD Memory).......... 8W-80-31

C302 (RHD Memory)................ 8W-80-32

C302 (RHD Memory)................ 8W-80-32

C303 (LHD)....................... 8W-80-32

C303 (LHD)....................... 8W-80-33

C303 (RHD)....................... 8W-80-33

C303 (RHD)....................... 8W-80-33

C304............................. 8W-80-34

C304............................. 8W-80-34

C305............................. 8W-80-34

C305............................. 8W-80-34

C306............................. 8W-80-35

C306............................. 8W-80-35

C307 (Heated Seats)................. 8W-80-35

C307 (Heated Seats)................. 8W-80-35

C308............................. 8W-80-36

C308............................. 8W-80-36

C309............................. 8W-80-36

C309............................. 8W-80-37

C310 (Front Console)................ 8W-80-37

C310 (Front Console)................ 8W-80-37

C311 ............................. 8W-80-37

C311 ............................. 8W-80-38

C312............................. 8W-80-38

C312............................. 8W-80-39

RS8W-80 CONNECTOR PIN-OUTS8W-80-1

ProCarManuals.com

Page 1190 of 2177

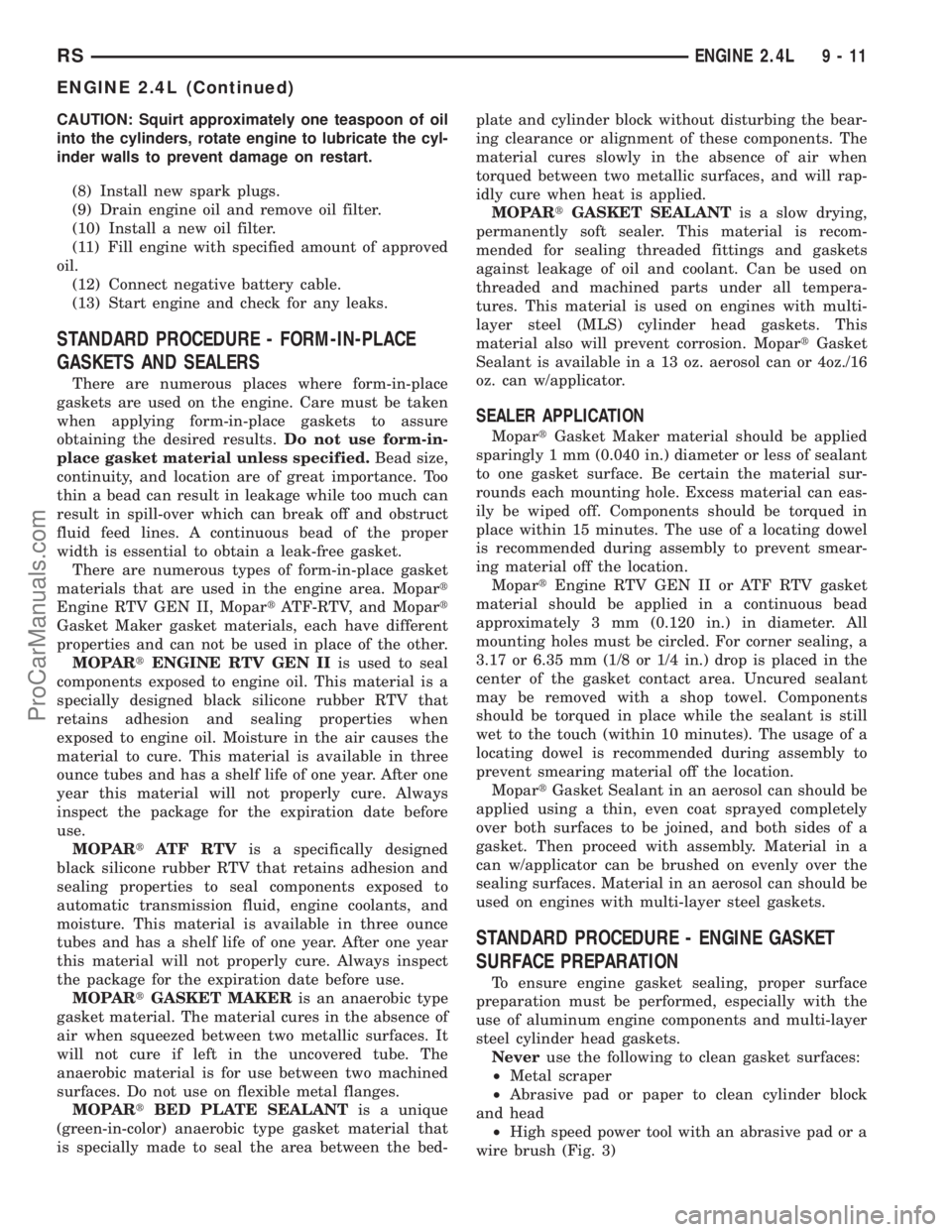

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Install a new oil filter.

(11) Fill engine with specified amount of approved

oil.

(12) Connect negative battery cable.

(13) Start engine and check for any leaks.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

anaerobic material is for use between two machined

surfaces. Do not use on flexible metal flanges.

MOPARtBED PLATE SEALANTis a unique

(green-in-color) anaerobic type gasket material that

is specially made to seal the area between the bed-plate and cylinder block without disturbing the bear-

ing clearance or alignment of these components. The

material cures slowly in the absence of air when

torqued between two metallic surfaces, and will rap-

idly cure when heat is applied.

MOPARtGASKET SEALANTis a slow drying,

permanently soft sealer. This material is recom-

mended for sealing threaded fittings and gaskets

against leakage of oil and coolant. Can be used on

threaded and machined parts under all tempera-

tures. This material is used on engines with multi-

layer steel (MLS) cylinder head gaskets. This

material also will prevent corrosion. MopartGasket

Sealant is available in a 13 oz. aerosol can or 4oz./16

oz. can w/applicator.

SEALER APPLICATION

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 in.) diameter or less of sealant

to one gasket surface. Be certain the material sur-

rounds each mounting hole. Excess material can eas-

ily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

MopartEngine RTV GEN II or ATF RTV gasket

material should be applied in a continuous bead

approximately 3 mm (0.120 in.) in diameter. All

mounting holes must be circled. For corner sealing, a

3.17 or 6.35 mm (1/8 or 1/4 in.) drop is placed in the

center of the gasket contact area. Uncured sealant

may be removed with a shop towel. Components

should be torqued in place while the sealant is still

wet to the touch (within 10 minutes). The usage of a

locating dowel is recommended during assembly to

prevent smearing material off the location.

MopartGasket Sealant in an aerosol can should be

applied using a thin, even coat sprayed completely

over both surfaces to be joined, and both sides of a

gasket. Then proceed with assembly. Material in a

can w/applicator can be brushed on evenly over the

sealing surfaces. Material in an aerosol can should be

used on engines with multi-layer steel gaskets.

STANDARD PROCEDURE - ENGINE GASKET

SURFACE PREPARATION

To ensure engine gasket sealing, proper surface

preparation must be performed, especially with the

use of aluminum engine components and multi-layer

steel cylinder head gaskets.

Neveruse the following to clean gasket surfaces:

²Metal scraper

²Abrasive pad or paper to clean cylinder block

and head

²High speed power tool with an abrasive pad or a

wire brush (Fig. 3)

RSENGINE 2.4L9-11

ENGINE 2.4L (Continued)

ProCarManuals.com

Page 1263 of 2177

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379

kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

STANDARD PROCEDURE

STANDARD PROCEDURE - MEASURING

BEARING CLEARANCE USING PLASTIGAGE

Engine crankshaft bearing clearances can be deter-

mined by use of Plastigage or equivalent. The follow-

ing is the recommended procedure for the use of

Plastigage:

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 3). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

(3) Remove the bearing cap and compare the

width of the flattened Plastigage with the metric

scale provided on the package. Locate the band clos-est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Compare clearance measurements to specs found in

engine specifications (Refer to 9 - ENGINE - SPECI-

FICATIONS).Plastigage generally is accompa-

nied by two scales. One scale is in inches, the

other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

(4) Install the proper crankshaft bearings to

achieve the specified bearing clearances.

STANDARD PROCEDURE - FORM-IN-PLACE

GASKETS AND SEALERS

There are numerous places where form-in-place

gaskets are used on the engine. Care must be taken

when applying form-in-place gaskets to assure

obtaining the desired results.Do not use form-in-

place gasket material unless specified.Bead size,

continuity, and location are of great importance. Too

thin a bead can result in leakage while too much can

result in spill-over which can break off and obstruct

fluid feed lines. A continuous bead of the proper

width is essential to obtain a leak-free gasket.

There are numerous types of form-in-place gasket

materials that are used in the engine area. Mopart

Engine RTV GEN II, MopartATF-RTV, and Mopart

Gasket Maker gasket materials, each have different

properties and can not be used in place of the other.

MOPARtENGINE RTV GEN IIis used to seal

components exposed to engine oil. This material is a

specially designed black silicone rubber RTV that

retains adhesion and sealing properties when

exposed to engine oil. Moisture in the air causes the

material to cure. This material is available in three

ounce tubes and has a shelf life of one year. After one

year this material will not properly cure. Always

inspect the package for the expiration date before

use.

MOPARtATF RTVis a specifically designed

black silicone rubber RTV that retains adhesion and

sealing properties to seal components exposed to

automatic transmission fluid, engine coolants, and

moisture. This material is available in three ounce

tubes and has a shelf life of one year. After one year

this material will not properly cure. Always inspect

the package for the expiration date before use.

MOPARtGASKET MAKERis an anaerobic type

gasket material. The material cures in the absence of

air when squeezed between two metallic surfaces. It

will not cure if left in the uncovered tube. The

Fig. 3 Plastigage Placed in Lower ShellÐTypical

1 - PLASTIGAGE

9 - 84 ENGINE 3.3/3.8LRS

ENGINE 3.3/3.8L (Continued)

ProCarManuals.com

Page 1439 of 2177

FLUID

STANDARD PROCEDURE - POWER STEERING

FLUID LEVEL CHECKING

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT INJURY

FROM MOVING PARTS AND TO ENSURE ACCU-

RATE FLUID LEVEL READING.

The fluid level can be read on the exterior of the

power steering fluid reservoir. The fluid level should

be within the ªFILL RANGEº when the fluid is at

normal ambient temperature, approximately 21ÉC to

27ÉC (70ÉF to 80ÉF) (Fig. 17).

Before removing the power steering filler cap, wipe

the reservoir filler cap free of dirt and debris. Do not

overfill the power steering system.Use only

MopartATF+4 Automatic Transmission Fluid

(MS-9602) in the power steering system.For

additional information on Automatic Transmission

Fluid, (Refer to LUBRICATION & MAINTENANCE/

FLUID TYPES - DESCRIPTION).

CAUTION: Use only MoparTATF+4 Automatic Trans-

mission Fluid (MS-9602). Use of other MoparT

power steering fluids (MS5931 and MS9933) should

be avoided to ensure peak performance of the

power steering system under all operating condi-

tions.

FLUID COOLER

DESCRIPTION

All models (except 2.5L Diesel) are equipped with a

cooler for the power steering system fluid. The power

steering fluid cooler is located on the front suspen-sion cradle crossmember reinforcement (Fig. 18).

There are two different size coolers depending on

model and options. There is a standard 6-inch and an

8-inch.

OPERATION

The purpose of the power steering fluid cooler is to

keep the temperature of the power steering system

fluid from rising to a level that would affect the per-

formance of the power steering system.

The cooler used on this vehicle is referred to as a

fluid-to-air type cooler. This means that the air flow

across the tubes (and fines surrounding them) of the

cooler is used to extract the heat from the cooler

which it has absorbed from the power steering fluid

flowing through it. The cooler is placed in the power

steering fluid return line, between the steering gear

and the power steering fluid reservoir.

REMOVAL

(1) Using a siphon pump, remove as much fluid as

possible from the power steering fluid reservoir.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(3) Remove the hose clamps at the cooler and

remove the hoses from the cooler inlet and outlet

tubes.

(4) Remove the 2 bolts attaching the power steer-

ing cooler cradle crossmember reinforcement (Fig.

18). Remove the cooler.

Fig. 17 Power Steering Fluid Reservoir

Fig. 18 Power Steering Cooler

1 - CRADLE CROSSMEMBER REINFORCEMENT

2 - POWER STEERING COOLER

19 - 44 PUMPRS

ProCarManuals.com

Page 1448 of 2177

TRANSMISSION/TRANSAXLE

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT..................1

T850 MANUAL TRANSAXLE...............2141TE AUTOMATIC TRANSAXLE............116

POWER TRANSFER UNIT

TABLE OF CONTENTS

page page

POWER TRANSFER UNIT

DESCRIPTION..........................1

OPERATION............................3

DIAGNOSIS AND TESTING

SEAL IDENTIFICATION..................3

FLUID LEAK DIAGNOSIS................3

STANDARD PROCEDURE

STANDARD PROCEDURE - FLUID LEVEL

INSPECTION..........................4

STANDARD PROCEDURE - PTU FLUID

CHANGE.............................5

REMOVAL.............................5

INSTALLATION..........................6

ADJUSTMENTS

OUTPUT FLANGE SHIM SELECTION.......7

SPECIFICATIONS

TORQUE.............................7

SPECIAL TOOLS

SDP POWER TRANSFER UNIT............8

DIFFERENTIAL CARRIER SEAL

REMOVAL.............................9

INSTALLATION..........................9

END COVER BALL BEARING

REMOVAL.............................9INSTALLATION.........................10

END COVER SEAL

REMOVAL.............................11

INSTALLATION.........................11

HALF SHAFT INNER SEAL

REMOVAL.............................12

INSTALLATION.........................12

INPUT SHAFT COVER SEAL

REMOVAL.............................13

INSTALLATION.........................14

INPUT SHAFT END SEAL

REMOVAL.............................15

INSTALLATION.........................16

INPUT SHAFT SEAL

REMOVAL.............................17

INSTALLATION.........................18

OUTER HALF SHAFT SEAL

REMOVAL.............................19

INSTALLATION.........................19

REAR COVER O-RING

REMOVAL.............................19

INSTALLATION.........................20

POWER TRANSFER UNIT

DESCRIPTION

The Power Transfer Unit (P.T.U.) is attached to a

modified automatic transaxle case where the right

half shaft extension housing would normally be

located.

The Power Transfer Unit is sealed from the trans-

axle and has its own oil sump. The Unit uses MopartSAE 80W-90 Gear and Axle Lubricant (MS-9020) and

holds 1.15 liters (1.22 quarts).

Service of the Power Transfer Unit is limited to:

²Fluid Change

²Seals

²Gaskets

²One ball bearing

²Output flange

If the ring gear and pinion, any tapered roller

bearings, case, covers, or pinion carrier fail the entire

unit must be replaced.

RSTRANSMISSION/TRANSAXLE21-1

ProCarManuals.com

Page 1503 of 2177

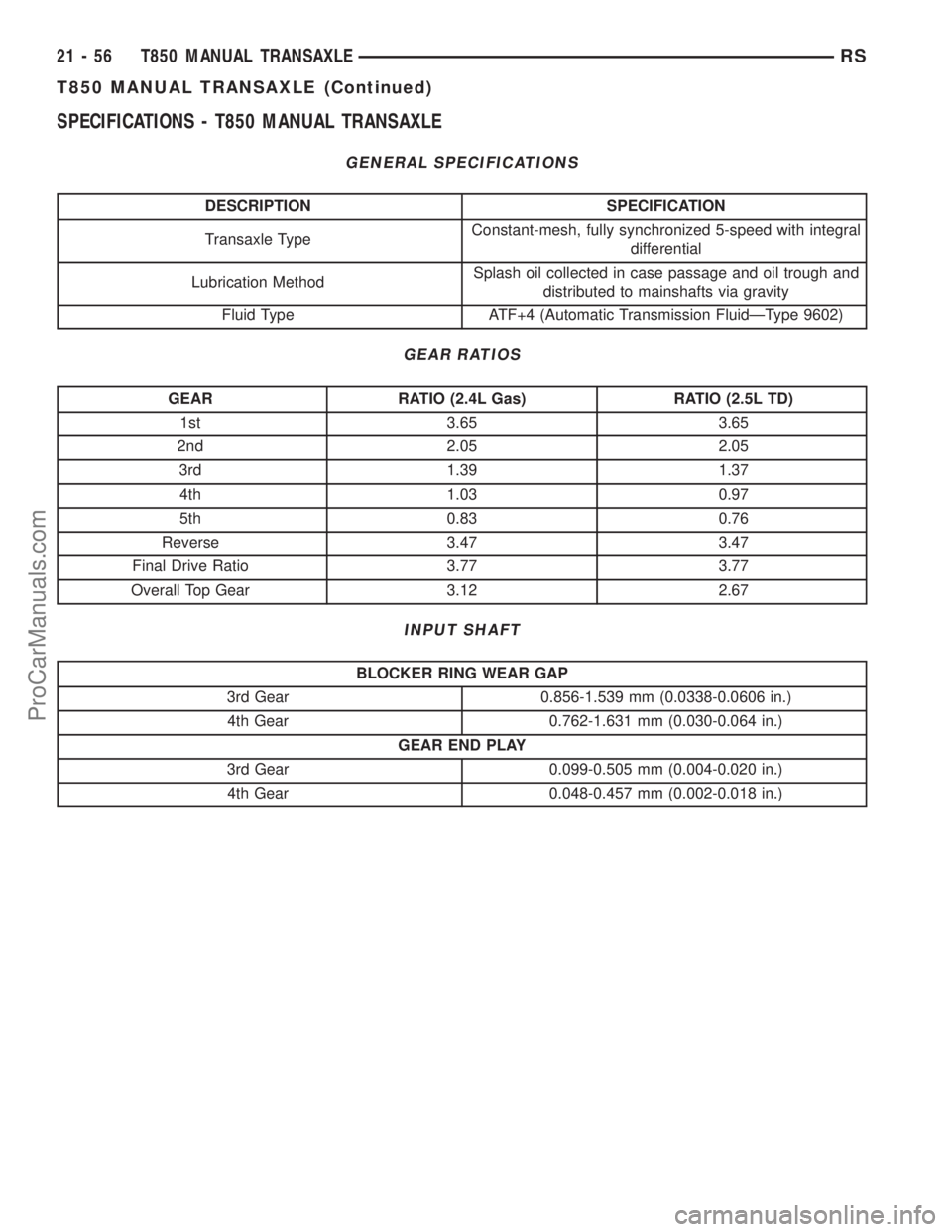

SPECIFICATIONS - T850 MANUAL TRANSAXLE

GENERAL SPECIFICATIONS

DESCRIPTION SPECIFICATION

Transaxle TypeConstant-mesh, fully synchronized 5-speed with integral

differential

Lubrication MethodSplash oil collected in case passage and oil trough and

distributed to mainshafts via gravity

Fluid Type ATF+4 (Automatic Transmission FluidÐType 9602)

GEAR RATIOS

GEAR RATIO (2.4L Gas) RATIO (2.5L TD)

1st 3.65 3.65

2nd 2.05 2.05

3rd 1.39 1.37

4th 1.03 0.97

5th 0.83 0.76

Reverse 3.47 3.47

Final Drive Ratio 3.77 3.77

Overall Top Gear 3.12 2.67

INPUT SHAFT

BLOCKER RING WEAR GAP

3rd Gear 0.856-1.539 mm (0.0338-0.0606 in.)

4th Gear 0.762-1.631 mm (0.030-0.064 in.)

GEAR END PLAY

3rd Gear 0.099-0.505 mm (0.004-0.020 in.)

4th Gear 0.048-0.457 mm (0.002-0.018 in.)

21 - 56 T850 MANUAL TRANSAXLERS

T850 MANUAL TRANSAXLE (Continued)

ProCarManuals.com

Page 1563 of 2177

41TE AUTOMATIC TRANSAXLE

TABLE OF CONTENTS

page page

41TE AUTOMATIC TRANSAXLE

DESCRIPTION........................117

OPERATION..........................119

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - 41TE

TRANSAXLE GENERAL DIAGNOSIS......119

DIAGNOSIS AND TESTING - ROAD TEST . . 119

DIAGNOSIS AND TESTING - HYDRAULIC

PRESSURE TESTS...................120

DIAGNOSIS AND TESTING - CLUTCH AIR

PRESSURE TESTS...................122

DIAGNOSIS AND TESTING - TORQUE

CONVERTER HOUSING FLUID LEAKAGE . . 123

REMOVAL............................124

DISASSEMBLY........................125

ASSEMBLY...........................144

INSTALLATION........................166

SCHEMATICS AND DIAGRAMS

41TE TRANSAXLE HYDRAULIC

SCHEMATICS.......................169

SPECIFICATIONS - 41TE TRANSAXLE......181

SPECIAL TOOLS

41TE AUTOMATIC TRANSAXLE.........183

ACCUMULATOR

DESCRIPTION........................188

OPERATION..........................189

AUTOSTICK SWITCH

DESCRIPTION........................189

OPERATION..........................189

DRIVING CLUTCHES

DESCRIPTION........................190

OPERATION..........................190

FINAL DRIVE

DISASSEMBLY........................190

ASSEMBLY...........................195

ADJUSTMENTS

ADJUSTMENT - DIFFERENTIAL BEARING

PRELOAD..........................199

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK . . . 201

STANDARD PROCEDURE - FLUID AND

FILTER SERVICE.....................203

GEAR SHIFT CABLE

REMOVAL............................204

INSTALLATION........................205

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT.......206HOLDING CLUTCHES

DESCRIPTION........................207

OPERATION..........................207

INPUT CLUTCH ASSEMBLY

DISASSEMBLY........................208

ASSEMBLY...........................216

OIL PUMP

DESCRIPTION........................230

OPERATION..........................230

DISASSEMBLY........................230

ASSEMBLY...........................232

PLANETARY GEARTRAIN

DESCRIPTION........................232

OPERATION..........................232

SEAL - OIL PUMP

REMOVAL............................232

INSTALLATION........................233

SHIFT INTERLOCK SOLENOID

DESCRIPTION........................233

OPERATION..........................233

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK

SOLENOID..........................235

REMOVAL............................235

INSTALLATION........................236

SOLENOID/PRESSURE SWITCH ASSY

DESCRIPTION........................237

OPERATION..........................237

REMOVAL............................238

INSTALLATION........................239

SPEED SENSOR - INPUT

DESCRIPTION........................239

OPERATION..........................240

REMOVAL............................240

INSTALLATION........................240

SPEED SENSOR - OUTPUT

DESCRIPTION........................241

OPERATION..........................241

REMOVAL............................241

INSTALLATION........................242

TORQUE CONVERTER

DESCRIPTION........................242

OPERATION..........................245

REMOVAL............................247

INSTALLATION........................247

TRANSMISSION CONTROL RELAY

DESCRIPTION........................247

OPERATION..........................248

21 - 116 41TE AUTOMATIC TRANSAXLERS

ProCarManuals.com

Page 1564 of 2177

TRANSMISSION RANGE SENSOR

DESCRIPTION........................248

OPERATION..........................248

REMOVAL............................249

INSTALLATION........................249

TRD LINK

DESCRIPTION........................249

OPERATION..........................249VALVE BODY

DESCRIPTION........................250

OPERATION..........................250

REMOVAL............................251

DISASSEMBLY........................252

ASSEMBLY...........................257

INSTALLATION........................262

41TE AUTOMATIC

TRANSAXLE

DESCRIPTION

The 41TE (Fig. 1) is a four-speed transaxle that is

a conventional hydraulic/mechanical assembly with

an integral differential, and is controlled with adap-

tive electronic controls and monitors. The hydraulic

system of the transaxle consists of the transaxle

fluid, fluid passages, hydraulic valves, and various

line pressure control components. An input clutch

assembly which houses the underdrive, overdrive,

and reverse clutches is used. It also utilizes separate

holding clutches: 2nd/4th gear and Low/Reverse. The

primary mechanical components of the transaxle con-

sist of the following:

²Three multiple disc input clutches

²Two multiple disc holding clutches

²Four hydraulic accumulators

²Two planetary gear sets

²Hydraulic oil pump

²Valve body

²Solenoid/Pressure switch assembly

²Integral differential assemblyControl of the transaxle is accomplished by fully

adaptive electronics. Optimum shift scheduling is

accomplished through continuous real-time sensor

feedback information provided to the Powertrain

Control Module (PCM) or Transmission Control Mod-

ule (TCM).

The PCM/TCM is the heart of the electronic control

system and relies on information from various direct

and indirect inputs (sensors, switches, etc.) to deter-

mine driver demand and vehicle operating condi-

tions. With this information, the PCM/TCM can

calculate and perform timely and quality shifts

through various output or control devices (solenoid

pack, transmission control relay, etc.).

The PCM/TCM also performs certain self-diagnos-

tic functions and provides comprehensive information

(sensor data, DTC's, etc.) which is helpful in proper

diagnosis and repair. This information can be viewed

with the DRB scan tool.

RS41TE AUTOMATIC TRANSAXLE21 - 117

ProCarManuals.com