brake pads CHRYSLER CARAVAN 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 167 of 2177

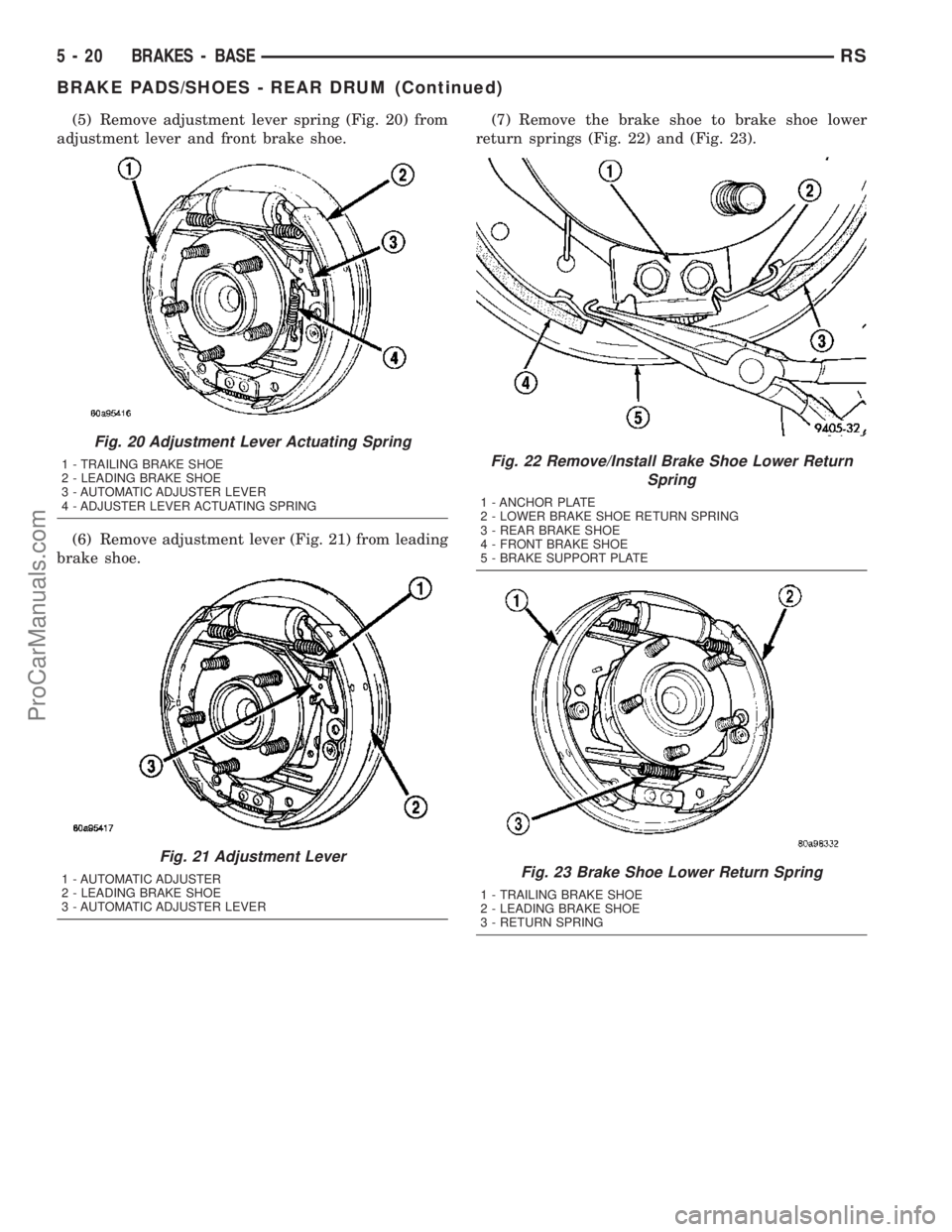

(5) Remove adjustment lever spring (Fig. 20) from

adjustment lever and front brake shoe.

(6) Remove adjustment lever (Fig. 21) from leading

brake shoe.(7) Remove the brake shoe to brake shoe lower

return springs (Fig. 22) and (Fig. 23).

Fig. 20 Adjustment Lever Actuating Spring

1 - TRAILING BRAKE SHOE

2 - LEADING BRAKE SHOE

3 - AUTOMATIC ADJUSTER LEVER

4 - ADJUSTER LEVER ACTUATING SPRING

Fig. 21 Adjustment Lever

1 - AUTOMATIC ADJUSTER

2 - LEADING BRAKE SHOE

3 - AUTOMATIC ADJUSTER LEVER

Fig. 22 Remove/Install Brake Shoe Lower Return

Spring

1 - ANCHOR PLATE

2 - LOWER BRAKE SHOE RETURN SPRING

3 - REAR BRAKE SHOE

4 - FRONT BRAKE SHOE

5 - BRAKE SUPPORT PLATE

Fig. 23 Brake Shoe Lower Return Spring

1 - TRAILING BRAKE SHOE

2 - LEADING BRAKE SHOE

3 - RETURN SPRING

5 - 20 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DRUM (Continued)

ProCarManuals.com

Page 168 of 2177

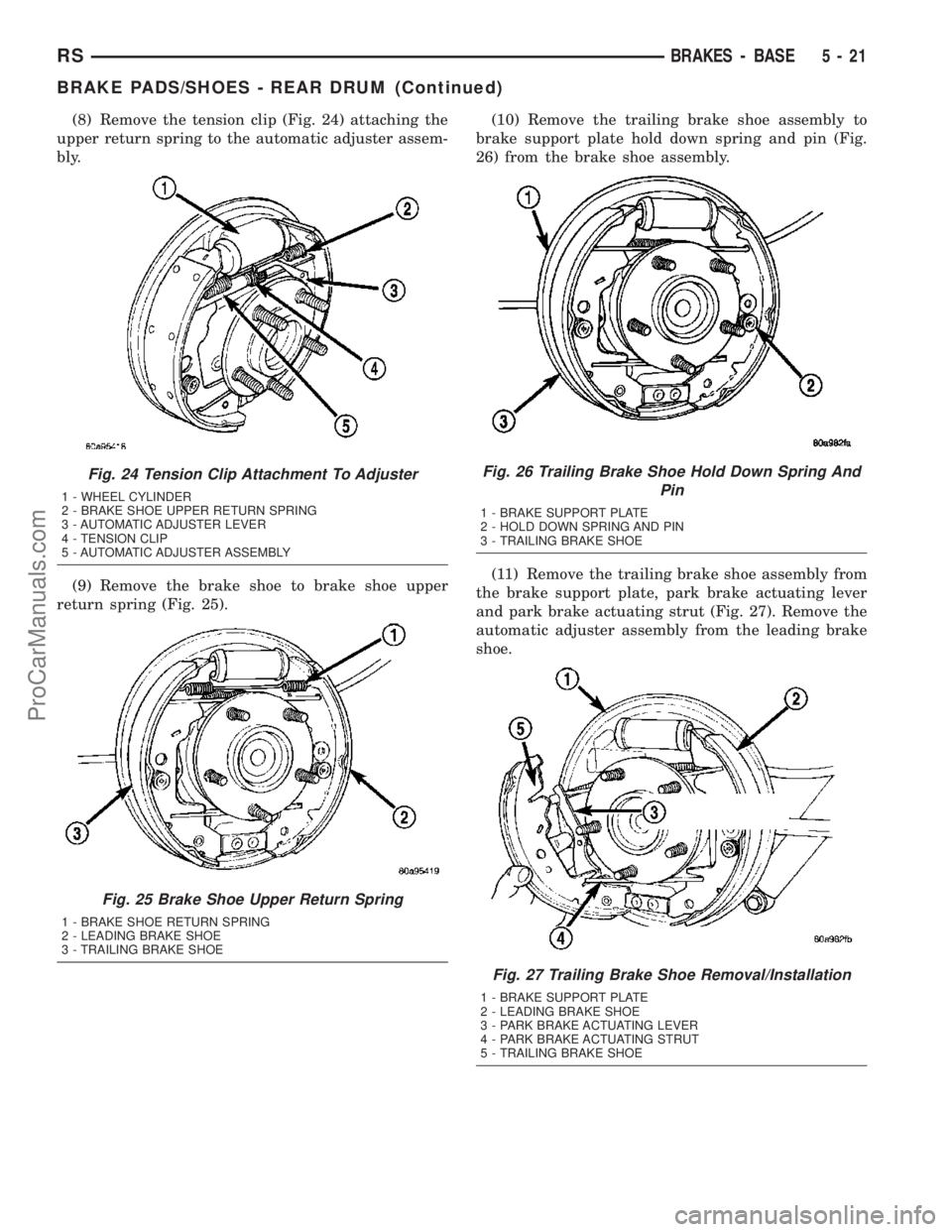

(8) Remove the tension clip (Fig. 24) attaching the

upper return spring to the automatic adjuster assem-

bly.

(9) Remove the brake shoe to brake shoe upper

return spring (Fig. 25).(10) Remove the trailing brake shoe assembly to

brake support plate hold down spring and pin (Fig.

26) from the brake shoe assembly.

(11) Remove the trailing brake shoe assembly from

the brake support plate, park brake actuating lever

and park brake actuating strut (Fig. 27). Remove the

automatic adjuster assembly from the leading brake

shoe.

Fig. 24 Tension Clip Attachment To Adjuster

1 - WHEEL CYLINDER

2 - BRAKE SHOE UPPER RETURN SPRING

3 - AUTOMATIC ADJUSTER LEVER

4 - TENSION CLIP

5 - AUTOMATIC ADJUSTER ASSEMBLY

Fig. 25 Brake Shoe Upper Return Spring

1 - BRAKE SHOE RETURN SPRING

2 - LEADING BRAKE SHOE

3 - TRAILING BRAKE SHOE

Fig. 26 Trailing Brake Shoe Hold Down Spring And

Pin

1 - BRAKE SUPPORT PLATE

2 - HOLD DOWN SPRING AND PIN

3 - TRAILING BRAKE SHOE

Fig. 27 Trailing Brake Shoe Removal/Installation

1 - BRAKE SUPPORT PLATE

2 - LEADING BRAKE SHOE

3 - PARK BRAKE ACTUATING LEVER

4 - PARK BRAKE ACTUATING STRUT

5 - TRAILING BRAKE SHOE

RSBRAKES - BASE5-21

BRAKE PADS/SHOES - REAR DRUM (Continued)

ProCarManuals.com

Page 169 of 2177

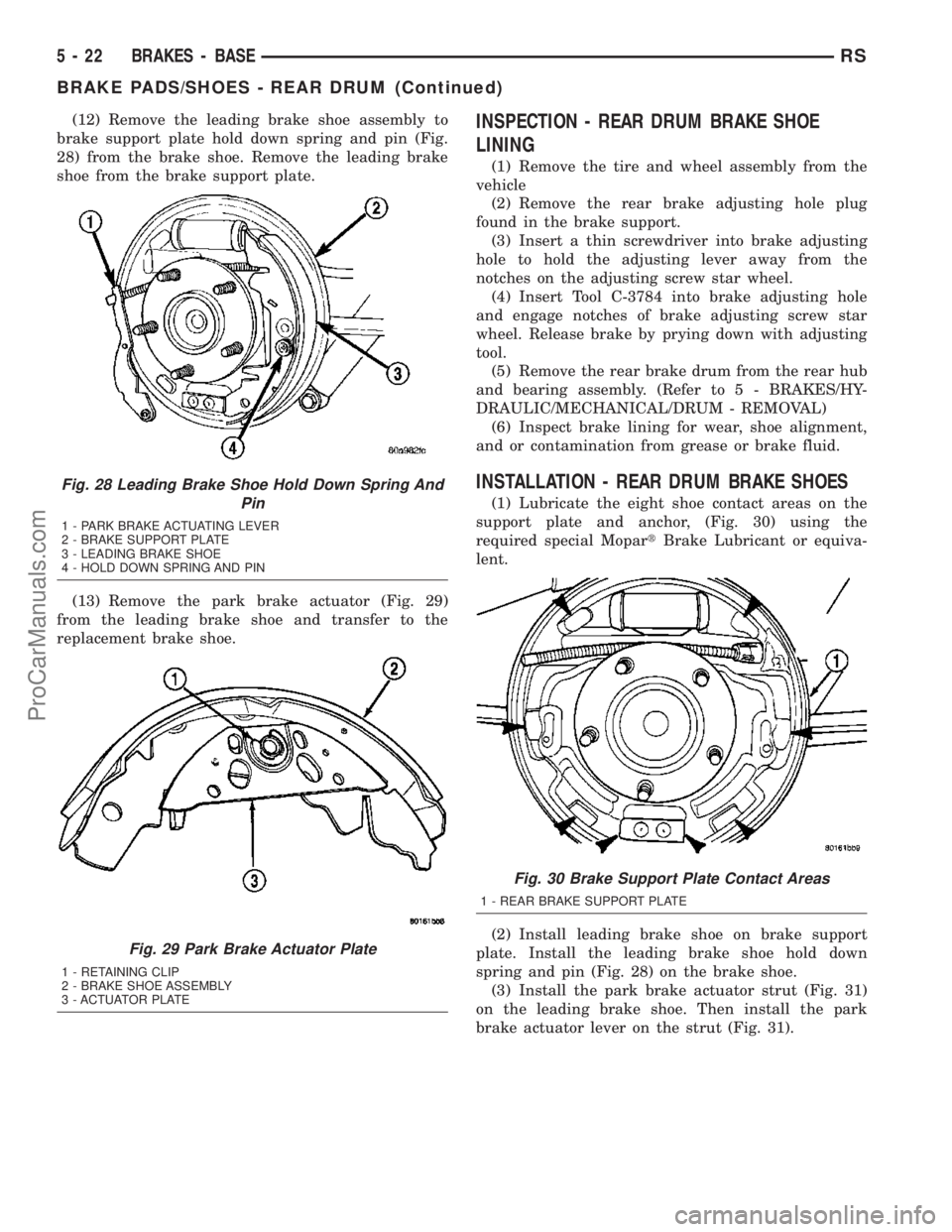

(12) Remove the leading brake shoe assembly to

brake support plate hold down spring and pin (Fig.

28) from the brake shoe. Remove the leading brake

shoe from the brake support plate.

(13) Remove the park brake actuator (Fig. 29)

from the leading brake shoe and transfer to the

replacement brake shoe.INSPECTION - REAR DRUM BRAKE SHOE

LINING

(1) Remove the tire and wheel assembly from the

vehicle

(2) Remove the rear brake adjusting hole plug

found in the brake support.

(3) Insert a thin screwdriver into brake adjusting

hole to hold the adjusting lever away from the

notches on the adjusting screw star wheel.

(4) Insert Tool C-3784 into brake adjusting hole

and engage notches of brake adjusting screw star

wheel. Release brake by prying down with adjusting

tool.

(5) Remove the rear brake drum from the rear hub

and bearing assembly. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/DRUM - REMOVAL)

(6) Inspect brake lining for wear, shoe alignment,

and or contamination from grease or brake fluid.

INSTALLATION - REAR DRUM BRAKE SHOES

(1) Lubricate the eight shoe contact areas on the

support plate and anchor, (Fig. 30) using the

required special MopartBrake Lubricant or equiva-

lent.

(2) Install leading brake shoe on brake support

plate. Install the leading brake shoe hold down

spring and pin (Fig. 28) on the brake shoe.

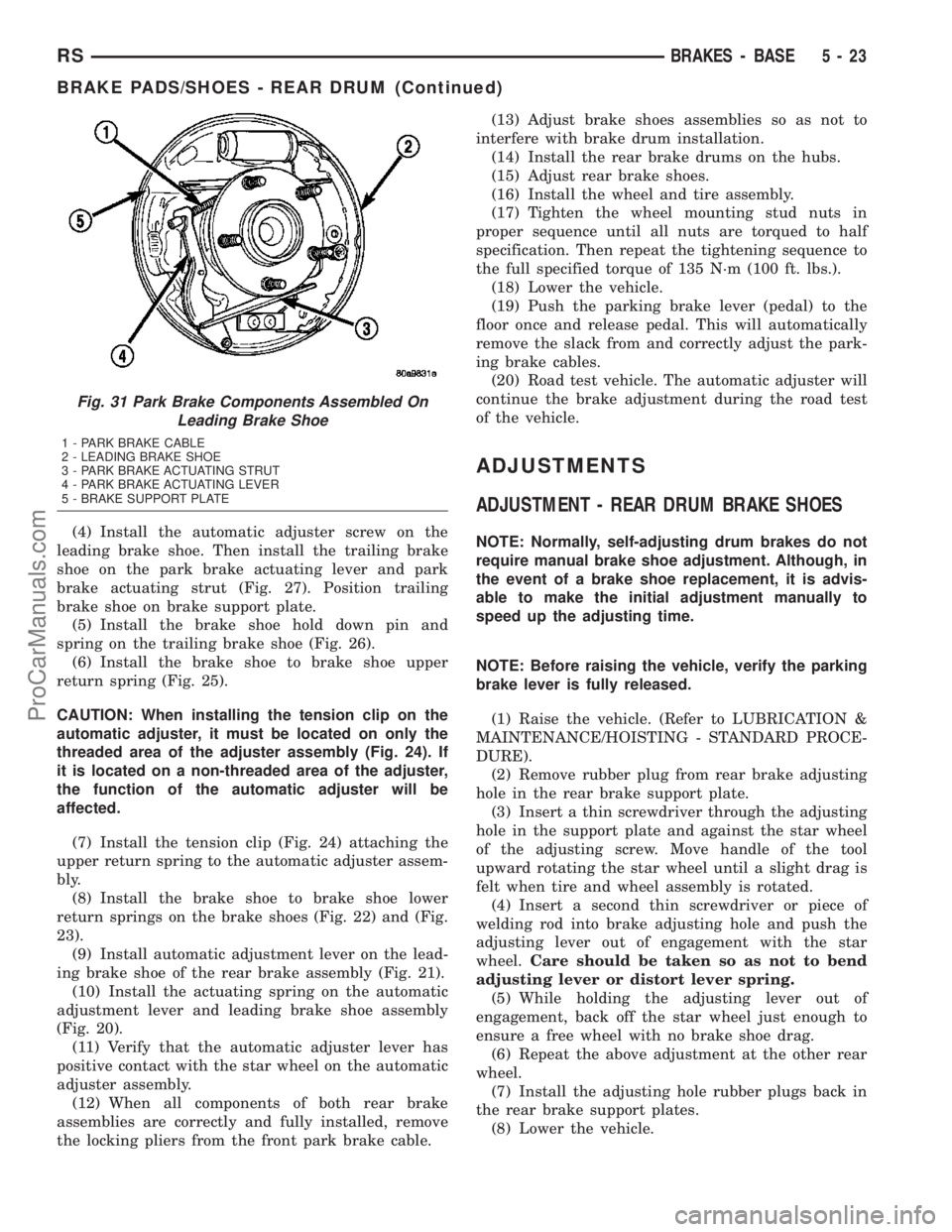

(3) Install the park brake actuator strut (Fig. 31)

on the leading brake shoe. Then install the park

brake actuator lever on the strut (Fig. 31).

Fig. 28 Leading Brake Shoe Hold Down Spring And

Pin

1 - PARK BRAKE ACTUATING LEVER

2 - BRAKE SUPPORT PLATE

3 - LEADING BRAKE SHOE

4 - HOLD DOWN SPRING AND PIN

Fig. 29 Park Brake Actuator Plate

1 - RETAINING CLIP

2 - BRAKE SHOE ASSEMBLY

3 - ACTUATOR PLATE

Fig. 30 Brake Support Plate Contact Areas

1 - REAR BRAKE SUPPORT PLATE

5 - 22 BRAKES - BASERS

BRAKE PADS/SHOES - REAR DRUM (Continued)

ProCarManuals.com

Page 170 of 2177

(4) Install the automatic adjuster screw on the

leading brake shoe. Then install the trailing brake

shoe on the park brake actuating lever and park

brake actuating strut (Fig. 27). Position trailing

brake shoe on brake support plate.

(5) Install the brake shoe hold down pin and

spring on the trailing brake shoe (Fig. 26).

(6) Install the brake shoe to brake shoe upper

return spring (Fig. 25).

CAUTION: When installing the tension clip on the

automatic adjuster, it must be located on only the

threaded area of the adjuster assembly (Fig. 24). If

it is located on a non-threaded area of the adjuster,

the function of the automatic adjuster will be

affected.

(7) Install the tension clip (Fig. 24) attaching the

upper return spring to the automatic adjuster assem-

bly.

(8) Install the brake shoe to brake shoe lower

return springs on the brake shoes (Fig. 22) and (Fig.

23).

(9) Install automatic adjustment lever on the lead-

ing brake shoe of the rear brake assembly (Fig. 21).

(10) Install the actuating spring on the automatic

adjustment lever and leading brake shoe assembly

(Fig. 20).

(11) Verify that the automatic adjuster lever has

positive contact with the star wheel on the automatic

adjuster assembly.

(12) When all components of both rear brake

assemblies are correctly and fully installed, remove

the locking pliers from the front park brake cable.(13) Adjust brake shoes assemblies so as not to

interfere with brake drum installation.

(14) Install the rear brake drums on the hubs.

(15) Adjust rear brake shoes.

(16) Install the wheel and tire assembly.

(17) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(18) Lower the vehicle.

(19) Push the parking brake lever (pedal) to the

floor once and release pedal. This will automatically

remove the slack from and correctly adjust the park-

ing brake cables.

(20) Road test vehicle. The automatic adjuster will

continue the brake adjustment during the road test

of the vehicle.

ADJUSTMENTS

ADJUSTMENT - REAR DRUM BRAKE SHOES

NOTE: Normally, self-adjusting drum brakes do not

require manual brake shoe adjustment. Although, in

the event of a brake shoe replacement, it is advis-

able to make the initial adjustment manually to

speed up the adjusting time.

NOTE: Before raising the vehicle, verify the parking

brake lever is fully released.

(1) Raise the vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(2) Remove rubber plug from rear brake adjusting

hole in the rear brake support plate.

(3) Insert a thin screwdriver through the adjusting

hole in the support plate and against the star wheel

of the adjusting screw. Move handle of the tool

upward rotating the star wheel until a slight drag is

felt when tire and wheel assembly is rotated.

(4) Insert a second thin screwdriver or piece of

welding rod into brake adjusting hole and push the

adjusting lever out of engagement with the star

wheel.Care should be taken so as not to bend

adjusting lever or distort lever spring.

(5) While holding the adjusting lever out of

engagement, back off the star wheel just enough to

ensure a free wheel with no brake shoe drag.

(6) Repeat the above adjustment at the other rear

wheel.

(7) Install the adjusting hole rubber plugs back in

the rear brake support plates.

(8) Lower the vehicle.

Fig. 31 Park Brake Components Assembled On

Leading Brake Shoe

1 - PARK BRAKE CABLE

2 - LEADING BRAKE SHOE

3 - PARK BRAKE ACTUATING STRUT

4 - PARK BRAKE ACTUATING LEVER

5 - BRAKE SUPPORT PLATE

RSBRAKES - BASE5-23

BRAKE PADS/SHOES - REAR DRUM (Continued)

ProCarManuals.com

Page 178 of 2177

(7) Tighten the wheel mounting stud nuts in

proper sequence until all nuts are torqued to half

specification. Then repeat the tightening sequence to

the full specified torque of 135 N´m (100 ft. lbs.).

(8) Lower the vehicle.

(9) Remove the brake pedal depressor (holding)

tool.

(10) Bleed the hydraulic brake circuit to the brake

caliper. (Refer to 5 - BRAKES - STANDARD PROCE-

DURE)

(11) Road test the vehicle and make several stops

to wear off any foreign material on the brakes and to

seat the brake shoe linings.

DISC BRAKE CALIPER

ADAPTER

REMOVAL - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove front wheel and tire assembly, disc

brake caliper and brake shoes. (Refer to 5 - BRAKES/

HYDRAULIC/MECHANICAL/BRAKE PADS/SHOES

- REMOVAL)

(3) Remove two bolts fastening adapter to steering

knuckle, then remove disc brake caliper adapter.

INSTALLATION - FRONT DISC BRAKE CALIPER

ADAPTER

(1) Place adapter over brake rotor and align

adapter mounting holes to knuckle.

CAUTION: Adapter mounting bolts have a special

DacrometTcoating applied to resist corrosion. If

mounting bolts need to be replaced, use only

MoparTreplacement parts.

(2) Install adapter mounting bolts and tighten to

169 N´m (125 ft. lbs.) torque.

(3) Install brake shoes, disc brake caliper and

wheel and tire assembly. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/BRAKE PADS/SHOES -

INSTALLATION)

(4) Lower vehicle.

(5) Pump the brake pedal several times to set the

pads to the brake rotor.

(6) Check and adjust brake fluid level as neces-

sary.

DISC BRAKE CALIPER GUIDE

PINS

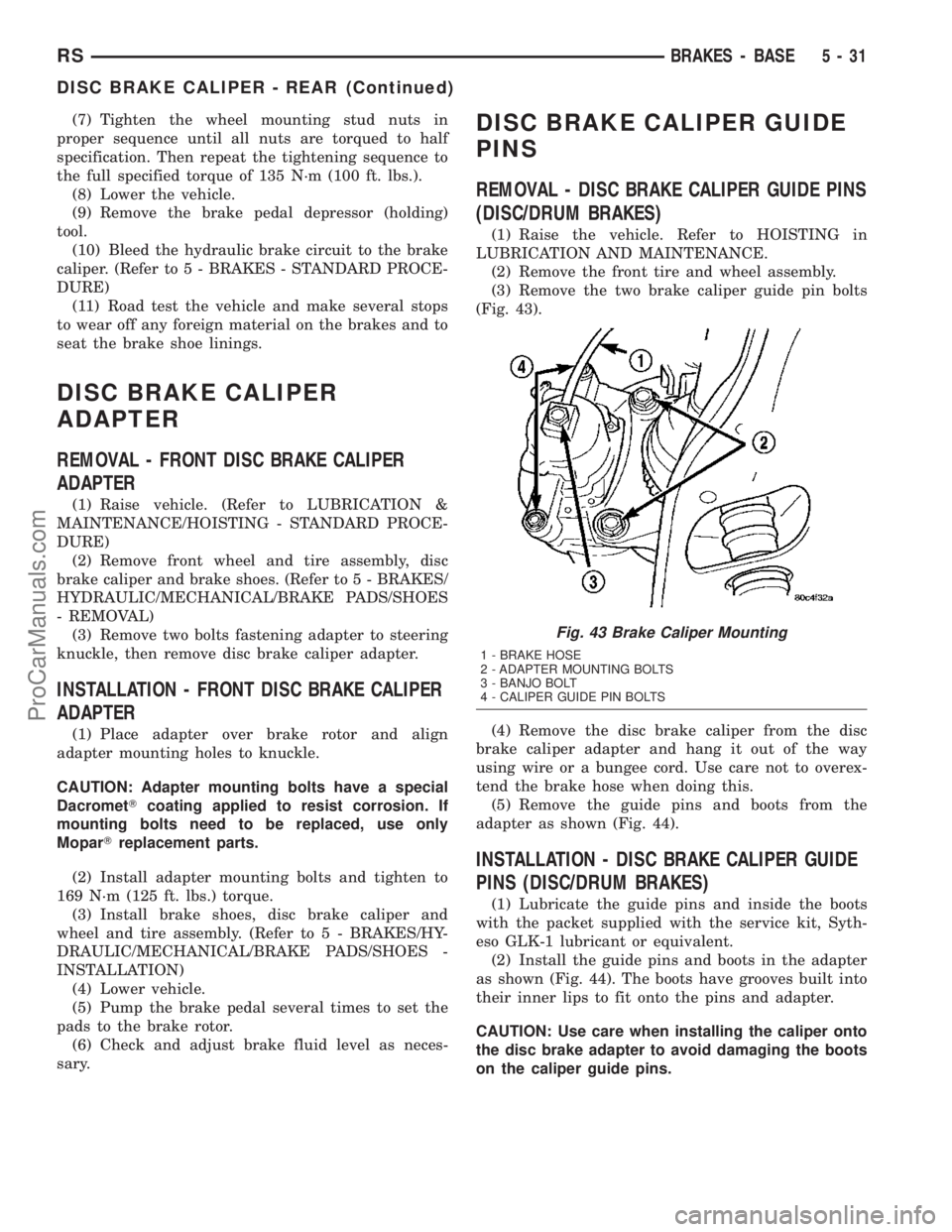

REMOVAL - DISC BRAKE CALIPER GUIDE PINS

(DISC/DRUM BRAKES)

(1) Raise the vehicle. Refer to HOISTING in

LUBRICATION AND MAINTENANCE.

(2) Remove the front tire and wheel assembly.

(3) Remove the two brake caliper guide pin bolts

(Fig. 43).

(4) Remove the disc brake caliper from the disc

brake caliper adapter and hang it out of the way

using wire or a bungee cord. Use care not to overex-

tend the brake hose when doing this.

(5) Remove the guide pins and boots from the

adapter as shown (Fig. 44).

INSTALLATION - DISC BRAKE CALIPER GUIDE

PINS (DISC/DRUM BRAKES)

(1) Lubricate the guide pins and inside the boots

with the packet supplied with the service kit, Syth-

eso GLK-1 lubricant or equivalent.

(2) Install the guide pins and boots in the adapter

as shown (Fig. 44). The boots have grooves built into

their inner lips to fit onto the pins and adapter.

CAUTION: Use care when installing the caliper onto

the disc brake adapter to avoid damaging the boots

on the caliper guide pins.

Fig. 43 Brake Caliper Mounting

1 - BRAKE HOSE

2 - ADAPTER MOUNTING BOLTS

3 - BANJO BOLT

4 - CALIPER GUIDE PIN BOLTS

RSBRAKES - BASE5-31

DISC BRAKE CALIPER - REAR (Continued)

ProCarManuals.com

Page 200 of 2177

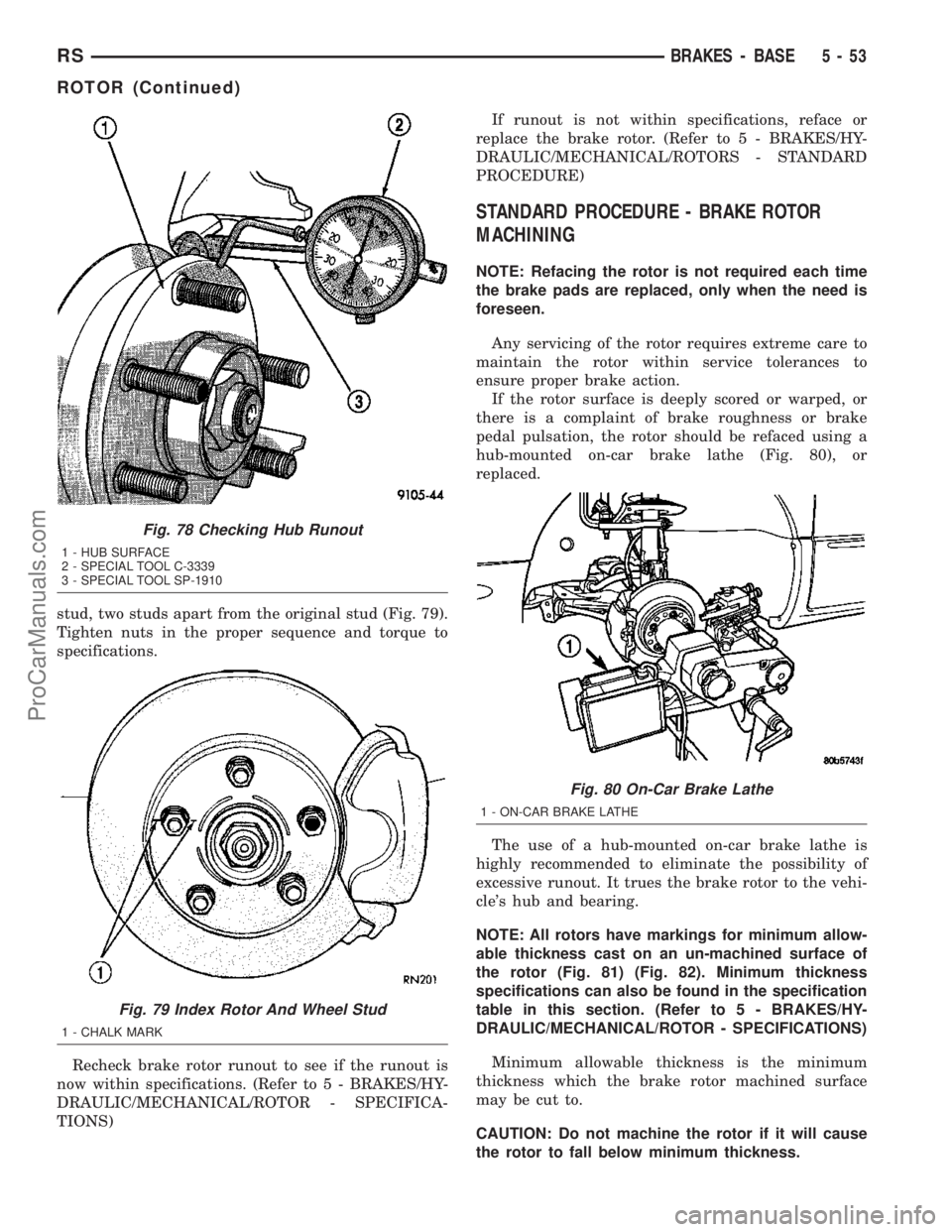

stud, two studs apart from the original stud (Fig. 79).

Tighten nuts in the proper sequence and torque to

specifications.

Recheck brake rotor runout to see if the runout is

now within specifications. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTOR - SPECIFICA-

TIONS)If runout is not within specifications, reface or

replace the brake rotor. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTORS - STANDARD

PROCEDURE)

STANDARD PROCEDURE - BRAKE ROTOR

MACHINING

NOTE: Refacing the rotor is not required each time

the brake pads are replaced, only when the need is

foreseen.

Any servicing of the rotor requires extreme care to

maintain the rotor within service tolerances to

ensure proper brake action.

If the rotor surface is deeply scored or warped, or

there is a complaint of brake roughness or brake

pedal pulsation, the rotor should be refaced using a

hub-mounted on-car brake lathe (Fig. 80), or

replaced.

The use of a hub-mounted on-car brake lathe is

highly recommended to eliminate the possibility of

excessive runout. It trues the brake rotor to the vehi-

cle's hub and bearing.

NOTE: All rotors have markings for minimum allow-

able thickness cast on an un-machined surface of

the rotor (Fig. 81) (Fig. 82). Minimum thickness

specifications can also be found in the specification

table in this section. (Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/ROTOR - SPECIFICATIONS)

Minimum allowable thickness is the minimum

thickness which the brake rotor machined surface

may be cut to.

CAUTION: Do not machine the rotor if it will cause

the rotor to fall below minimum thickness.

Fig. 78 Checking Hub Runout

1 - HUB SURFACE

2 - SPECIAL TOOL C-3339

3 - SPECIAL TOOL SP-1910

Fig. 79 Index Rotor And Wheel Stud

1 - CHALK MARK

Fig. 80 On-Car Brake Lathe

1 - ON-CAR BRAKE LATHE

RSBRAKES - BASE5-53

ROTOR (Continued)

ProCarManuals.com

Page 203 of 2177

SUPPORT PLATE - DRUM

BRAKE

REMOVAL

(1) Using a brake pedal depressor, move and

secure brake pedal to a position past its first 1 inch

of travel. This will prevent brake fluid from draining

out of master cylinder when brake tube is remove

from wheel cylinder.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(3) Remove wheel and tire assembly.

(4) Disconnect brake tube from rear of wheel cylin-

der. Cap open ends

(5) Remove brake drum.

(6) Remove brake shoes from brake support plate.

(Refer to 5 - BRAKES/HYDRAULIC/MECHANICAL/

BRAKE PADS/SHOES - REMOVAL).

(7) Remove the 2 bolts attaching the wheel cylin-

der to the brake support plate.

(8) Remove the wheel cylinder from the brake sup-

port plate.

(9) Disconnect the park brake cable from the park

brake actuation lever.

(10) Using a suitable tool such as a 14 mm box

wrench (Fig. 84) or an aircraft type hose clamp, com-

press the flared legs on park brake cable retainer.

Then pull the park brake cable out of brake support

plate.

(11) Remove the rear hub and bearing. (Refer to 2

- SUSPENSION/REAR/HUB / BEARING -

REMOVAL)(12) Remove the rear brake support plate from the

rear axle.

INSTALLATION

(1) Install the 4 hub and bearing to axle mounting

bolts into the mounting holes in the flange of the

rear axle.

(2) Install the rear brake support plate on the 4

mounting bolts installed in the flange of the rear axle

(Fig. 85).

(3) Install the rear hub and bearing (and connect

wheel speed sensor where applicable) stopping short

of installing the brake drum. (Refer to 2 - SUSPEN-

SION/REAR/HUB / BEARING - INSTALLATION)

(4) Install the rear park brake cable into its

mounting hole in the rear brake support plate.

(5) Install the park brake cable on the park brake

actuation lever.

(6) Apply sealant such as Mopar Gasket-In-A-Tube

or equivalent around the wheel cylinder opening in

the brake support plate.

(7) Install wheel cylinder onto brake support.

Install and tighten the wheel cylinder to brake sup-

port plate attaching bolts to 8 N´m (75 in. lbs.)

torque.

(8) Install brake tube into wheel cylinder. Tighten

tube nut to a torque of 17 N´m (145 in. lbs.) torque.

(9) Install the rear brake shoes on the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(10) Install brake drum.

(11) Install wheel and tire.

(12) Tighten wheel stud nuts to 135 N´m (100 ft.

lbs.).

Fig. 84 Removing Park Brake Cable From Brake

Support Plate

1 - PARK BRAKE CABLE

2 - CABLE RETAINER

3 - 14 mm BOX WRENCH

4 - BRAKE SUPPORT PLATE

Fig. 85 Brake Support Plate Mounted On Bearing

Attaching Bolts

1 - REAR BRAKE SUPPORT PLATE

2 - HUB/BEARING MOUNTING BOLTS

5 - 56 BRAKES - BASERS

ProCarManuals.com

Page 204 of 2177

(13) Adjust drum brake shoes. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS)

(14) Remove brake pedal depressor tool.

(15) Bleed the brake system as necessary. (Refer to

5 - BRAKES - BASE - STANDARD PROCEDURE).

(16) Lower the vehicle.

WHEEL CYLINDERS

REMOVAL

(1) Using a brake pedal depressor, move and

secure brake pedal to a position past its first 1 inch

of travel. This will prevent brake fluid from draining

out of master cylinder when brake tube is remove

from wheel cylinder.

(2) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE).

(3) Remove wheel and tire assembly.

(4) Disconnect brake tube from rear of wheel cylin-

der. Cap open ends

(5) Remove brake drum.

(6) Remove brake shoes from brake support plate

(Discard if contaminated).(Refer to 5 - BRAKES/HY-

DRAULIC/MECHANICAL/BRAKE PADS/SHOES -

REMOVAL)

(7) Remove the 2 bolts attaching the wheel cylin-

der to the brake support plate.

(8) Remove the wheel cylinder from the brake sup-

port plate.

INSPECTION

With brake drums removed, inspect the wheel cyl-

inder boots for evidence of a brake fluid leak. Visu-

ally check the boots for cuts, tears, or heat cracks. If

any of these conditions exist, the wheel cylinders

should be completely cleaned, inspected and new

parts installed.

If a wheel cylinder is leaking and the brake lining

material is saturated with brake fluid, the brake

shoes must be replaced.

INSTALLATION

(1) Apply sealant such as Mopar Gasket-In-A-Tube

or equivalent around the wheel cylinder opening in

the brake support plate.

(2) Install wheel cylinder onto brake support.

Install and tighten the wheel cylinder to brake sup-

port plate attaching bolts to 8 N´m (75 in. lbs.)

torque.

(3) Install brake tube into wheel cylinder. Tighten

tube nut to a torque of 17 N´m (145 in. lbs.) torque.

(4) Install the rear brake shoes on the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-CHANICAL/BRAKE PADS/SHOES -

INSTALLATION).

(5) Install brake drum.

(6) Install wheel and tire. Install and tighten

wheel lug nuts to 135 N´m (100 ft. lbs.).

(7) Adjust drum brake shoes. (Refer to 5 -

BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS)

(8) Remove brake pedal depressor tool.

(9) Bleed the brake system as necessary. (Refer to

5 - BRAKES - BASE - STANDARD PROCEDURE).

(10) Lower vehicle.

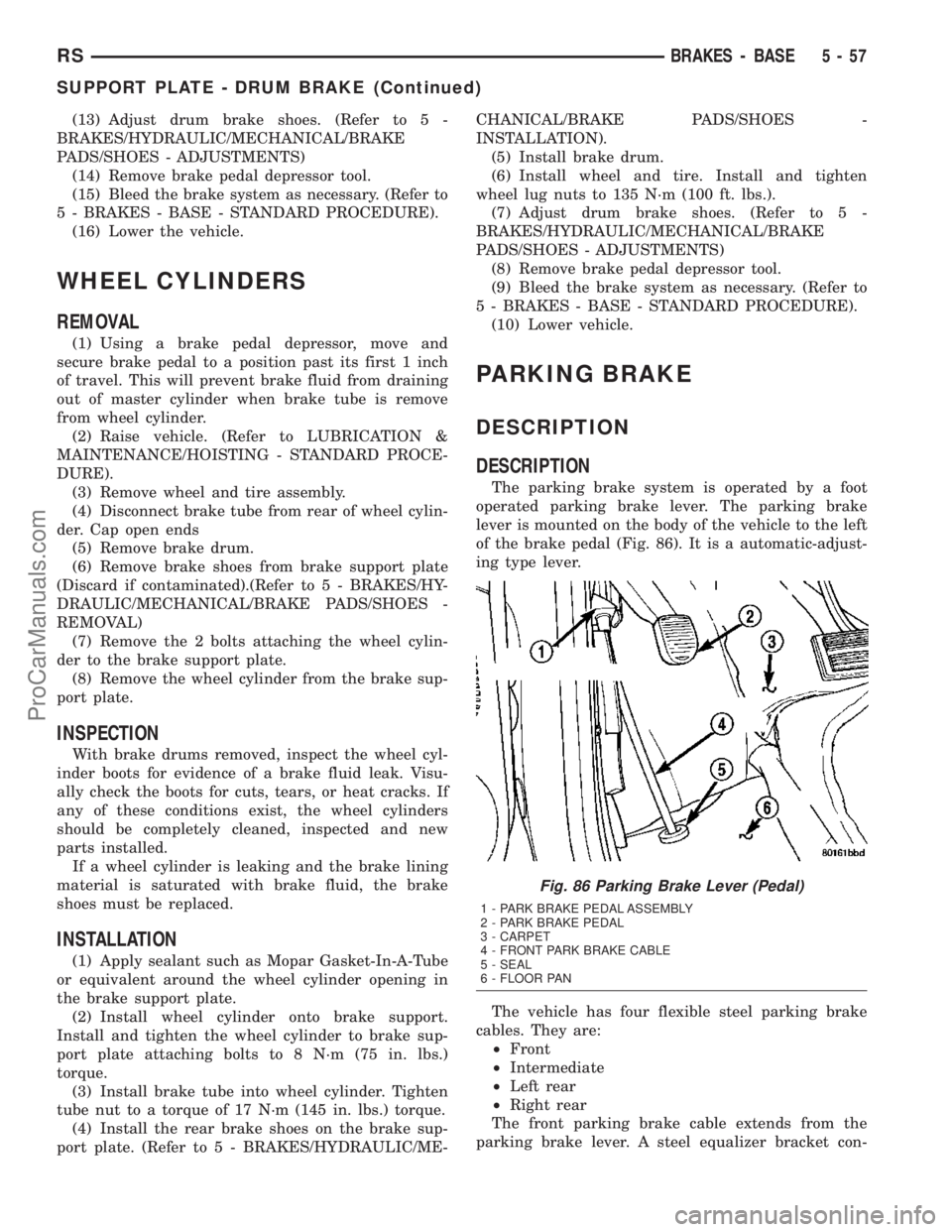

PARKING BRAKE

DESCRIPTION

DESCRIPTION

The parking brake system is operated by a foot

operated parking brake lever. The parking brake

lever is mounted on the body of the vehicle to the left

of the brake pedal (Fig. 86). It is a automatic-adjust-

ing type lever.

The vehicle has four flexible steel parking brake

cables. They are:

²Front

²Intermediate

²Left rear

²Right rear

The front parking brake cable extends from the

parking brake lever. A steel equalizer bracket con-

Fig. 86 Parking Brake Lever (Pedal)

1 - PARK BRAKE PEDAL ASSEMBLY

2 - PARK BRAKE PEDAL

3 - CARPET

4 - FRONT PARK BRAKE CABLE

5 - SEAL

6 - FLOOR PAN

RSBRAKES - BASE5-57

SUPPORT PLATE - DRUM BRAKE (Continued)

ProCarManuals.com

Page 208 of 2177

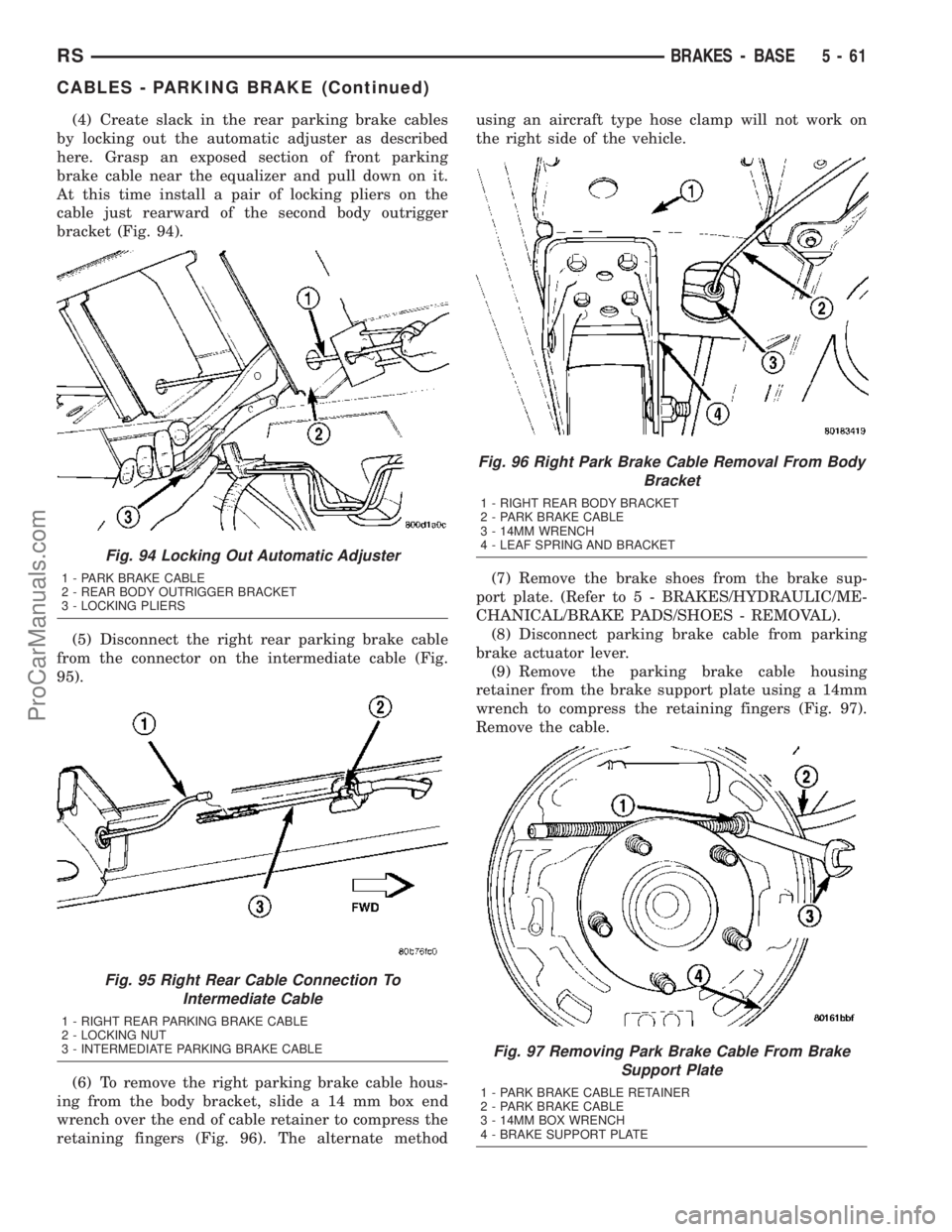

(4) Create slack in the rear parking brake cables

by locking out the automatic adjuster as described

here. Grasp an exposed section of front parking

brake cable near the equalizer and pull down on it.

At this time install a pair of locking pliers on the

cable just rearward of the second body outrigger

bracket (Fig. 94).

(5) Disconnect the right rear parking brake cable

from the connector on the intermediate cable (Fig.

95).

(6) To remove the right parking brake cable hous-

ing from the body bracket, slide a 14 mm box end

wrench over the end of cable retainer to compress the

retaining fingers (Fig. 96). The alternate methodusing an aircraft type hose clamp will not work on

the right side of the vehicle.

(7) Remove the brake shoes from the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES - REMOVAL).

(8) Disconnect parking brake cable from parking

brake actuator lever.

(9) Remove the parking brake cable housing

retainer from the brake support plate using a 14mm

wrench to compress the retaining fingers (Fig. 97).

Remove the cable.

Fig. 94 Locking Out Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 95 Right Rear Cable Connection To

Intermediate Cable

1 - RIGHT REAR PARKING BRAKE CABLE

2 - LOCKING NUT

3 - INTERMEDIATE PARKING BRAKE CABLE

Fig. 96 Right Park Brake Cable Removal From Body

Bracket

1 - RIGHT REAR BODY BRACKET

2 - PARK BRAKE CABLE

3 - 14MM WRENCH

4 - LEAF SPRING AND BRACKET

Fig. 97 Removing Park Brake Cable From Brake

Support Plate

1 - PARK BRAKE CABLE RETAINER

2 - PARK BRAKE CABLE

3 - 14MM BOX WRENCH

4 - BRAKE SUPPORT PLATE

RSBRAKES - BASE5-61

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com

Page 209 of 2177

REMOVAL - PARKING BRAKE CABLE (LEFT

REAR)

(1) Raise vehicle on jackstands or centered on a

hoist. (Refer to LUBRICATION & MAINTENANCE/

HOISTING - STANDARD PROCEDURE).

(2) Remove rear tire and wheel assembly.

(3) Remove rear brake drum from the rear wheel

of the vehicle requiring service to the rear park

brake cable.

(4) Create slack in rear park brake cables by lock-

ing out the automatic adjuster as described here.

Grasp an exposed section of front park brake cable

near the equalizer and pull down on it. Then install

a pair of locking pliers on the cable just rearward of

the second body outrigger bracket (Fig. 98).

(5) Disconnect the left rear parking brake cable

from the parking brake cable equalizer (Fig. 99).

(6) To remove parking brake cable housing from

the body bracket, slide a 14 mm box end wrench over

retainer end compressing the three fingers (Fig. 100).

Alternate method is to use an aircraft type hose

clamp.

(7) Remove the brake shoes from the brake sup-

port plate. (Refer to 5 - BRAKES/HYDRAULIC/ME-

CHANICAL/BRAKE PADS/SHOES - REMOVAL).

(8) Disconnect parking brake cable from parking

brake actuator lever.(9) Remove the parking brake cable housing

retainer from the brake support plate using a 14mm

wrench to compress the retaining fingers (Fig. 101).

Fig. 98 Locked Out Park Brake Automatic Adjuster

1 - PARK BRAKE CABLE

2 - REAR BODY OUTRIGGER BRACKET

3 - LOCKING PLIERS

Fig. 99 Parking Brake Cables At Equalizer

1 - EQUALIZER

2 - LEFT REAR PARKING BRAKE CABLE

3 - LOCKING NUT

4 - INTERMEDIATE PARKING BRAKE CABLE

5 - FRONT PARKING BRAKE CABLE

Fig. 100 Parking Brake Cable Removal From Body

Bracket

1 - LEFT REAR PARK BRAKE CABLE

2 - BODY BRACKET

3 - LEAF SPRING MOUNTING BRACKET

4 - CABLE RETAINER

5 - 14MM BOX WRENCH

5 - 62 BRAKES - BASERS

CABLES - PARKING BRAKE (Continued)

ProCarManuals.com