instrument panel CHRYSLER CARAVAN 2003 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 253 of 2177

(10) Using Tool 6638A, disconnect clutch master

cylinder ªquick connectº fitting (Fig. 17). Disengage

plumbing retainer from body stud.

(11) Remove master cylinder reservoir-to-strut

tower nuts (Fig. 18). Reposition reservoir off to side.

(12) Remove clutch master cylinder from dash

panel by rotating clockwise 45É and removing from

dash panel (Fig. 18).(13) Remove master cylinder and plumbing from

engine compartment. Use care not to bend or kink

plumbing. Note plumbing routing to aid in installa-

tion.

INSTALLATION

(1) Install master cylinder into position, while

routing plumbing as originally installed.

(2) Insert master cylinder pushrod through dash

panel (Fig. 18) and rotate 45É counter-clockwise to

secure.

(3) Connect master cylinder plumbing quick-con-

nect fitting. An audible ªclickº should be heard. Ver-

ify connection by pulling outward.

(4) Install master cylinder reservoir onto strut

tower. Install and tighten two (2) master cylinder

reservoir-to-strut tower nuts to 11 N´m (100 in. lbs.)

(Fig. 18).

(5) Install windshield wiper module assembly

(Refer to 8 - ELECTRICAL/WIPERS/WASHERS/

WIPER MODULE - INSTALLATION).

(6) Install battery tray.

(7) Install battery.

(8) Install battery shield.

(9) Connect master cylinder pushrod to clutch

pedal lever (Fig. 16). Install retainer clip.

(10) Install knee bolster and instrument panel

lower silencer (Fig. 15) (Fig. 14).

(11) Connect battery cables.

Fig. 16 Master Cylinder Pushrod at Pedal

1 - MASTER CYLINDER PUSHROD

2 - CLUTCH/BRAKE PEDAL ASSEMBLY

3 - PUSHROD RETAINER

Fig. 17 Disconnect Quick-Connect Using Tool 6638A

1 - QUICK CONNECT FITTING

2 - TOOL 6638A

Fig. 18 Clutch Master Cylinder Removal/Installation

1 - CLUTCH MASTER CYLINDER

2 - RESERVOIR

3 - NUT (2)

6 - 10 CLUTCHRS

MASTER CYLINDER - LHD (Continued)

ProCarManuals.com

Page 256 of 2177

CLUTCH PEDAL INTERLOCK

SWITCH

REMOVAL

LHD

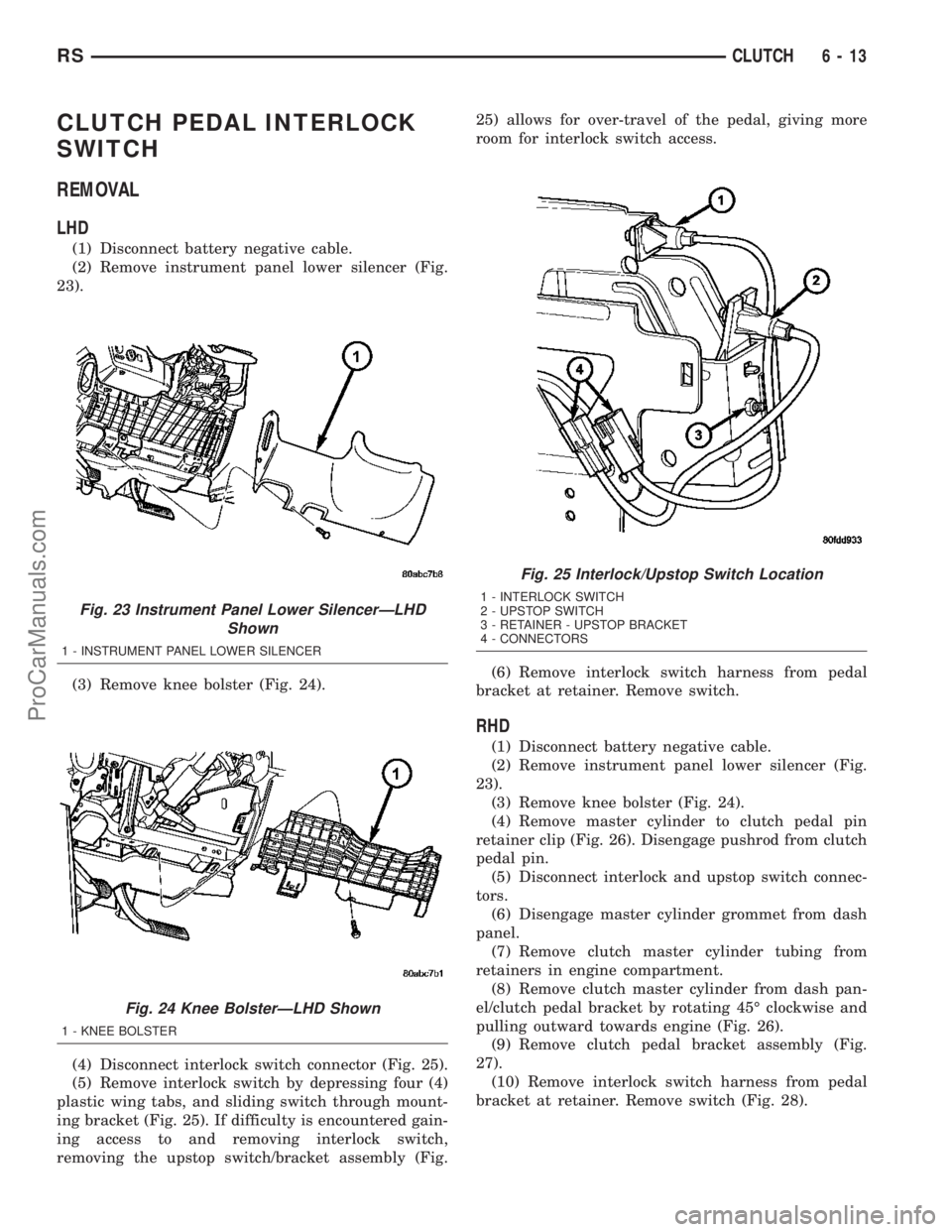

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

23).

(3) Remove knee bolster (Fig. 24).

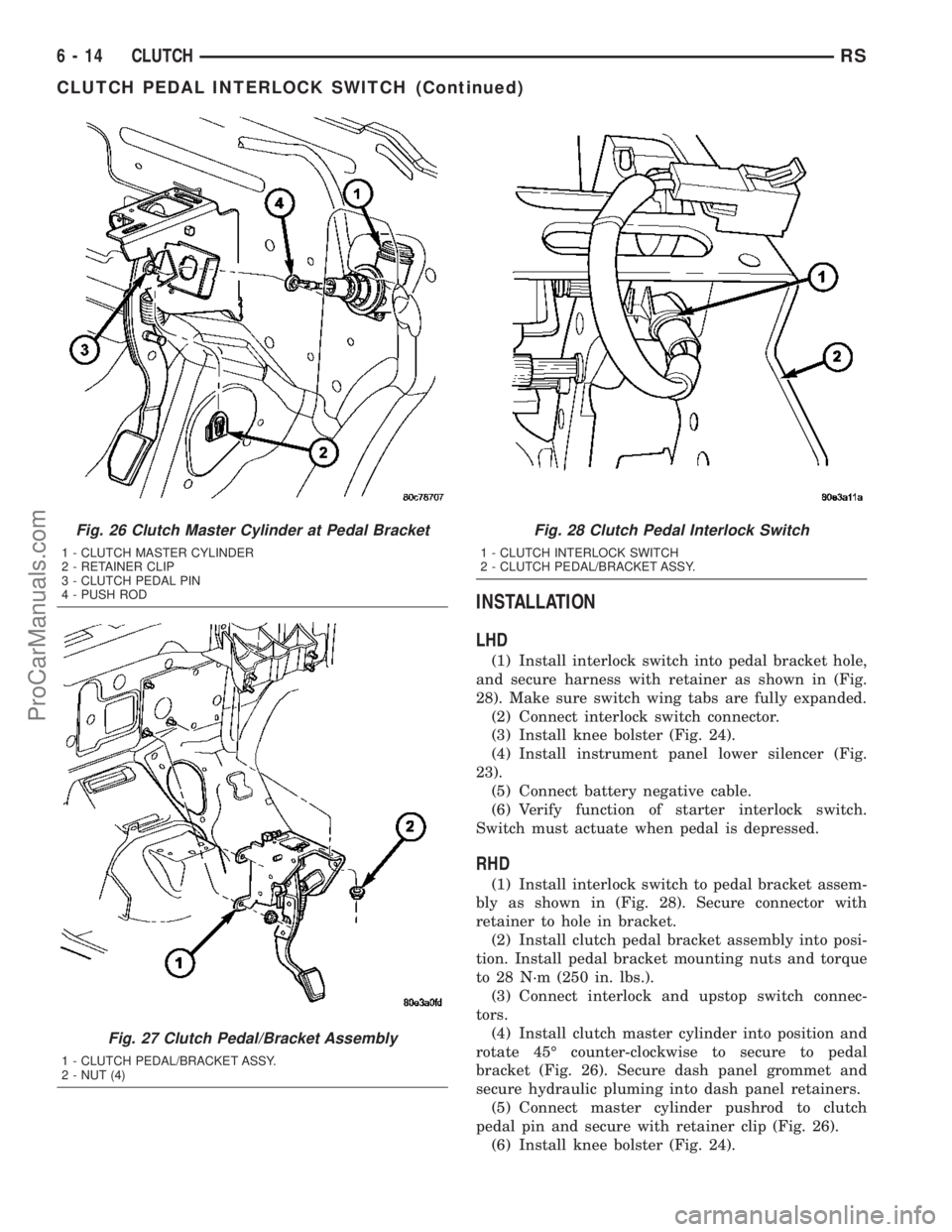

(4) Disconnect interlock switch connector (Fig. 25).

(5) Remove interlock switch by depressing four (4)

plastic wing tabs, and sliding switch through mount-

ing bracket (Fig. 25). If difficulty is encountered gain-

ing access to and removing interlock switch,

removing the upstop switch/bracket assembly (Fig.25) allows for over-travel of the pedal, giving more

room for interlock switch access.

(6) Remove interlock switch harness from pedal

bracket at retainer. Remove switch.

RHD

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

23).

(3) Remove knee bolster (Fig. 24).

(4) Remove master cylinder to clutch pedal pin

retainer clip (Fig. 26). Disengage pushrod from clutch

pedal pin.

(5) Disconnect interlock and upstop switch connec-

tors.

(6) Disengage master cylinder grommet from dash

panel.

(7) Remove clutch master cylinder tubing from

retainers in engine compartment.

(8) Remove clutch master cylinder from dash pan-

el/clutch pedal bracket by rotating 45É clockwise and

pulling outward towards engine (Fig. 26).

(9) Remove clutch pedal bracket assembly (Fig.

27).

(10) Remove interlock switch harness from pedal

bracket at retainer. Remove switch (Fig. 28).

Fig. 23 Instrument Panel Lower SilencerÐLHD

Shown

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 24 Knee BolsterÐLHD Shown

1 - KNEE BOLSTER

Fig. 25 Interlock/Upstop Switch Location

1 - INTERLOCK SWITCH

2 - UPSTOP SWITCH

3 - RETAINER - UPSTOP BRACKET

4 - CONNECTORS

RSCLUTCH6-13

ProCarManuals.com

Page 257 of 2177

INSTALLATION

LHD

(1) Install interlock switch into pedal bracket hole,

and secure harness with retainer as shown in (Fig.

28). Make sure switch wing tabs are fully expanded.

(2) Connect interlock switch connector.

(3) Install knee bolster (Fig. 24).

(4) Install instrument panel lower silencer (Fig.

23).

(5) Connect battery negative cable.

(6) Verify function of starter interlock switch.

Switch must actuate when pedal is depressed.

RHD

(1) Install interlock switch to pedal bracket assem-

bly as shown in (Fig. 28). Secure connector with

retainer to hole in bracket.

(2) Install clutch pedal bracket assembly into posi-

tion. Install pedal bracket mounting nuts and torque

to 28 N´m (250 in. lbs.).

(3) Connect interlock and upstop switch connec-

tors.

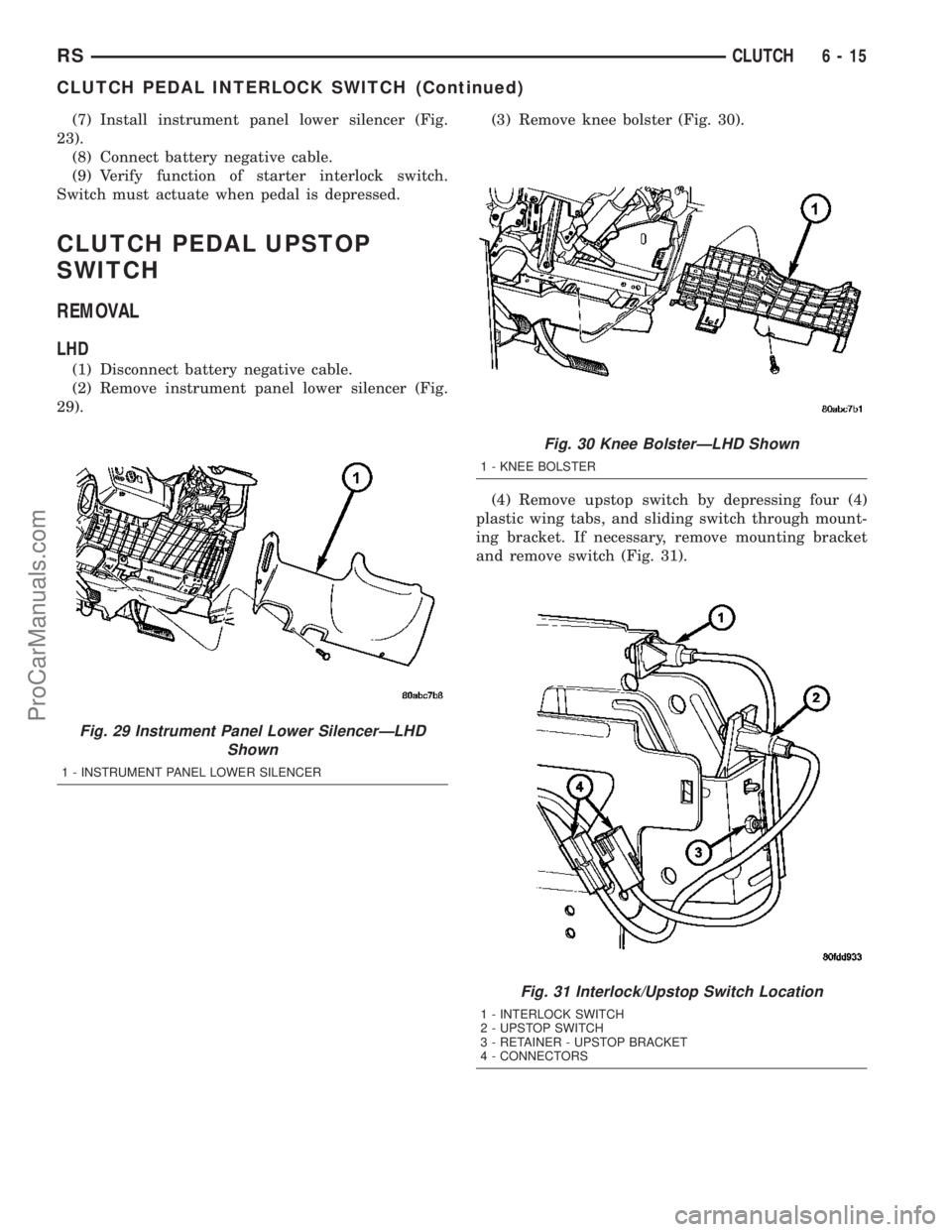

(4) Install clutch master cylinder into position and

rotate 45É counter-clockwise to secure to pedal

bracket (Fig. 26). Secure dash panel grommet and

secure hydraulic pluming into dash panel retainers.

(5) Connect master cylinder pushrod to clutch

pedal pin and secure with retainer clip (Fig. 26).

(6) Install knee bolster (Fig. 24).

Fig. 26 Clutch Master Cylinder at Pedal Bracket

1 - CLUTCH MASTER CYLINDER

2 - RETAINER CLIP

3 - CLUTCH PEDAL PIN

4 - PUSH ROD

Fig. 27 Clutch Pedal/Bracket Assembly

1 - CLUTCH PEDAL/BRACKET ASSY.

2 - NUT (4)

Fig. 28 Clutch Pedal Interlock Switch

1 - CLUTCH INTERLOCK SWITCH

2 - CLUTCH PEDAL/BRACKET ASSY.

6 - 14 CLUTCHRS

CLUTCH PEDAL INTERLOCK SWITCH (Continued)

ProCarManuals.com

Page 258 of 2177

(7) Install instrument panel lower silencer (Fig.

23).

(8) Connect battery negative cable.

(9) Verify function of starter interlock switch.

Switch must actuate when pedal is depressed.

CLUTCH PEDAL UPSTOP

SWITCH

REMOVAL

LHD

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

29).(3) Remove knee bolster (Fig. 30).

(4) Remove upstop switch by depressing four (4)

plastic wing tabs, and sliding switch through mount-

ing bracket. If necessary, remove mounting bracket

and remove switch (Fig. 31).

Fig. 29 Instrument Panel Lower SilencerÐLHD

Shown

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 30 Knee BolsterÐLHD Shown

1 - KNEE BOLSTER

Fig. 31 Interlock/Upstop Switch Location

1 - INTERLOCK SWITCH

2 - UPSTOP SWITCH

3 - RETAINER - UPSTOP BRACKET

4 - CONNECTORS

RSCLUTCH6-15

CLUTCH PEDAL INTERLOCK SWITCH (Continued)

ProCarManuals.com

Page 259 of 2177

RHD

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower silencer (Fig.

29).

(3) Remove knee bolster (Fig. 30).

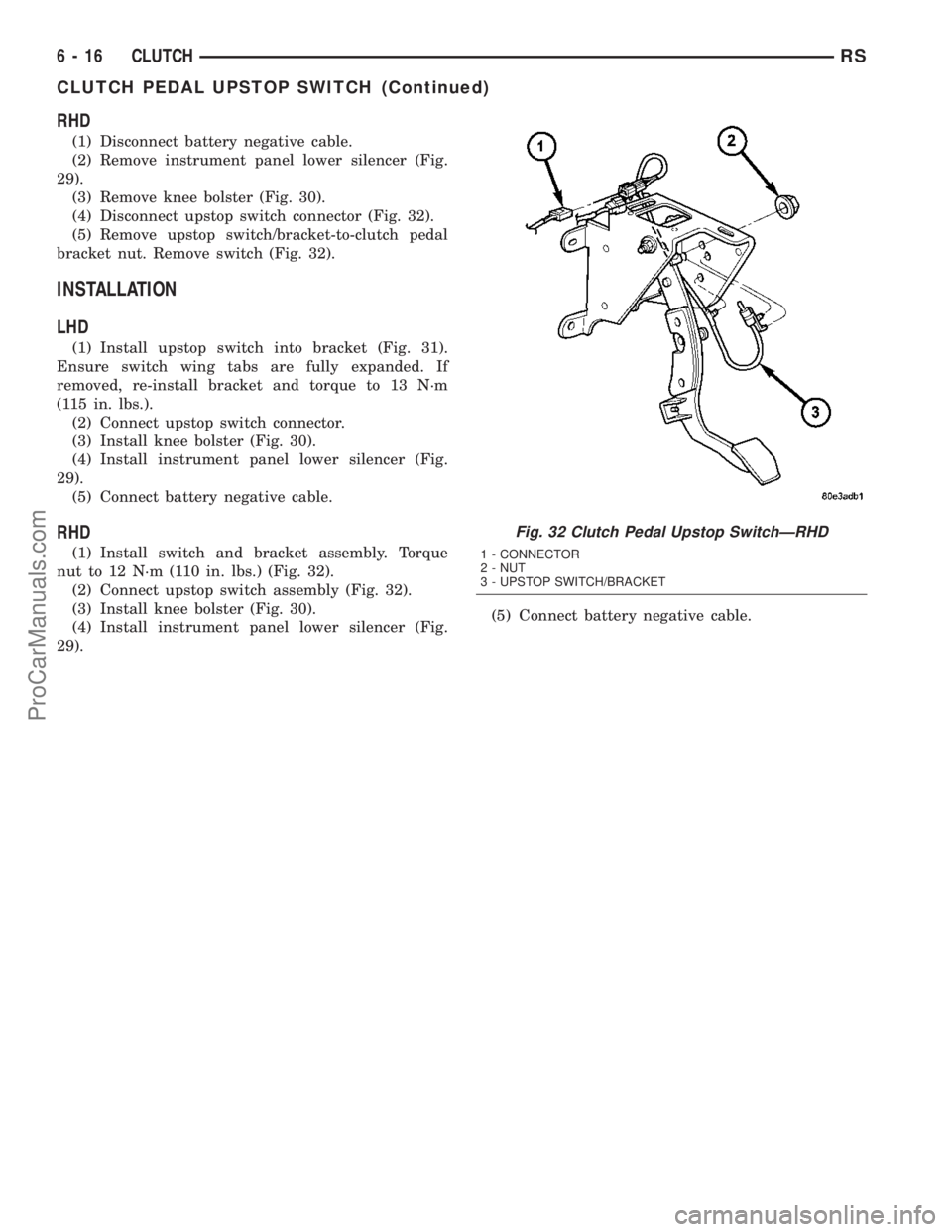

(4) Disconnect upstop switch connector (Fig. 32).

(5) Remove upstop switch/bracket-to-clutch pedal

bracket nut. Remove switch (Fig. 32).

INSTALLATION

LHD

(1) Install upstop switch into bracket (Fig. 31).

Ensure switch wing tabs are fully expanded. If

removed, re-install bracket and torque to 13 N´m

(115 in. lbs.).

(2) Connect upstop switch connector.

(3) Install knee bolster (Fig. 30).

(4) Install instrument panel lower silencer (Fig.

29).

(5) Connect battery negative cable.

RHD

(1) Install switch and bracket assembly. Torque

nut to 12 N´m (110 in. lbs.) (Fig. 32).

(2) Connect upstop switch assembly (Fig. 32).

(3) Install knee bolster (Fig. 30).

(4) Install instrument panel lower silencer (Fig.

29).(5) Connect battery negative cable.

Fig. 32 Clutch Pedal Upstop SwitchÐRHD

1 - CONNECTOR

2 - NUT

3 - UPSTOP SWITCH/BRACKET

6 - 16 CLUTCHRS

CLUTCH PEDAL UPSTOP SWITCH (Continued)

ProCarManuals.com

Page 298 of 2177

AUDIO

TABLE OF CONTENTS

page page

AUDIO/VIDEO

DESCRIPTION..........................1

OPERATION............................2

DIAGNOSIS AND TESTING - AUDIO..........2

ANTENNA BODY AND CABLE

DESCRIPTION..........................4

OPERATION............................4

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE..........................4

REMOVAL.............................5

INSTALLATION..........................6

ANTENNA MODULE - EXPORT

DESCRIPTION..........................6

OPERATION............................6

DIAGNOSIS AND TESTING - ANTENNA

MODULE - EXPORT....................7

REMOVAL.............................7

INSTALLATION..........................7

CD CHANGER

DESCRIPTION..........................7

OPERATION............................7

REMOVAL.............................8

INSTALLATION..........................8

DVD PLAYER

DESCRIPTION..........................8

OPERATION............................8

REMOVAL.............................8

INSTALLATION..........................8

INSTRUMENT PANEL ANTENNA CABLE

REMOVAL.............................8

INSTALLATION..........................9QUARTER GLASS INTEGRAL ANTENNA -

EXPORT

DESCRIPTION..........................9

OPERATION............................9

DIAGNOSIS AND TESTING - QUARTER

GLASS INTEGRAL ANTENNA - EXPORT.....9

RADIO

DESCRIPTION.........................10

OPERATION...........................10

DIAGNOSIS AND TESTING - RADIO.........10

REMOVAL.............................11

INSTALLATION.........................11

RADIO NOISE SUPPRESSION COMPONENTS

DESCRIPTION.........................11

OPERATION...........................12

REMOTE SWITCHES

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING - REMOTE

SWITCHES..........................12

REMOVAL.............................13

INSTALLATION.........................14

SPEAKER

DIAGNOSIS AND TESTING - SPEAKER......14

REMOVAL.............................14

INSTALLATION.........................15

VIDEO SCREEN

DESCRIPTION.........................16

OPERATION...........................16

REMOVAL.............................16

INSTALLATION.........................16

AUDIO/VIDEO

DESCRIPTION

An audio system is standard factory-installed

equipment on this model. A rear seat video system is

an available option. Several combinations of radio

receivers are offered on this model. The audio/video

system uses an ignition switched source of battery

current so that the system will only operate when

the ignition switch is in the RUN or ACCESSORY/

ACCESSORY DELAY positions.

The audio system includes the following compo-

nents:

²Antenna

²CD changer (if equipped)

²DVD player (if equipped)²Radio noise suppression components

²Radio receiver

²Speakers

²Video screen (if equipped)

Certain functions and features of the audio/video

system rely upon resources shared with other elec-

tronic modules in the vehicle over the Programmable

Communication Interface (PCI) bus network. The

data bus network allows the sharing of sensor infor-

mation. For diagnosis of these electronic modules or

of the data bus network, the use of a DRB IIItscan

tool and the proper Diagnostic Procedures manual

are recommended.

Refer to the appropriate wiring information in this

service manual for complete standard and premium

audio system circuit diagrams. The wiring informa-

tion includes proper wire and connector repair proce-

RSAUDIO8A-1

ProCarManuals.com

Page 299 of 2177

dures, further details on wire harness routing and

retention, as well as pin-out and location views for

the various wire harness connectors, splices, and

grounds.

OPERATION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with this vehicle.

DIAGNOSIS AND TESTING - AUDIO

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

harness routing and retention, connector pin-out

information and location views for the various wire

harness connectors, splices and grounds.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SPEAKERS FAULTY. 6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY. 1. CHECK RADIO FUSES IN FUSE BLOCK MODULE.

REPLACE FUSES, IF REQUIRED.

2. RADIO CONNECTOR

FAULTY.2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. WIRING FAULTY. 3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. GROUND FAULTY. 4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. RADIO FAULTY. 5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8A - 2 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com

Page 301 of 2177

CONDITION POSSIBLE CAUSE CORRECTION

HEADPHONES

WILL NOT HOLD

A CHANNEL OR

HAVE STATIC1. WEAK BATTERIES IN

THE HEADPHONES.1. REPLACE BATTERIES.

2. CLOSENESS TO

RADIO TRANSMITTER

SUCH AS A RADIO

TOWER, AIRPORT

TRANSMITTER OR

SOME MOBILE

RADIOS.2. MOVE TO AN AREA AWAY FREE FROM THESE

CONDITIONS.

REMOTE

CONTROL

INOPERATIVE1. WEAK BATTERIES IN

THE REMOTE

CONTROL.1. REPLACE BATTERIES.

2. OPERATION

CONSTRAINT OF

SYSTEM2. MAKE SURE THAT REAR AUDIO IS IN A DIFFERENT MODE

THAN FRONT SPEAKERS. REMOTE CONTROL WILL NOT

WORK WHEN BOTH ARE IN THE SAME MODE.

ANTENNA BODY AND CABLE

DESCRIPTION

All models use a fixed-length stainless steel rod-

type antenna mast, installed at the right front fender

of the vehicle. The antenna mast is connected to the

center wire of the coaxial antenna cable, and is not

grounded to any part of the vehicle.

OPERATION

To minimize static, the antenna base must have a

good ground. The coaxial antenna cable shield (the

outer wire mesh of the cable) is grounded to the

antenna base and the radio chassis.

The antenna coaxial cable has an additional dis-

connect, located near the right end of the instrument

panel. This additional disconnect allows the instru-

ment panel assembly to be removed and installed

without removing the radio.

DIAGNOSIS AND TESTING - ANTENNA BODY

AND CABLE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

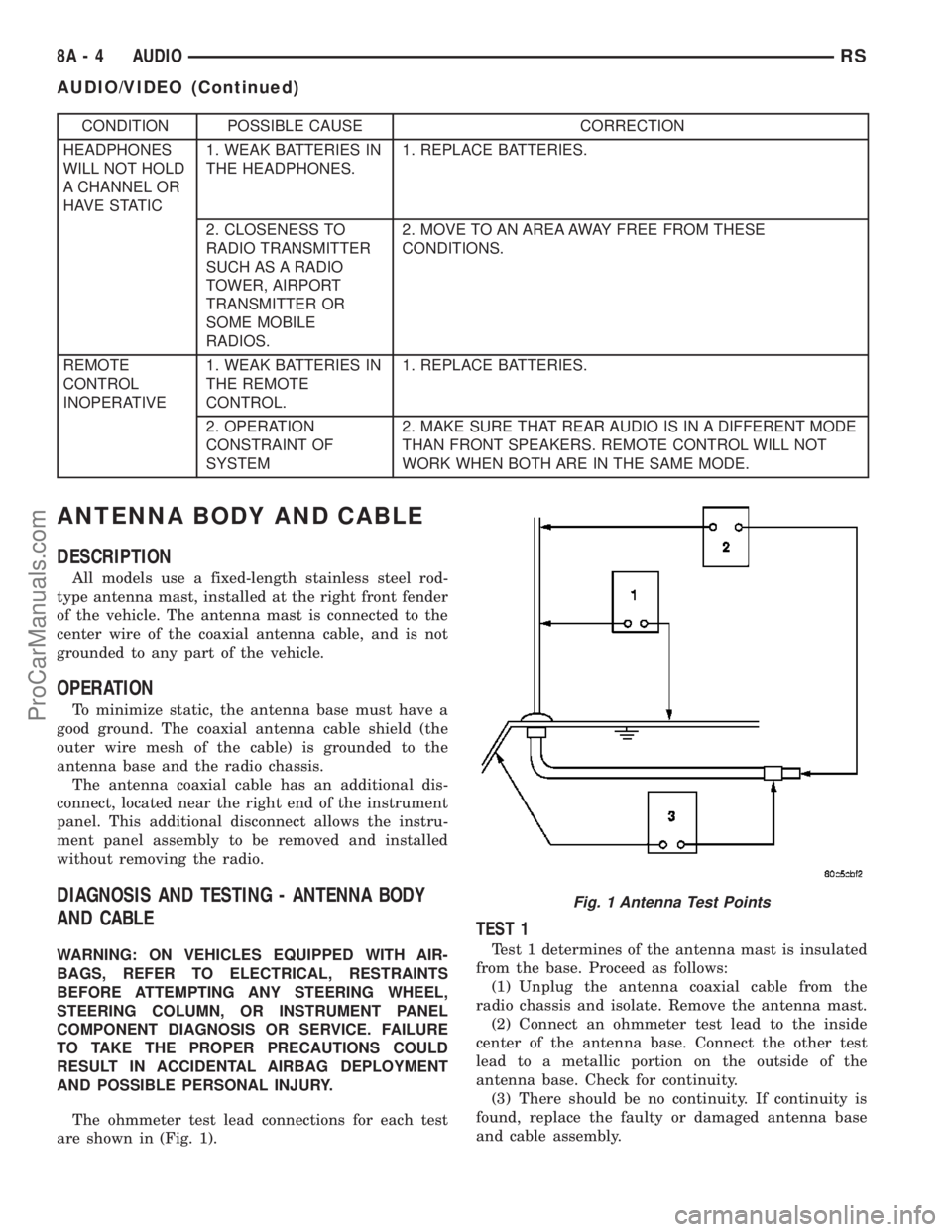

The ohmmeter test lead connections for each test

are shown in (Fig. 1).

TEST 1

Test 1 determines of the antenna mast is insulated

from the base. Proceed as follows:

(1) Unplug the antenna coaxial cable from the

radio chassis and isolate. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to a metallic portion on the outside of the

antenna base. Check for continuity.

(3) There should be no continuity. If continuity is

found, replace the faulty or damaged antenna base

and cable assembly.

Fig. 1 Antenna Test Points

8A - 4 AUDIORS

AUDIO/VIDEO (Continued)

ProCarManuals.com

Page 302 of 2177

TEST 2

Test 2 checks the antenna for an open circuit as

follows:

(1) Unplug the antenna coaxial cable connector

from the radio chassis. Remove the antenna mast.

(2) Connect an ohmmeter test lead to the inside

center of the antenna base. Connect the other test

lead to the center pin of the antenna coaxial cable

connector.

(3) Continuity should exist (the ohmmeter should

only register a fraction of an ohm). High or infinite

resistance indicates damage to the base and cable

assembly. Replace the faulty base and cable if

required.

TEST 3

Test 3 checks the condition of the ground between

the antenna base and the vehicle body as follows:

(1) Connect one ohmmeter test lead to the fender

on an exposed metal area. Connect the other test

lead to the outer crimp on the antenna coaxial cable

connector.(2) The resistance should be less than (1) ohm.

(3) If the resistance is more than (1) ohm, clean

and/or tighten the antenna base to the fender mount-

ing hardware.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove glove box from instrument panel,

(Refer to 23 - BODY/INSTRUMENT PANEL/GLOVE

BOX - REMOVAL).

(3) Disconnect antenna cable connector from exten-

sion cable (Fig. 2).

(4) Remove right kick trim panel.

(5) Disengage rubber grommet insulator from door

hinge pillar.

(6) Pull antenna cable through hinge pillar into

opening between door hinges.

(7) Hoist and support vehicle on safety stands.

(8) Remove front wheel.

(9) Remove front wheelhouse splash shield. (Refer

to 23 - BODY/EXTERIOR/LF WHEELHOUSE

SPLASH SHIELD - REMOVAL).

Fig. 2 Antenna Cable

1 - CAP NUT

2 - ADAPTER

3 - FENDER

4 - CABLE TO RADIO (EXTENSION CABLE)5 - A-PILLAR

6 - RUBBER GROMMET

7 - ANTENNA CABLE AND BODY ASSEMBLY

8 - RUBBER GROMMET

RSAUDIO8A-5

ANTENNA BODY AND CABLE (Continued)

ProCarManuals.com

Page 303 of 2177

(10) Remove antenna mast from antenna base

(Fig. 3).

(11) Using cap nut tool, remove cap nut holding

antenna base to front fender (Fig. 4).(12) Remove antenna base from under front

fender.

INSTALLATION

(1) Install antenna base to underside of front

fender.

(2) Install cap nut holding antenna base to front

fender.

(3) Install antenna mast to antenna base.

(4) Install front wheelhouse splash shield.

(5) Install front wheel.

(6) Lower vehicle.

(7) Push antenna cable through opening in hinge

pillar.

(8) Insert rubber grommet into door hinge pillar.

(9) Install kick panel.

(10) Connect antenna cable connector to extension

cable.

(11) Install glove box to instrument panel.

(12) Connect the battery negative cable.

ANTENNA MODULE - EXPORT

DESCRIPTION

The antenna module is an electromagnetic circuit

component designed to capture and enhance RF

(Radio Frequency) signals in both the AM and FM

broadcast bands. The antenna module is mounted to

the right rear roof rail under the headliner. The mod-

ule is grounded through the mounting bracket and

fastener. The module has a two wire electrical con-

nector that connects to the integral radio antenna,

located on the right rear quarter glass. There is also

an electrical connector for battery voltage and a coax

cable connector.

OPERATION

The antenna module receives both AM and FM

radio signals supplied by the side window integral

radio antenna system and selectively amplifies them.

The amplified signal is then sent through the body

length coax cable to the radio input.

Fig. 3 Antenna Mast

1 - ANTENNA MAST

2 - ADAPTER

3 - CAP NUT

Fig. 4 Antenna Cap Nut

1 - CAP NUT

2 - ANTENNA ADAPTER

3 - TOOL

8A - 6 AUDIORS

ANTENNA BODY AND CABLE (Continued)

ProCarManuals.com