ignition CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 352 of 2177

CONVENTIONAL BATTERY CHARGING TIME TABLE

Charging

Amperage5 Amps10

Amps20 Amps

Open Circuit

VoltageHours Charging @ 21É C

(70É F)

12.25 to 12.49 6 hours 3 hours 1.5

hours

12.00 to 12.24 10 hours 5 hours 2.5

hours

10.00 to 11.99 14 hours 7 hours 3.5

hours

Below 10.00 18 hours 9 hours 4.5

hours

STANDARD PROCEDURE - OPEN-CIRCUIT

VOLTAGE TEST

A battery open-circuit voltage (no load) test will

show the approximate state-of-charge of a battery.

This test can be used if no other battery tester is

available.

Before proceeding with this test, completely charge

the battery. Refer to Standard Procedures for the

proper battery charging procedures.

(1) Before measuring the open-circuit voltage, the

surface charge must be removed from the battery.

Turn on the headlamps for fifteen seconds, then

allow up to five minutes for the battery voltage to

stabilize.

(2) Disconnect and isolate both battery cables, neg-

ative cable first.

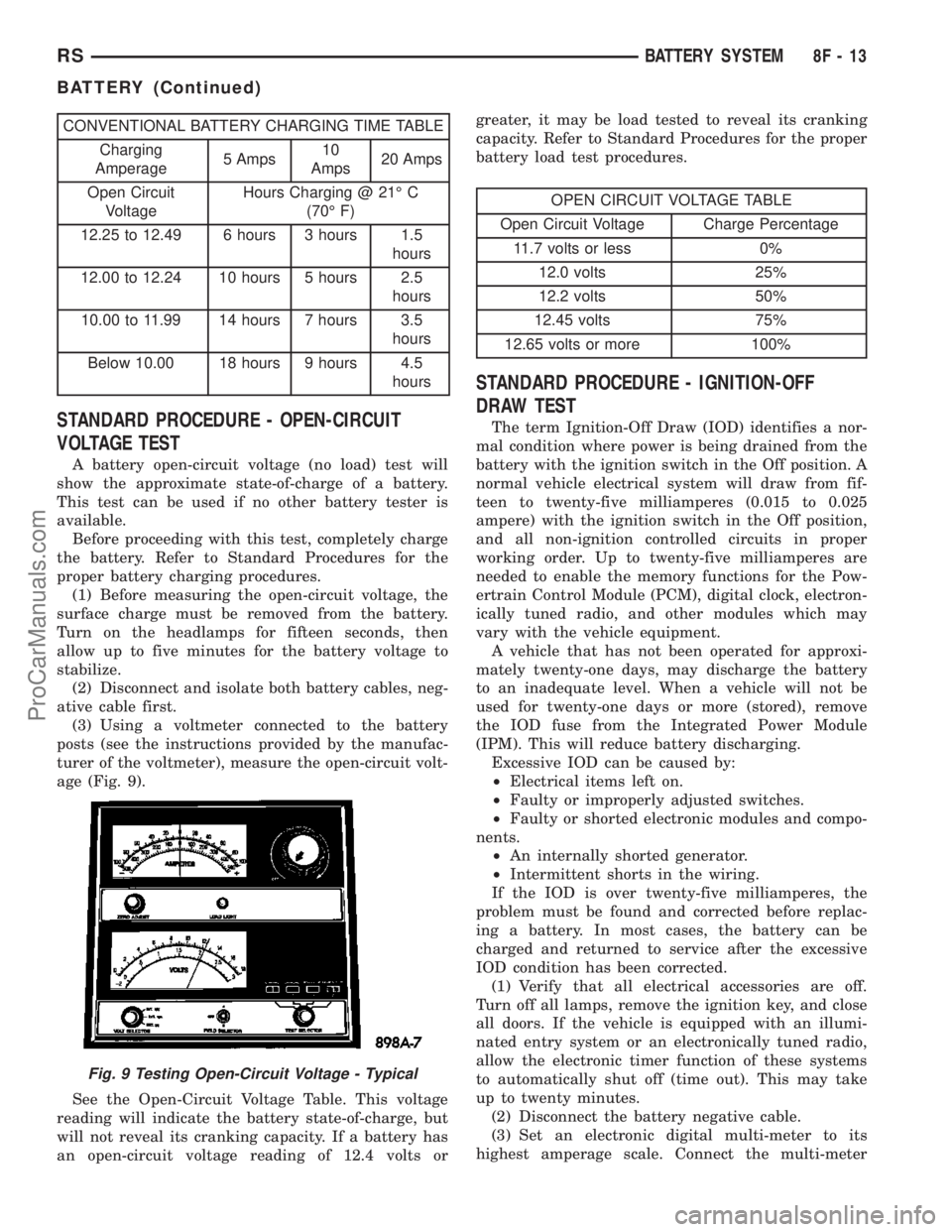

(3) Using a voltmeter connected to the battery

posts (see the instructions provided by the manufac-

turer of the voltmeter), measure the open-circuit volt-

age (Fig. 9).

See the Open-Circuit Voltage Table. This voltage

reading will indicate the battery state-of-charge, but

will not reveal its cranking capacity. If a battery has

an open-circuit voltage reading of 12.4 volts orgreater, it may be load tested to reveal its cranking

capacity. Refer to Standard Procedures for the proper

battery load test procedures.

OPEN CIRCUIT VOLTAGE TABLE

Open Circuit Voltage Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.45 volts 75%

12.65 volts or more 100%

STANDARD PROCEDURE - IGNITION-OFF

DRAW TEST

The term Ignition-Off Draw (IOD) identifies a nor-

mal condition where power is being drained from the

battery with the ignition switch in the Off position. A

normal vehicle electrical system will draw from fif-

teen to twenty-five milliamperes (0.015 to 0.025

ampere) with the ignition switch in the Off position,

and all non-ignition controlled circuits in proper

working order. Up to twenty-five milliamperes are

needed to enable the memory functions for the Pow-

ertrain Control Module (PCM), digital clock, electron-

ically tuned radio, and other modules which may

vary with the vehicle equipment.

A vehicle that has not been operated for approxi-

mately twenty-one days, may discharge the battery

to an inadequate level. When a vehicle will not be

used for twenty-one days or more (stored), remove

the IOD fuse from the Integrated Power Module

(IPM). This will reduce battery discharging.

Excessive IOD can be caused by:

²Electrical items left on.

²Faulty or improperly adjusted switches.

²Faulty or shorted electronic modules and compo-

nents.

²An internally shorted generator.

²Intermittent shorts in the wiring.

If the IOD is over twenty-five milliamperes, the

problem must be found and corrected before replac-

ing a battery. In most cases, the battery can be

charged and returned to service after the excessive

IOD condition has been corrected.

(1) Verify that all electrical accessories are off.

Turn off all lamps, remove the ignition key, and close

all doors. If the vehicle is equipped with an illumi-

nated entry system or an electronically tuned radio,

allow the electronic timer function of these systems

to automatically shut off (time out). This may take

up to twenty minutes.

(2) Disconnect the battery negative cable.

(3) Set an electronic digital multi-meter to its

highest amperage scale. Connect the multi-meter

Fig. 9 Testing Open-Circuit Voltage - Typical

RSBATTERY SYSTEM8F-13

BATTERY (Continued)

ProCarManuals.com

Page 354 of 2177

REMOVAL - BATTERY

WARNING: A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES AND SAFETY GLASSES SHOULD

BE WORN WHEN REMOVING OR SERVICING A

BATTERY.

WARNING: REMOVE METALLIC JEWELRY TO

AVOID INJURY BY ACCIDENTAL ARCING OF BAT-

TERY CURRENT.

(1) Verify that the ignition switch and all accesso-

ries are OFF.

(2) Disconnect the battery cables from the battery

posts, negative first (Fig. 12).

(3) Remove the battery hold down retaining nut.

(4) Remove the battery hold down bracket.

(5) Remove the battery from the vehicle.

INSTALLATION

(1) Position the battery in the battery tray.

(2) Install the battery hold down bracket and

retaining nut. Torque the nut to 20 N´m (180 in. lbs.).

(3) Connect the battery cables to the battery posts,

positive cable first. Torque terminal fasteners to 5

N´m (40 in. lbs.).

BATTERY HOLDDOWN

DESCRIPTION

The battery hold down hardware consists of a

molded plastic lip that is integral to the outboard

edge of the battery tray and support unit, a molded

steel hold down bracket and a single hex nut with a

coned washer.

When installing a battery into the battery tray, be

certain that the hold down hardware is properly

installed and that the fasteners are tightened to the

proper specifications. Improper hold down fastener

tightness, whether too loose or too tight, can result in

damage to the battery, the vehicle or both. Refer to

Battery Hold Downsin this section of this service

manual for the location of the proper battery hold

down installation procedures, including the proper

hold down fastener tightness specifications.

OPERATION

The battery holddown secures the battery in the

battery tray. This holddown is designed to prevent

battery movement during the most extreme vehicle

operation conditions. Periodic removal and lubrica-

tion of the battery holddown hardware is recom-

mended to prevent hardware seizure at a later date.

Fig. 11 HOOK INSIDE BATTERY CELLS - LOW-

MAINTENANCE BATTERY ONLY

1 - TOP OF BATTERY

2 - HOOK INSIDE BATTERY CELLS

Fig. 12 BATTERY POSITION & ORIENTATION

1 - BATTERY THERMOWRAP (IF EQUIPPED)

2 - INTEGRATED POWER MODULE

3 - FRONT CONTROL MODULE

RSBATTERY SYSTEM8F-15

BATTERY (Continued)

ProCarManuals.com

Page 355 of 2177

NOTE: Never operate a vehicle without a battery

holddown device properly installed. Damage to the

vehicle, components and battery could result.

REMOVAL

All of the battery hold down hardware can be ser-

viced without removal of the battery or the battery

tray and support unit.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Remove the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit.

(3) Remove the battery hold down bracket from

the battery tray and support unit.

INSTALLATION

(1) Install the battery hold down bracket in the

battery tray and support unit.

(2) Install the nut with washer that secures the

battery hold down bracket to the battery tray and

support unit. Torque to 20 N´m (180 in. lbs.).

BATTERY CABLES

DESCRIPTION

The battery cables are large gauge, stranded cop-

per wires sheathed within a heavy plastic or syn-

thetic rubber insulating jacket. The wire used in the

battery cables combines excellent flexibility and reli-

ability with high electrical current carrying capacity.

Refer toWiring Diagramsin the index of this ser-

vice manual for the location of the proper battery

cable wire gauge information.

A clamping type female battery terminal made of

stamped metal is attached to one end of the battery

cable wire. A square headed pinch-bolt and hex nut

are installed at the open end of the female battery

terminal clamp. Large eyelet type terminals are

crimped onto the opposite end of the battery cable

wire and then solder-dipped. The battery positive

cable wires have a red insulating jacket to provide

visual identification and feature a larger female bat-

tery terminal clamp to allow connection to the larger

battery positive terminal post. The battery negative

cable wires have a black insulating jacket and a

smaller female battery terminal clamp.

The battery cables cannot be repaired and, if dam-

aged or faulty they must be replaced. Both the bat-

tery positive and negative cables are available for

service replacement only as a unit with the battery

wire harness, which may include portions of the wir-

ing circuits for the generator and other components

on some models. Refer toWiring Diagramsin theindex of this service manual for the location of more

information on the various wiring circuits included in

the battery wire harness for the vehicle being ser-

viced.

OPERATION

The battery cables connect the battery terminal

posts to the vehicle electrical system. These cables

also provide a path back to the battery for electrical

current generated by the charging system for restor-

ing the voltage potential of the battery. The female

battery terminal clamps on the ends of the battery

cable wires provide a strong and reliable connection

of the battery cable to the battery terminal posts.

The terminal pinch bolts allow the female terminal

clamps to be tightened around the male terminal

posts on the top of the battery. The eyelet terminals

secured to the opposite ends of the battery cable

wires from the female battery terminal clamps pro-

vide secure and reliable connection of the battery

cables to the vehicle electrical system.

The battery positive cable terminal clamp is

attached to the ends of two wires. One wire has an

eyelet terminal that connects the battery positive

cable to the B(+) terminal stud of the Integrated

Power Module (IPM), and the other wire has an eye-

let terminal that connects the battery positive cable

to the B(+) terminal stud of the engine starter motor

solenoid. The battery negative cable terminal clamp

is also attached to the ends of two wires. One wire

has an eyelet terminal that connects the battery neg-

ative cable to the vehicle powertrain through a stud

on the left side of the engine cylinder block. The

other wire has an eyelet terminal that connects the

battery negative cable to the vehicle body through a

ground screw on the left front fender inner shield,

near the battery.

DIAGNOSIS AND TESTING - BATTERY CABLE

A voltage drop test will determine if there is exces-

sive resistance in the battery cable terminal connec-

tions or the battery cable. If excessive resistance is

found in the battery cable connections, the connec-

tion point should be disassembled, cleaned of all cor-

rosion or foreign material, then reassembled.

Following reassembly, check the voltage drop for the

battery cable connection and the battery cable again

to confirm repair.

When performing the voltage drop test, it is impor-

tant to remember that the voltage drop is giving an

indication of the resistance between the two points at

which the voltmeter probes are attached.EXAM-

PLE:When testing the resistance of the battery pos-

itive cable, touch the voltmeter leads to the battery

positive cable terminal clamp and to the battery pos-

itive cable eyelet terminal at the starter solenoid

8F - 16 BATTERY SYSTEMRS

BATTERY HOLDDOWN (Continued)

ProCarManuals.com

Page 356 of 2177

B(+) terminal stud. If you probe the battery positive

terminal post and the battery positive cable eyelet

terminal at the starter solenoid B(+) terminal stud,

you are reading the combined voltage drop in the

battery positive cable terminal clamp-to-terminal

post connection and the battery positive cable.

VOLTAGE DROP TEST

The following operation will require a voltmeter

accurate to 1/10 (0.10) volt. Before performing this

test, be certain that the following procedures are

accomplished:

²The battery is fully-charged and load tested.

Refer to Standard Procedures for the proper battery

charging and load test procedures.

²Fully engage the parking brake.

²If the vehicle is equipped with an automatic

transmission, place the gearshift selector lever in the

Park position. If the vehicle is equipped with a man-

ual transmission, place the gearshift selector lever in

the Neutral position and block the clutch pedal in the

fully depressed position.

²Verify that all lamps and accessories are turned

off.

²To prevent the engine from starting, remove the

Automatic Shut Down (ASD) relay. The ASD relay is

located in the Intelligent Power Module (IPM), in the

engine compartment. See the fuse and relay layout

label affixed to the underside of the IPM cover for

ASD relay identification and location.

(1) Connect the positive lead of the voltmeter to

the battery negative terminal post. Connect the neg-

ative lead of the voltmeter to the battery negative

cable terminal clamp (Fig. 13). Rotate and hold the

ignition switch in the Start position. Observe the

voltmeter. If voltage is detected, correct the poor con-

nection between the battery negative cable terminal

clamp and the battery negative terminal post.

(2) Connect the positive lead of the voltmeter to

the battery positive terminal post. Connect the nega-

tive lead of the voltmeter to the battery positive cable

terminal clamp (Fig. 14). Rotate and hold the ignition

switch in the Start position. Observe the voltmeter. If

voltage is detected, correct the poor connection

between the battery positive cable terminal clamp

and the battery positive terminal post.

(3) Connect the voltmeter to measure between the

battery positive cable terminal clamp and the starter

solenoid B(+) terminal stud (Fig. 15). Rotate and hold

the ignition switch in the Start position. Observe the

voltmeter. If the reading is above 0.2 volt, clean and

tighten the battery positive cable eyelet terminal con-

nection at the starter solenoid B(+) terminal stud.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery positive cable.(4) Connect the voltmeter to measure between the

battery negative cable terminal clamp and a good

clean ground on the engine block (Fig. 16). Rotate

and hold the ignition switch in the Start position.

Observe the voltmeter. If the reading is above 0.2

volt, clean and tighten the battery negative cable

eyelet terminal connection to the engine block.

Repeat the test. If the reading is still above 0.2 volt,

replace the faulty battery negative cable.

Fig. 13 Testing Battery Negative Connection

Resistance

1 - VOLTMETER

2 - BATTERY

Fig. 14 Testing Battery Positive Connection

Resistance

1 - VOLTMETER

2 - BATTERY

RSBATTERY SYSTEM8F-17

BATTERY CABLES (Continued)

ProCarManuals.com

Page 357 of 2177

REMOVAL

The battery cables on this model may include por-

tions of wiring circuits for the generator and other

components on the vehicle. If battery cable replace-

ment is required, it will be necessary to extract the

cables out of the engine wire harness assembly. Use

care not to damage the other wires and circuits

which are also packaged into the engine wire harness

assembly.

(1) Turn the ignition switch to the Off position. Be

certain that all electrical accessories are turned off.

(2) Disconnect and isolate the negative battery

cable terminal.

(3) Remove the battery thermowrap (if equipped)

from the battery tray.

(4) Remove the tape from the engine wire harness

assembly, to access the desired battery cable.(5) One at a time, trace and disconnect the battery

cable retaining fasteners and routing clips until the

desired cable is free from the vehicle.

(6) Feed the battery cable out of the vehicle.

INSTALLATION

(1) Position the battery cable in the vehicle.

(2) One at a time, trace and install the battery

cable retaining fasteners and routing clips until the

desired cable is properly installed in the engine wire

harness assembly.

(3) Install the tape on the engine wire harness

assembly.

(4) Install the battery thermowrap (if equipped) on

the battery tray.

(5) Connect the negative battery cable terminal.

BATTERY TRAY

DESCRIPTION

The battery is mounted in a molded plastic battery

tray and support unit located in the left front corner

of the engine compartment. The battery tray and

support unit is secured with two nuts, one is located

directly under the battery and the other is located on

the right side of the tray which also serves as a cool-

ant bottle neck retaining bolt. An additional bolt is

located directly under the battery.

Fig. 15 Testing Battery Positive Cable Resistance

1 - BATTERY

2 - VOLTMETER

3 - STARTER MOTOR

Fig. 16 Testing Ground Circuit Resistance

1 - VOLTMETER

2 - BATTERY

3 - ENGINE GROUND

Fig. 17 RS BATTERY TRAY

1 - ENGINE VACUUM RESERVOIR

2 - BATTERY TRAY ASSEMBLY

3 - DRAINAGE HOSE

8F - 18 BATTERY SYSTEMRS

BATTERY CABLES (Continued)

ProCarManuals.com

Page 359 of 2177

CHARGING

TABLE OF CONTENTS

page page

CHARGING

DESCRIPTION - CHARGING SYSTEM.......20

OPERATION - CHARGING SYSTEM.........20

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM.................21

SPECIFICATIONS

GENERATOR........................22

TORQUE............................22

SPECIFICATIONS - BATTERY

TEMPERATURE SENSOR...............22

SPECIAL TOOLS.......................23

BATTERY TEMPERATURE SENSOR

DESCRIPTION.........................23

OPERATION...........................23

REMOVAL.............................23

GENERATOR

DESCRIPTION.........................23OPERATION...........................23

REMOVAL

REMOVAL - 2.4L......................23

REMOVAL - 3.3/3.8L...................24

INSTALLATION

INSTALLATION - 2.4L..................24

INSTALLATION - 3.3/3.8L................24

GENERATOR DECOUPLER PULLEY

DESCRIPTION.........................25

OPERATION...........................25

DIAGNOSIS AND TESTING - GENERATOR

DECOUPLER PULLEY..................25

REMOVAL.............................26

INSTALLATION.........................26

VOLTAGE REGULATOR

DESCRIPTION.........................27

OPERATION...........................27

CHARGING

DESCRIPTION - CHARGING SYSTEM

The charging system consists of:

²Generator

²Decoupler Pulley (If equipped)

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to the Ignition System sec-

tion for information)

²Battery (refer to the Battery section for informa-

tion)

²Ambient Air Temperature (If equipped)

²Inlet Air Temperature (calculated battery tem-

perature)(If equipped)

²Voltmeter (refer to the Instrument Cluster sec-

tion for information if equipped)

²Wiring harness and connections (refer to the

Wiring section for information)

²Accessory drive belt (refer to the Cooling section

for more information)

²Battery Temperature sensor (if equipped)

OPERATION - CHARGING SYSTEM

The charging system is turned on and off with the

ignition switch. The system is on when the engine is

running and the ASD relay is energized. The ASD

relay is energized when the PCM grounds the ASD

control circuit. (SBEC vehicles) This voltage is con-

nected through the PCM or IPM (intelligent powermodule) (if equipped) and supplied to one of the gen-

erator field terminals (Gen. Source +) at the back of

the generator.

The generator is driven by the engine through a

serpentine belt and pulley or decoupler pulley

arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

(SBEC vehicles) An Inlet air temperature sensor is

used to calculate the temperature near the battery.

This temperature data, along with data from moni-

tored line voltage (battery voltage sense circuit), is

used by the PCM to vary the battery charging rate.

This is done by cycling the ground path to control the

strength of the rotor magnetic field. The PCM then

compensates and regulates generator current output

accordingly to maintain system voltage at the tar-

geted system voltage based on battery temperature.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including EVR

(field control) circuitry, are monitored by the PCM.

Each monitored circuit is assigned a Diagnostic Trou-

ble Code (DTC). The PCM will store a DTC in elec-

tronic memory for certain failures it detects and

illuminate the (MIL) lamp. Refer to On-Board Diag-

nostics in the Electronic Control Modules(Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

8F - 20 CHARGINGRS

ProCarManuals.com

Page 360 of 2177

ULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) section for more DTC information.

The Check Gauges Lamp (if equipped) or Battery

Lamp monitors:charging system voltage,engine

coolant temperature and engine oil pressure. If an

extreme condition is indicated, the lamp will be illu-

minated. The signal to activate the lamp is sent via

the PCI bus circuits. The lamp is located on the

instrument panel. Refer to the Instrument Cluster

section for additional information.

(If equipped with inlet air temperature sensor) The

PCM uses the inlet air temperature sensor to control

the charge system voltage. This temperature, along

with data from monitored line voltage, is used by the

PCM to vary the battery charging rate. The system

voltage is higher at cold temperatures and is gradu-

ally reduced as the calculated battery temperature

increases.

The ambient temperature sensor is used to control

the battery voltage based upon ambient temperature

(approximation of battery temperature). The PCM

maintains the optimal output of the generator by

monitoring battery voltage and controlling it to a

range of 13.5 - 14.7 volts based on battery tempera-

ture. The system target voltage is 13.5 ± 14.7 volts.

However the actual voltage go below this during

heavy electrical loads and generator speeds. Also the

actual voltage can be lower than the target voltage

between the battery and the battery voltage sense

circuit, approximately 0.2 Ð 0.3 volts.

DIAGNOSIS AND TESTING - ON-BOARD

DIAGNOSTIC SYSTEM

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the OBD system. Some

circuits are checked continuously and some are

checked only under certain conditions.

If the OBD system senses that a monitored circuit

is bad, it will put a DTC into electronic memory. The

DTC will stay in electronic memory as long as the

circuit continues to be bad. The PCM is programmed

to clear the memory after 40 good trip if the problem

does not occur again.

DIAGNOSTIC TROUBLE CODES

A DTC description can be read using the DRBIIIt

scan tool. Refer to the appropriate Powertrain Diag-

nostic Procedures manual for information.

A DTC does not identify which component in a cir-

cuit is bad. Thus, a DTC should be treated as a

symptom, not as the cause for the problem. In some

cases, because of the design of the diagnostic test

procedure, a DTC can be the reason for another DTCto be set. Therefore, it is important that the test pro-

cedures be followed in sequence, to understand what

caused a DTC to be set.

ERASING DIAGNOSTIC TROUBLE CODES

The DRBIIItScan Tool must be used to erase a

DTC.

The following procedures may be used to diagnose

the charging system if:

²the check gauges lamp or battery lamp is illumi-

nated with the engine running

²the voltmeter (if equipped) does not register

properly

²an undercharged or overcharged battery condi-

tion occurs.

Remember that an undercharged battery is often

caused by:

²accessories being left on with the engine not

running

²a faulty or improperly adjusted switch that

allows a lamp to stay on. Refer to Ignition-Off Draw

Test (Refer to 8 - ELECTRICAL/BATTERY SYSTEM/

BATTERY - STANDARD PROCEDURE)

²loose generator belt.

INSPECTION

The Powertrain Control Module (PCM) monitors

critical input and output circuits of the charging sys-

tem, making sure they are operational. A Diagnostic

Trouble Code (DTC) is assigned to each input and

output circuit monitored by the On-Board Diagnostic

(OBD) system. Some charging system circuits are

checked continuously, and some are checked only

under certain conditions.

Refer to Diagnostic Trouble Codes in; Powertrain

Control Module; Electronic Control Modules for more

DTC information. This will include a complete list of

DTC's including DTC's for the charging system.

To perform a complete test of the charging system,

refer to the appropriate Powertrain Diagnostic Proce-

dures service manual and the DRBIIItscan tool.

Perform the following inspections before attaching

the scan tool.

(1) Inspect the battery condition. Refer to the Bat-

tery section (Refer to 8 - ELECTRICAL/BATTERY

SYSTEM - DIAGNOSIS AND TESTING) for proce-

dures.

(2) Inspect condition of battery cable terminals,

battery posts, connections at engine block, starter

solenoid and relay. They should be clean and tight.

Repair as required.

(3) Inspect all fuses in both the fuseblock and

Power Distribution Center (PDC) or IPM (if

equipped) for tightness in receptacles. They should be

properly installed and tight. Repair or replace as

required.

RSCHARGING8F-21

CHARGING (Continued)

ProCarManuals.com

Page 367 of 2177

STARTING

TABLE OF CONTENTS

page page

STARTING

DESCRIPTION.........................28

OPERATION...........................28

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST.......................28

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST........................30

DIAGNOSIS AND TESTING - FEED CIRCUIT

RESISTANCE TEST....................32

DIAGNOSIS AND TESTING - FEED CIRCUIT

TEST...............................33SPECIFICATIONS

Torques.............................33

STARTER ...........................34

STARTER MOTOR

REMOVAL

REMOVAL - 2.4L......................34

REMOVAL - 3.3/3.8L...................35

INSTALLATION

INSTALLATION - 2.4L..................35

INSTALLATION - 3.3/3.8L................36

STARTING

DESCRIPTION

The starting system consists of:

²Starter relay

²Starter motor (including an integral starter sole-

noid)

Other components to be considered as part of start-

ing system are:

²Battery

²Battery cables

²Ignition switch and key lock cylinder

²Clutch pedal position switch (manual transmis-

sion)

²Park/neutral position switch (automatic trans-

mission)

²Wire harnesses and connections.

The Battery, Starting, and Charging systems oper-

ate in conjunction with one another, and must be

tested as a complete system. For correct operation of

starting/charging systems, all components used in

these 3 systems must perform within specifications.

When attempting to diagnose any of these systems, it

is important that you keep their interdependency in

mind.

The diagnostic procedures used in each of these

groups include the most basic conventional diagnostic

methods, to the more sophisticated On-Board Diag-

nostics (OBD) built into the Powertrain Control Mod-

ule (PCM). Use of an induction-type milliampere

ammeter, volt/ohmmeter, battery charger, carbon pile

rheostat (load tester), and 12-volt test lamp may be

required.

OPERATION

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The PCM controls a double start over-ride safety

that does not allow the starter to be engaged if the

engine is already running.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - STARTING

SYSTEM TEST

For circuit descriptions and diagrams, refer to the

Wiring Diagrams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO THE PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

INSPECTION

Before removing any unit from the starting system

for repair or diagnosis, perform the following inspec-

tions:

²Battery- Visually inspect the battery for indi-

cations of physical damage and loose or corroded

cable connections. Determine the state-of-charge and

cranking capacity of the battery. Charge or replace

8F - 28 STARTINGRS

ProCarManuals.com

Page 368 of 2177

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

RSSTARTING8F-29

STARTING (Continued)

ProCarManuals.com

Page 369 of 2177

CONDITION POSSIBLE CAUSE CORRECTION

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. STARTER ASSEMBLY

FAULTY.3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. ENGINE SEIZED. 4. REFER TO THE ENGINE SECTION, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.5. INSPECT FOR LOOSE CONNECTIONS.

6. FAULTY TEETH ON

RING GEAR.6. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

8F - 30 STARTINGRS

STARTING (Continued)

ProCarManuals.com