power steering CHRYSLER CARAVAN 2003 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 436 of 2177

MULTI-FUNCTION SWITCH

DESCRIPTION - TURN SIGNAL SYSTEM

The turn signals are actuated with a lever on

Multi-Function Switch, located on the left side of the

steering wheel. The signals are automatically turned

off by a canceling cam (two lobes molded to the clock

spring mechanism). The cam comes in contact with

the cancel actuator on the turn signal (multi-func-

tion) switch assembly. Either cam lobe, pushing on

the cancel actuator, returns the switch to the OFF

position. The multi-function switch is a resistive

MUX switch that feeds inputs to the BCM.

OPERATION - TURN SIGNAL SYSTEM

Lane change signaling is actuated by applying par-

tial turn signal stalk movement toward the direction

desired until the indicator lamps flashes in the

instrument cluster. When the switch stalk is released

the stalk will spring back into the neutral position

turning OFF the turn signal.

With the ignition switch ON and the turn signal

switch stalk actuated left or right, current flows

through the:

²Multi-function switch

²Body Control Module

²Integrated Power Module (IPM)

²Turn indicator lamp

²Front and rear turn signal bulbs.

A chime will sound after the vehicle has traveled a

distance of approximately 1.0 mile and a speed of 15

mph, with the turn signal ON.

DIAGNOSIS AND TESTING - MULTI-FUNCTION

SWITCH

To test turn signal, headlamp beam select and opti-

cal horn portion of the multi-function switch:(1) Remove the multi-function switch, refer to

Electrical, Lamps/Lighting - Exterior, Multi-Function

Switch, Removal, and Installation.

(2) Using an ohmmeter check the resistance read-

ings between multi-function switch pins. Refer to

Wiring Diagrams for proper pin numbers and the

MULTI-FUNCTION SWITCH RESISTANCE table.

MULTI-FUNCTION SWITCH RESISTANCE

SWITCH

POSITIONPIN NUMBER RESISTANCE

LEFT 2 AND 3 2.7V 5%

RIGHT 2 AND 3 1KV 5%

OPTICAL

HORN2 AND 4 1.7KV 5%

HI BEAM 2 AND 4 2.32KV 5%

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove upper and lower steering column

shrouds. Refer to Steering, Column, Shroud,

Removal.

(3) Disconnect wire connector from back of multi-

function switch.

(4) Remove screws holding multi-function switch to

steering column adapter collar.

(5) Remove the multi-function switch.

INSTALLATION

(1) Position the switch on to the steering column.

(2) Install the two retaining screws.

(3) Connect the wire harness connector.

(4) Install the upper and lower steering column

shrouds. Refer to Steering, Column, Shroud, Installa-

tion.

(5) Connect the battery negative cable.

PARK/TURN SIGNAL LAMP

REMOVAL

(1) Disconnect and isolate battery negative cable.

(2) Remove headlamp retaining screws.

(3) Twist socket counter - clockwise and remove

(Fig. 27).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Twist socket into headlamp.

(3) Install headlamp retaining screws.

(4) Reconnect battery negative cable.

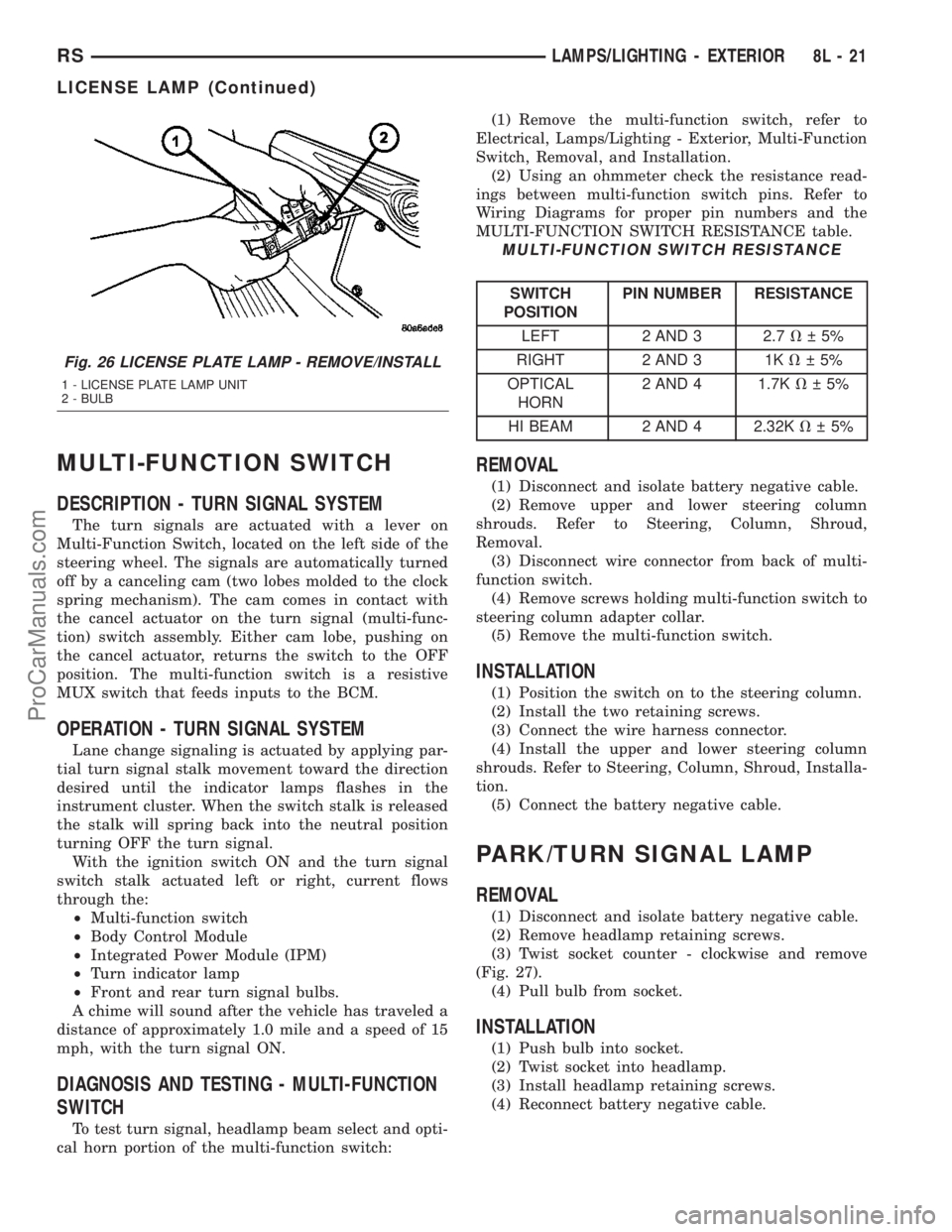

Fig. 26 LICENSE PLATE LAMP - REMOVE/INSTALL

1 - LICENSE PLATE LAMP UNIT

2 - BULB

RSLAMPS/LIGHTING - EXTERIOR8L-21

LICENSE LAMP (Continued)

ProCarManuals.com

Page 503 of 2177

ered. This defeats the day-detect logic. If OK, go to

Step 8. If not OK, replace the faulty mirror unit.

(8) With the mirror darkened, place the transmis-

sion gear selector lever in the Reverse position. The

automatic day/night mirror should return to its nor-

mal reflectance. If not OK, replace the faulty mirror

unit.

Bench testing both mirrors can be done, of care is

exercised. For an inside mirror, the pin closest to he

mount is 12V (+), the next is 12V (-). The third is

reverse override. The fourth is outside mirror (+),

and the fifth is outside mirror (-).Do not apply 12

volts to the fourth and fifth pins.With 12 volts

on pins 1 and 2, the mirror can be tested by blocking

the rear sensor and shining a light into the forward

sensor. For an outside mirror, there is a 2±pin con-

nector. Applying 1.2 volts will cause the mirror to

dim. If the mirror does not dim, the entire glass

assembly can be replaced just as it is when the glass

is broken.

WARNING: Do not apply 12 volts to the outside mir-

ror. Damage to the mirror will result.

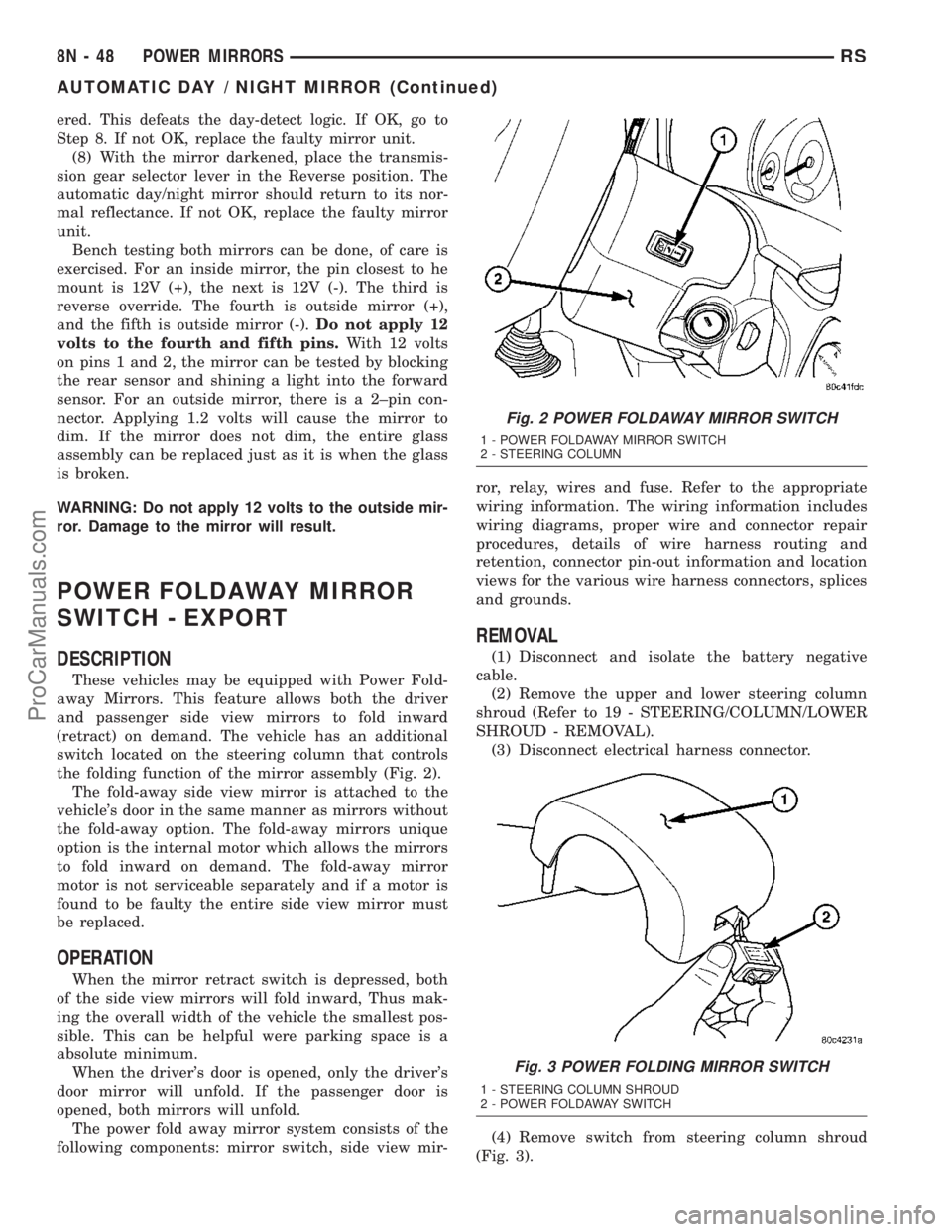

POWER FOLDAWAY MIRROR

SWITCH - EXPORT

DESCRIPTION

These vehicles may be equipped with Power Fold-

away Mirrors. This feature allows both the driver

and passenger side view mirrors to fold inward

(retract) on demand. The vehicle has an additional

switch located on the steering column that controls

the folding function of the mirror assembly (Fig. 2).

The fold-away side view mirror is attached to the

vehicle's door in the same manner as mirrors without

the fold-away option. The fold-away mirrors unique

option is the internal motor which allows the mirrors

to fold inward on demand. The fold-away mirror

motor is not serviceable separately and if a motor is

found to be faulty the entire side view mirror must

be replaced.

OPERATION

When the mirror retract switch is depressed, both

of the side view mirrors will fold inward, Thus mak-

ing the overall width of the vehicle the smallest pos-

sible. This can be helpful were parking space is a

absolute minimum.

When the driver's door is opened, only the driver's

door mirror will unfold. If the passenger door is

opened, both mirrors will unfold.

The power fold away mirror system consists of the

following components: mirror switch, side view mir-ror, relay, wires and fuse. Refer to the appropriate

wiring information. The wiring information includes

wiring diagrams, proper wire and connector repair

procedures, details of wire harness routing and

retention, connector pin-out information and location

views for the various wire harness connectors, splices

and grounds.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the upper and lower steering column

shroud (Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(3) Disconnect electrical harness connector.

(4) Remove switch from steering column shroud

(Fig. 3).

Fig. 2 POWER FOLDAWAY MIRROR SWITCH

1 - POWER FOLDAWAY MIRROR SWITCH

2 - STEERING COLUMN

Fig. 3 POWER FOLDING MIRROR SWITCH

1 - STEERING COLUMN SHROUD

2 - POWER FOLDAWAY SWITCH

8N - 48 POWER MIRRORSRS

AUTOMATIC DAY / NIGHT MIRROR (Continued)

ProCarManuals.com

Page 504 of 2177

INSTALLATION

(1) Install switch to steering column shroud.

(2) Connect wire harness connector.

(3) Install the upper and lower steering column

shroud (Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(4) Connect the battery negative cable.

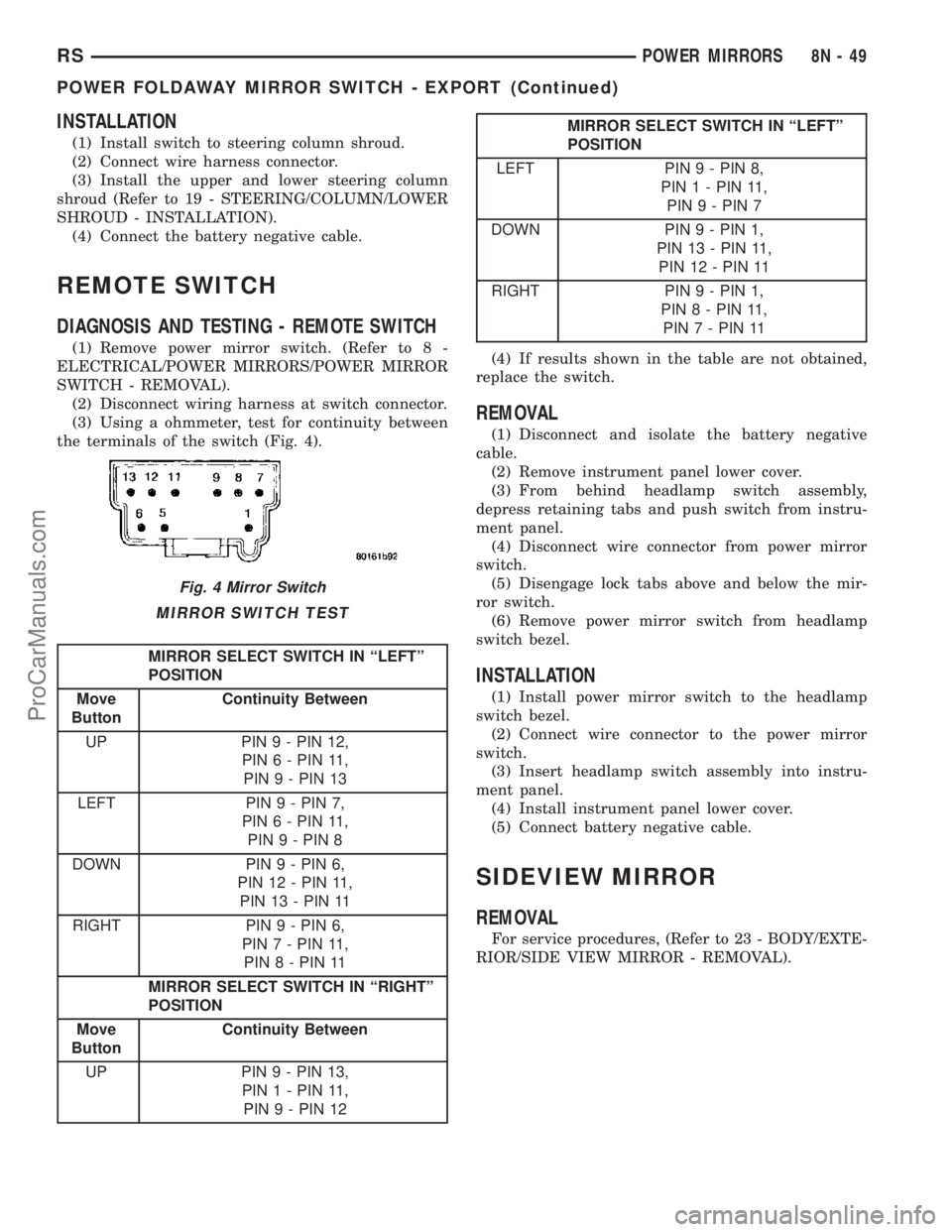

REMOTE SWITCH

DIAGNOSIS AND TESTING - REMOTE SWITCH

(1) Remove power mirror switch. (Refer to 8 -

ELECTRICAL/POWER MIRRORS/POWER MIRROR

SWITCH - REMOVAL).

(2) Disconnect wiring harness at switch connector.

(3) Using a ohmmeter, test for continuity between

the terminals of the switch (Fig. 4).

MIRROR SWITCH TEST

MIRROR SELECT SWITCH IN ªLEFTº

POSITION

Move

ButtonContinuity Between

UP PIN 9 - PIN 12,

PIN 6 - PIN 11,

PIN 9 - PIN 13

LEFT PIN 9 - PIN 7,

PIN 6 - PIN 11,

PIN 9 - PIN 8

DOWN PIN 9 - PIN 6,

PIN 12 - PIN 11,

PIN 13 - PIN 11

RIGHT PIN 9 - PIN 6,

PIN 7 - PIN 11,

PIN 8 - PIN 11

MIRROR SELECT SWITCH IN ªRIGHTº

POSITION

Move

ButtonContinuity Between

UP PIN 9 - PIN 13,

PIN 1 - PIN 11,

PIN 9 - PIN 12

MIRROR SELECT SWITCH IN ªLEFTº

POSITION

LEFT PIN 9 - PIN 8,

PIN 1 - PIN 11,

PIN 9 - PIN 7

DOWN PIN 9 - PIN 1,

PIN 13 - PIN 11,

PIN 12 - PIN 11

RIGHT PIN 9 - PIN 1,

PIN 8 - PIN 11,

PIN 7 - PIN 11

(4) If results shown in the table are not obtained,

replace the switch.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove instrument panel lower cover.

(3) From behind headlamp switch assembly,

depress retaining tabs and push switch from instru-

ment panel.

(4) Disconnect wire connector from power mirror

switch.

(5) Disengage lock tabs above and below the mir-

ror switch.

(6) Remove power mirror switch from headlamp

switch bezel.

INSTALLATION

(1) Install power mirror switch to the headlamp

switch bezel.

(2) Connect wire connector to the power mirror

switch.

(3) Insert headlamp switch assembly into instru-

ment panel.

(4) Install instrument panel lower cover.

(5) Connect battery negative cable.

SIDEVIEW MIRROR

REMOVAL

For service procedures, (Refer to 23 - BODY/EXTE-

RIOR/SIDE VIEW MIRROR - REMOVAL).

Fig. 4 Mirror Switch

RSPOWER MIRRORS8N-49

POWER FOLDAWAY MIRROR SWITCH - EXPORT (Continued)

ProCarManuals.com

Page 540 of 2177

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................5

INSTALLATION..........................5

SWITCH

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 30 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral (ATX) or

1st/2nd gear (MTX). The speed control can be disen-

gaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

ProCarManuals.com

Page 545 of 2177

SWITCH

DESCRIPTION

There are two separate switch pods that operate

the speed control system and are located on the

steering wheel.

OPERATION

The speed control system has five separate resis-

tive switches that provide a single multiplexed

(MUX) voltage inputs to the PCM.The switch names

are: ON, OFF, SET, COAST, RESUME, ACCEL, TAP-

UP, COAST, and CANCEL. Based on conditions when

the buttons are pushed (and released), the five volt-

ages ranges provided to the PCM result in the follow-

ing functions: ON, OFF, SET, COAST, RESUME,

ACCEL, TAP-UP, TAP-DOWN, COAST, and CAN-

CEL. Refer to the Speed Control Section for more

information

Also the PCM receives an input from the brake

switch to sense whether the brake pedal has been

depressed. When the PCM receives the brake

depressed input, it turns off power to the speed con-

trol servo and disengages speed control. Also the

power to the servo is supplied through the brake

switch, which opens the circuit when the brake pedal

is depressed.

The individual switches cannot be repaired. If one

switch fails, the entire switch module must be

replaced.

REMOVAL

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.

WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Remove the negative battery cable.

(2) Turn off ignition.

(3) Remove the air bag, refer to the restraint sec-

tion for more information.

(4) Remove the screw from bottom of the switch.

(5) Remove switch from steering wheel.

(6) Disconnect two-way electrical connector.

(7) Repeat for the other switch.

INSTALLATION

The speed control switches are mounted in the

steering wheel and wired through the clock spring

device under the airbag module.WARNING: IF REMOVAL OF AIRBAG MODULE IS

NECESSARY, REFER TO THE RESTRAINT SYS-

TEMS SECTION FOR MORE INFORMATION.

(1) Connect two-way electrical connector.

(2) Install switch.

(3) Install screw for the switch.

(4) Repeat for the other switch.

(5) Install the air bag, refer to the restraint section

for more information.

(6) Install the negative battery cable.

VACUUM RESERVOIR

DESCRIPTION

The vacuum reservoir is located in the engine com-

partment. It is made of plastic.

OPERATION

The reservoir stores engine vacuum. Manifold vac-

uum is supplied from the brake booster check valve.

The speed control vacuum supply hose has a check

valve at the source (brake booster) to maintain the

highest available vacuum level in the servo, reservoir

and vacuum hoses. When engine vacuum drops, as in

climbing a grade while driving, the reservoir supplies

the vacuum needed to maintain proper speed control

operation. The vacuum reservoir cannot be repaired

and must be replaced if faulty.

REMOVAL

(1) Release hood latch and open hood.

(2) Disconnect the negative battery cable.

(3) Disconnect the vacuum line to the battery tray/

vacuum reservoir.

(4) Remove battery tray/vacuum reservoir, refer to

the Battery section for more information.

INSTALLATION

(1) Install battery tray/vacuum reservoir, refer to

the Battery section for more information.

(2) Connect vacuum line that leads to the battery

tray/vacuum reservoir.

(3) Connect the negative battery cable.

8P - 6 SPEED CONTROLRS

ProCarManuals.com

Page 546 of 2177

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM..................3

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............3

HOOD AJAR SWITCH - EXPORT

REMOVAL.............................3INSTALLATION..........................3

TRANSPONDER KEY

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING.......................4

VTSS/SKIS INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, and ignition action for

unauthorized operation (hood and liftgate for RG -

Export). The alarm activates:

²Sounding of the horn

²Flashing of the headlamps/park/tail lamps

²Flashing of the headlamps

²An engine kill feature (with SKIS)

SENTRY KEY IMMOBILIZER SYSTEM

The Sentry Key Immobilizer System (SKIS) is

available as a factory-installed option on this vehicle.

It is designed to provide passive protection against

unauthorized vehicle use by disabling the engine,

after two (2) seconds of running, whenever an invalid

key is used to start the vehicle. The SKIS is active

whenever the ignition is on and does not require any

customer intervention. The primary components of

the system are the Sentry Key Immobilizer Module

(SKIM), Sentry Key (ignition key with a transponder

molded into the head), indicator light, Body Control

Module (BCM), and the Powertrain Control Module

(PCM). The SKIM is mounted to the steering column

with the molded, integral antenna mounted on the

ignition housing. The indicator light, is located in the

Mechanical Instrument Cluster (MIC).

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper SKIM communication to the

PCM, the PCM will shut off fuel after two seconds of

run time. The engine will not re-crank on the key

cycle that the failure occurred, a full key down

sequence must be performed for the engine to crank

again. After six consecutive fuel shut-offs, the engine

will no longer crank on subsequent key cycles. The

failure must be corrected and a valid communication

process between the SKIM and the PCM must occur

for the engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches.

For vehicles equipped with SKIS, the doors do not

have to be locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the Mechanical

Instrument Cluster (MIC) will flash quickly for 16

seconds, indicating that arming is in progress. If no

monitored systems are activated during this period,

the system will arm. The LED will extinguish unless

the liftgate is open. If the liftgate is open, the LED

will flash at a slower rate.

This indicates that the system is armed. If fault is

detected on the driver key cylinder input, the indica-

tor LED will remain solid during the arming process,

although the system will still arm. If the indicator

LED does not illuminate at all upon door closing it

indicates that the system is not arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the ignition key/

RSVEHICLE THEFT SECURITY8Q-1

ProCarManuals.com

Page 577 of 2177

DESCRIPTION - CIRCUIT FUNCTIONS

All circuits in the diagrams use an alpha/numeric

code to identify the wire and it's function. To identify

which circuit code applies to a system, refer to the

Circuit Identification Code Chart. This chart shows

the main circuits only and does not show the second-

ary codes that may apply to some models.

CIRCUIT IDENTIFICATION CODE CHART

CIRCUIT FUNCTION

A BATTERY FEED

B BRAKE CONTROLS

C CLIMATE CONTROLS

D DIAGNOSTIC CIRCUITS

E DIMMING ILLUMINATION

CIRCUITS

F FUSED CIRCUITS

G MONITORING CIRCUITS

(GAUGES)

H OPEN

I NOT USED

J OPEN

K POWERTRAIN CONTROL

MODULE

L EXTERIOR LIGHTING

M INTERIOR LIGHTING

N NOT USED

O NOT USED

P POWER OPTION (BATTERY

FEED)

Q POWER OPTIONS (IGNITION

FEED)

R PASSIVE RESTRAINT

S SUSPENSION/STEERING

T TRANSMISSION/TRANSAXLE/

TRANSFER CASE

U OPEN

V SPEED CONTROL, WIPER/

WASHER

W OPEN

X AUDIO SYSTEMS

Y OPEN

Z GROUNDS

DESCRIPTION - SECTION IDENTIFICATION AND

INFORMATION

The wiring diagrams are grouped into individual

sections. If a component is most likely found in a par-

ticular group, it will be shown complete (all wires,

connectors, and pins) within that group. For exam-

ple, the Auto Shutdown Relay is most likely to be

found in Group 30, so it is shown there complete. It

can, however, be shown partially in another group if

it contains some associated wiring.

Splice diagrams in Section 8W-70 show the entire

splice and provide references to other sections the

splices serves. Section 8W-70 only contains splice dia-

grams that are not shown in their entirety some-

where else in the wiring diagrams.

Section 8W-80 shows each connector and the cir-

cuits involved with that connector. The connectors

are identified using the name/number on the dia-

gram pages.

WIRING SECTION CHART

GROUP TOPIC

8W-01 thru

8W-09General information and Diagram

Overview

8W-10 thru

8W-19Main Sources of Power and

Vehicle Grounding

8W-20 thru

8W-29Starting and Charging

8W-30 thru

8W-39Powertrain/Drivetrain Systems

8W-40 thru

8W-49Body Electrical items and A/C

8W-50 thru

8W-59Exterior Lighting, Wipers and

Trailer Tow

8W-60 thru

8W-69Power Accessories

8W-70 Splice Information

8W-80 Connector Pin Outs

8W-91 Connector, Ground and Splice

Locations

8W - 01 - 6 8W-01 WIRING DIAGRAM INFORMATIONRS

WIRING DIAGRAM INFORMATION (Continued)

ProCarManuals.com

Page 1118 of 2177

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

C317 BK Right Sliding Door 31

C318 (Trailer Tow) BK Left Quarter N/S

C319 Left Side Liftgate N/S

C320 DKGY Driver Power Seat on Seat Harness N/S

C321 DKGY Under Passenger Seat N/S

C322 BK On Seat Harness to Body 31

C324 BK Left Sliding Door N/S

C325 BK Right Sliding Door 31

C326 YL At Driver Side Airbag N/S

C327 YL At Passenger Side Airbag N/S

C328 Front of Left Quarter 46

C329 (Diesel) BK Near Fuel Tank 33

C330 (Diesel) LTGY Left Rear Engine Compartment N/S

C331 (Diesel) BK Left Rear Engine Compartment N/S

Cabin Heater RHD) At Heater N/S

Cabin Heater Assist C1 (Diesel) BK Top of Engine 15, 16

Cabin Heater Assist C2 (Diesel) BK Top of Engine 15, 16

Camshaft Position Sensor (Gas) BK Rear of Cylinder Head

Right Side of Engine11

Camshaft Position Sensor

(Diesel)BK Rear of Cylinder Head 15, 16

CD Changer Behind CD Changer N/S

Center Dome Lamp GY At Lamp N/S

Center High Mounted Stop Lamp BK At Lamp 48

Clockspring - C1 WT Steering Column 19, 20, 21, 22, 30

Clockspring - C2 YL Steering Column 19, 20, 21, 22, 30

Clockspring - C3 BK Steering Column N/S

Clockspring - C4 BK Steering Column N/S

Clockspring - C5 YL Steering Column N/S

Clutch Pedal Interlock Switch

(Diesel)RD At Switch/Driver Side 41

Clutch Pedal Upstop Switch

(Diesel)BK At Switch/Driver Side 41

Controller Anti-Lock Brake BK Right Side of Engine Compartment 11, 16, 17, 18

Crank Case Ventilation Heater

(Diesel)BK Top of Cylinder Head 15

Crankshaft Position Sensor

(Diesel)BK Rear of Engine 16

Crankshaft Position Sensor (Gas) BK Rear of Engine 13, 17

Data Link Connector WT Lower Instrument Panel Near

Steering Column40, 41

Dosing Pump BK Top of Engine N/S

Driver Airbag Squib1 BN Steering Column N/S

Driver Airbag Squib2 BK Steering Column N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-3

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1120 of 2177

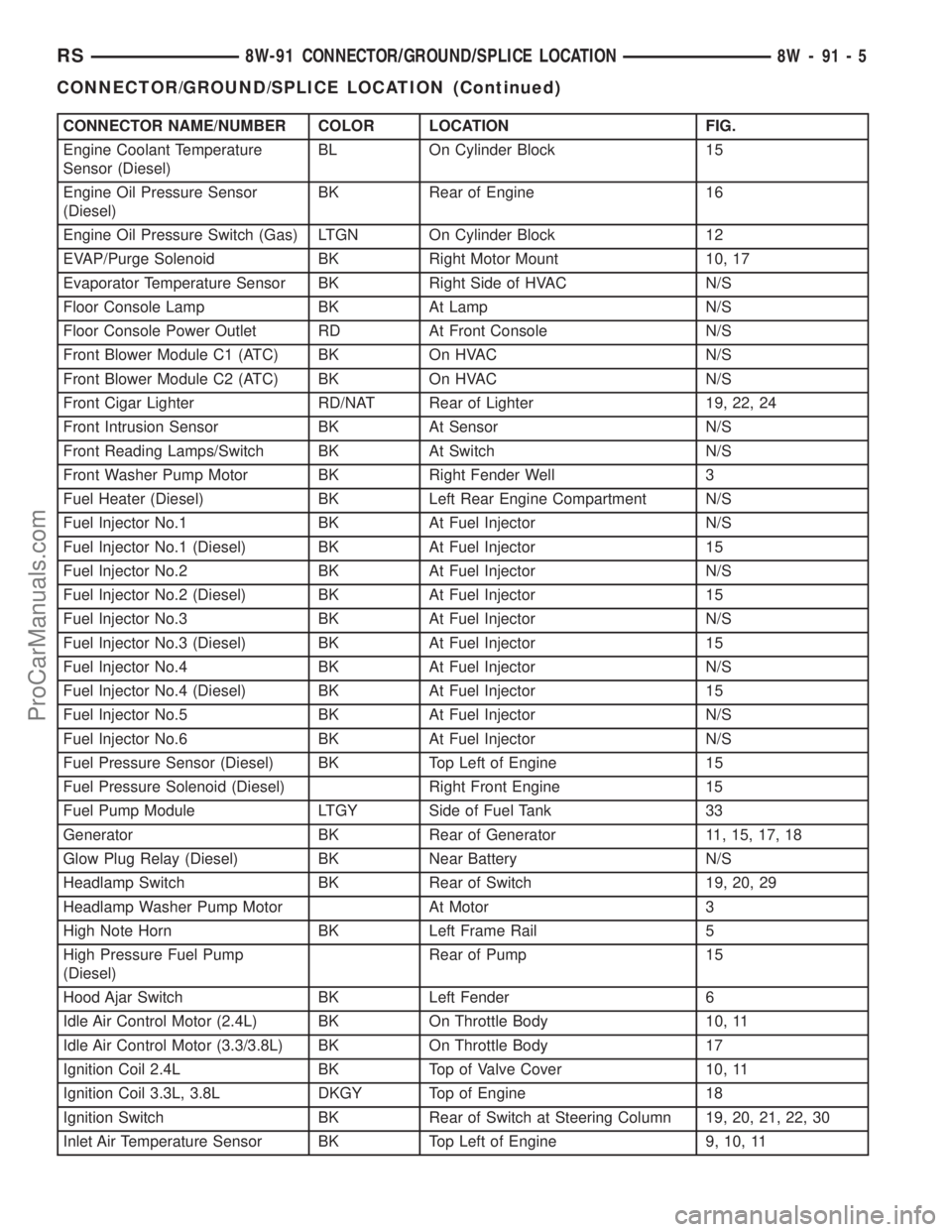

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Engine Coolant Temperature

Sensor (Diesel)BL On Cylinder Block 15

Engine Oil Pressure Sensor

(Diesel)BK Rear of Engine 16

Engine Oil Pressure Switch (Gas) LTGN On Cylinder Block 12

EVAP/Purge Solenoid BK Right Motor Mount 10, 17

Evaporator Temperature Sensor BK Right Side of HVAC N/S

Floor Console Lamp BK At Lamp N/S

Floor Console Power Outlet RD At Front Console N/S

Front Blower Module C1 (ATC) BK On HVAC N/S

Front Blower Module C2 (ATC) BK On HVAC N/S

Front Cigar Lighter RD/NAT Rear of Lighter 19, 22, 24

Front Intrusion Sensor BK At Sensor N/S

Front Reading Lamps/Switch BK At Switch N/S

Front Washer Pump Motor BK Right Fender Well 3

Fuel Heater (Diesel) BK Left Rear Engine Compartment N/S

Fuel Injector No.1 BK At Fuel Injector N/S

Fuel Injector No.1 (Diesel) BK At Fuel Injector 15

Fuel Injector No.2 BK At Fuel Injector N/S

Fuel Injector No.2 (Diesel) BK At Fuel Injector 15

Fuel Injector No.3 BK At Fuel Injector N/S

Fuel Injector No.3 (Diesel) BK At Fuel Injector 15

Fuel Injector No.4 BK At Fuel Injector N/S

Fuel Injector No.4 (Diesel) BK At Fuel Injector 15

Fuel Injector No.5 BK At Fuel Injector N/S

Fuel Injector No.6 BK At Fuel Injector N/S

Fuel Pressure Sensor (Diesel) BK Top Left of Engine 15

Fuel Pressure Solenoid (Diesel) Right Front Engine 15

Fuel Pump Module LTGY Side of Fuel Tank 33

Generator BK Rear of Generator 11, 15, 17, 18

Glow Plug Relay (Diesel) BK Near Battery N/S

Headlamp Switch BK Rear of Switch 19, 20, 29

Headlamp Washer Pump Motor At Motor 3

High Note Horn BK Left Frame Rail 5

High Pressure Fuel Pump

(Diesel)Rear of Pump 15

Hood Ajar Switch BK Left Fender 6

Idle Air Control Motor (2.4L) BK On Throttle Body 10, 11

Idle Air Control Motor (3.3/3.8L) BK On Throttle Body 17

Ignition Coil 2.4L BK Top of Valve Cover 10, 11

Ignition Coil 3.3L, 3.8L DKGY Top of Engine 18

Ignition Switch BK Rear of Switch at Steering Column 19, 20, 21, 22, 30

Inlet Air Temperature Sensor BK Top Left of Engine 9, 10, 11

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-5

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com

Page 1122 of 2177

CONNECTOR NAME/NUMBER COLOR LOCATION FIG.

Left Rear Vent Motor NAT At Motor 45, 46

Left Rear Wheel Speed Sensor BK Center Rear of Floor Pan 46

Left Remote Radio Switch Steering Wheel N/S

Left Repeater Lamp GY Left Front Fender 4, 35

Left Seat Airbag YL Left Seat N/S

Left Side Impact Airbag Control

ModuleYL/RD Left B Pillar 39

Left Sliding Door Control Module

C1BK Left Sliding Door N/S

Left Sliding Door Control Module

C2BK/RD Left Sliding Door N/S

Left Sliding Door Latch Sensing

SwitchBK Left Sliding Door N/S

Left Sliding Door Lock Motor BK Left Sliding Door N/S

Left Sliding Door Lock Motor/Ajar

SwitchBK Left Sliding Door N/S

Left Sliding Door Motor BK Left Sliding Door N/S

Left Speed Control Switch WT Steering Wheel N/S

Left Stop/Turn Signal Relay BK Left Quarter Panel N/S

Left Turn Signal Lamp OR AT Lamp N/S

Left Visor/Vanity Lamp BK At Lamp N/S

License Lamp DKGY At Lamp 48

Lift Pump Motor BK Left Rear Engine Compartment N/S

Liftgate Ajar Switch (Manual

Release)BK At Latch 48

Liftgate Ajar Switch (Power

Release)BK Lower Liftgate 48

Liftgate Cinch/Release Motor BL Liftgate 48

Liftgate Cylinder Lock Switch BK At Switch 48

Liftgate Left Pinch Sensor BK Left Side of Liftgate N/S

Liftgate Right Pinch Sensor BK Right Side of Liftgate N/S

Low Note Horn BK Left Frame Rail 5

Manifold Absolute Pressure

SensorBK On Intake 11

Mass Air Flow Sensor (Diesel) OR Top of Engine 15, 16

Memory Seat/Mirror Module C1 GY Under Driver Seat N/S

Memory Seat/Mirror Module C2 GY Under Driver Seat N/S

Memory Seat/Mirror Module C3 WT Under Driver Seat N/S

Memory Seat/Mirror Module C4 GY Under Driver Seat N/S

Memory Seat Front Vertical Motor RD Under Seat N/S

Memory Seat Front Vertical

Position SensorBK Under Seat N/S

Memory Seat Horizontal Motor BK Under Seat N/S

RS8W-91 CONNECTOR/GROUND/SPLICE LOCATION8W-91-7

CONNECTOR/GROUND/SPLICE LOCATION (Continued)

ProCarManuals.com