key CHRYSLER CARAVAN 2003 Manual Online

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 1561 of 2177

SYNCHRONIZER

DESCRIPTION

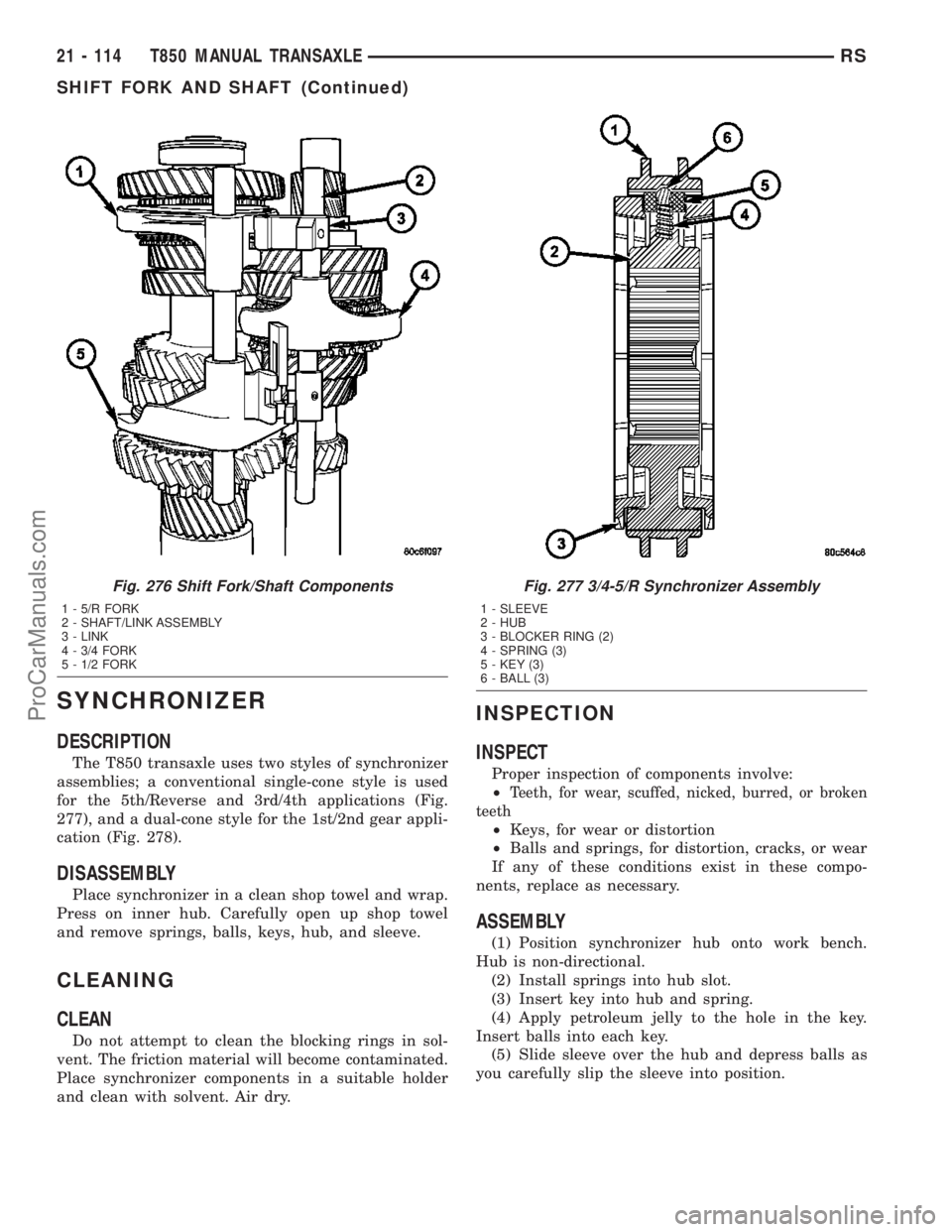

The T850 transaxle uses two styles of synchronizer

assemblies; a conventional single-cone style is used

for the 5th/Reverse and 3rd/4th applications (Fig.

277), and a dual-cone style for the 1st/2nd gear appli-

cation (Fig. 278).

DISASSEMBLY

Place synchronizer in a clean shop towel and wrap.

Press on inner hub. Carefully open up shop towel

and remove springs, balls, keys, hub, and sleeve.

CLEANING

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECTION

INSPECT

Proper inspection of components involve:

²

Teeth, for wear, scuffed, nicked, burred, or broken

teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

ASSEMBLY

(1) Position synchronizer hub onto work bench.

Hub is non-directional.

(2) Install springs into hub slot.

(3) Insert key into hub and spring.

(4) Apply petroleum jelly to the hole in the key.

Insert balls into each key.

(5) Slide sleeve over the hub and depress balls as

you carefully slip the sleeve into position.

Fig. 276 Shift Fork/Shaft Components

1 - 5/R FORK

2 - SHAFT/LINK ASSEMBLY

3 - LINK

4 - 3/4 FORK

5 - 1/2 FORK

Fig. 277 3/4-5/R Synchronizer Assembly

1 - SLEEVE

2 - HUB

3 - BLOCKER RING (2)

4 - SPRING (3)

5 - KEY (3)

6 - BALL (3)

21 - 114 T850 MANUAL TRANSAXLERS

SHIFT FORK AND SHAFT (Continued)

ProCarManuals.com

Page 1562 of 2177

VEHICLE SPEED SENSOR

REMOVAL

(1) Raise vehicle on hoist.

(2)

Disconnect the speed sensor connector (Fig. 279).

CAUTION: Clean area around speed sensor before

removing to prevent dirt from entering the transaxle

during speed sensor removal.

(3) Remove speed sensor retaining bolt (Fig. 279).

(4) Remove speed sensor from transaxle.

CAUTION: Carefully remove vehicle speed sensor

so that sensor drive gear does not fall into trans-

axle. Should sensor drive gear fall into the trans-

axle during sensor removal, drive gear must be

reattached to sensor.

(5) Remove speed sensor drive gear from speed

sensor.

INSTALLATION

(1) Install pinion gear to speed sensor (Fig. 279).

(2) Using a NEW o-ring, install the speed sensor

to the transaxle (Fig. 279).

(3) Install the bolt and torque to 7 N´m (60 in.

lbs.).

(4) Connect speed sensor connector (Fig. 279).

(5) Lower vehicle and road test to verify proper

speedometer operation.

Fig. 278 1/2 Synchronizer Assembly

1 - SLEEVE

2 - REACTOR RING (2)

3 - HUB

4 - BLOCKER RING (2)

5 - SLEEVE

6 - FRICTION CONE (2)

7 - SPRING (3)

8 - KEY (3)

9 - BALL (3)

Fig. 279 Speed Sensor and Pinion Removal/

InstallationÐTypical

1 - CONNECTOR

2 - SENSOR

3 - O-RING

4 - GEAR

RST850 MANUAL TRANSAXLE21 - 115

SYNCHRONIZER (Continued)

ProCarManuals.com

Page 1653 of 2177

(4) Install knee bolster (Fig. 220).

(5) Install instrument panel lower silencer (Fig.

221).

(6) Install gear shift cable to transaxle upper

mount bracket (Fig. 222). An audible ªclickº should

be heard.

(7) Connect gear shift cable end to transaxle man-

ual valve lever (Fig. 222).

(8) Adjust gearshift cable. (Refer to 21 - TRANS-

MISSION/TRANSAXLE/AUTOMATIC - 41TE/GEAR

SHIFT CABLE - ADJUSTMENTS)

(9) Install speed control servo into position.

(10) Install battery.

(11) Install battery shield.

(12) Connect battery cables.

ADJUSTMENTS

GEARSHIFT CABLE ADJUSTMENT

VERIFICATION

(1) Place gearshift lever in gated park (P).

(2) Attempt to move vehicle by rocking back and

forth on level ground. If vehicle does not move,

attempt to start engine. If engine starts, the park

position is correct.

(3) Set parking brake.

(4) Turn key to on/run and depress brake pedal.

Place gearshift lever in neutral (N).

(5) Attempt to start engine. If engine starts in

both neutral (N) or park (P), gearshift cable is

adjusted properly. No adjustment is required.

(6) If engine does not start in either park (P) or

neutral (N), perform adjustment procedure.

Fig. 220 Knee Bolster

1 - KNEE BOLSTER

Fig. 221 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 222 Gearshift Cable at Transaxle

1 - MANUAL VALVE LEVER

2 - GEAR SHIFT CABLE

3 - UPPER MOUNT BRACKET

21 - 206 41TE AUTOMATIC TRANSAXLERS

GEAR SHIFT CABLE (Continued)

ProCarManuals.com

Page 1654 of 2177

ADJUSTMENT

(1) Park the vehicle on level ground and set the

parking brake.

(2) Place the gearshift lever in gated park (P) and

remove ignition key.

(3) Loosen the cable adjustment screw at the

transaxle manual valve lever (Fig. 223).

(4) Pull the gearshift lever fully forward to the

park detent position.

(5) Release the park brake, then rock the vehicle

to assure it is in park. Reset the park brake.

(6) Tighten the cable adjustment screw to 8 N´m

(70 in. lbs.). Gearshift cable should now be properly

adjusted.

(7) Verify adjustment by using the verification pro-

cedure.

HOLDING CLUTCHES

DESCRIPTION

Two hydraulically applied multi-disc clutches are

used to hold planetary geartrain components station-

ary while the input clutches drive others. The 2/4

and Low/Reverse clutches are considered holding

clutches and are contained at the rear of the trans-

axle case. (Fig. 224).

OPERATION

NOTE: Refer to the ªElements In Useº chart in Diag-

nosis and Testing for a collective view of which

clutch elements are applied at each position of the

selector lever.

2/4 CLUTCH

The 2/4 clutch is hydraulically applied in second

and fourth gears by pressurized fluid against the 2/4

clutch piston. When the 2/4 clutch is applied, the

front sun gear assembly is held or grounded to the

transaxle case.

LOW/REVERSE CLUTCH

The Low/Reverse clutch is hydraulically applied in

park, reverse, neutral, and first gears by pressurized

fluid against the Low/Reverse clutch piston. When

the Low/Reverse clutch is applied, the front planet

carrier/rear annulus assembly is held or grounded to

the transaxle case.

Fig. 223 Gearshift Cable Adjustment

1 - GEARSHIFT CABLE ADJUSTMENT SCREW

2 - GEARSHIFT CABLE

Fig. 224 2/4 and Low/Reverse Clutches

1 - FRONT PLANET CARRIER/REAR ANNULUS

2 - 2/4 CLUTCH

3 - L/R CLUTCH

4 - REAR PLANET CARRIER/FRONT ANNULUS

5 - REAR SUN GEAR

6 - FRONT SUN GEAR ASSEMBLY

RS41TE AUTOMATIC TRANSAXLE21 - 207

GEAR SHIFT CABLE (Continued)

ProCarManuals.com

Page 1680 of 2177

INSTALLATION

(1) Using Tool C-4193, install oil pump seal (Fig.

290).

(2) Install transaxle to vehicle (Refer to 21 -

TRANSMISSION/TRANSAXLE/AUTOMATIC - 41TE

- INSTALLATION).

SHIFT INTERLOCK SOLENOID

DESCRIPTION

The Brake/Transmission Shift Interlock system

consists of an electro-magnetic solenoid mounted to

the steering column (Fig. 291). The solenoid's plunger

consists of an integrated hook, which operates the

shift lever pawl (part of shift lever assembly), and a

plunger return spring (Fig. 292). The solenoid also

has an integrated bracket, which facilitates fastening

to the steering column.

OPERATION

The Brake/Transmission Shift Interlock (BTSI) Sole-

noid prevents the transmission shift lever from being

moved out of PARK (P) unless the brake pedal is

applied. The BTSI solenoid is hardwired to and con-

trolled by the Intelligent Power Module (IPM). Battery

voltage is applied to one side of the solenoid with the

ignition key is in either the OFF, ON/RUN, or START

positions (Fig. 293). The ground side of the solenoid is

controlled by a driver within the IPM. It relies on volt-

age supplied from the stop lamp switch to the stop

lamp sense circuit within the IPM to tell when the

brake pedal is depressed. When the brake pedal is

depressed, the ground circuit opens, de-energizing the

solenoid. When the brake pedal is released, the ground

circuit is closed, energizing the solenoid.

When the ignition key is in either the OFF,

ON/RUN, or START positions, the BTSI solenoid is

energized, and the solenoid plunger hook pulls the

shift lever pawl into position, prohibiting the shift

lever from moving out of PARK (P) (Fig. 294). When

the brake pedal is depressed, the ground circuit

opens, de-energizing the solenoid. This moves the

gearshift lever pawl out of the way (Fig. 295), allow-

ing the shift lever to be moved into any gear position.

Fig. 290 Install Oil Pump Seal

1 - TOOL C-4193

2 - HANDLE TOOL C-4171

Fig. 291 Brake/Transmission Shift Interlock (BTSI)

Solenoid Location

1 - BTSI SOLENOID

Fig. 292 Solenoid Plunger and Return Spring

1 - PLUNGER

2 - RETURN SPRING

3 - BTSI SOLENOID

RS41TE AUTOMATIC TRANSAXLE21 - 233

SEAL - OIL PUMP (Continued)

ProCarManuals.com

Page 1681 of 2177

A conventional mechanical interlock system is also

used. This system manually prohibits shifter move-

ment when the ignition switch is in the LOCK or

ACC positions. Solenoid operation is not required in

these key positions.

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

Fig. 293 Ignition Key/Switch Positions

1 - ACC

2 - LOCK

3 - OFF

4 - ON/RUN

5-START

Fig. 294 Pawl Engaged to Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

Fig. 295 Pawl Disengaged From Shift Lever

1 - GEAR SHIFT LEVER

2 - GEAR SHIFT LEVER PAWL

21 - 234 41TE AUTOMATIC TRANSAXLERS

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1682 of 2177

DIAGNOSIS AND TESTING - BRAKE/

TRANSMISSION SHIFT INTERLOCK SOLENOID

For intended BTSI system operation, refer to the

following chart:

ACTION EXPECTED RESPONSE

1. Turn key to the9OFF9

position.1. Shifter CAN be shifted

out of park with brake

pedal applied.

2. Turn key to the

9ON/RUN9position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

9ON/RUN9position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the9LOCK9or9ACC9

position.4. Key cannot be

returned to the9LOCK9or

9ACC9position.

5. Return shifter to

9PARK9and try to remove

the key.5. Key can be removed

(after returning to9LOCK9

position).

6. With the key removed,

try to shift out of9PARK9.6. Shifter cannot be

shifted out of9PARK9.

NOTE: Any failure to meet these expected

responses requires system repair. Refer to the

appropriate Diagnostic Information.

REMOVAL

(1) Disconnect battery negative cable.

(2) Remove instrument panel lower shroud (Fig.

296).(3) Remove knee bolster (Fig. 297).

(4) Remove steering column lower shroud.

(5) Disconnect brake/transmission shift interlock

(BTSI) solenoid connector (Fig. 298).

(6) Remove two (2) solenoid-to-column screws (Fig.

299).

(7) Remove solenoid.

Fig. 296 Instrument Panel Lower Silencer

1 - INSTRUMENT PANEL LOWER SILENCER

Fig. 297 Knee Bolster

1 - KNEE BOLSTER

Fig. 298 BTSI Solenoid Connector

1 - BTSI SOLENOID

2 - SOLENOID CONNECTOR

RS41TE AUTOMATIC TRANSAXLE21 - 235

SHIFT INTERLOCK SOLENOID (Continued)

ProCarManuals.com

Page 1695 of 2177

OPERATION

The relay is supplied fused B+ voltage, energized

by the PCM/TCM, and is used to supply power to the

solenoid pack when the transmission is in normal

operating mode. When the relay is ªoffº, no power is

supplied to the solenoid pack and the transmission is

in ªlimp-inº mode. After a controller reset (ignition

key turned to the ªrunº position or after cranking

engine), the PCM/TCM energizes the relay. Prior to

this, the PCM/TCM verifies that the contacts are

open by checking for no voltage at the switched bat-

tery terminals. After this is verified, the voltage at

the solenoid pack pressure switches is checked. After

the relay is energized, the PCM/TCM monitors the

terminals to verify that the voltage is greater than 3

volts.

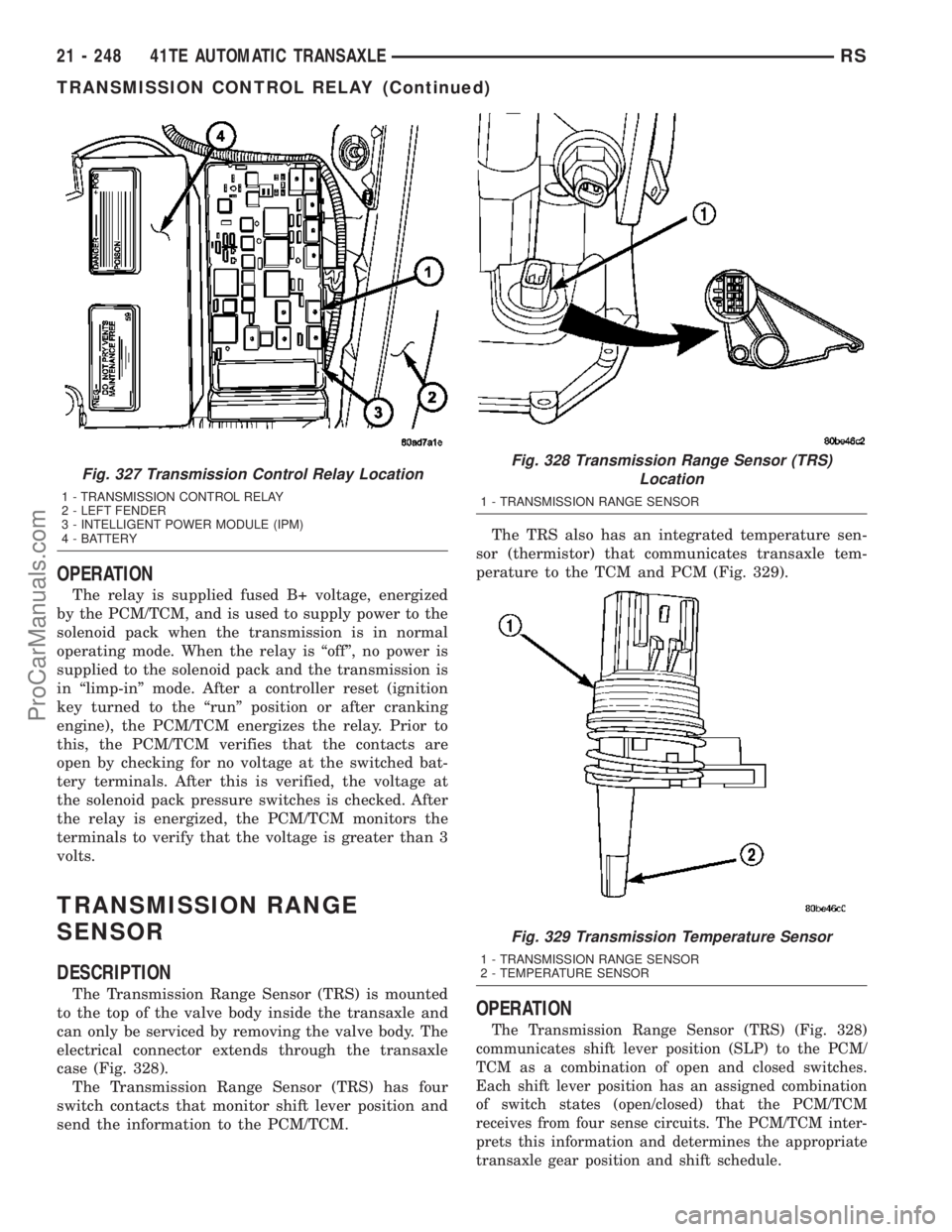

TRANSMISSION RANGE

SENSOR

DESCRIPTION

The Transmission Range Sensor (TRS) is mounted

to the top of the valve body inside the transaxle and

can only be serviced by removing the valve body. The

electrical connector extends through the transaxle

case (Fig. 328).

The Transmission Range Sensor (TRS) has four

switch contacts that monitor shift lever position and

send the information to the PCM/TCM.The TRS also has an integrated temperature sen-

sor (thermistor) that communicates transaxle tem-

perature to the TCM and PCM (Fig. 329).

OPERATION

The Transmission Range Sensor (TRS) (Fig. 328)

communicates shift lever position (SLP) to the PCM/

TCM as a combination of open and closed switches.

Each shift lever position has an assigned combination

of switch states (open/closed) that the PCM/TCM

receives from four sense circuits. The PCM/TCM inter-

prets this information and determines the appropriate

transaxle gear position and shift schedule.

Fig. 327 Transmission Control Relay Location

1 - TRANSMISSION CONTROL RELAY

2 - LEFT FENDER

3 - INTELLIGENT POWER MODULE (IPM)

4 - BATTERY

Fig. 328 Transmission Range Sensor (TRS)

Location

1 - TRANSMISSION RANGE SENSOR

Fig. 329 Transmission Temperature Sensor

1 - TRANSMISSION RANGE SENSOR

2 - TEMPERATURE SENSOR

21 - 248 41TE AUTOMATIC TRANSAXLERS

TRANSMISSION CONTROL RELAY (Continued)

ProCarManuals.com

Page 1745 of 2177

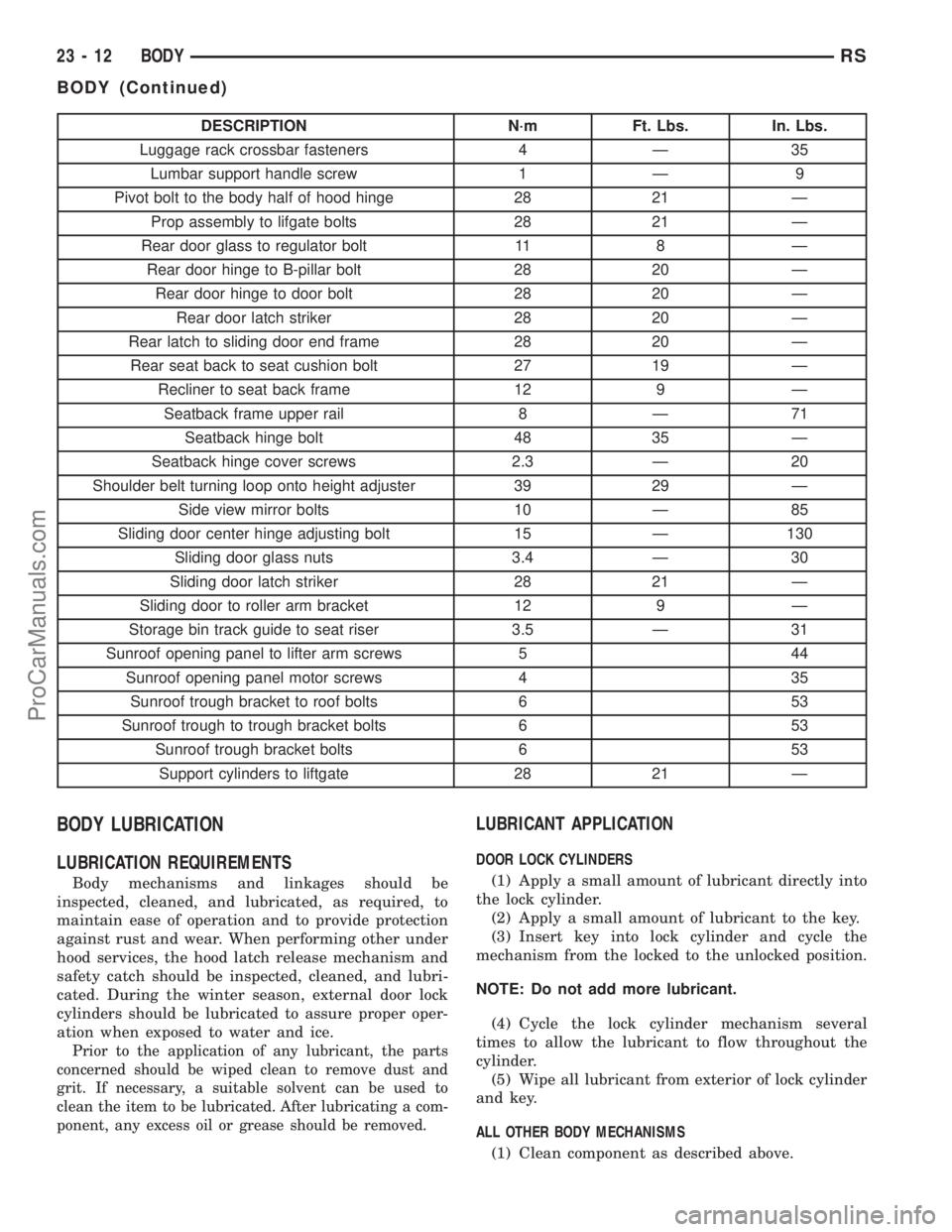

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Luggage rack crossbar fasteners 4 Ð 35

Lumbar support handle screw 1 Ð 9

Pivot bolt to the body half of hood hinge 28 21 Ð

Prop assembly to lifgate bolts 28 21 Ð

Rear door glass to regulator bolt 11 8 Ð

Rear door hinge to B-pillar bolt 28 20 Ð

Rear door hinge to door bolt 28 20 Ð

Rear door latch striker 28 20 Ð

Rear latch to sliding door end frame 28 20 Ð

Rear seat back to seat cushion bolt 27 19 Ð

Recliner to seat back frame 12 9 Ð

Seatback frame upper rail 8 Ð 71

Seatback hinge bolt 48 35 Ð

Seatback hinge cover screws 2.3 Ð 20

Shoulder belt turning loop onto height adjuster 39 29 Ð

Side view mirror bolts 10 Ð 85

Sliding door center hinge adjusting bolt 15 Ð 130

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a com-

ponent, any excess oil or grease should be removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.

ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

23 - 12 BODYRS

BODY (Continued)

ProCarManuals.com

Page 1751 of 2177

HINGE

REMOVAL

(1) Release front door latch and open door.

(2) Mark hinge foot print on both door and pillar

to aid when installing door.

(3) Support door on suitable lifting device.

(4) Remove bolts attaching front door to door

hinge.

(5) Remove bolts attaching hinge to pillar.

(6) Remove door hinge from vehicle.

INSTALLATION

CAUTION: When installing a new hinge, make sure

that the head of each hinge pin is fully seated into

the door hinge. Also, remove the plastic shipping

clip and replace it with the correct metal retaining

clip once the hinge pin is seated.

(1) Paint hinge prior to installation, if necessary.

(2) Position door hinge on vehicle.

(3) Install bolts attaching hinge to pillar. Tighten

bolts to 34 N´m (25 ft. lbs.).

(4) Install bolts attaching front door to door hinge.

Tighten bolts to 34 N´m (25 ft. lbs.).

(5) Align door to achieve equal spacing to sur-

rounding body panels. Panels should be flush across

all gaps.

(6) Verify door alignment and operation. Adjust as

necessary.

LATCH

REMOVAL

(1) Roll door glass up.

(2) Remove front door trim panel. (Refer to 23 -

BODY/DOOR - FRONT/TRIM PANEL - REMOVAL)

(3) Remove watershield as necessary to gain access

to the outside door handle.

(4) Through access hole at rear of inner door

panel, disconnect wire connector from power door

lock motor, if equipped.

(5) Disengage clips holding linkage to door latch

(Fig. 8).

(6) Remove linkages from door latch.

(7) Remove screws attaching door latch to door end

frame (Fig. 9).

(8) Remove door latch from door.

Fig. 8 LATCH ASSEMBLY

1 - OUTSIDE HANDLE TO LATCH LINK

2 - KEY CYLINDER TO LATCH LINK

3 - LATCH ASSEMBLY

4 - INSIDE HANDLE LINK AND SLEEVE

5 - LOCK KNOB LINK

Fig. 9 FRONT DOOR LATCH

1 - FRONT DOOR

2 - LATCH ASSEMBLY

3 - INSIDE HANDLE LINK

23 - 18 DOOR - FRONTRS

ProCarManuals.com