ABS CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 28 of 2177

* This maintenance is recommended by the manu-

facture to the owner but is not required to maintain

the emissions warranty.

³ This maintenance is not required if previously

replaced.

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.

CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

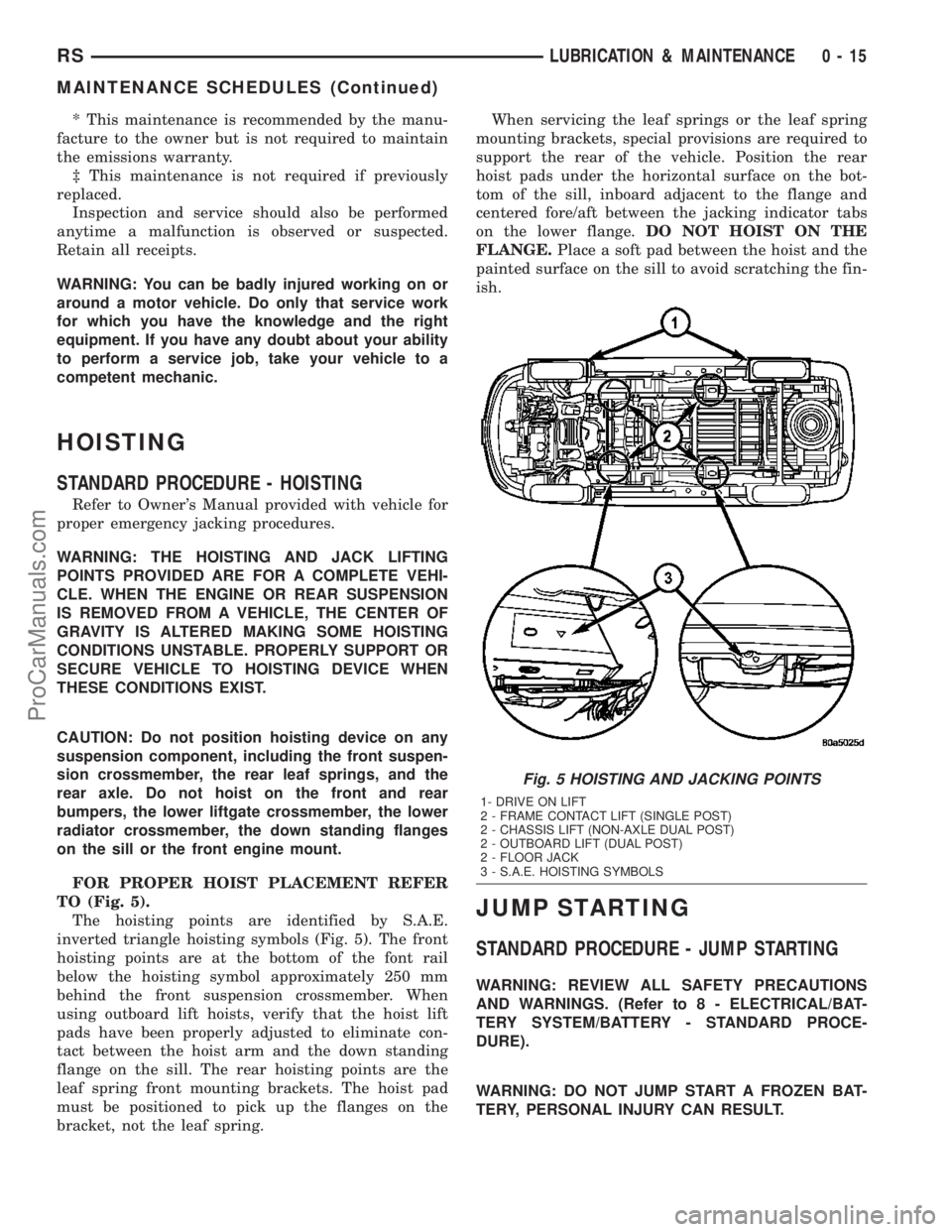

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 5).

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

JUMP STARTING

STANDARD PROCEDURE - JUMP STARTING

WARNING: REVIEW ALL SAFETY PRECAUTIONS

AND WARNINGS. (Refer to 8 - ELECTRICAL/BAT-

TERY SYSTEM/BATTERY - STANDARD PROCE-

DURE).

WARNING: DO NOT JUMP START A FROZEN BAT-

TERY, PERSONAL INJURY CAN RESULT.

Fig. 5 HOISTING AND JACKING POINTS

1- DRIVE ON LIFT

2 - FRAME CONTACT LIFT (SINGLE POST)

2 - CHASSIS LIFT (NON-AXLE DUAL POST)

2 - OUTBOARD LIFT (DUAL POST)

2 - FLOOR JACK

3 - S.A.E. HOISTING SYMBOLS

RSLUBRICATION & MAINTENANCE0-15

MAINTENANCE SCHEDULES (Continued)

ProCarManuals.com

Page 30 of 2177

TOWING

STANDARD PROCEDURE - TOWING

WARNINGS AND CAUTIONS

WARNING: DO NOT ALLOW TOWING ATTACHMENT

DEVICES TO CONTACT THE FUEL TANK OR LINES,

FUEL LEAK CAN RESULT.

DO NOT LIFT OR TOW VEHICLE BY FRONT OR

REAR BUMPER.

DO NOT GO UNDER A LIFTED VEHICLE IF NOT

SUPPORTED PROPERLY ON SAFETY STANDS.

DO NOT ALLOW PASSENGERS TO RIDE IN A

TOWED VEHICLE.

USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust sys-

tem, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle.

Do not secure vehicle to towing device by the use

of front or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing.

Refer to state and local rules and regulations before

towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

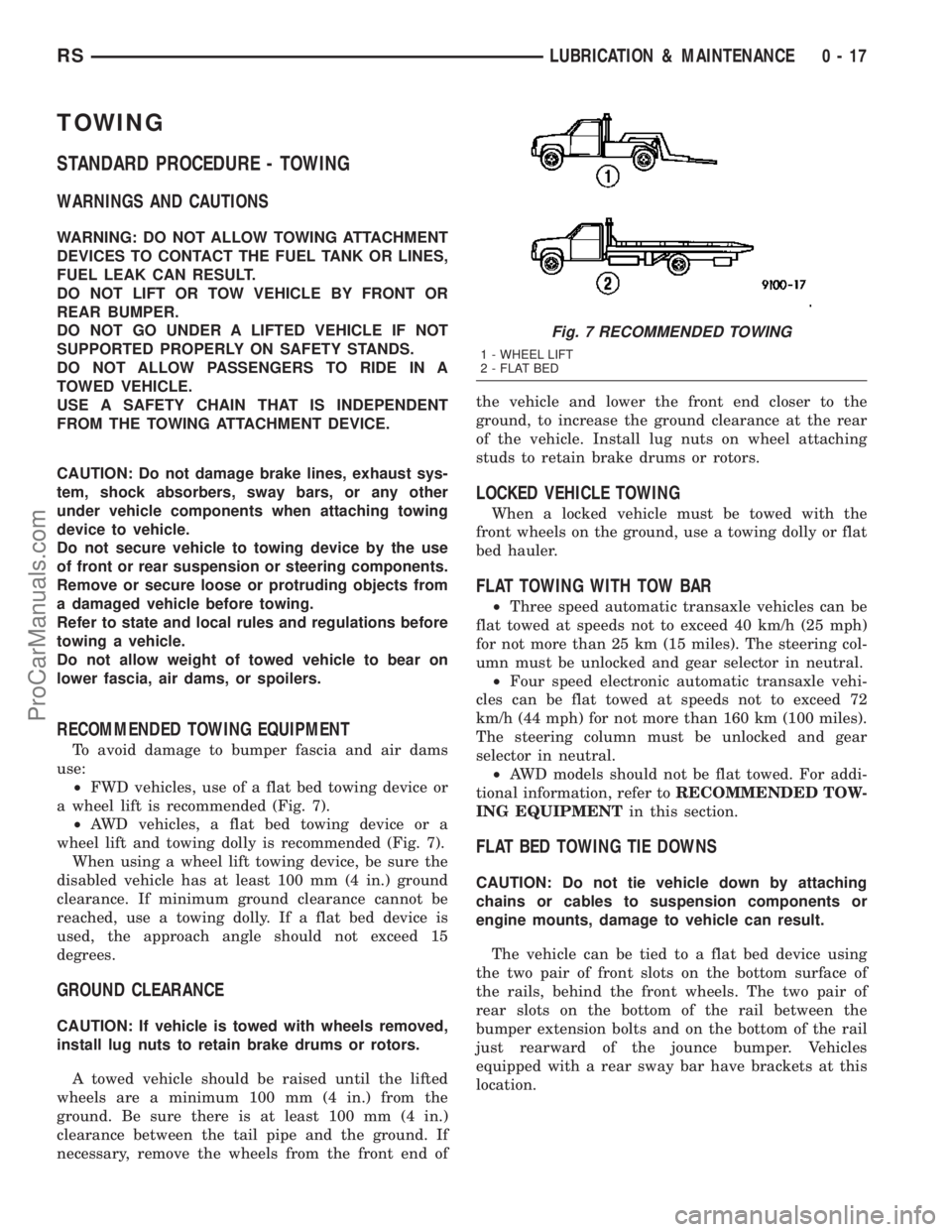

RECOMMENDED TOWING EQUIPMENT

To avoid damage to bumper fascia and air dams

use:

²FWD vehicles, use of a flat bed towing device or

a wheel lift is recommended (Fig. 7).

²AWD vehicles, a flat bed towing device or a

wheel lift and towing dolly is recommended (Fig. 7).

When using a wheel lift towing device, be sure the

disabled vehicle has at least 100 mm (4 in.) ground

clearance. If minimum ground clearance cannot be

reached, use a towing dolly. If a flat bed device is

used, the approach angle should not exceed 15

degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels removed,

install lug nuts to retain brake drums or rotors.

A towed vehicle should be raised until the lifted

wheels are a minimum 100 mm (4 in.) from the

ground. Be sure there is at least 100 mm (4 in.)

clearance between the tail pipe and the ground. If

necessary, remove the wheels from the front end ofthe vehicle and lower the front end closer to the

ground, to increase the ground clearance at the rear

of the vehicle. Install lug nuts on wheel attaching

studs to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²Three speed automatic transaxle vehicles can be

flat towed at speeds not to exceed 40 km/h (25 mph)

for not more than 25 km (15 miles). The steering col-

umn must be unlocked and gear selector in neutral.

²Four speed electronic automatic transaxle vehi-

cles can be flat towed at speeds not to exceed 72

km/h (44 mph) for not more than 160 km (100 miles).

The steering column must be unlocked and gear

selector in neutral.

²AWD models should not be flat towed. For addi-

tional information, refer toRECOMMENDED TOW-

ING EQUIPMENTin this section.

FLAT BED TOWING TIE DOWNS

CAUTION: Do not tie vehicle down by attaching

chains or cables to suspension components or

engine mounts, damage to vehicle can result.

The vehicle can be tied to a flat bed device using

the two pair of front slots on the bottom surface of

the rails, behind the front wheels. The two pair of

rear slots on the bottom of the rail between the

bumper extension bolts and on the bottom of the rail

just rearward of the jounce bumper. Vehicles

equipped with a rear sway bar have brackets at this

location.

Fig. 7 RECOMMENDED TOWING

1 - WHEEL LIFT

2 - FLAT BED

RSLUBRICATION & MAINTENANCE0-17

ProCarManuals.com

Page 45 of 2177

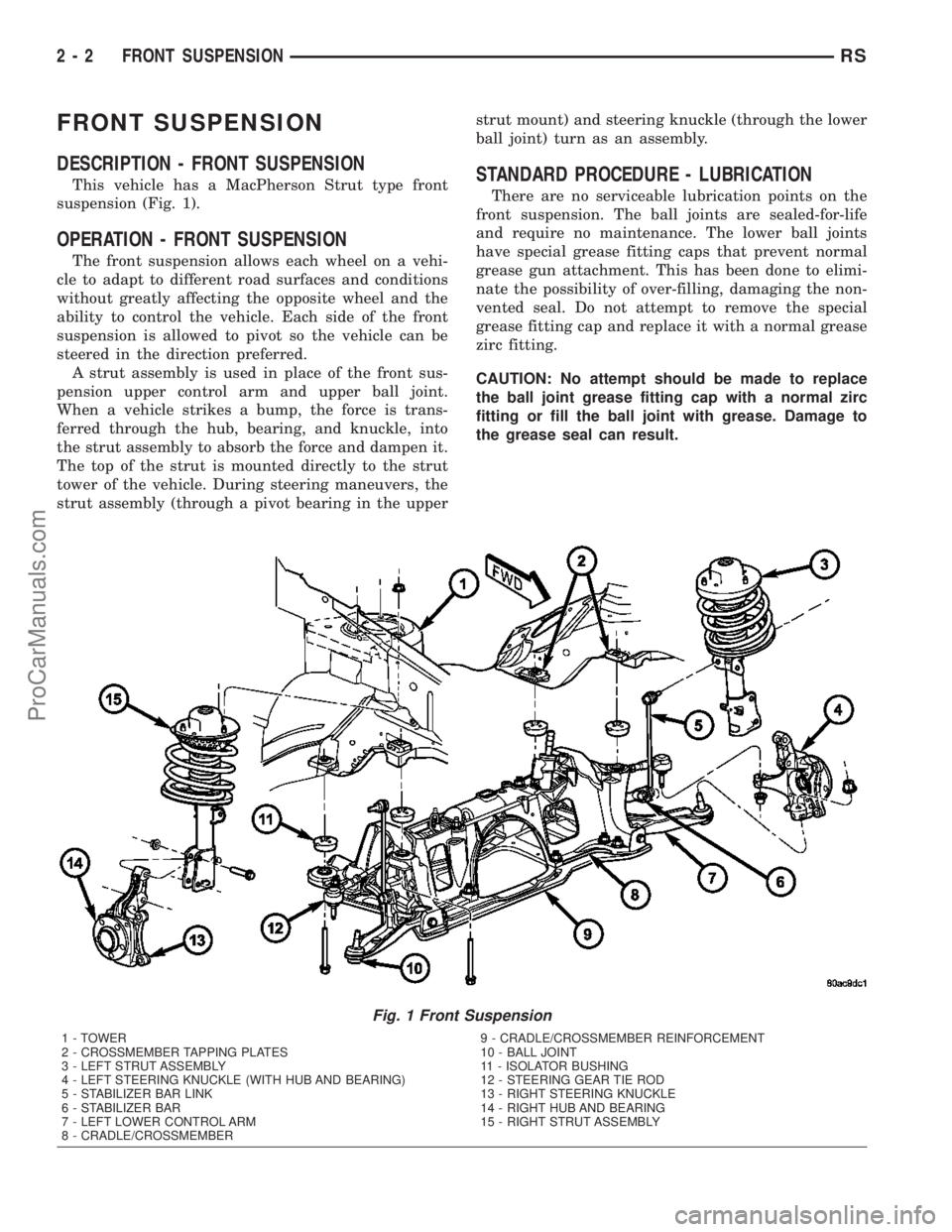

FRONT SUSPENSION

DESCRIPTION - FRONT SUSPENSION

This vehicle has a MacPherson Strut type front

suspension (Fig. 1).

OPERATION - FRONT SUSPENSION

The front suspension allows each wheel on a vehi-

cle to adapt to different road surfaces and conditions

without greatly affecting the opposite wheel and the

ability to control the vehicle. Each side of the front

suspension is allowed to pivot so the vehicle can be

steered in the direction preferred.

A strut assembly is used in place of the front sus-

pension upper control arm and upper ball joint.

When a vehicle strikes a bump, the force is trans-

ferred through the hub, bearing, and knuckle, into

the strut assembly to absorb the force and dampen it.

The top of the strut is mounted directly to the strut

tower of the vehicle. During steering maneuvers, the

strut assembly (through a pivot bearing in the upperstrut mount) and steering knuckle (through the lower

ball joint) turn as an assembly.

STANDARD PROCEDURE - LUBRICATION

There are no serviceable lubrication points on the

front suspension. The ball joints are sealed-for-life

and require no maintenance. The lower ball joints

have special grease fitting caps that prevent normal

grease gun attachment. This has been done to elimi-

nate the possibility of over-filling, damaging the non-

vented seal. Do not attempt to remove the special

grease fitting cap and replace it with a normal grease

zirc fitting.

CAUTION: No attempt should be made to replace

the ball joint grease fitting cap with a normal zirc

fitting or fill the ball joint with grease. Damage to

the grease seal can result.

Fig. 1 Front Suspension

1 - TOWER

2 - CROSSMEMBER TAPPING PLATES

3 - LEFT STRUT ASSEMBLY

4 - LEFT STEERING KNUCKLE (WITH HUB AND BEARING)

5 - STABILIZER BAR LINK

6 - STABILIZER BAR

7 - LEFT LOWER CONTROL ARM

8 - CRADLE/CROSSMEMBER9 - CRADLE/CROSSMEMBER REINFORCEMENT

10 - BALL JOINT

11 - ISOLATOR BUSHING

12 - STEERING GEAR TIE ROD

13 - RIGHT STEERING KNUCKLE

14 - RIGHT HUB AND BEARING

15 - RIGHT STRUT ASSEMBLY

2 - 2 FRONT SUSPENSIONRS

ProCarManuals.com

Page 48 of 2177

HUB / BEARING

DESCRIPTION

The front wheel bearing and front wheel hub of

this vehicle are a hub and bearing unit type assem-

bly (Unit III). This unit combines the front wheel

mounting hub (flange) and the front wheel bearing

into a sealed one-piece unit. The hub and bearing is

mounted to the center of the steering knuckle (Fig.

1). It is retained by four mounting bolts accessible

from the inboard side of the steering knuckle. The

hub flange has five wheel mounting studs.

The wheel mounting studs used to mount the tire

and wheel to the vehicle are the only replaceable

components of the hub and bearing assembly. Other-

wise, the hub and bearing is serviced only as a com-

plete assembly.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the driveshaft, along

with the tire and wheel. The five wheel mounting

studs mount the tire and wheel, and brake rotor to

the vehicle.

DIAGNOSIS AND TESTING - HUB AND

BEARING

The condition of the front hub and bearing assem-

bly is diagnosed using the inspection and testing pro-

cedure detailed below.

The bearing contained in the Unit III front hub/

bearing assembly will produce noise and vibration

when worn or damaged. The noise will generally

change when the bearings are loaded. A road test of

the vehicle is normally required to determine the

location of a worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

constant speed, swerve the vehicle back and forth

from the left and to the right. This will load and

unload the bearings and change the noise level.

When bearing damage is slight, the noise is some-

times noticeable at lower speeds and at other times

is more noticeable at speeds above 105 km/h (65

mph).

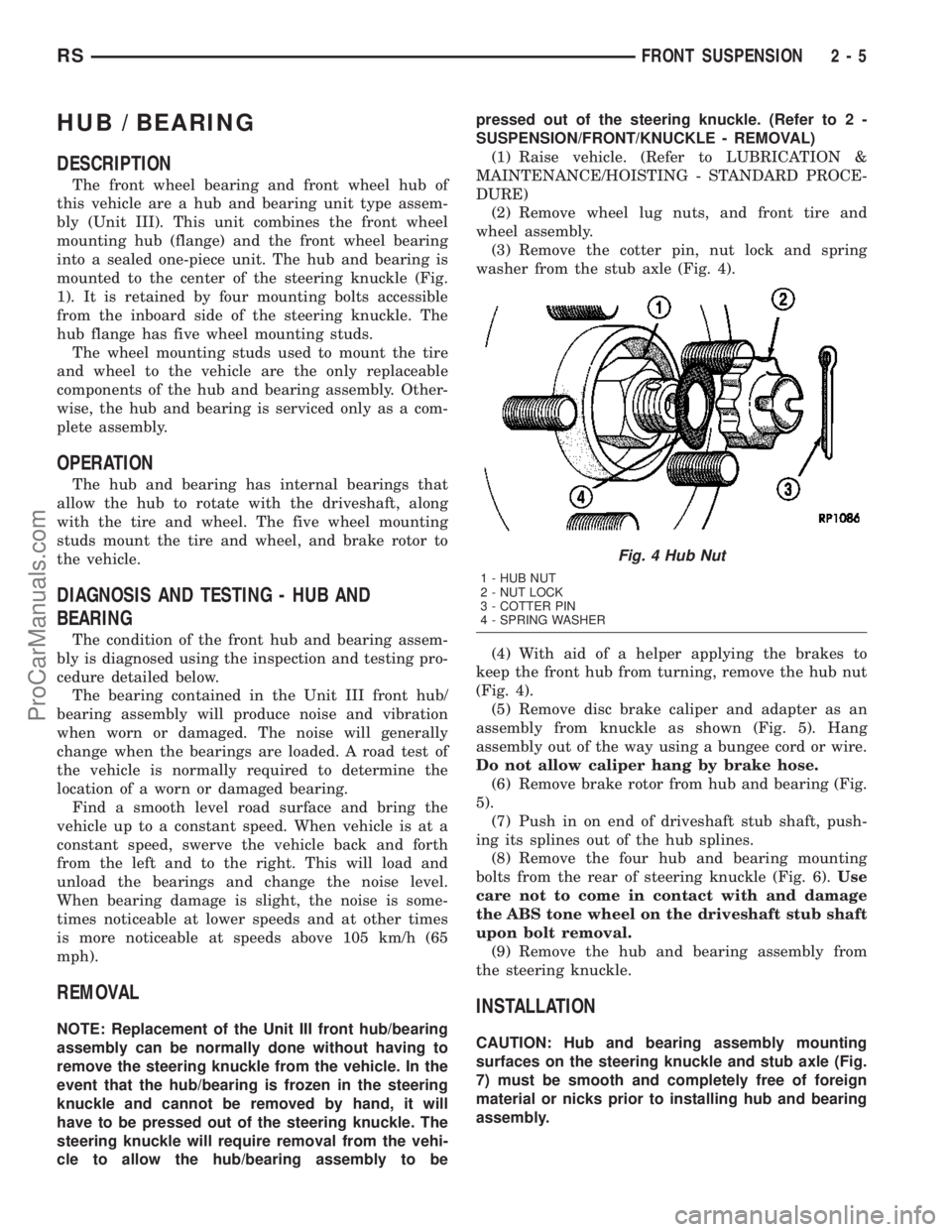

REMOVAL

NOTE: Replacement of the Unit III front hub/bearing

assembly can be normally done without having to

remove the steering knuckle from the vehicle. In the

event that the hub/bearing is frozen in the steering

knuckle and cannot be removed by hand, it will

have to be pressed out of the steering knuckle. The

steering knuckle will require removal from the vehi-

cle to allow the hub/bearing assembly to bepressed out of the steering knuckle. (Refer to 2 -

SUSPENSION/FRONT/KNUCKLE - REMOVAL)

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Remove wheel lug nuts, and front tire and

wheel assembly.

(3) Remove the cotter pin, nut lock and spring

washer from the stub axle (Fig. 4).

(4) With aid of a helper applying the brakes to

keep the front hub from turning, remove the hub nut

(Fig. 4).

(5) Remove disc brake caliper and adapter as an

assembly from knuckle as shown (Fig. 5). Hang

assembly out of the way using a bungee cord or wire.

Do not allow caliper hang by brake hose.

(6) Remove brake rotor from hub and bearing (Fig.

5).

(7) Push in on end of driveshaft stub shaft, push-

ing its splines out of the hub splines.

(8) Remove the four hub and bearing mounting

bolts from the rear of steering knuckle (Fig. 6).Use

care not to come in contact with and damage

the ABS tone wheel on the driveshaft stub shaft

upon bolt removal.

(9) Remove the hub and bearing assembly from

the steering knuckle.

INSTALLATION

CAUTION: Hub and bearing assembly mounting

surfaces on the steering knuckle and stub axle (Fig.

7) must be smooth and completely free of foreign

material or nicks prior to installing hub and bearing

assembly.

Fig. 4 Hub Nut

1 - HUB NUT

2 - NUT LOCK

3 - COTTER PIN

4 - SPRING WASHER

RSFRONT SUSPENSION2-5

ProCarManuals.com

Page 69 of 2177

REAR SUSPENSION

TABLE OF CONTENTS

page page

REAR SUSPENSION

DESCRIPTION - REAR SUSPENSION.......26

OPERATION - REAR SUSPENSION.........26

SPECIFICATIONS

REAR SUSPENSION FASTENER TORQUE . . 27

SPECIAL TOOLS

REAR SUSPENSION...................28

BUSHINGS

REMOVAL - LEAF SPRING FRONT BUSHING . 28

INSTALLATION - LEAF SPRING FRONT

BUSHING...........................29

HUB / BEARING

DESCRIPTION.........................30

OPERATION...........................30

DIAGNOSIS AND TESTING - HUB AND

BEARING............................30

REMOVAL.............................31

INSTALLATION.........................32

JOUNCE BUMPER

DESCRIPTION.........................35

OPERATION...........................35

REMOVAL

REMOVAL - AWD AND HEAVY DUTY......35

REMOVAL - FRONT-WHEEL-DRIVE.......35

INSTALLATION

INSTALLATION - AWD AND HEAVY DUTY . . . 35

INSTALLATION - FRONT-WHEEL-DRIVE....36

SHOCK ABSORBER

DESCRIPTION.........................36

OPERATION...........................36

REMOVAL - SHOCK ABSORBER...........36DISASSEMBLY - SHOCK ABSORBER (UPPER

BUSHING)...........................36

ASSEMBLY - SHOCK ABSORBER (UPPER

BUSHING)...........................37

INSTALLATION - SHOCK ABSORBER........38

SPRING - AWD

REMOVAL - AWD.......................38

INSTALLATION - AWD....................39

SPRING - FWD

REMOVAL - FWD.......................40

INSTALLATION - FWD...................41

SPRING MOUNTS - FRONT

REMOVAL.............................42

INSTALLATION.........................42

SPRING MOUNTS - REAR

REMOVAL.............................43

INSTALLATION.........................43

STABILIZER BAR

DESCRIPTION.........................43

OPERATION...........................44

REMOVAL

REMOVAL - AWD......................44

REMOVAL - FWD.....................44

INSTALLATION

INSTALLATION - AWD..................44

INSTALLATION - FWD..................44

TRACK BAR

DESCRIPTION.........................44

OPERATION...........................44

REMOVAL.............................44

INSTALLATION.........................45

REAR SUSPENSION

DESCRIPTION - REAR SUSPENSION

The rear suspension design on this vehicle uses

leaf springs, and a tube and casting axle (Fig. 1) (Fig.

2). The leaf springs used on the rear suspension of

this vehicle are of either a mono-leaf or multi-leaf

design.

There are 2 different rear suspension designs

available:

²Front-Wheel-Drive

²All-Wheel-Drive

The rear axle used on Front-Wheel-Drive applica-

tions of this vehicle is mounted to the rear leaf

springs using isolator bushings at the axle mounting

brackets.The rear axle used on All-Wheel-Drive applications

of this vehicle is also mounted to the rear leaf

springs, but does not use isolator bushings between

the rear axle and the leaf springs.

Each side of the rear suspension consists of these

major components:

²Leaf spring

²Jounce bumper

²Shock absorber

²Hub and bearing

²Track bar (one per suspension)

²Stabilizer bar (one per suspension)

OPERATION - REAR SUSPENSION

This rear suspension is designed to handle the var-

ious load requirements of the vehicle yet allow for a

comfortable ride.

2 - 26 REAR SUSPENSIONRS

ProCarManuals.com

Page 71 of 2177

DESCRIPTION N´mFt.

Lbs.In.

Lbs.

Leaf Spring Plate-To-Axle

Bolts95 70 Ð

Leaf Spring Rear Mount-To-

Body Bolts61 45 Ð

Leaf Spring Shackle Plate

Nuts61 45 Ð

Shock Absorber Mounting

Bolts88 65 Ð

Stabilizer Bar Bushing

Retainer Bolts61 45 Ð

Stabilizer Bar Link Nuts 61 45 Ð

Stabilizer Bar Link Frame

Bracket Mounting Bolts61 45 Ð

Track Bar Bracket-To-Body

Mount Bolts61 45 Ð

Track Bar Pivot Bolts 95 70 Ð

Wheel Mounting (Lug) Nut 135 100 Ð

SPECIAL TOOLS

REAR SUSPENSION

BUSHINGS

REMOVAL - LEAF SPRING FRONT BUSHING

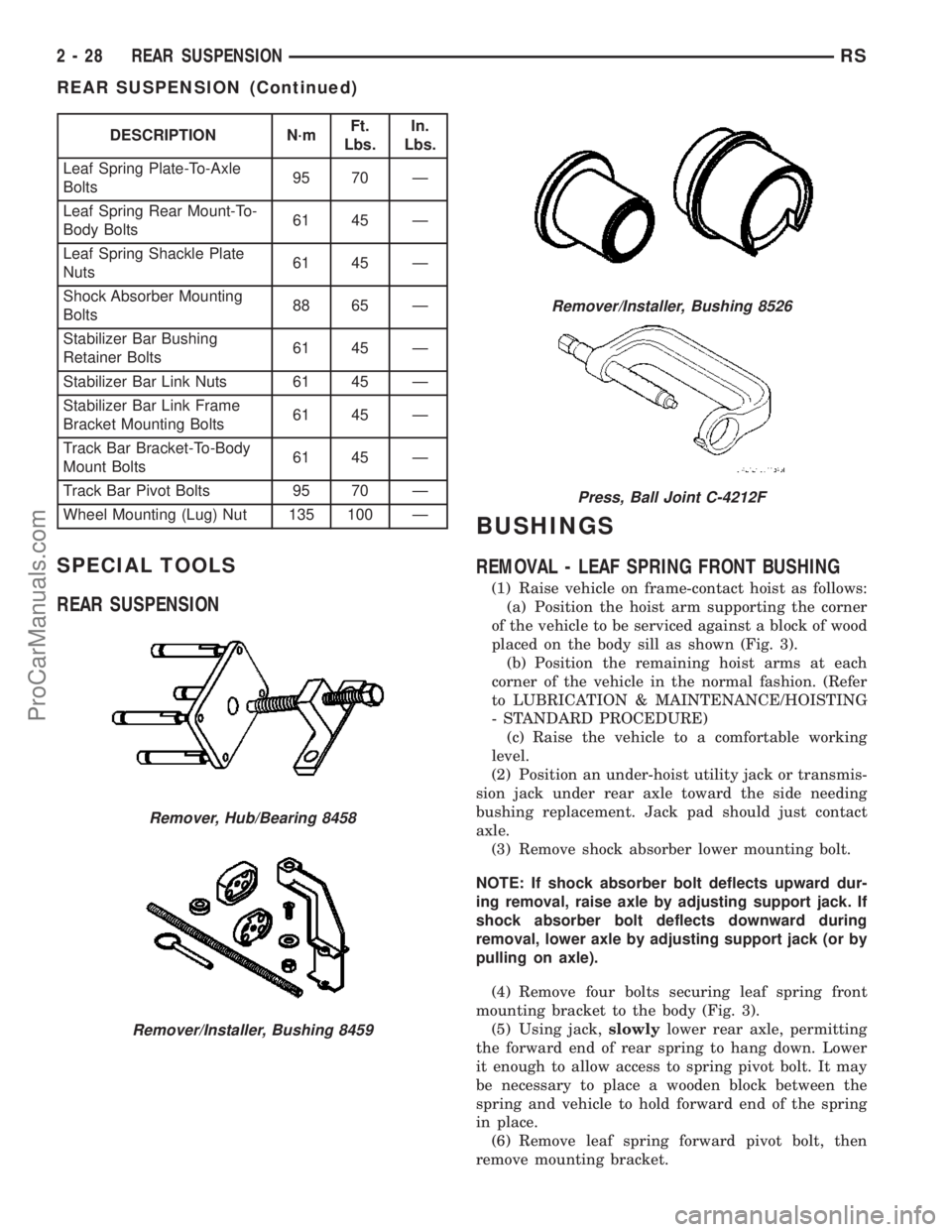

(1) Raise vehicle on frame-contact hoist as follows:

(a) Position the hoist arm supporting the corner

of the vehicle to be serviced against a block of wood

placed on the body sill as shown (Fig. 3).

(b) Position the remaining hoist arms at each

corner of the vehicle in the normal fashion. (Refer

to LUBRICATION & MAINTENANCE/HOISTING

- STANDARD PROCEDURE)

(c) Raise the vehicle to a comfortable working

level.

(2) Position an under-hoist utility jack or transmis-

sion jack under rear axle toward the side needing

bushing replacement. Jack pad should just contact

axle.

(3) Remove shock absorber lower mounting bolt.

NOTE: If shock absorber bolt deflects upward dur-

ing removal, raise axle by adjusting support jack. If

shock absorber bolt deflects downward during

removal, lower axle by adjusting support jack (or by

pulling on axle).

(4) Remove four bolts securing leaf spring front

mounting bracket to the body (Fig. 3).

(5) Using jack,slowlylower rear axle, permitting

the forward end of rear spring to hang down. Lower

it enough to allow access to spring pivot bolt. It may

be necessary to place a wooden block between the

spring and vehicle to hold forward end of the spring

in place.

(6) Remove leaf spring forward pivot bolt, then

remove mounting bracket.

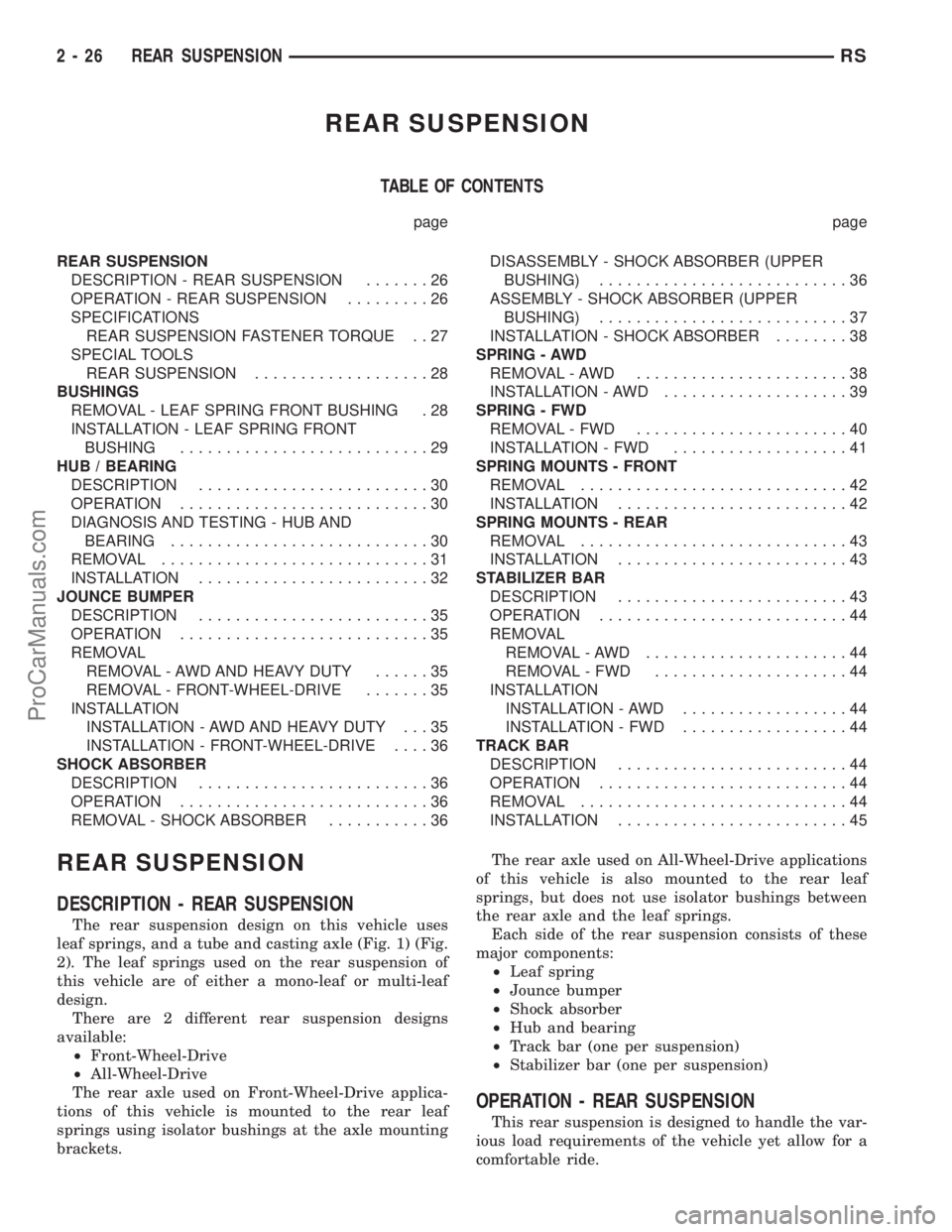

Remover, Hub/Bearing 8458

Remover/Installer, Bushing 8459

Remover/Installer, Bushing 8526

Press, Ball Joint C-4212F

2 - 28 REAR SUSPENSIONRS

REAR SUSPENSION (Continued)

ProCarManuals.com

Page 72 of 2177

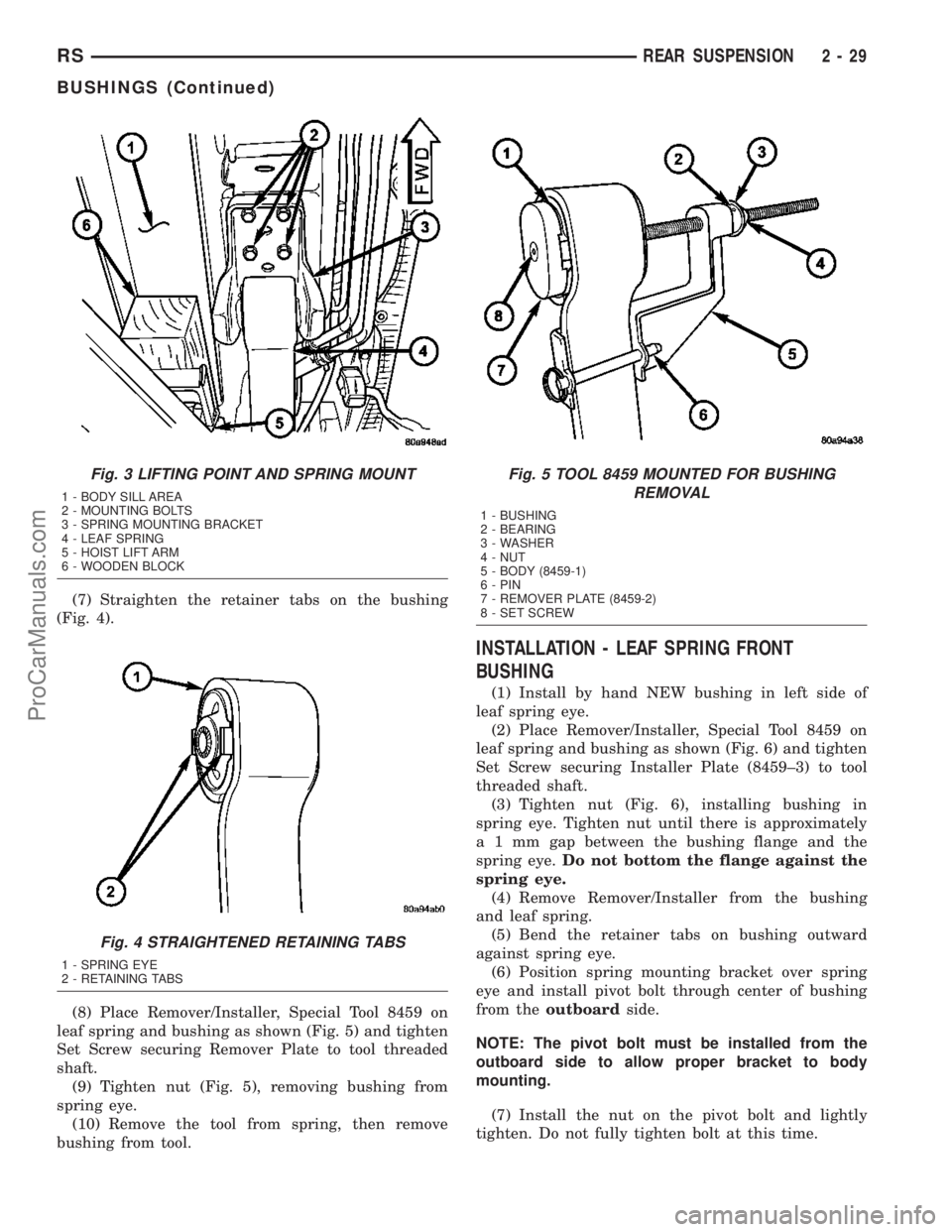

(7) Straighten the retainer tabs on the bushing

(Fig. 4).

(8) Place Remover/Installer, Special Tool 8459 on

leaf spring and bushing as shown (Fig. 5) and tighten

Set Screw securing Remover Plate to tool threaded

shaft.

(9) Tighten nut (Fig. 5), removing bushing from

spring eye.

(10) Remove the tool from spring, then remove

bushing from tool.

INSTALLATION - LEAF SPRING FRONT

BUSHING

(1) Install by hand NEW bushing in left side of

leaf spring eye.

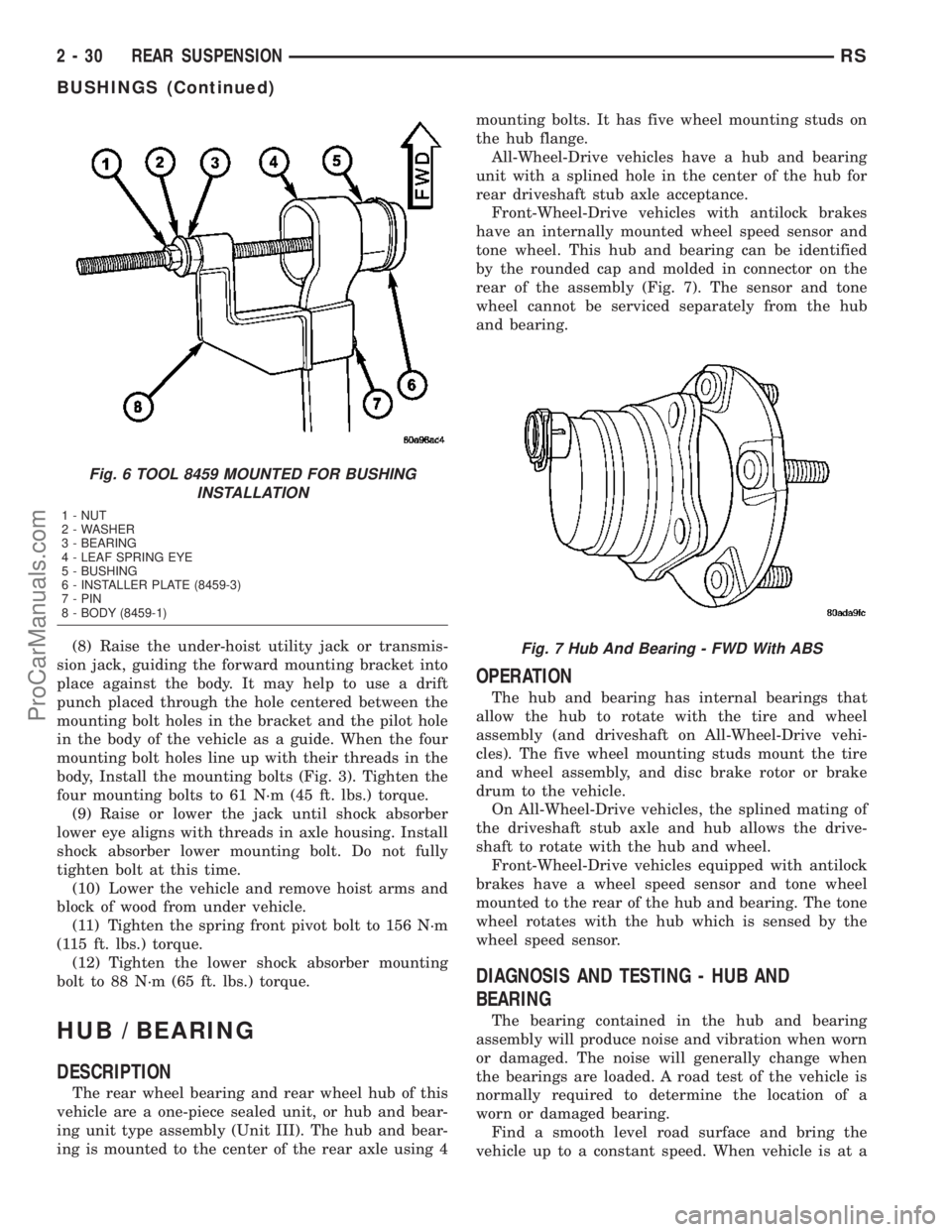

(2) Place Remover/Installer, Special Tool 8459 on

leaf spring and bushing as shown (Fig. 6) and tighten

Set Screw securing Installer Plate (8459±3) to tool

threaded shaft.

(3) Tighten nut (Fig. 6), installing bushing in

spring eye. Tighten nut until there is approximately

a 1 mm gap between the bushing flange and the

spring eye.Do not bottom the flange against the

spring eye.

(4) Remove Remover/Installer from the bushing

and leaf spring.

(5) Bend the retainer tabs on bushing outward

against spring eye.

(6) Position spring mounting bracket over spring

eye and install pivot bolt through center of bushing

from theoutboardside.

NOTE: The pivot bolt must be installed from the

outboard side to allow proper bracket to body

mounting.

(7) Install the nut on the pivot bolt and lightly

tighten. Do not fully tighten bolt at this time.

Fig. 3 LIFTING POINT AND SPRING MOUNT

1 - BODY SILL AREA

2 - MOUNTING BOLTS

3 - SPRING MOUNTING BRACKET

4 - LEAF SPRING

5 - HOIST LIFT ARM

6 - WOODEN BLOCK

Fig. 4 STRAIGHTENED RETAINING TABS

1 - SPRING EYE

2 - RETAINING TABS

Fig. 5 TOOL 8459 MOUNTED FOR BUSHING

REMOVAL

1 - BUSHING

2 - BEARING

3 - WASHER

4 - NUT

5 - BODY (8459-1)

6 - PIN

7 - REMOVER PLATE (8459-2)

8 - SET SCREW

RSREAR SUSPENSION2-29

BUSHINGS (Continued)

ProCarManuals.com

Page 73 of 2177

(8) Raise the under-hoist utility jack or transmis-

sion jack, guiding the forward mounting bracket into

place against the body. It may help to use a drift

punch placed through the hole centered between the

mounting bolt holes in the bracket and the pilot hole

in the body of the vehicle as a guide. When the four

mounting bolt holes line up with their threads in the

body, Install the mounting bolts (Fig. 3). Tighten the

four mounting bolts to 61 N´m (45 ft. lbs.) torque.

(9) Raise or lower the jack until shock absorber

lower eye aligns with threads in axle housing. Install

shock absorber lower mounting bolt. Do not fully

tighten bolt at this time.

(10) Lower the vehicle and remove hoist arms and

block of wood from under vehicle.

(11) Tighten the spring front pivot bolt to 156 N´m

(115 ft. lbs.) torque.

(12) Tighten the lower shock absorber mounting

bolt to 88 N´m (65 ft. lbs.) torque.

HUB / BEARING

DESCRIPTION

The rear wheel bearing and rear wheel hub of this

vehicle are a one-piece sealed unit, or hub and bear-

ing unit type assembly (Unit III). The hub and bear-

ing is mounted to the center of the rear axle using 4mounting bolts. It has five wheel mounting studs on

the hub flange.

All-Wheel-Drive vehicles have a hub and bearing

unit with a splined hole in the center of the hub for

rear driveshaft stub axle acceptance.

Front-Wheel-Drive vehicles with antilock brakes

have an internally mounted wheel speed sensor and

tone wheel. This hub and bearing can be identified

by the rounded cap and molded in connector on the

rear of the assembly (Fig. 7). The sensor and tone

wheel cannot be serviced separately from the hub

and bearing.

OPERATION

The hub and bearing has internal bearings that

allow the hub to rotate with the tire and wheel

assembly (and driveshaft on All-Wheel-Drive vehi-

cles). The five wheel mounting studs mount the tire

and wheel assembly, and disc brake rotor or brake

drum to the vehicle.

On All-Wheel-Drive vehicles, the splined mating of

the driveshaft stub axle and hub allows the drive-

shaft to rotate with the hub and wheel.

Front-Wheel-Drive vehicles equipped with antilock

brakes have a wheel speed sensor and tone wheel

mounted to the rear of the hub and bearing. The tone

wheel rotates with the hub which is sensed by the

wheel speed sensor.

DIAGNOSIS AND TESTING - HUB AND

BEARING

The bearing contained in the hub and bearing

assembly will produce noise and vibration when worn

or damaged. The noise will generally change when

the bearings are loaded. A road test of the vehicle is

normally required to determine the location of a

worn or damaged bearing.

Find a smooth level road surface and bring the

vehicle up to a constant speed. When vehicle is at a

Fig. 6 TOOL 8459 MOUNTED FOR BUSHING

INSTALLATION

1 - NUT

2 - WASHER

3 - BEARING

4 - LEAF SPRING EYE

5 - BUSHING

6 - INSTALLER PLATE (8459-3)

7 - PIN

8 - BODY (8459-1)

Fig. 7 Hub And Bearing - FWD With ABS

2 - 30 REAR SUSPENSIONRS

BUSHINGS (Continued)

ProCarManuals.com

Page 76 of 2177

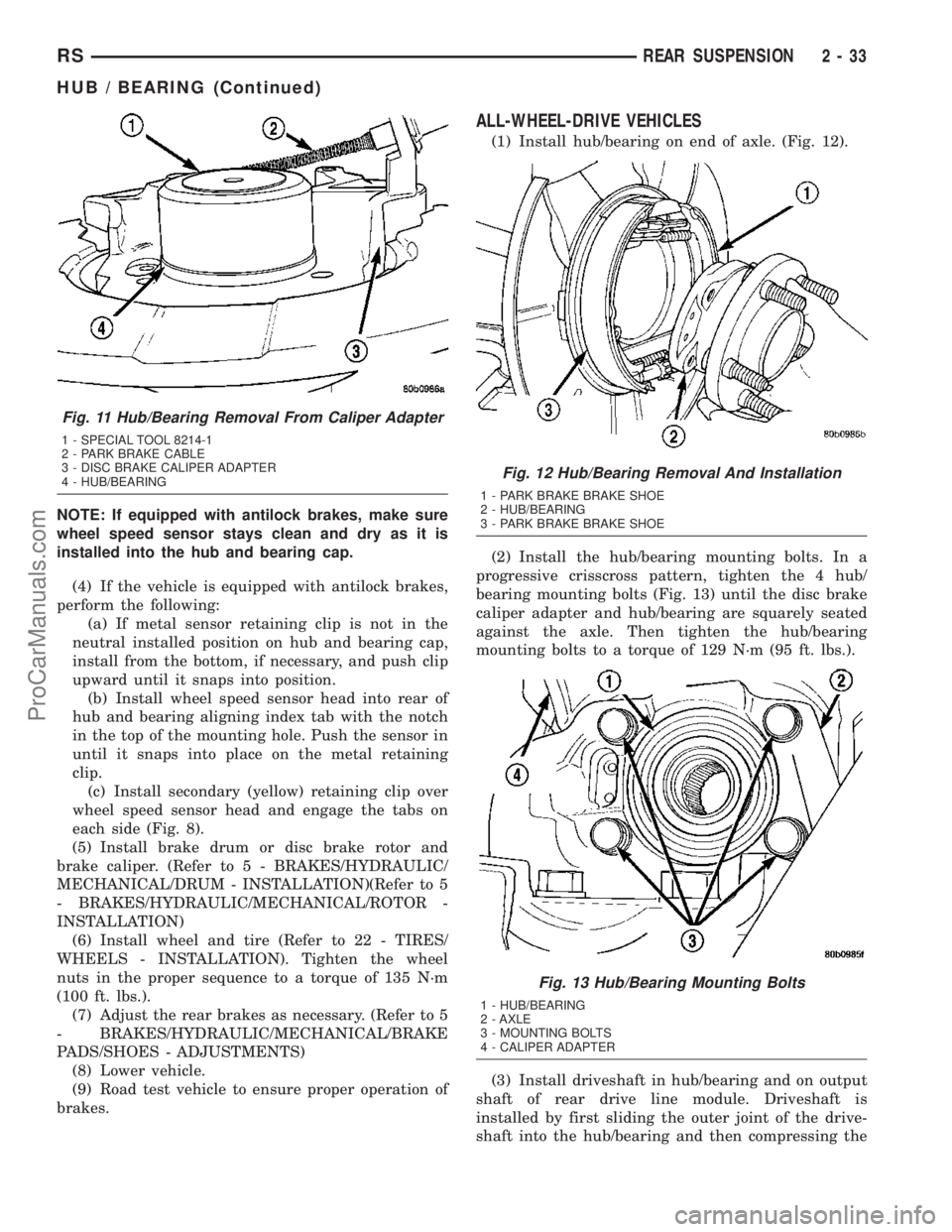

NOTE: If equipped with antilock brakes, make sure

wheel speed sensor stays clean and dry as it is

installed into the hub and bearing cap.

(4) If the vehicle is equipped with antilock brakes,

perform the following:

(a) If metal sensor retaining clip is not in the

neutral installed position on hub and bearing cap,

install from the bottom, if necessary, and push clip

upward until it snaps into position.

(b) Install wheel speed sensor head into rear of

hub and bearing aligning index tab with the notch

in the top of the mounting hole. Push the sensor in

until it snaps into place on the metal retaining

clip.

(c) Install secondary (yellow) retaining clip over

wheel speed sensor head and engage the tabs on

each side (Fig. 8).

(5) Install brake drum or disc brake rotor and

brake caliper. (Refer to 5 - BRAKES/HYDRAULIC/

MECHANICAL/DRUM - INSTALLATION)(Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/ROTOR -

INSTALLATION)

(6) Install wheel and tire (Refer to 22 - TIRES/

WHEELS - INSTALLATION). Tighten the wheel

nuts in the proper sequence to a torque of 135 N´m

(100 ft. lbs.).

(7) Adjust the rear brakes as necessary. (Refer to 5

- BRAKES/HYDRAULIC/MECHANICAL/BRAKE

PADS/SHOES - ADJUSTMENTS)

(8) Lower vehicle.

(9) Road test vehicle to ensure proper operation of

brakes.

ALL-WHEEL-DRIVE VEHICLES

(1) Install hub/bearing on end of axle. (Fig. 12).

(2) Install the hub/bearing mounting bolts. In a

progressive crisscross pattern, tighten the 4 hub/

bearing mounting bolts (Fig. 13) until the disc brake

caliper adapter and hub/bearing are squarely seated

against the axle. Then tighten the hub/bearing

mounting bolts to a torque of 129 N´m (95 ft. lbs.).

(3) Install driveshaft in hub/bearing and on output

shaft of rear drive line module. Driveshaft is

installed by first sliding the outer joint of the drive-

shaft into the hub/bearing and then compressing the

Fig. 11 Hub/Bearing Removal From Caliper Adapter

1 - SPECIAL TOOL 8214-1

2 - PARK BRAKE CABLE

3 - DISC BRAKE CALIPER ADAPTER

4 - HUB/BEARING

Fig. 12 Hub/Bearing Removal And Installation

1 - PARK BRAKE BRAKE SHOE

2 - HUB/BEARING

3 - PARK BRAKE BRAKE SHOE

Fig. 13 Hub/Bearing Mounting Bolts

1 - HUB/BEARING

2 - AXLE

3 - MOUNTING BOLTS

4 - CALIPER ADAPTER

RSREAR SUSPENSION2-33

HUB / BEARING (Continued)

ProCarManuals.com

Page 79 of 2177

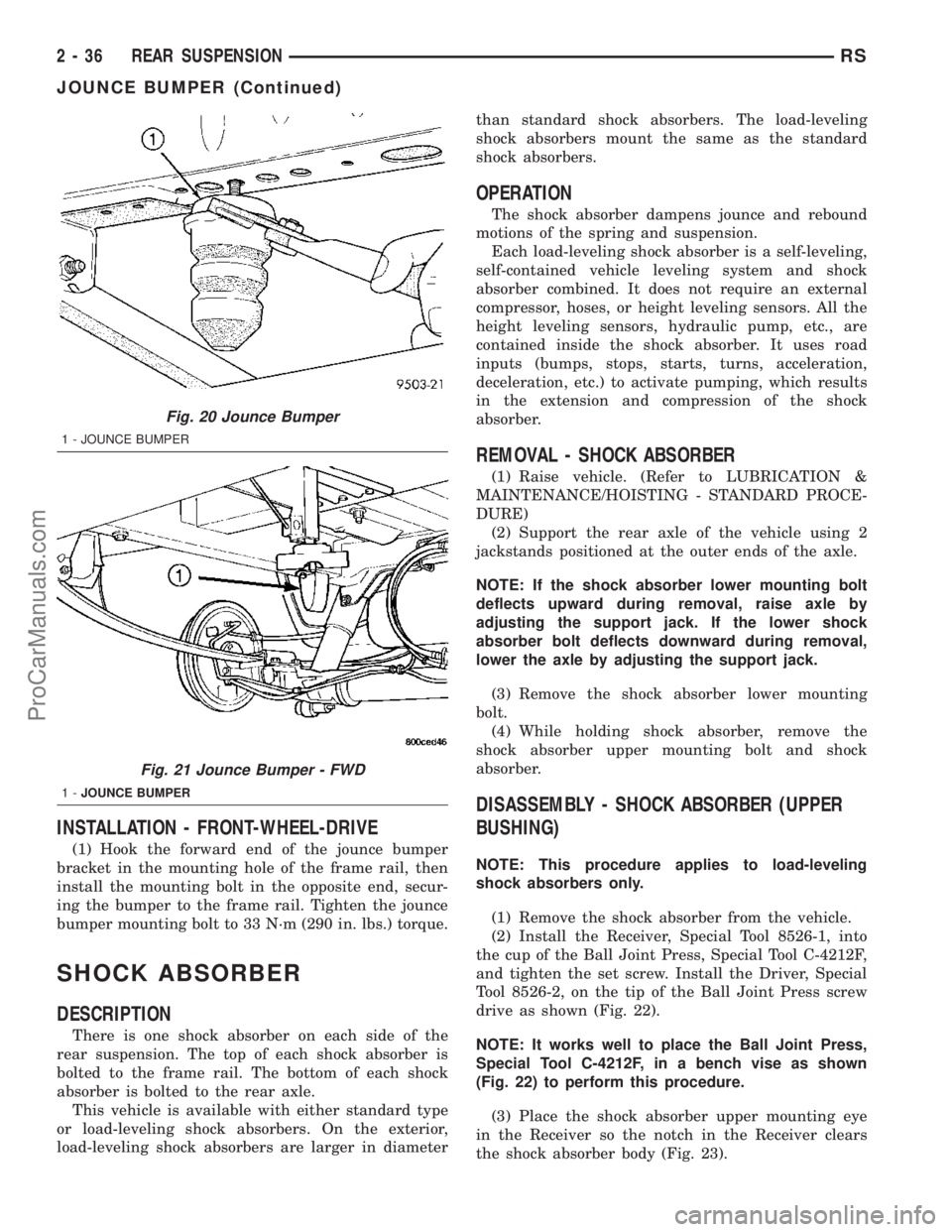

INSTALLATION - FRONT-WHEEL-DRIVE

(1) Hook the forward end of the jounce bumper

bracket in the mounting hole of the frame rail, then

install the mounting bolt in the opposite end, secur-

ing the bumper to the frame rail. Tighten the jounce

bumper mounting bolt to 33 N´m (290 in. lbs.) torque.

SHOCK ABSORBER

DESCRIPTION

There is one shock absorber on each side of the

rear suspension. The top of each shock absorber is

bolted to the frame rail. The bottom of each shock

absorber is bolted to the rear axle.

This vehicle is available with either standard type

or load-leveling shock absorbers. On the exterior,

load-leveling shock absorbers are larger in diameterthan standard shock absorbers. The load-leveling

shock absorbers mount the same as the standard

shock absorbers.

OPERATION

The shock absorber dampens jounce and rebound

motions of the spring and suspension.

Each load-leveling shock absorber is a self-leveling,

self-contained vehicle leveling system and shock

absorber combined. It does not require an external

compressor, hoses, or height leveling sensors. All the

height leveling sensors, hydraulic pump, etc., are

contained inside the shock absorber. It uses road

inputs (bumps, stops, starts, turns, acceleration,

deceleration, etc.) to activate pumping, which results

in the extension and compression of the shock

absorber.

REMOVAL - SHOCK ABSORBER

(1) Raise vehicle. (Refer to LUBRICATION &

MAINTENANCE/HOISTING - STANDARD PROCE-

DURE)

(2) Support the rear axle of the vehicle using 2

jackstands positioned at the outer ends of the axle.

NOTE: If the shock absorber lower mounting bolt

deflects upward during removal, raise axle by

adjusting the support jack. If the lower shock

absorber bolt deflects downward during removal,

lower the axle by adjusting the support jack.

(3) Remove the shock absorber lower mounting

bolt.

(4) While holding shock absorber, remove the

shock absorber upper mounting bolt and shock

absorber.

DISASSEMBLY - SHOCK ABSORBER (UPPER

BUSHING)

NOTE: This procedure applies to load-leveling

shock absorbers only.

(1) Remove the shock absorber from the vehicle.

(2) Install the Receiver, Special Tool 8526-1, into

the cup of the Ball Joint Press, Special Tool C-4212F,

and tighten the set screw. Install the Driver, Special

Tool 8526-2, on the tip of the Ball Joint Press screw

drive as shown (Fig. 22).

NOTE: It works well to place the Ball Joint Press,

Special Tool C-4212F, in a bench vise as shown

(Fig. 22) to perform this procedure.

(3) Place the shock absorber upper mounting eye

in the Receiver so the notch in the Receiver clears

the shock absorber body (Fig. 23).

Fig. 20 Jounce Bumper

1 - JOUNCE BUMPER

Fig. 21 Jounce Bumper - FWD

1-JOUNCE BUMPER

2 - 36 REAR SUSPENSIONRS

JOUNCE BUMPER (Continued)

ProCarManuals.com