remote start CHRYSLER CARAVAN 2003 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2003, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2003Pages: 2177, PDF Size: 59.81 MB

Page 309 of 2177

motors, and fuel pumps that have been found to be

potential sources of RFI or EMI.

OPERATION

There are two common strategies that can be used

to suppress Radio Frequency Interference (RFI) and

ElectroMagnetic Interference (EMI) radio noise. The

first suppression strategy involves preventing the

production of RFI and EMI electromagnetic signals

at their sources. The second suppression strategy

involves preventing the reception of RFI and EMI

electromagnetic signals by the audio system compo-

nents.

The use of braided ground straps in key locations

is part of the RFI and EMI prevention strategy.

These ground straps ensure adequate ground paths,

particularly for high current components such as

many of those found in the starting, charging, igni-

tion, engine control and transmission control sys-

tems. An insufficient ground path for any of these

high current components may result in radio noise

caused by induced voltages created as the high cur-

rent seeks alternative ground paths through compo-

nents or circuits intended for use by, or in close

proximity to the audio system components or circuits.

Preventing the reception of RFI and EMI is accom-

plished by ensuring that the audio system compo-

nents are correctly installed in the vehicle. Loose,

corroded or improperly soldered wire harness connec-

tions, improperly routed wiring and inadequate audio

system component grounding can all contribute to

the reception of RFI and EMI. A properly grounded

antenna body and radio chassis, as well as a shielded

antenna coaxial cable with clean and tight connec-

tions will each help reduce the potential for reception

of RFI and EMI.

REMOTE SWITCHES

DESCRIPTION

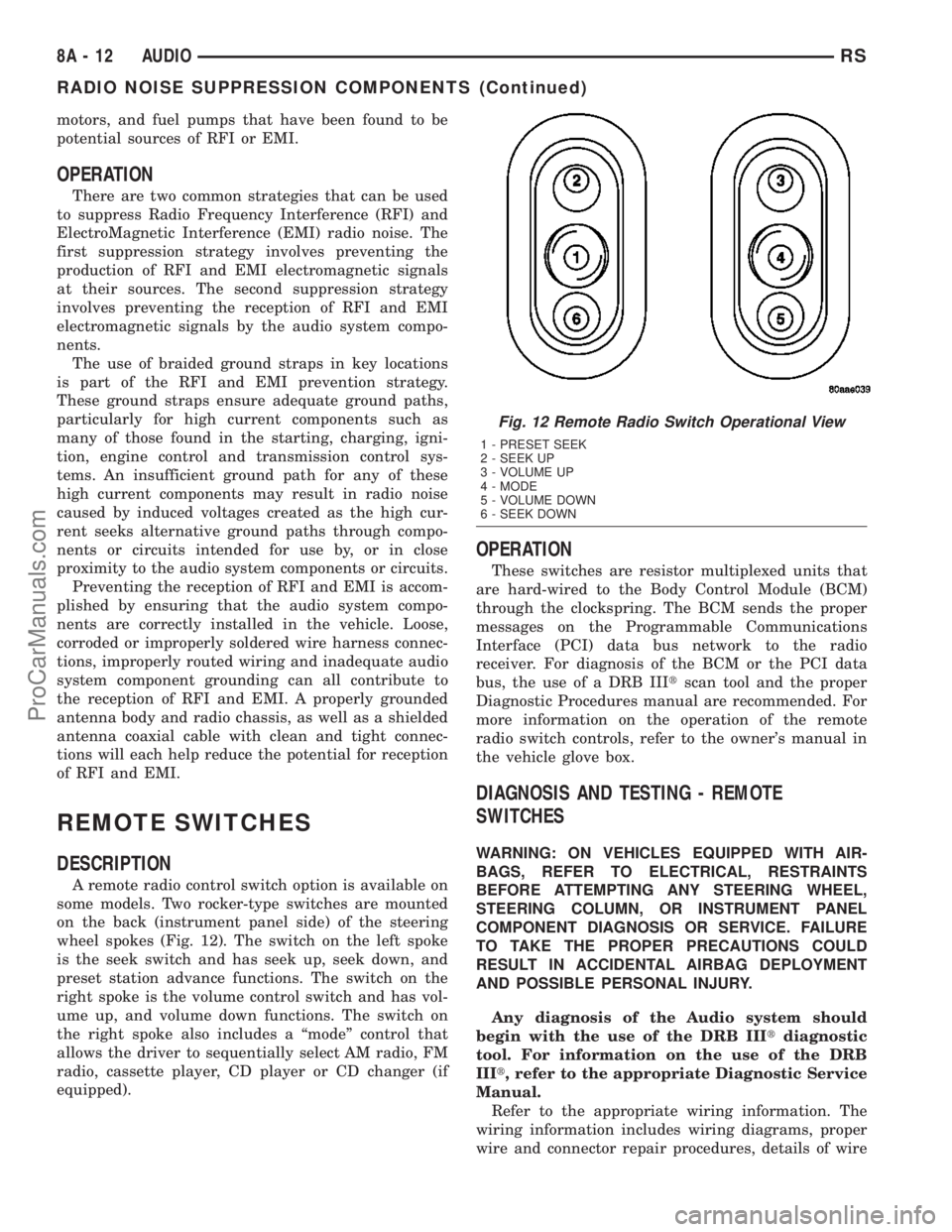

A remote radio control switch option is available on

some models. Two rocker-type switches are mounted

on the back (instrument panel side) of the steering

wheel spokes (Fig. 12). The switch on the left spoke

is the seek switch and has seek up, seek down, and

preset station advance functions. The switch on the

right spoke is the volume control switch and has vol-

ume up, and volume down functions. The switch on

the right spoke also includes a ªmodeº control that

allows the driver to sequentially select AM radio, FM

radio, cassette player, CD player or CD changer (if

equipped).

OPERATION

These switches are resistor multiplexed units that

are hard-wired to the Body Control Module (BCM)

through the clockspring. The BCM sends the proper

messages on the Programmable Communications

Interface (PCI) data bus network to the radio

receiver. For diagnosis of the BCM or the PCI data

bus, the use of a DRB IIItscan tool and the proper

Diagnostic Procedures manual are recommended. For

more information on the operation of the remote

radio switch controls, refer to the owner's manual in

the vehicle glove box.

DIAGNOSIS AND TESTING - REMOTE

SWITCHES

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL

COMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

Any diagnosis of the Audio system should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Service

Manual.

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, details of wire

Fig. 12 Remote Radio Switch Operational View

1 - PRESET SEEK

2 - SEEK UP

3 - VOLUME UP

4 - MODE

5 - VOLUME DOWN

6 - SEEK DOWN

8A - 12 AUDIORS

RADIO NOISE SUPPRESSION COMPONENTS (Continued)

ProCarManuals.com

Page 368 of 2177

the battery, if required. Refer to the Battery section

for more information.

²Ignition Switch- Visually inspect the ignition

switch for indications of physical damage and loose

or corroded wire harness connections.

²Transmission Range Sensor or Park/Neu-

tral Switch- Visually inspect the transmission

range sensor for indications of physical damage and

loose or corroded wire harness connections.

²Starter Relay- Visually inspect the starter

relay for indications of physical damage and loose or

corroded wire harness connections.

²Starter Motor- Visually inspect the starter

motor for indications of physical damage and loose or

corroded wire harness connections.²Starter Solenoid- Visually inspect the starter

solenoid for indications of physical damage and loose

or corroded wire harness connections.

²Wiring- Visually inspect the wire harness for

damage. Repair or replace any faulty wiring, as

required. Check for loose or corroded wire harness

connections at main engine ground and remote jump

post.

²Power Distribution Center (PDC)- Visually

inspect the B+ connections at the PDC for physical

damage and loose or corroded harness connections.

STARTING SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

STARTER FAILS

TO ENGAGE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY, IF

REQUIRED.

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO FEED CIRCUIT RESISTANCE TEST AND FEED

CIRCUIT TEST IN THIS SECTION.

3. STARTER RELAY

FAULTY.3. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

4. IGNITION SWITCH

FAULTY.4. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION OR 8 WIRING DIAGRAMS. REPLACE SWITCH, IF

NECESSARY.

5. PARK/NEUTRAL

POSITION SWITCH

(AUTO TRANS) FAULTY

OR MIS-ADJUSTED.5. REFER PARK/NEUTRAL POSITION SWITCH TEST, IN THE

TRANSAXLE. SECTION FOR MORE INFORMATION. REPLACE

SWITCH, IF NECESSARY.

6. CLUTCH INTERLOCK

SWITCH (MAN TRANS)

FAULTY.6. REFER TO CLUTCH PEDAL POSITION SWITCH TEST, IN

THE CLUTCH. SECTION. REPLACE SWITCH, IF NECESSARY.

7. STARTER SOLENOID

FAULTY.7. REFER TO SOLENOID TEST, IN THIS SECTION. REPLACE

STARTER ASSEMBLY, IF NECESSARY.

8. STARTER ASSEMBLY

FAULTY.8. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

9. FAULTY TEETH ON

RING GEAR.9. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

10. PCM DOUBLE

START OVERRIDE

OUTPUT FAILURE.10. REFER TO PCM DIAGNOSTIC. CHECK FOR CONTINUITY

BETWEEN PCM AND TERMINAL 85. REPAIR OPEN CIRCUIT

AS REQUIRED. IF OK, PCM MAY BE DEFECTIVE.

STARTER

ENGAGES,

FAILS TO TURN

ENGINE.1. BATTERY

DISCHARGED OR

FAULTY.1. REFER TO THE BATTERY SECTION FOR MORE

INFORMATION. CHARGE OR REPLACE BATTERY AS

NECESSARY.

RSSTARTING8F-29

STARTING (Continued)

ProCarManuals.com

Page 370 of 2177

(3) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(4) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(5) Connect a remote starter switch or a jumper

wire between the remote battery positive post and

terminal 87 of the starter relay connector.

(a) If engine cranks, starter/starter solenoid is

good. Go to the Starter Relay Test.

(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid and from the battery positive ter-

minal to starter post for loose or corroded connec-

tions. Particularly at starter terminals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter. Inspect the ring gear

teeth.

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK/NEUTRAL POSITION

WITH THE PARKING BRAKE APPLIED.

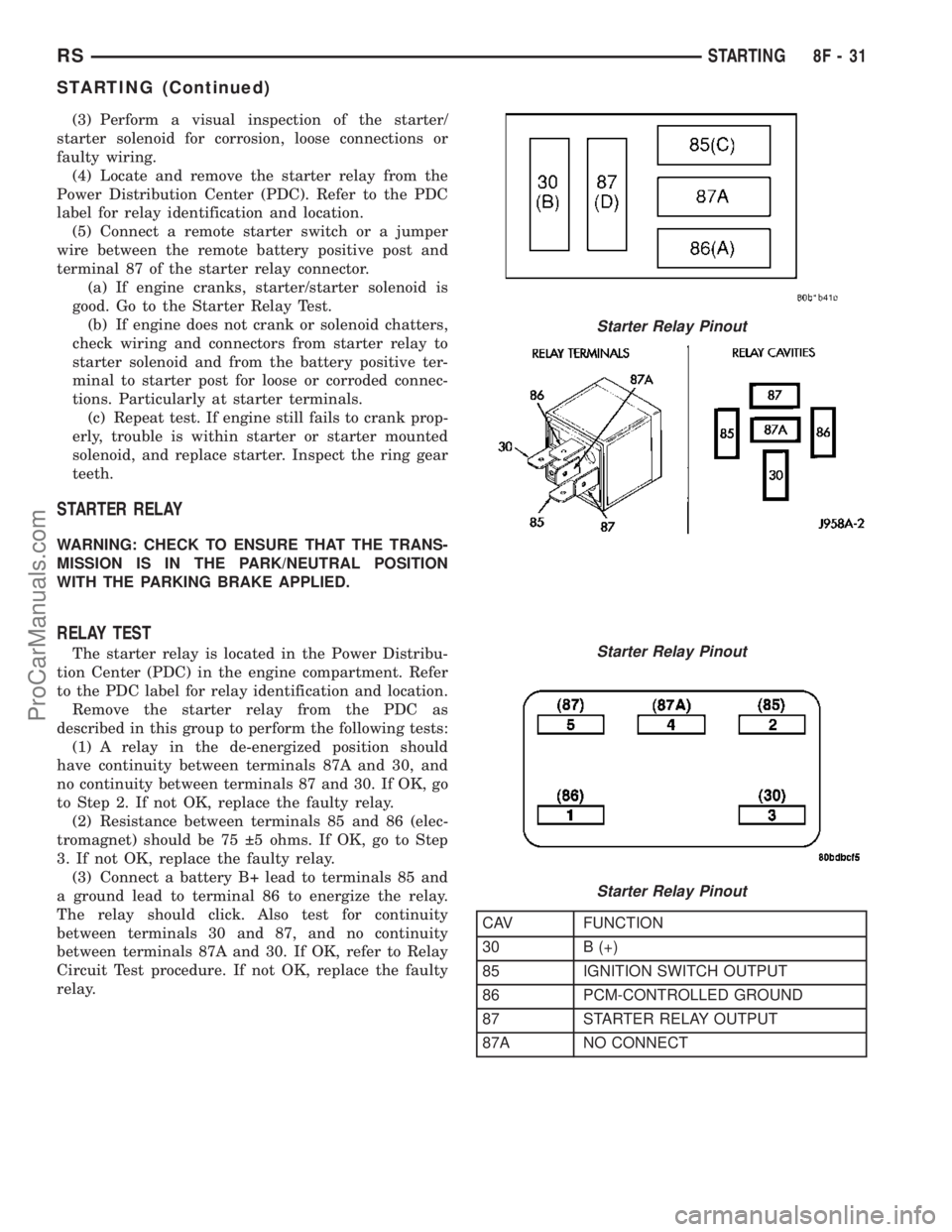

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 75 5 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 85 and

a ground lead to terminal 86 to energize the relay.

The relay should click. Also test for continuity

between terminals 30 and 87, and no continuity

between terminals 87A and 30. If OK, refer to Relay

Circuit Test procedure. If not OK, replace the faulty

relay.

CAV FUNCTION

30 B (+)

85 IGNITION SWITCH OUTPUT

86 PCM-CONTROLLED GROUND

87 STARTER RELAY OUTPUT

87A NO CONNECT

Starter Relay Pinout

Starter Relay Pinout

Starter Relay Pinout

RSSTARTING8F-31

STARTING (Continued)

ProCarManuals.com

Page 498 of 2177

STANDARD PROCEDURE - RKE TRANSMITTER

PROGRAMING

(1) Using a functional key fob transmitter, unlock

the vehicle and disarm the Vehicle Theft Security

System.

(2) Insert ignition key into the ignition switch.

(3) Turn the ignition switch to RUN position with-

out starting engine.

(4) Using a functional key fob transmitter, press

and hold the UNLOCK button for a minimum five

seconds (maximum ten seconds).

(5) While still holding UNLOCK button, and

before ten seconds passes, press the PANIC button

and release both at the same time. A single chime

will sound to indicate that the transmitter program-

ming mode has been entered (allow 3 seconds for

chime to sound).

(6) Within 30 seconds of the chime, press and

release the ªLOCKº and ªUNLOCKº buttons on the

transmitter at the same time. Then press and release

any button on the same transmitter and a chime will

sound after successfully programming the transmit-

ter.

(7) Repeat steps 5 and 6 for all transmitters that

will be used with this vehicle (up to 4 total).

(8) Turn ignition to the OFF position. Transmitter

programming mode will discontinue after 60 seconds.

All transmitter programming must be com-

pleted within time specified.

SPECIFICATIONS

RANGE

Normal operation range is up to a distance of 7

meters (23 ft.) of the vehicle. Range may be better or

worse depending on the environment around the

vehicle. Closeness to a radio frequency transmitter

such as a radio station tower that is broadcasting on

105 MHz FM or a 156 MHz 2±way communication

station, may degrade operational range, while range

in an open field will be enhanced.

BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. Therecommended battery is Duracell DL 2016 or equiva-

lent, TWO cells are required. Battery life is about

three years minimum.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

REMOTE KEYLESS ENTRY

MODULE

DESCRIPTION

The RKE module is capable of retaining up to four

different Vehicle Access Codes.

OPERATION

Whenever the vehicle battery power is interrupted

the RKE Module will retain all vehicle access codes

in its memory. When replacing or adding a key fob

transmitter (maximum 4) a DRB IIItscan tool is

required to program the RKE Module to accept the

new Vehicle Access Code if a customer owned trans-

mitter is not available. Refer to Electrical, Remote

Keyless Entry Module, Standard Procedure - Pro-

gramming RKE Module or the Proper Body Diagnos-

tic Procedures manual.

DIAGNOSIS AND TESTING - REMOTE KEYLESS

ENTRY MODULE

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Refer to the

proper Body Diagnostic Procedures Manual for test-

ing the Remote Keyless Entry system using a

DRB IIItscan tool. Also refer to other interrelated

systems groups within this manual:

²Vehicle Theft Security System

²Power Seats

²Power Mirrors

RSPOWER LOCKS8N-43

KEYLESS ENTRY TRANSMITTER (Continued)

ProCarManuals.com

Page 546 of 2177

VEHICLE THEFT SECURITY

TABLE OF CONTENTS

page page

VEHICLE THEFT SECURITY

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM..................3

DIAGNOSIS AND TESTING - VEHICLE

THEFT SECURITY SYSTEM..............3

HOOD AJAR SWITCH - EXPORT

REMOVAL.............................3INSTALLATION..........................3

TRANSPONDER KEY

DESCRIPTION..........................3

OPERATION............................3

STANDARD PROCEDURE - TRANSPONDER

PROGRAMMING.......................4

VTSS/SKIS INDICATOR LAMP

DESCRIPTION..........................5

OPERATION............................5

VEHICLE THEFT SECURITY

DESCRIPTION

VEHICLE THEFT SECURITY SYSTEM

The Vehicle Theft Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, and ignition action for

unauthorized operation (hood and liftgate for RG -

Export). The alarm activates:

²Sounding of the horn

²Flashing of the headlamps/park/tail lamps

²Flashing of the headlamps

²An engine kill feature (with SKIS)

SENTRY KEY IMMOBILIZER SYSTEM

The Sentry Key Immobilizer System (SKIS) is

available as a factory-installed option on this vehicle.

It is designed to provide passive protection against

unauthorized vehicle use by disabling the engine,

after two (2) seconds of running, whenever an invalid

key is used to start the vehicle. The SKIS is active

whenever the ignition is on and does not require any

customer intervention. The primary components of

the system are the Sentry Key Immobilizer Module

(SKIM), Sentry Key (ignition key with a transponder

molded into the head), indicator light, Body Control

Module (BCM), and the Powertrain Control Module

(PCM). The SKIM is mounted to the steering column

with the molded, integral antenna mounted on the

ignition housing. The indicator light, is located in the

Mechanical Instrument Cluster (MIC).

OPERATION

VEHICLE THEFT SECURITY SYSTEM

Upon failure of proper SKIM communication to the

PCM, the PCM will shut off fuel after two seconds of

run time. The engine will not re-crank on the key

cycle that the failure occurred, a full key down

sequence must be performed for the engine to crank

again. After six consecutive fuel shut-offs, the engine

will no longer crank on subsequent key cycles. The

failure must be corrected and a valid communication

process between the SKIM and the PCM must occur

for the engine to crank and start again.

The electronics for the VTSS are part of the Body

Control Module (BCM). The system is armed when

the vehicle is locked using the:

²Power door lock switches (with any door ajar)

²Remote Keyless Entry transmitter.

²Door Cylinder Lock Switches.

For vehicles equipped with SKIS, the doors do not

have to be locked to enable the fuel shut off feature.

After the vehicle is locked and the last door is

closed, the set LED indicator in the Mechanical

Instrument Cluster (MIC) will flash quickly for 16

seconds, indicating that arming is in progress. If no

monitored systems are activated during this period,

the system will arm. The LED will extinguish unless

the liftgate is open. If the liftgate is open, the LED

will flash at a slower rate.

This indicates that the system is armed. If fault is

detected on the driver key cylinder input, the indica-

tor LED will remain solid during the arming process,

although the system will still arm. If the indicator

LED does not illuminate at all upon door closing it

indicates that the system is not arming.

Passive disarming occurs upon normal vehicle

entry by unlocking either door with the ignition key/

RSVEHICLE THEFT SECURITY8Q-1

ProCarManuals.com

Page 547 of 2177

remote transmitter. This disarming will also halt the

alarm once it has been activated.

A tamper alert exists to notify the driver that the

VTSS had been activated. This alert consists of 3

horn pulses when the vehicle is disarmed.

NOTE: The VTSS will not arm by pushing down the

door lock mechanism. This will manually override

the system.

For Door Cylinder Lock Switch Removal and

Installation, refer to Electrical, Power Locks, Door

Cylinder Lock Switch.

If the VTSS is triggered, the horn will pulse, head-

lamps/marker lamps will flash, and the VTSS warn-

ing lamp will flash. If BCM determines the threat to

be false and the VTSS is not triggered again, the sys-

tem will shut down and rearm itself after three min-

utes. If a trigger is still active, the alarm will

continue for an additional 15 minutes without the

horn. The VTSS monitors the passenger compart-

ment (for RG - Export it also monitors the engine

compartment. If a malfunction occurs in the engine

compartment, the passenger compartment would still

arm and function normally).

NOTE: System will not arm if passenger compart-

ment is not secure.

NOTE: (RG - Export - If hood is not secure during

the arming sequence, the lamp will stay lit and not

flash. The system will arm with hood not secured

and the liftgate open).

ARMING THE VTSS - METHOD A

(1) With the key removed from the ignition lock

and any door open (excluding liftgate), actuate one of

the following:

²Power door lock button to LOCK,

²Key fob LOCK button

²Driver door lock key cylinder to locked position.

(2) Close all opened doors. Liftgate can remain

open.

(3) After the last door is closed, an arming time-

out period of sixteen seconds will start, then the

VTSS will become armed.

ARMING THE VTSS - METHOD B

Actuating the key fob transmitter LOCK button,

key locking the front doors with the doors closed and

the ignition locked will begin the arming time-out

period. If method A, 16 second time-out sequence was

in process when method B was actuated, the 16 sec-

ond time-out will restart from the time of the second

actuation.If the security lamp does not illuminate at all upon

final door closure, it indicates that the system is not

arming.

The current VTSS status armed or disarmed shall

be maintained in memory to prevent battery discon-

nects from disarming the system.

TRIGGERING THE VTSS

After the VTSS is armed, the following actions will

trigger the alarm:

²Opening any door (excluding liftgate).

²Opening the hood (RG - Export)

²Turning the ignition to the RUN position.

NOTE: When the VTSS is ARMED, the interior

power door lock switch ªUNLOCKº will be disabled

until the vehicle is disarmed.

CAUTION: The VTSS indicator LED will trigger and

engine will continue to run if the vehicle is

equipped with SKIS and the proper key is used to

start the vehicle. This condition will occur if the

VTSS has been triggered. If valid key is used, VTSS

will disarm

SENTRY KEY IMMOBILIZER SYSTEM

The SKIS includes keys from the factory which are

pre-programmed. Each SKIM will recognize a maxi-

mum of eight Sentry Keys. If the customer would

like to own additional keys other than those provided

with the vehicle, they can be purchased from any

authorized dealer. These keys must be programmed

to the SKIM on the vehicle in order for the system to

recognize them as valid keys. This can be done by

the dealer with a DRB IIItscan tool or by a cus-

tomer if this feature is available in their market and

they have two (2) valid keys already available to

them. Refer to the Service Procedures portion of this

system for additional details. The SKIS performs a

self-test each time the ignition switch is turned to

the ON position and will store Diagnostic Trouble

Codes (DTC's) if a system malfunction is detected.

The SKIS can be diagnosed and any stored DTC's

can be retrieved using a DRB IIItscan tool as

described in the appropriate Body Diagnostic Proce-

dures manual.

8Q - 2 VEHICLE THEFT SECURITYRS

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com

Page 548 of 2177

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SENTRY KEY

IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS,

WARNINGS, BEFORE ATTEMPTING COMPONENT

DIAGNOSIS OR SERVICE. FAILURE TO TAKE THE

PROPER PRECAUTIONS COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System involves the use of

a DRB IIITscan tool. Refer to the proper Body Diag-

nostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB IIIt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) is receiving the PCI bus messages.

Refer to the proper Body Diagnostic Procedures man-

ual, and Wiring Diagrams for complete circuit

descriptions and diagrams.

(1) Check the fuses in the Integrated Power Mod-

ule (IPM). If OK, go to Step 2. If not OK, repair the

shorted circuit or component as required and replace

the faulty fuse.

(2) Disconnect and isolate the battery negative

remote cable from the remote terminal. Unplug the

wire harness connector at the SKIM. Check for con-

tinuity between the ground circuit cavity of the

SKIM wire harness connector and a good ground.

There should be continuity. If OK, go to Step 3. If not

OK, repair the open circuit to ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the

IPM as required.

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB IIItscan tool

and the proper Body Diagnostic Procedures manual

to complete the diagnosis of the SKIS. If not OK,

repair the open circuit to the fuse in the IPM as

required.

DIAGNOSIS AND TESTING - VEHICLE THEFT

SECURITY SYSTEM

Refer to the appropriate wiring information. The

wiring information includes wiring diagrams, proper

wire and connector repair procedures, further details

on wire harness routing and retention, as well as

pin-out and location views for the various wire har-

ness connectors, splices and grounds. Using a DRB

IIItscan tool. Refer to the proper Body Diagnostic

Procedures Manual for test procedures.

HOOD AJAR SWITCH -

EXPORT

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Using a small flat blade screwdriver, pry trig-

ger switch from the bracket on the left fender well.

(3) Disconnect the hood ajar switch from the wire

connector and remove from vehicle.

INSTALLATION

(1) Connect the hood ajar switch to the wire conec-

tor.

(2) Press the hood ajar switch into position on the

bracket located on the left inner fender well.

(3) Reconnect the battery negative cable.

(4) Close the hood and check for proper operation.

TRANSPONDER KEY

DESCRIPTION

The Sentry Key Immobilizer System (SKIS) uses a

transponder chip that is integral to each ignition key

(Fig. 1) to communicate with the Sentry Key Immo-

bilizer Module (SKIM). Ignition keys are supplied

with the vehicle when it is shipped from the factory.

The transponder chip is undermolded within the

head of the key. This undermold is hidden beneath

an overmolded rubber cap.

OPERATION

Each Sentry Key has a unique transponder identi-

fication code permanently programmed into it by the

manufacturer. Likewise, the SKIM has a unique

9Secret Key9code programmed into it by the manu-

facturer as well. When a Sentry Key is programmed

into the memory of the SKIM, the SKIM stores the

transponder identification code from the Sentry Key,

and the Sentry Key learns the9Secret Key9code from

the SKIM. Once the Sentry Key learns the9Secret

Key9code of the SKIM, it is also permanently pro-

RSVEHICLE THEFT SECURITY8Q-3

VEHICLE THEFT SECURITY (Continued)

ProCarManuals.com

Page 589 of 2177

Component Page

Leak Detection Pump................... 8W-30

License Lamp...................... 8W-51, 61

Lift Pump Motor....................... 8W-30

Lift Pump Relay....................... 8W-30

Liftgate Ajar Switch.................. 8W-39, 61

Liftgate Cinch/Release Motor.............. 8W-61

Liftgate Cylinder Lock Switch............. 8W-39

Liftgate Flood Lamps................... 8W-44

Liftgate Left Pinch Sensor................ 8W-61

Liftgate Right Pinch Sensor............... 8W-61

Low Beam Lamps...................... 8W-50

Manifold Absolute Pressure Sensor......... 8W-30

Mass Air Flow Sensor................... 8W-30

Memory Seat/Mirror Module............ 8W-62, 63

Memory Set Switch..................... 8W-63

Message Center........................ 8W-46

Mid Reading Lamps.................... 8W-44

Mode Door Actuator..................... 8W-42

Multi-Function Switch............. 8W-50, 52, 53

Name Brand Speaker Relay............... 8W-47

Natural Vacuum Leak Detection Assembly.... 8W-30

Output Speed Sensor.................... 8W-31

Overhead Console................... 8W-43, 49

Oxygen Sensors........................ 8W-30

Park Lamp Relay...................... 8W-10

Park Lamps.......................... 8W-50

Park/Turn Signal Lamps................. 8W-50

Parking Brake Switch................... 8W-40

Passenger Airbag...................... 8W-43

Passenger Folding Mirror Relay............ 8W-62

Power Folding Mirror Switch.............. 8W-62

Power Liftgate Module.................. 8W-61

Power Liftgate Motor.................... 8W-61

Power Mirror Switch.................... 8W-62

Power Mirrors......................... 8W-62

Power Outlet.......................... 8W-41

Power Seat Circuit Breaker............... 8W-10

Power Seat Front Riser Motors............ 8W-63

Power Seat Front Riser Position Sensors..... 8W-63

Power Seat Horizontal Motors............. 8W-63

Power Seat Horizontal Position Sensors...... 8W-63

Power Seat Rear Riser Motors............. 8W-63

Power Seat Rear Riser Position Sensors...... 8W-63

Power Seat Recliner Motors............... 8W-63

Power Seat Recliner Position Sensors........ 8W-63

Power Seat Switches.................... 8W-63

Power Window Circuit Breaker............ 8W-10

Power Window Motor................... 8W-60

Power Window Switch................... 8W-60

Powertrain Control Module............... 8W-30

PTC's............................... 8W-10

Radiator Fans......................... 8W-42

Radiator Fan Relays.................... 8W-42

Radio............................... 8W-47

Reading Lamps........................ 8W-44

Rear A/C-Heater Unit................... 8W-42

Component Page

Rear Auto Temp Control Switch............ 8W-42

Rear Blower Front Control Switch.......... 8W-42

Rear Blower Motor Power Module.......... 8W-42

Rear Blower Motor Relay................. 8W-42

Rear Blower Motor..................... 8W-42

Rear Blower Rear Control Switch........... 8W-42

Rear Dome Lamp...................... 8W-44

Rear Intrusion Sensor................... 8W-39

Rear Mode Motor...................... 8W-42

Rear Power Outlet...................... 8W-41

Rear Temperature Motor................. 8W-42

Rear Washer Pump Motor................ 8W-53

Rear Window Defogger Grid............... 8W-48

Rear Wiper Motor...................... 8W-53

Recirculation Door Actuator............... 8W-42

Remote Keyless Entry Antenna............ 8W-61

Remote Keyless Entry Module............. 8W-61

Remote Radio Switches.................. 8W-47

Repeater Lamps....................... 8W-52

Splices.............................. 8W-70

Seat Airbags.......................... 8W-43

Seat Belt Tensioner..................... 8W-43

Sentry Key Immobilizer Module............ 8W-39

Side Impact Airbag Control Modules........ 8W-43

Siren............................... 8W-39

Sliding Door Control Modules........... 8W-43, 61

Sliding Door Latch Sensing Switches........ 8W-61

Sliding Door Lock Motors................ 8W-61

Sliding Door Lock Motor/Ajar Switches...... 8W-61

Sliding Door Motors.................... 8W-61

Solenoid/Pressure Switch Assy............. 8W-31

Speakers............................. 8W-47

Speed Control Servo.................... 8W-33

Speed Control Switches.................. 8W-33

Starter Motor Relay.................... 8W-21

Starter Motor......................... 8W-21

Stop/Turn Signal Relays................. 8W-54

Sunroof Module........................ 8W-64

Sunroof Switch........................ 8W-64

Thatcham Alarm Indicator................ 8W-39

Thatcham Alarm Module................. 8W-39

Throttle Position Sensor................. 8W-30

Traction Control Switch.................. 8W-35

Trailer Tow Connector................... 8W-54

Transmission Control Module.............. 8W-31

Transmission Control Relay............... 8W-31

Transmission Range Sensor............... 8W-31

Turn Signal Lamps..................... 8W-52

Vehicle Speed Sensor.................... 8W-30

Vent Motors.......................... 8W-60

Visor/Vanity Lamps..................... 8W-44

Washer Fluid Level Switch............... 8W-53

Water In Fuel Sensor................... 8W-30

Wheel Speed Sensors.................... 8W-35

8W - 02 - 2 8W-02 COMPONENT INDEXRS

ProCarManuals.com

Page 591 of 2177

Component Page

Headlamp Washer Relay........ 8W-10-26, 56, 67

High Note Horn.................... 8W-10-36

Horn Relay.................. 8W-10-17, 36, 63

Ignition Coil....................... 8W-10-44

Ignition Switch . . . 8W-10-18, 25, 37, 38, 47, 48, 49,

52, 57, 58, 64

Instrument Cluster............... 8W-10-25, 55

Integrated Power

Module............. 8W-10-3, 4, 5, 13, 15, 16,

17, 18, 19, 20, 21, 22, 23, 24, 25, 26,

27, 29, 30, 31, 33, 36, 37, 38, 39, 40,

41, 42, 43, 44, 45, 46, 47, 48, 50, 51,

52, 53, 55, 56, 57, 58, 59, 60, 61, 62,

63, 64, 65, 66, 67, 68, 69, 70, 72

Leak Detection Pump................ 8W-10-50

Left B-Pillar Switch................. 8W-10-33

Left Combination Relay.............. 8W-10-71

Left Door Speaker.................. 8W-10-40

Left Fog Lamp.................. 8W-10-15, 27

Left Front Park/Turn Signal Lamp . . 8W-10-15, 28,

60, 69

Left Headlamp..................... 8W-10-61

Left Headlamp Leveling Motor . . . 8W-10-29, 66, 69

Left High Beam Lamp............... 8W-10-62

Left Low Beam Lamp................ 8W-10-62

Left Park Lamp................. 8W-10-29, 69

Left Power Mirror................... 8W-10-40

Left Rear Lamp Assembly . 8W-10-28, 29, 69, 70, 71

Left Rear Speaker.................. 8W-10-40

Left Repeater Lamp................. 8W-10-55

Left Side Impact Airbag Control Module . 8W-10-66

Left Sliding Door Control Module....... 8W-10-56

Left Stop/Turn Signal Relay........... 8W-10-71

Left Turn Signal Lamp............... 8W-10-60

License Lamp................ 8W-10-28, 29, 69

Lift Pump Motor................. 8W-10-23, 45

Lift Pump Relay................. 8W-10-23, 45

Low Note Horn..................... 8W-10-36

Mass Air Flow Sensor................ 8W-10-46

Memory Seat/Mirror Module.......... 8W-10-53

Message Center.................... 8W-10-55

Name Brand Speaker Relay..... 8W-10-20, 40, 63

Overhead Console................... 8W-10-41

Oxygen Sensor 1/1 Upstream.......... 8W-10-44

Oxygen Sensor 1/2 Downstream........ 8W-10-44

Park Lamp Relay.......... 8W-10-15, 28, 29, 63

Passenger Door Lock Switch........ 8W-10-31, 33

Passenger Folding Mirror

Relay............... 8W-10-22, 24, 47, 48, 51

Passenger Heated Seat Module........ 8W-10-54

Passenger Power Seat Switch.......... 8W-10-54

Passenger Power Window Switch....... 8W-10-31

Power Liftgate Module............... 8W-10-56

Power Mirror Switch........ 8W-10-22, 24, 50, 51

Power Outlet...................... 8W-10-36Component Page

Power Seat Circuit Breaker........ 8W-10-25, 53

Power Window Circuit Breaker...... 8W-10-16, 31

Power Window Switch............... 8W-10-34

Powertrain Control

Module.......... 8W-10-18, 21, 22, 37, 42, 43,

44, 47, 48, 50, 59, 65, 66, 72

PTC4 ......................... 8W-10-20, 40

PTC7 ................... 8W-10-16, 17, 18, 36

Radiator Fan Relay............ 8W-10-26, 55, 59

Radiator Fan Relay No. 1.......... 8W-10-13, 46

Radiator Fan Relay No. 2....... 8W-10-26, 46, 55

Radiator Fan Relay No. 3............. 8W-10-46

Radio......................... 8W-10-32, 41

Rear A/C-Heater Unit............. 8W-10-19, 39

Rear Blower Motor Relay.... 8W-10-19, 20, 39, 67

Rear Power Outlet............ 8W-10-16, 31, 32

Rear Washer Pump Motor....... 8W-10-16, 31, 72

Rear Window Defogger Grid........ 8W-10-20, 40

Rear Wiper Motor................... 8W-10-33

Remote Keyless Entry Module......... 8W-10-41

Right B-Pillar Switch................ 8W-10-33

Right Combination Relay............. 8W-10-71

Right Door Speaker................. 8W-10-40

Right Fog Lamp................. 8W-10-15, 27

Right Front Park/Turn Signal

Lamp.................. 8W-10-15, 28, 60, 64

Right Headlamp.................... 8W-10-61

Right Headlamp Leveling Motor . . 8W-10-29, 64, 66

Right High Beam Lamp.............. 8W-10-62

Right Low Beam Lamp............... 8W-10-62

Right Park Lamp................ 8W-10-29, 64

Right Power Mirror................. 8W-10-40

Right Rear Lamp Assembly . . . 8W-10-15, 28, 29, 70

Right Rear Speaker................. 8W-10-40

Right Repeater Lamp................ 8W-10-55

Right Side Impact Airbag Control

Module......................... 8W-10-66

Right Sliding Door Control Module..... 8W-10-56

Right Stop/Turn Signal Relay.......... 8W-10-71

Right Turn Signal Lamp.............. 8W-10-60

Sentry Key Immobilizer

Module.............. 8W-10-41, 49, 52, 57, 58

Solenoid/Pressure Switch Assy...... 8W-10-42, 43

Starter Motor.......... 8W-10-13, 14, 18, 37, 38

Starter Motor Relay...... 8W-10-18, 37, 38, 57, 58

Sunroof Module.................... 8W-10-56

Thatcham Alarm Module....... 8W-10-49, 52, 58

Trailer Tow Connector............ 8W-10-28, 69

Transmission Control

Module........... 8W-10-21, 37, 43, 65, 66, 72

Transmission Control Relay..... 8W-10-21, 42, 43

Vehicle Speed Sensor................ 8W-10-45

Washer Fluid Level Switch............ 8W-10-64

Wiper Module................ 8W-10-16, 30, 63

8W - 10 - 2 8W-10 POWER DISTRIBUTIONRS

ProCarManuals.com

Page 1432 of 2177

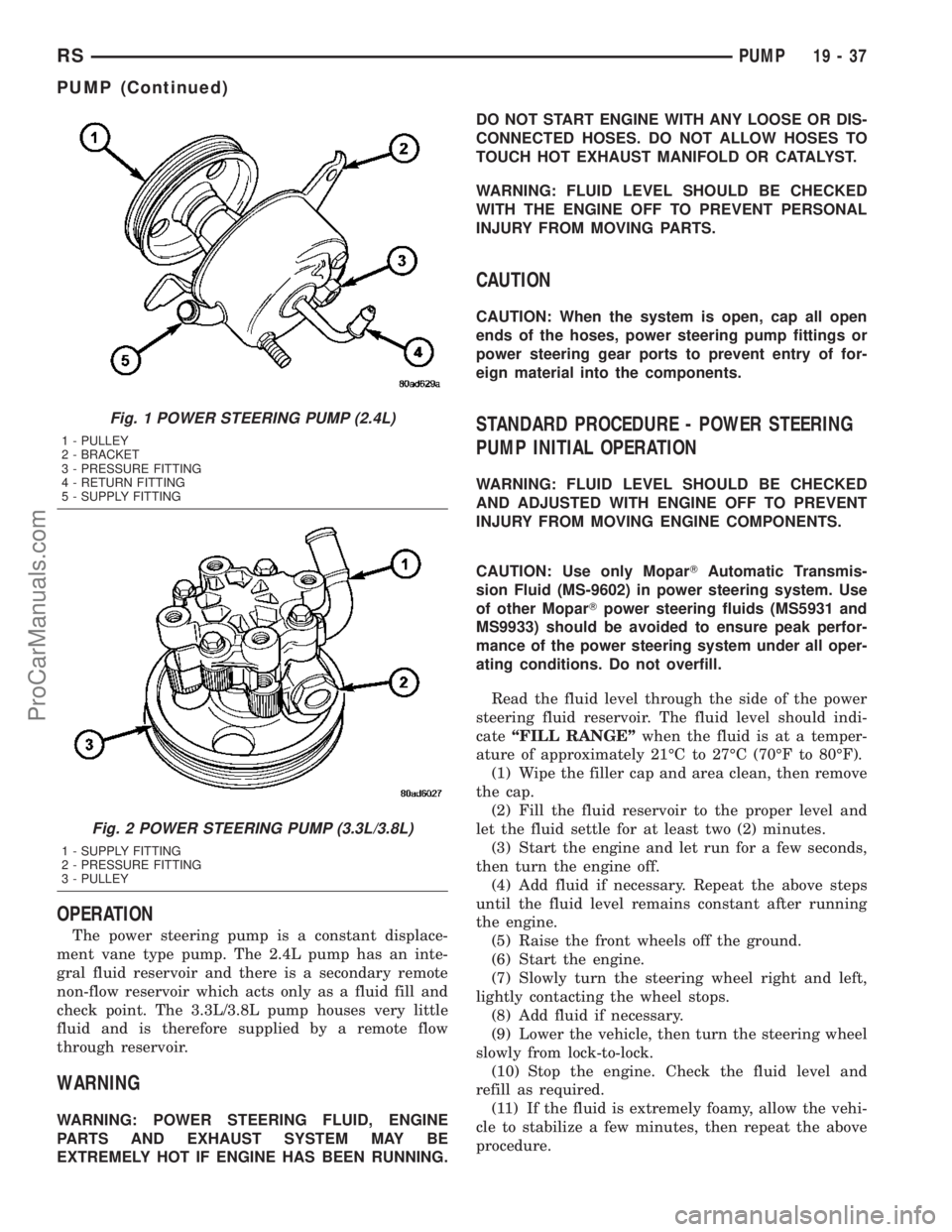

OPERATION

The power steering pump is a constant displace-

ment vane type pump. The 2.4L pump has an inte-

gral fluid reservoir and there is a secondary remote

non-flow reservoir which acts only as a fluid fill and

check point. The 3.3L/3.8L pump houses very little

fluid and is therefore supplied by a remote flow

through reservoir.

WARNING

WARNING: POWER STEERING FLUID, ENGINE

PARTS AND EXHAUST SYSTEM MAY BE

EXTREMELY HOT IF ENGINE HAS BEEN RUNNING.DO NOT START ENGINE WITH ANY LOOSE OR DIS-

CONNECTED HOSES. DO NOT ALLOW HOSES TO

TOUCH HOT EXHAUST MANIFOLD OR CATALYST.

WARNING: FLUID LEVEL SHOULD BE CHECKED

WITH THE ENGINE OFF TO PREVENT PERSONAL

INJURY FROM MOVING PARTS.

CAUTION

CAUTION: When the system is open, cap all open

ends of the hoses, power steering pump fittings or

power steering gear ports to prevent entry of for-

eign material into the components.

STANDARD PROCEDURE - POWER STEERING

PUMP INITIAL OPERATION

WARNING: FLUID LEVEL SHOULD BE CHECKED

AND ADJUSTED WITH ENGINE OFF TO PREVENT

INJURY FROM MOVING ENGINE COMPONENTS.

CAUTION: Use only MoparTAutomatic Transmis-

sion Fluid (MS-9602) in power steering system. Use

of other MoparTpower steering fluids (MS5931 and

MS9933) should be avoided to ensure peak perfor-

mance of the power steering system under all oper-

ating conditions. Do not overfill.

Read the fluid level through the side of the power

steering fluid reservoir. The fluid level should indi-

cateªFILL RANGEºwhen the fluid is at a temper-

ature of approximately 21ÉC to 27ÉC (70ÉF to 80ÉF).

(1) Wipe the filler cap and area clean, then remove

the cap.

(2) Fill the fluid reservoir to the proper level and

let the fluid settle for at least two (2) minutes.

(3) Start the engine and let run for a few seconds,

then turn the engine off.

(4) Add fluid if necessary. Repeat the above steps

until the fluid level remains constant after running

the engine.

(5) Raise the front wheels off the ground.

(6) Start the engine.

(7) Slowly turn the steering wheel right and left,

lightly contacting the wheel stops.

(8) Add fluid if necessary.

(9) Lower the vehicle, then turn the steering wheel

slowly from lock-to-lock.

(10) Stop the engine. Check the fluid level and

refill as required.

(11) If the fluid is extremely foamy, allow the vehi-

cle to stabilize a few minutes, then repeat the above

procedure.

Fig. 1 POWER STEERING PUMP (2.4L)

1 - PULLEY

2 - BRACKET

3 - PRESSURE FITTING

4 - RETURN FITTING

5 - SUPPLY FITTING

Fig. 2 POWER STEERING PUMP (3.3L/3.8L)

1 - SUPPLY FITTING

2 - PRESSURE FITTING

3 - PULLEY

RSPUMP19-37

PUMP (Continued)

ProCarManuals.com