power steering CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2171 of 2339

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the center bezel from the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL -

REMOVAL).

(3) Place the instrument panel center bezel unit

face down on a suitable work surface. Take the

proper precautions to protect the center bezel from

cosmetic damage.

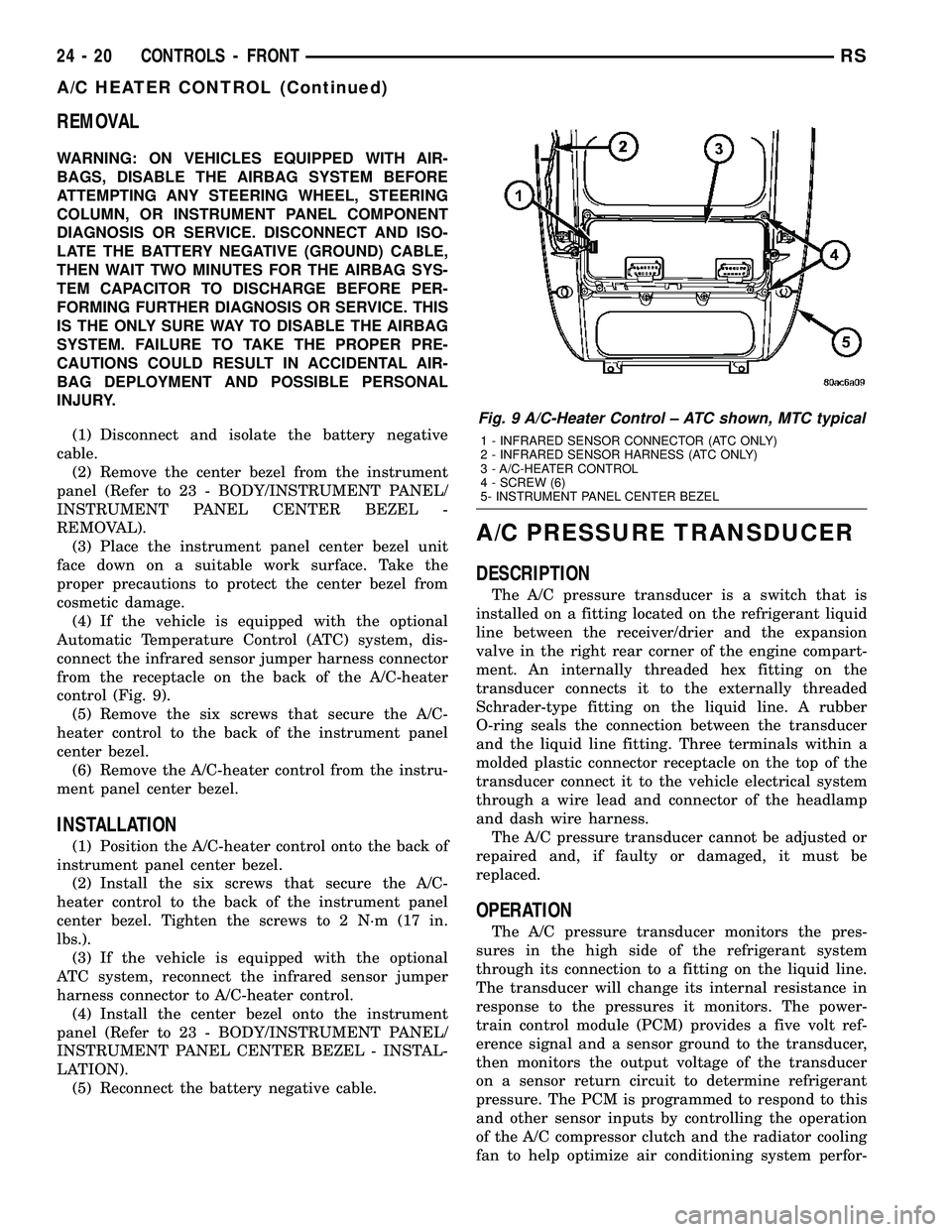

(4) If the vehicle is equipped with the optional

Automatic Temperature Control (ATC) system, dis-

connect the infrared sensor jumper harness connector

from the receptacle on the back of the A/C-heater

control (Fig. 9).

(5) Remove the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel.

(6) Remove the A/C-heater control from the instru-

ment panel center bezel.

INSTALLATION

(1) Position the A/C-heater control onto the back of

instrument panel center bezel.

(2) Install the six screws that secure the A/C-

heater control to the back of the instrument panel

center bezel. Tighten the screws to 2 N´m (17 in.

lbs.).

(3) If the vehicle is equipped with the optional

ATC system, reconnect the infrared sensor jumper

harness connector to A/C-heater control.

(4) Install the center bezel onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

INSTRUMENT PANEL CENTER BEZEL - INSTAL-

LATION).

(5) Reconnect the battery negative cable.

A/C PRESSURE TRANSDUCER

DESCRIPTION

The A/C pressure transducer is a switch that is

installed on a fitting located on the refrigerant liquid

line between the receiver/drier and the expansion

valve in the right rear corner of the engine compart-

ment. An internally threaded hex fitting on the

transducer connects it to the externally threaded

Schrader-type fitting on the liquid line. A rubber

O-ring seals the connection between the transducer

and the liquid line fitting. Three terminals within a

molded plastic connector receptacle on the top of the

transducer connect it to the vehicle electrical system

through a wire lead and connector of the headlamp

and dash wire harness.

The A/C pressure transducer cannot be adjusted or

repaired and, if faulty or damaged, it must be

replaced.

OPERATION

The A/C pressure transducer monitors the pres-

sures in the high side of the refrigerant system

through its connection to a fitting on the liquid line.

The transducer will change its internal resistance in

response to the pressures it monitors. The power-

train control module (PCM) provides a five volt ref-

erence signal and a sensor ground to the transducer,

then monitors the output voltage of the transducer

on a sensor return circuit to determine refrigerant

pressure. The PCM is programmed to respond to this

and other sensor inputs by controlling the operation

of the A/C compressor clutch and the radiator cooling

fan to help optimize air conditioning system perfor-

Fig. 9 A/C-Heater Control ± ATC shown, MTC typical

1 - INFRARED SENSOR CONNECTOR (ATC ONLY)

2 - INFRARED SENSOR HARNESS (ATC ONLY)

3 - A/C-HEATER CONTROL

4 - SCREW (6)

5- INSTRUMENT PANEL CENTER BEZEL

24 - 20 CONTROLS - FRONTRS

A/C HEATER CONTROL (Continued)

Page 2181 of 2339

INSTALLATION

(1) Position the mode door actuator onto the HVAC

distribution housing. If necessary, rotate the actuator

slightly to align the splines on the actuator output

shaft with those in the mode door linkage.

(2) Install the two screws that secure the mode

door actuator to the distribution housing. Tighten the

screws to 2 N´m (17 in. lbs.).

(3) Connect the wire harness connector to the

mode door actuator.

(4) Install the silencer under the driver side end of

the instrument panel (Refer to 23 - BODY/INSTRU-

MENT PANEL/INSTRUMENT PANEL SILENCER -

INSTALLATION).

(5) Reconnect the negative battery cable.

(6) Perform the A/C-heater control calibration pro-

cedure (Refer to 24 - HEATING & AIR CONDITION-

ING/CONTROLS - FRONT/A/C-HEATER CONTROL

- STANDARD PROCEDURE - HEATER-A/C CON-

TROL CALIBRATION).

POWER MODULE - BLOWER

MOTOR

DESCRIPTION

A blower motor power module is used on this

model when it is equipped with the optional Auto-

matic Temperature Control (ATC) system. Models

equipped with the standard manual heater-A/C sys-

tem use a blower motor resistor block, instead of the

blower motor power module (Refer to 24 - HEATING

& AIR CONDITIONING/CONTROLS/BLOWER

MOTOR RESISTOR BLOCK - DESCRIPTION).

The blower motor power module is mounted to the

rear of the HVAC housing, directly behind the glove

box opening in the instrument panel. The module

consists of a molded plastic mounting plate with two

integral connector receptacles. Concealed behind the

mounting plate is the power module electronic cir-

cuitry and a large finned, heat sink. The blower

motor power module is accessed for service by remov-

ing the glove box from the instrument panel.

OPERATION

The blower motor power module is connected to the

vehicle electrical system through a dedicated lead

and connector from the instrument panel wire har-

ness. A second connector receptacle receives a wire

lead connector from the blower motor. The blower

motor power module allows the microprocessor-based

Automatic Temperature Control (ATC) heater-A/C

control module to calculate and provide infinitely

variable blower motor speeds based upon either man-

ual blower switch input or the ATC programming

using a Pulse Width Modulated (PWM) circuit strat-

egy. The PWM voltage is applied to a comparator cir-

cuit which compares the PWM signal voltage to the

blower motor feedback voltage. The resulting output

drives the power module circuitry, which adjusts the

voltage output received from the blower motor relay

to change or maintain the desired blower speed. The

blower motor power module is diagnosed using a

DRBIIItscan tool. Refer to Body Diagnostic Proce-

dures.

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

WARNING: THE HEAT SINK FOR THE BLOWER

MOTOR POWER MODULE MAY GET VERY HOT

DURING NORMAL OPERATION. IF THE BLOWER

MOTOR WAS TURNED ON PRIOR TO SERVICING

THE BLOWER MOTOR POWER MODULE, WAIT

FIVE MINUTES TO ALLOW THE HEAT SINK TO

COOL BEFORE PERFORMING DIAGNOSIS OR SER-

VICE. FAILURE TO TAKE THIS PRECAUTION CAN

RESULT IN PERSONAL INJURY.

24 - 30 CONTROLS - FRONTRS

MODE DOOR ACTUATOR (Continued)

Page 2197 of 2339

whenever the ignition switch is in the On position

and the A/C-heater control power is turned on.

The blower motor receives battery current when-

ever the front blower motor relay is energized. The

front blower motor relay output circuit is protected

by a fuse in the Integrated Power Module (IPM)

located in the engine compartment near the battery.

In the manual heater-A/C system, the blower motor

speed is controlled by regulating the path to ground

through the blower control switch and the blower

motor resistor. In the ATC system, the blower motor

speed is controlled by an electronic blower motor

power module, which uses a pulse width modulated

input from the ATC module and feedback from the

blower motor to regulate the blower motor ground

path it provides. The blower motor and wheel are

used to control the velocity of air moving through the

HVAC housing by spinning the blower wheel within

the housing at the selected speed or, in the ATC sys-

tem, at the selected or programmed speed.

DIAGNOSIS AND TESTING

FRONT BLOWER MOTOR

BLOWER MOTOR INOPERATIVE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

For circuit descriptions and diagrams, refer to the

appropriate wiring information. The wiring informa-

tion includes wiring, diagrams, proper wire and con-

nector repair procedures, further details on wire

harness routing and retention, as well as pin-out and

location views for the various wire harness connec-

tors, splices and grounds.BLOWER MOTOR ELECTRICAL DIAGNOSIS

(1) Check the fuse (Fuse 10 - 40 ampere) in the

Integrated Power Module (IPM). If OK, go to Step 2.

If not OK, repair the shorted circuit or component as

required and replace the faulty fuse.

(2) Turn the ignition switch to the On position. Be

certain that the A/C-heater control power is turned

on. Check for battery voltage at the fuse (Fuse 10 -

40 ampere) in the IPM. If OK, go to Step 3. If not

OK, check the front blower motor relay.

(3) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front HVAC wire harness connector

for the front blower motor resistor block (Manual

Temperature Control) or the front blower motor

power module (Automatic Temperature Control) from

the resistor or module connector receptacle. Recon-

nect the battery negative cable. Turn the ignition

switch to the On position. Be certain that the A/C-

heater control power is turned on. Check for battery

voltage at the fused front blower motor relay output

circuit cavity of the front HVAC wire harness connec-

tor for the front blower motor resistor block (MTC) or

the front blower motor power module (ATC). If OK,

go to Step 4. If not OK, repair the open fused front

blower motor relay output circuit to the IPM as

required.

(4) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Disconnect the front blower motor pigtail wire con-

nector from the connector receptacle of the front

blower motor resistor block (MTC) or the front

blower motor power module (ATC). Use jumper wires

to connect a battery and ground feeds to the blower

motor pigtail wire connector. The blower motor

should operate. If OK with MTC, proceed to diagno-

sis of the front blower motor resistor block (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/BLOWER MOTOR RESISTOR - DIAGNO-

SIS AND TESTING). If OK with ATC, use a DRBIII

scan tool to diagnose the front blower motor power

module. Refer to Body Diagnostic information. If not

OK with MTC or ATC, replace the faulty front blower

motor.

BLOWER MOTOR NOISE OR VIBRATION

Refer to the Blower Motor Noise/Vibration Diagno-

sis chart for basic checks of the blower motor when a

vibration or noise is present (Fig. 7).

24 - 46 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 2199 of 2339

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN AN ACCIDENTAL

AIRBAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY OR DEATH.

NOTE: The blower motor is located on the passen-

ger side of the vehicle under the instrument panel.

The blower motor can be removed from the vehicle

without having to remove the HVAC housing.

(1) Disconnect and isolate the negative battery

cable.

(2) Remove the passenger side cowl trim panel

(Refer to 23 - BODY/INTERIOR/COWL TRIM -

REMOVAL).

(3) Pull back the carpet to access the front upper

screw that secures the air inlet housing.

(4) Remove the recirculation door actuator (Refer

to 24 - HEATING & AIR CONDITIONING/CON-

TROLS - FRONT/RECIRCULATION DOOR ACTUA-

TOR - REMOVAL).

(5) Remove the recirculation door actuator wire

lead from the routing clip located on the lower air

inlet housing and position the wire lead aside.

(6) Disconnect the blower motor wire lead connec-

tor from the blower motor resistor block or power

module, depending on application.

(7) Remove the one screw (from the top) that

secures the lower air inlet housing to the upper air

inlet housing (Fig. 8).

(8) Remove the four screws (from the bottom) that

secure the lower air inlet housing to the upper air

inlet housing and the lower HVAC housing.

(9) Push the rubber blower motor wire lead grom-

met through the opening in the lower air inlet hous-

ing (Fig. 9).

(10) Feed the blower motor wire lead through the

opening in the lower air inlet housing and remove

the lower air inlet housing from the vehicle.(11) Position the recirculation-air door as neces-

sary to access and remove the three screws that

secure the blower motor to the lower half of the

HVAC housing.

Fig. 8 Lower Air Inlet Housing

1 - BLOWER MOTOR RESISTOR BLOCK/POWER MODULE

2 - BLOWER MOTOR WIRE LEAD

3 - LOWER HVAC HOUSING

4 - UPPER AIR INLET HOUSING

5 - UPPER SCREW (1)

6 - LOWER AIR INLET HOUSING

7 - RECIRCULATION DOOR ACTUATOR

8 - ACTUATOR WIRE LEAD

9 - LOWER SCREW (4)

Fig. 9 Blower Motor Wire Lead Grommet

1 - BLOWER MOTOR WIRE LEAD GROMMET

24 - 48 DISTRIBUTION - FRONTRS

BLOWER MOTOR (Continued)

Page 2200 of 2339

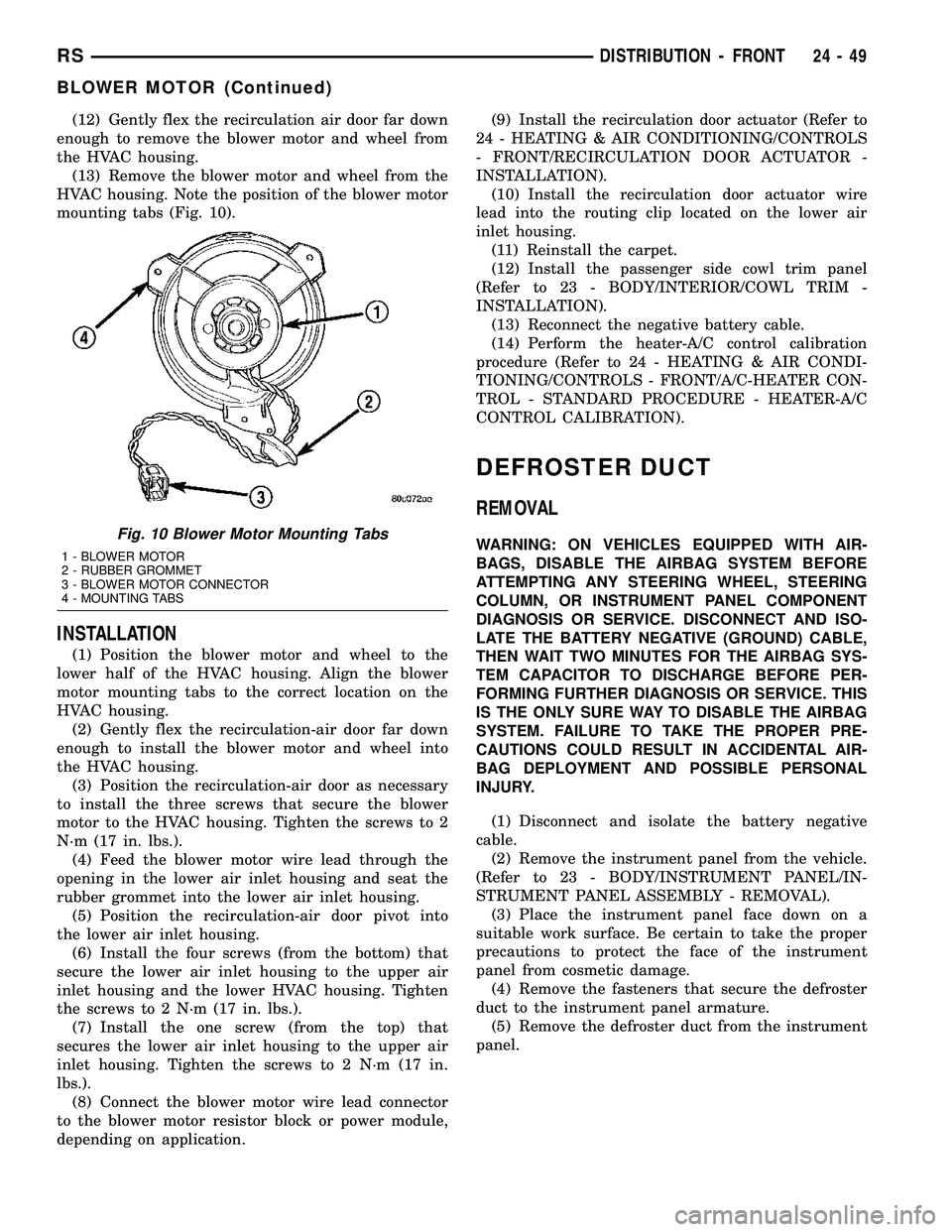

(12) Gently flex the recirculation air door far down

enough to remove the blower motor and wheel from

the HVAC housing.

(13) Remove the blower motor and wheel from the

HVAC housing. Note the position of the blower motor

mounting tabs (Fig. 10).

INSTALLATION

(1) Position the blower motor and wheel to the

lower half of the HVAC housing. Align the blower

motor mounting tabs to the correct location on the

HVAC housing.

(2) Gently flex the recirculation-air door far down

enough to install the blower motor and wheel into

the HVAC housing.

(3) Position the recirculation-air door as necessary

to install the three screws that secure the blower

motor to the HVAC housing. Tighten the screws to 2

N´m (17 in. lbs.).

(4) Feed the blower motor wire lead through the

opening in the lower air inlet housing and seat the

rubber grommet into the lower air inlet housing.

(5) Position the recirculation-air door pivot into

the lower air inlet housing.

(6) Install the four screws (from the bottom) that

secure the lower air inlet housing to the upper air

inlet housing and the lower HVAC housing. Tighten

the screws to 2 N´m (17 in. lbs.).

(7) Install the one screw (from the top) that

secures the lower air inlet housing to the upper air

inlet housing. Tighten the screws to 2 N´m (17 in.

lbs.).

(8) Connect the blower motor wire lead connector

to the blower motor resistor block or power module,

depending on application.(9) Install the recirculation door actuator (Refer to

24 - HEATING & AIR CONDITIONING/CONTROLS

- FRONT/RECIRCULATION DOOR ACTUATOR -

INSTALLATION).

(10) Install the recirculation door actuator wire

lead into the routing clip located on the lower air

inlet housing.

(11) Reinstall the carpet.

(12) Install the passenger side cowl trim panel

(Refer to 23 - BODY/INTERIOR/COWL TRIM -

INSTALLATION).

(13) Reconnect the negative battery cable.

(14) Perform the heater-A/C control calibration

procedure (Refer to 24 - HEATING & AIR CONDI-

TIONING/CONTROLS - FRONT/A/C-HEATER CON-

TROL - STANDARD PROCEDURE - HEATER-A/C

CONTROL CALIBRATION).

DEFROSTER DUCT

REMOVAL

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the instrument panel from the vehicle.

(Refer to 23 - BODY/INSTRUMENT PANEL/IN-

STRUMENT PANEL ASSEMBLY - REMOVAL).

(3) Place the instrument panel face down on a

suitable work surface. Be certain to take the proper

precautions to protect the face of the instrument

panel from cosmetic damage.

(4) Remove the fasteners that secure the defroster

duct to the instrument panel armature.

(5) Remove the defroster duct from the instrument

panel.Fig. 10 Blower Motor Mounting Tabs

1 - BLOWER MOTOR

2 - RUBBER GROMMET

3 - BLOWER MOTOR CONNECTOR

4 - MOUNTING TABS

RSDISTRIBUTION - FRONT24-49

BLOWER MOTOR (Continued)

Page 2236 of 2339

FRONT HEATER CORE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(2) Remove the brake lamp switch from its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(3) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER -

REMOVAL).

(4) Remove the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - REMOVAL).

(5) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

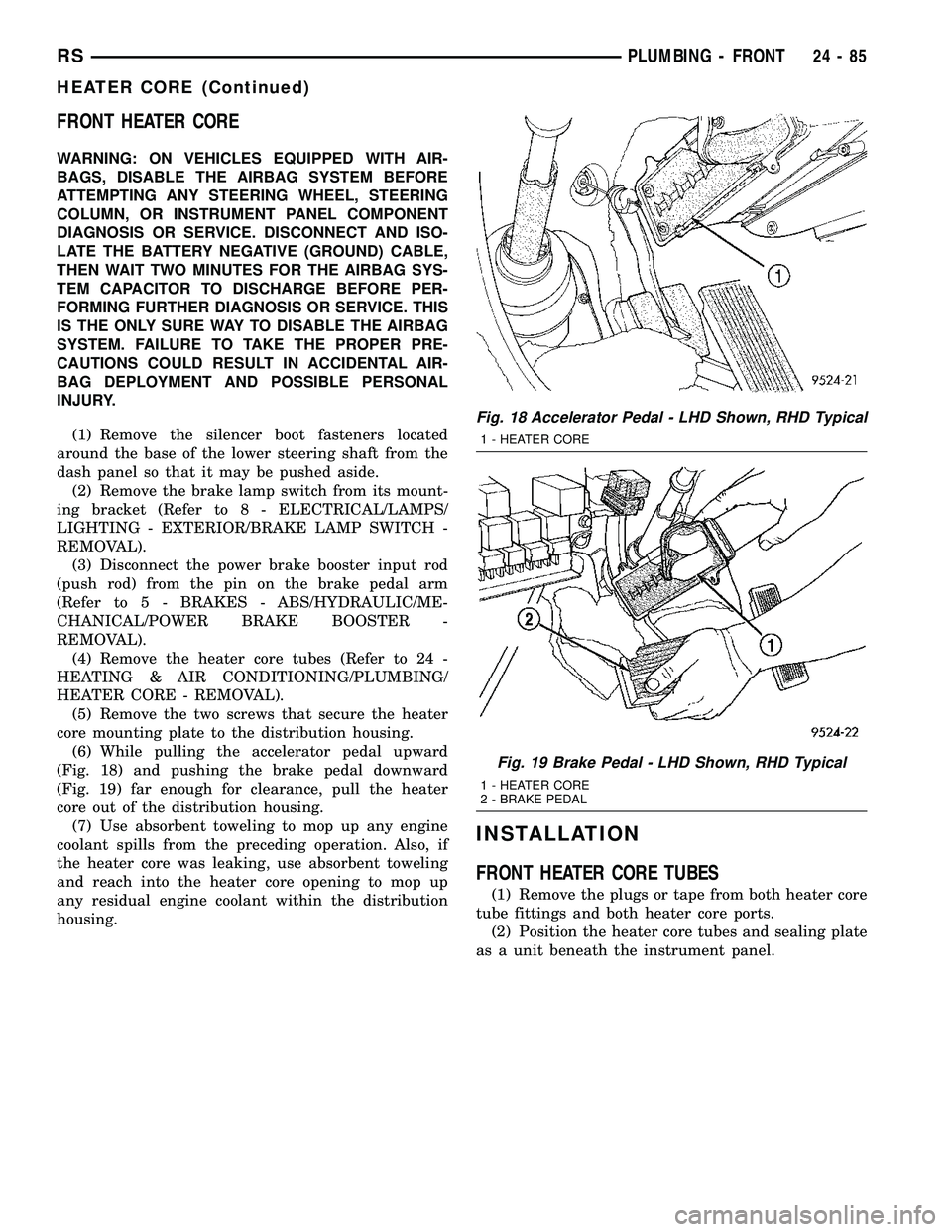

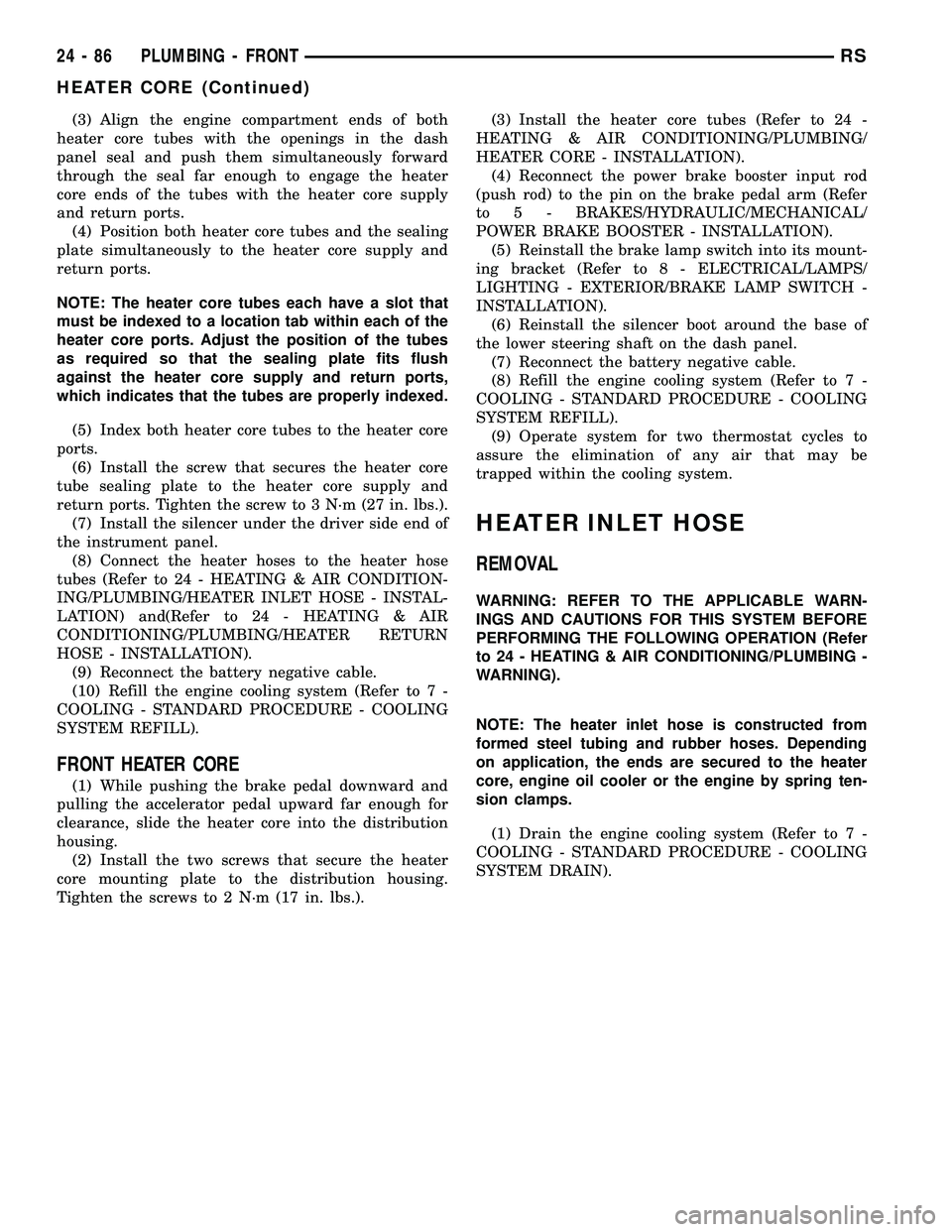

(6) While pulling the accelerator pedal upward

(Fig. 18) and pushing the brake pedal downward

(Fig. 19) far enough for clearance, pull the heater

core out of the distribution housing.

(7) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation. Also, if

the heater core was leaking, use absorbent toweling

and reach into the heater core opening to mop up

any residual engine coolant within the distribution

housing.

INSTALLATION

FRONT HEATER CORE TUBES

(1) Remove the plugs or tape from both heater core

tube fittings and both heater core ports.

(2) Position the heater core tubes and sealing plate

as a unit beneath the instrument panel.

Fig. 18 Accelerator Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

Fig. 19 Brake Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

2 - BRAKE PEDAL

RSPLUMBING - FRONT24-85

HEATER CORE (Continued)

Page 2237 of 2339

(3) Align the engine compartment ends of both

heater core tubes with the openings in the dash

panel seal and push them simultaneously forward

through the seal far enough to engage the heater

core ends of the tubes with the heater core supply

and return ports.

(4) Position both heater core tubes and the sealing

plate simultaneously to the heater core supply and

return ports.

NOTE: The heater core tubes each have a slot that

must be indexed to a location tab within each of the

heater core ports. Adjust the position of the tubes

as required so that the sealing plate fits flush

against the heater core supply and return ports,

which indicates that the tubes are properly indexed.

(5) Index both heater core tubes to the heater core

ports.

(6) Install the screw that secures the heater core

tube sealing plate to the heater core supply and

return ports. Tighten the screw to 3 N´m (27 in. lbs.).

(7) Install the silencer under the driver side end of

the instrument panel.

(8) Connect the heater hoses to the heater hose

tubes (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING/HEATER INLET HOSE - INSTAL-

LATION) and(Refer to 24 - HEATING & AIR

CONDITIONING/PLUMBING/HEATER RETURN

HOSE - INSTALLATION).

(9) Reconnect the battery negative cable.

(10) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

FRONT HEATER CORE

(1) While pushing the brake pedal downward and

pulling the accelerator pedal upward far enough for

clearance, slide the heater core into the distribution

housing.

(2) Install the two screws that secure the heater

core mounting plate to the distribution housing.

Tighten the screws to 2 N´m (17 in. lbs.).(3) Install the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - INSTALLATION).

(4) Reconnect the power brake booster input rod

(push rod) to the pin on the brake pedal arm (Refer

to 5 - BRAKES/HYDRAULIC/MECHANICAL/

POWER BRAKE BOOSTER - INSTALLATION).

(5) Reinstall the brake lamp switch into its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

INSTALLATION).

(6) Reinstall the silencer boot around the base of

the lower steering shaft on the dash panel.

(7) Reconnect the battery negative cable.

(8) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

(9) Operate system for two thermostat cycles to

assure the elimination of any air that may be

trapped within the cooling system.

HEATER INLET HOSE

REMOVAL

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

WARNING).

NOTE: The heater inlet hose is constructed from

formed steel tubing and rubber hoses. Depending

on application, the ends are secured to the heater

core, engine oil cooler or the engine by spring ten-

sion clamps.

(1) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM DRAIN).

24 - 86 PLUMBING - FRONTRS

HEATER CORE (Continued)

Page 2275 of 2339

The following is a list of the monitored compo-

nents:

²Catalyst Monitor

²Comprehensive Components

²EGR (if equipped)

²Fuel Control (rich/lean)

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Purge

²Misfire

²Natural Vacuum Leak Detection (NVLD)

COMPREHENSIVE COMPONENTS

Along with the major monitors, OBD II requires

that the diagnostic system monitor any component

that could affect emissions levels. In many cases,

these components were being tested under OBD I.

The OBD I requirements focused mainly on testing

emissions-related components for electrical opens and

shorts.

However, OBD II also requires that inputs from

powertrain components to the PCM be tested for

rationality, and that outputs to powertrain compo-

nents from the PCM be tested forfunctionality.

Methods for monitoring the various Comprehensive

Component monitoring include:

(1) Circuit Continuity

²Open

²Shorted high

²Shorted to ground

(2) Rationality or Proper Functioning

²Inputs tested for rationality

²Outputs tested for functionality

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply. All will set a DTC and illuminate the MIL in 1-

trip.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S) (slow response)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Natural Vacuum Leak Detection (NVLD)

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen in

the exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, misfire or

exhaust leak, the sensor produces a low voltage,

below 450 mV. When the oxygen content is lower,

caused by a rich condition, the sensor produces a

higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. The PCM is

programmed to maintain the optimum air/fuel ratio.

At this mixture ratio, the catalyst works best to

remove hydrocarbons (HC), carbon monoxide (CO)

and nitrous oxide (NOx) from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors, and purge.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse rate

is the time required for the sensor to switch from

lean to rich signal output once it is exposed to a

25 - 2 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2276 of 2339

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Many

times the condition is only temporey and the sensor

will recover. Under normal conditions the voltage sig-

nal surpasses the threshold, and a counter is incre-

mented by one. This is called the Half Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Signal Monitor is a two trip

monitor that is tested only once per trip. When the

Oxygen Sensor fails the test in two consecutive trips,

the MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Signal Monitor

if overlapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

²Ethenal content learn is taking place and the

ethenal used once flag is set

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR (NGC)

DESCRIPTIONÐIf the Oxygen sensor (O2S) DTC

as well as a O2S heater DTC is present, the O2S

Heater DTC MUST be repaired first. After the O2S

Heater is repaired, verify that the sensor circuit is

operating correctly.

The voltage reading taken from the O2S are very

temperature sensitive. The readings taken from the

O2S are not accurate below 300 degrees C. Heating

the O2S is done to allow the engine controller to shift

to closed loop control as soon as possible. The heating

element used to heat the O2S must be tested to

ensure that it is heating the sensor properly. Starting

with the introduction on the NGC module the strat-

egy for checking the heater circuit has changed. The

heater resistance is checked by the NGC almost

immediately after the engine is started. The same

O2S heater return pin used to read the heater resis-

tance is capable of detecting an open circuit, a

shorted high or shorted low condition.

RSEMISSIONS CONTROL25-3

EMISSIONS CONTROL (Continued)

Page 2304 of 2339

BACKLIGHT (EBL) SYSTEM, DIAGNOSISAND TESTING - ELECTRIC ..............8G-2

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-158

BACKSTOW STRAP - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-158

BAG RETAINER - INSTALLATION, PLASTIC GROCERY .................. 23-149

BAG RETAINER - REMOVAL, PLASTIC GROCERY ......................... 23-149

BALANCE - STANDARD PROCEDURE, TIRE AND WHEEL ..................... 22-5

BALANCE SHAFTS AND CARRIER ASSEMBLY - DESCRIPTION .............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - INSTALLATION .............9-73

BALANCE SHAFTS AND CARRIER ASSEMBLY - OPERATION ...............9-71

BALANCE SHAFTS AND CARRIER ASSEMBLY - REMOVAL .................9-71

BALL JOINT - DESCRIPTION, LOWER ......2-10

BALL JOINT - DIAGNOSIS AND TESTING, LOWER ............................. 2-10

BALL JOINT - OPERATION, LOWER .......2-10

BAR - DESCRIPTION, STABILIZER ....2-16,2-44

BAR - DESCRIPTION, TRACK ............2-45

BAR - INSPECTION, STABILIZER ..........2-17

BAR - INSTALLATION, STABILIZER ........2-17

BAR - INSTALLATION, TRACK ............2-46

BAR - OPERATION, STABILIZER ......2-16,2-44

BAR - OPERATION, TRACK ................2-46

BAR - REMOVAL, STABILIZER ...........2-17

BAR - REMOVAL, TRACK ...............2-46

BAR CUSHION - INSTALLATION, STABILIZER ...........................2-4

BAR CUSHION - REMOVAL, STABILIZER ....2-4

BASE BRAKE BLEEDING - STANDARD PROCEDURE ..........................5-8

BASE BRAKE SYSTEM - DIAGNOSIS AND TESTING .............................5-4

BASE BRAKE SYSTEM, SPECIAL TOOLS ....5-10

BASE BRAKES - DESCRIPTION ............5-3

BASE BRAKES - OPERATION ..............5-3

BASE BRAKES (EXPORT) - DESCRIPTION . . . 5-3

BASE COAT/CLEARCOAT FINISH - DESCRIPTION ...................... 23-101

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-135

BASE RISER - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-134

BASE TRAY - INSTALLATION, FLOOR CONSOLE ........................... 23-89

BASE TRAY - REMOVAL, FLOOR CONSOLE ........................... 23-89

BATTERY - DESCRIPTION ...............8F-7

BATTERY - OPERATION .................8F-9

BATTERY - REMOVAL .................8F-16

BATTERY - SPECIFICATIONS ............8N-24

BATTERY CABLES - DESCRIPTION .......8F-16

BATTERY CABLES - OPERATION .........8F-17

BATTERY CABLES, DIAGNOSIS AND TESTING ........................... 8F-17

BATTERY CHARGING, STANDARD PROCEDURE - CONVENTIONAL ..........8F-11

BATTERY CHARGING, STANDARD PROCEDURE - SPIRAL PLATE ...........8F-10

BATTERY, DIAGNOSIS AND TESTING ......8F-9

BATTERY ELECTROLYTE LEVEL, STANDARD PROCEDURE - CHECKING ....8F-14

BATTERY HOLDDOWN - INSTALLATION . . . 8F-16

BATTERY HOLDDOWN - REMOVAL .......8F-16

BATTERY REPLACEMENT - STANDARD PROCEDURE ........................ 8N-24

BATTERY, SPECIFICATIONS ..............8F-6

BATTERY SYSTEM - DESCRIPTION ........8F-1

BATTERY SYSTEM - OPERATION .........8F-2

BATTERY SYSTEM, DIAGNOSIS AND TESTING ............................ 8F-2

BATTERY SYSTEM SPECIAL TOOLS, SPECIAL TOOLS ...................... 8F-7

BATTERY TEMPERATURE SENSOR - DESCRIPTION ....................... 8F-24

BATTERY TEMPERATURE SENSOR - OPERATION ......................... 8F-24

BATTERY TEMPERATURE SENSOR - REMOVAL .......................... 8F-24

BATTERY TEMPERATURE SENSOR - SPECIFICATIONS ..................... 8F-23BATTERY TESTER, STANDARD

PROCEDURE - MICRO 420 .............8F-15

BATTERY TRAY - DESCRIPTION .........8F-19

BATTERY TRAY - INSTALLATION .........8F-20

BATTERY TRAY - REMOVAL ............8F-19

BEARING - DESCRIPTION, HUB .......2-30,2-5

BEARING - DIAGNOSIS AND TESTING, HUB............................. 2-31,2-5

BEARING - INSTALLATION, HUB .......2-33,2-5

BEARING - OPERATION, HUB .........2-30,2-5

BEARING - REMOVAL, HUB ..........2-31,2-5

BEARING CLEARANCE - STANDARD PROCEDURE, MEASURING

CONNECTING ROD ................... 9-123

BEARING CLEARANCE USING PLASTIGAGE - STANDARD

PROCEDURE, MEASURING ..........9-12,9-86

BEARING FITTING - STANDARD PROCEDURE, MAIN ................... 9-125

BEARING PRELOAD - ADJUSTMENT, DIFFERENTIAL ...................... 21-228

BEARING PRELOAD MEASUREMENT AND ADJUSTMENT, ADJUSTMENTS -

DIFFERENTIAL ....................... 21-79

BEARINGS - INSTALLATION, CRANKSHAFT MAIN .................. 9-127

BEARINGS - REMOVAL, CRANKSHAFT MAIN .............................. 9-127

BEARINGS (IN BLOCK) - DESCRIPTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSPECTION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - INSTALLATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - OPERATION, CAMSHAFT ......................... 9-118

BEARINGS (IN BLOCK) - REMOVAL, CAMSHAFT ......................... 9-118

BELLCRANK - INSTALLATION ...........23-35

BELLCRANK - REMOVAL ...............23-35

BELT - DIAGNOSIS AND TESTING, ACCESSORY DRIVE .....................7-7

BELT - FOLD-IN-FLOOR - INSTALLATION, SEAT BELT CENTER LAP ..............23-157

BELT - FOLD-IN-FLOOR - REMOVAL, SEAT BELT CENTER LAP ..............23-157

BELT - INSTALLATION, TIMING ...........9-67

BELT - REMOVAL, TIMING ..............9-65

BELT & RETRACTOR - FIRST ROW - OUTBOARD - INSTALLATION, SEAT ......8O-40

BELT & RETRACTOR - FIRST ROW - OUTBOARD - REMOVAL, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - INSTALLATION, SEAT ..........8O-39

BELT & RETRACTOR - OUTBOARD - FRONT - REMOVAL, SEAT ..............8O-38

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-42

BELT & RETRACTOR - SECOND ROW - LEFT OUTBOARD - REMOVAL, SEAT .....8O-42

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - INSTALLATION,

SEAT .............................. 8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD - REMOVAL, SEAT ....8O-40

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - INSTALLATION, SEAT ............8O-41

BELT & RETRACTOR - SECOND ROW - RIGHT OUTBOARD WITH REAR HVAC -

LWB - REMOVAL, SEAT ...............8O-41

BELT BUCKLE - FIRST ROW - BENCH - INSTALLATION, SEAT .................8O-37

BELT BUCKLE - FIRST ROW - BENCH - REMOVAL, SEAT ..................... 8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - INSTALLATION, SEAT ....8O-36

BELT BUCKLE - FIRST ROW INBOARD - QUAD BUCKET - REMOVAL, SEAT .......8O-35

BELT BUCKLE - FRONT INBOARD - INSTALLATION, SEAT .................8O-35

BELT BUCKLE - FRONT INBOARD - REMOVAL, SEAT ..................... 8O-35

BELT BUCKLE - SECOND ROW - THREE PASSENGER BENCH - INSTALLATION,

SEAT .............................. 8O-40BELT BUCKLE - SECOND ROW - THREE

PASSENGER BENCH - REMOVAL, SEAT . . . 8O-40

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - INSTALLATION, SEAT . . . 8O-38

BELT BUCKLE - SECOND ROW INBOARD - 50/50 BENCH - REMOVAL, SEAT .......8O-37

BELT CENTER LAP BELT - FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-157

BELT CENTER LAP BELT - FOLD-IN- FLOOR - REMOVAL, SEAT .............23-157

BELT COVER(S) - INSTALLATION, TIMING ............................. 9-64

BELT COVER(S) - REMOVAL, TIMING ......9-63

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - INSTALLATION, SEAT ........8O-38

BELT HEIGHT ADJUSTE R-BOR

C-PILLAR - REMOVAL, SEAT ...........8O-38

BELT HEIGHT ADJUSTER KNOB - INSTALLATION, SEAT .................8O-38

BELT HEIGHT ADJUSTER KNOB - REMOVAL, SEAT ..................... 8O-38

BELT MOLDING - INSTALLATION, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - INSTALLATION, FRONT DOOR OUTER ...................... 23-167

BELT MOLDING - REMOVAL, FRONT DOOR INNER ....................... 23-168

BELT MOLDING - REMOVAL, FRONT DOOR OUTER ...................... 23-167

BELT TENSION - STANDARD PROCEDURE, CHECKING POWER

STEERING ............................7-8

BELT TENSION SENSOR - DESCRIPTION . . . 8O-8

BELT TENSION SENSOR - OPERATION .....8O-9

BELT TENSION, SPECIFICATIONS - ACCESSORY DRIVE .....................7-5

BELT TENSIONER - 2.4L - INSTALLATION . . 7-11

BELT TENSIONER - 2.4L - REMOVAL ......7-11

BELT TENSIONER - 3.3/3.8L - INSTALLATION ........................ 7-12

BELT TENSIONER - 3.3/3.8L - REMOVAL . . . 7-12

BELT TENSIONER - DESCRIPTION, SEAT . . 8O-43

BELT TENSIONER - OPERATION, SEAT ....8O-43

BELT TENSIONER & PULLEY - INSTALLATION, TIMING .................9-70

BELT TENSIONER & PULLEY - REMOVAL, TIMING .................... 9-69

BELTS - 2.4L - ADJUSTMENTS, DRIVE .....7-10

BELTS - 2.4L - INSTALLATION, DRIVE ......7-9

BELTS - 2.4L - REMOVAL, DRIVE ..........7-9

BELTS - 3.3/3.8L - INSTALLATION, DRIVE . . 7-12

BELTS - 3.3/3.8L - REMOVAL, DRIVE ......7-11

BELTS - CLEANING, DRIVE ...............7-8

BELTS - INSPECTION, DRIVE .............7-8

BENCH - INSTALLATION, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50

SPLIT ............................. 23-146

BENCH - INSTALLATION, SEAT BELT BUCKLE - FIRST ROW ................8O-37

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW - THREE

PASSENGER ........................ 8O-40

BENCH - INSTALLATION, SEAT BELT BUCKLE - SECOND ROW INBOARD -

50/50 .............................. 8O-38

BENCH - INSTALLATION, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH - REMOVAL, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT . . 23-146

BENCH - REMOVAL, SEAT BELT BUCKLE - FIRST ROW ....................... 8O-36

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW - THREE PASSENGER ....8O-40

BENCH - REMOVAL, SEAT BELT BUCKLE - SECOND ROW INBOARD - 50/50 .......8O-37

BENCH - REMOVAL, SEAT CUSHION COVER - QUAD BUCKET, 50/50 SPLIT . . . 23-144

BENCH SEAT - REMOVAL, CHILD SEAT MODULE .......................... 23-104

BENCH SEAT BACK - INSTALLATION .....23-147

BENCH SEAT BACK - REMOVAL ........23-147

BENCH SEAT BACK COVER - INSTALLATION ...................... 23-148

BENCH SEAT BACK COVER - REMOVAL . . 23-148

BENCH SEAT BACK HINGE - REMOVAL . . 23-146

BENCH SEAT BACK PANEL - INSTALLATION ...................... 23-144

BENCH SEAT BACK PANEL - REMOVAL . . 23-143

RS INDEX3

Description Group-Page Description Group-Page Description Group-Page