service schedule CHRYSLER CARAVAN 2005 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 35 of 2339

At Each Oil Change

²Change the engine oil filter.

²Inspect the exhaust system.

²Inspect the brake hoses.

²Inspect the CV joints and front suspension com-

ponents.²Check the manual transmission fluid level.

²Check the coolant level, hoses, and clamps.

²Inspect engine accessory drive belts. Replace as

necessary.

²Inspect for the presence of water in the fuel fil-

ter/water separator unit.

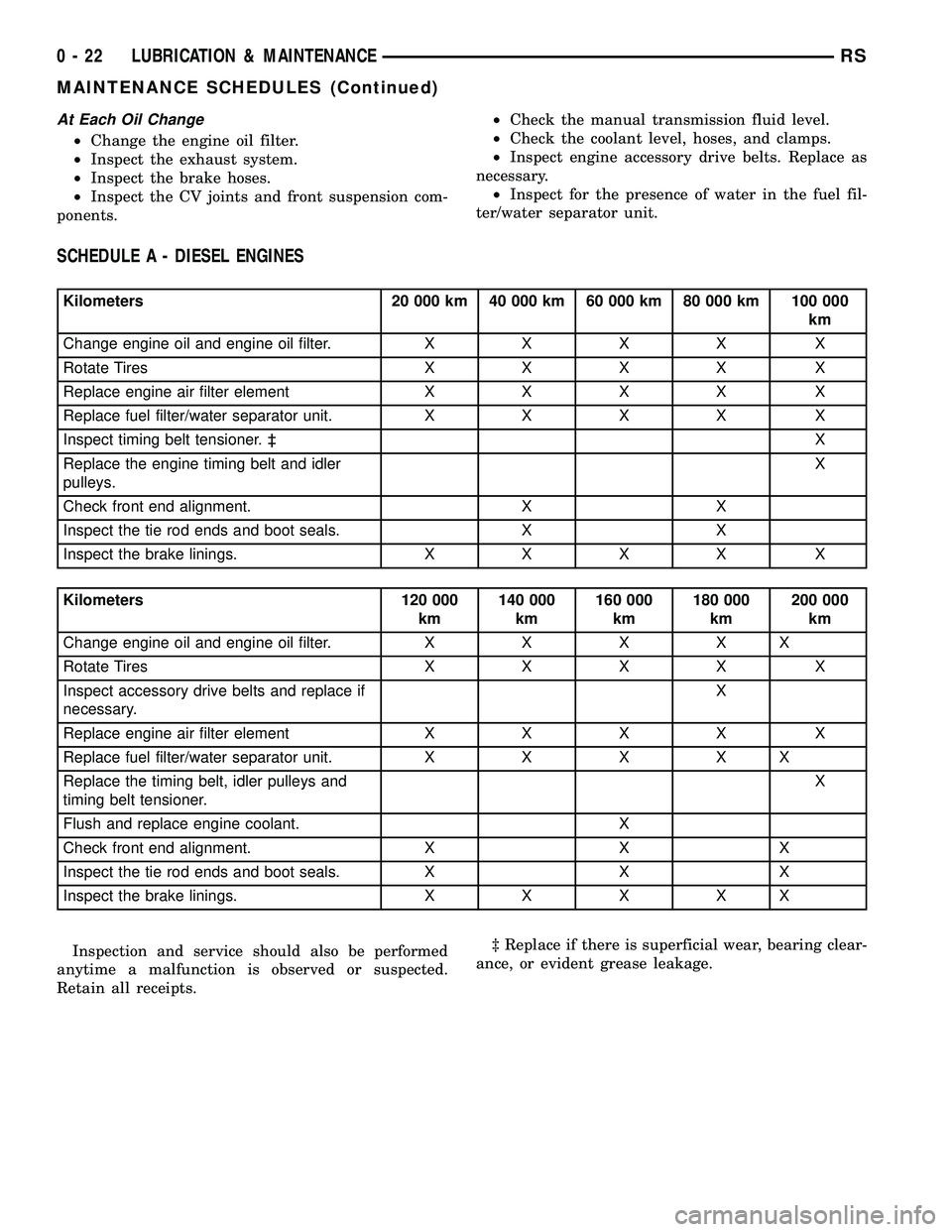

SCHEDULE A - DIESEL ENGINES

Kilometers 20 000 km 40 000 km 60 000 km 80 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Rotate TiresXXXX X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit.XXXX X

Inspect timing belt tensioner. ³X

Replace the engine timing belt and idler

pulleys.X

Check front end alignment. X X

Inspect the tie rod ends and boot seals. X X

Inspect the brake linings.XXXX X

Kilometers 120 000

km140 000

km160 000

km180 000

km200 000

km

Change engine oil and engine oil filter.XXXXX

Rotate TiresXXXX X

Inspect accessory drive belts and replace if

necessary.X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit.XXXXX

Replace the timing belt, idler pulleys and

timing belt tensioner.X

Flush and replace engine coolant. X

Check front end alignment. X X X

Inspect the tie rod ends and boot seals. X X X

Inspect the brake linings.XXXXX

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.³ Replace if there is superficial wear, bearing clear-

ance, or evident grease leakage.

0 - 22 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 36 of 2339

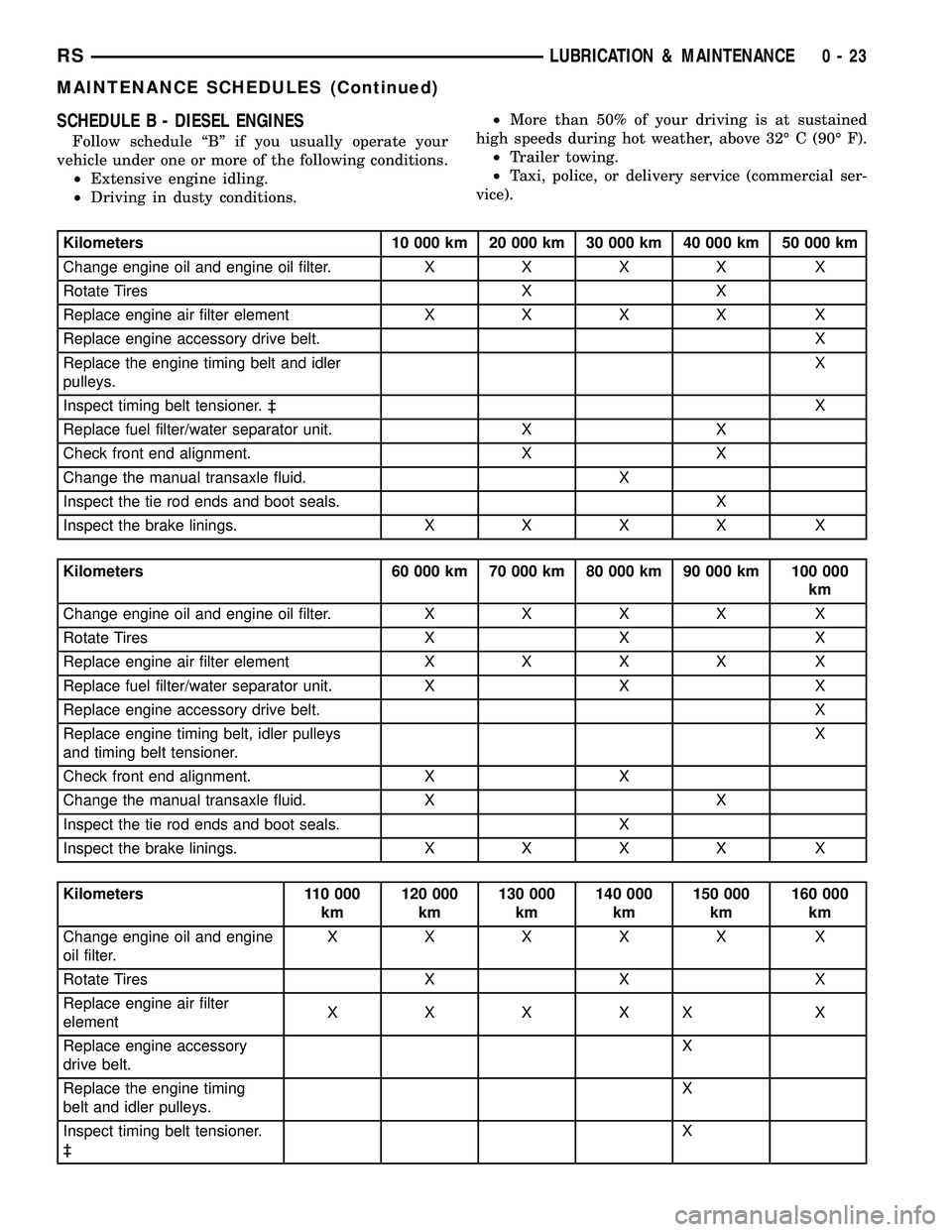

SCHEDULE B - DIESEL ENGINES

Follow schedule ªBº if you usually operate your

vehicle under one or more of the following conditions.

²Extensive engine idling.

²Driving in dusty conditions.²More than 50% of your driving is at sustained

high speeds during hot weather, above 32É C (90É F).

²Trailer towing.

²Taxi, police, or delivery service (commercial ser-

vice).

Kilometers 10 000 km 20 000 km 30 000 km 40 000 km 50 000 km

Change engine oil and engine oil filter.XXXX X

Rotate Tires X X

Replace engine air filter elementXXXX X

Replace engine accessory drive belt. X

Replace the engine timing belt and idler

pulleys.X

Inspect timing belt tensioner. ³X

Replace fuel filter/water separator unit. X X

Check front end alignment. X X

Change the manual transaxle fluid. X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 60 000 km 70 000 km 80 000 km 90 000 km 100 000

km

Change engine oil and engine oil filter.XXXX X

Rotate Tires X X X

Replace engine air filter elementXXXX X

Replace fuel filter/water separator unit. X X X

Replace engine accessory drive belt. X

Replace engine timing belt, idler pulleys

and timing belt tensioner.X

Check front end alignment. X X

Change the manual transaxle fluid. X X

Inspect the tie rod ends and boot seals. X

Inspect the brake linings.XXXX X

Kilometers 110 000

km120 000

km130 000

km140 000

km150 000

km160 000

km

Change engine oil and engine

oil filter.XXXXX X

Rotate Tires X X X

Replace engine air filter

elementXXXXX X

Replace engine accessory

drive belt.X

Replace the engine timing

belt and idler pulleys.X

Inspect timing belt tensioner.

³X

RSLUBRICATION & MAINTENANCE0-23

MAINTENANCE SCHEDULES (Continued)

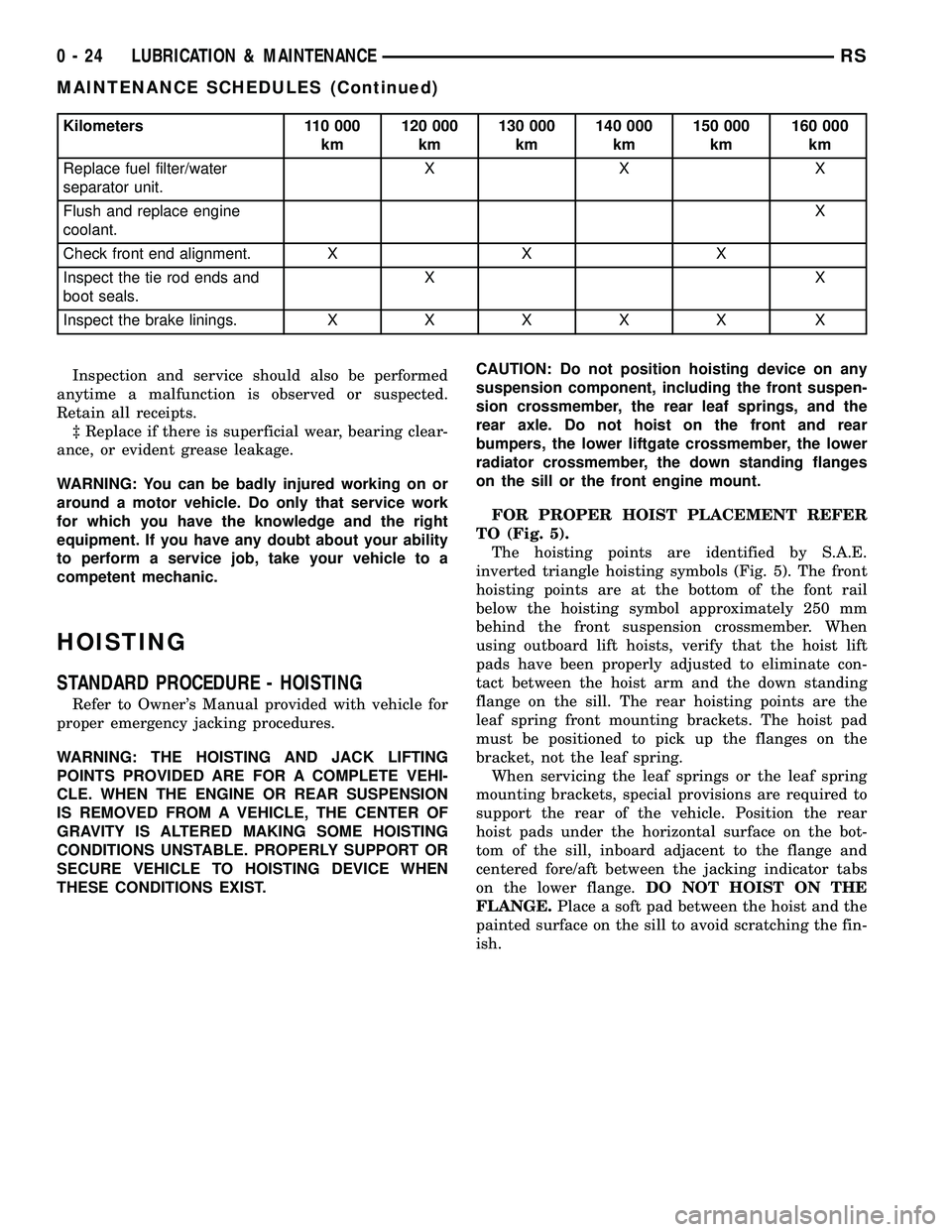

Page 37 of 2339

Kilometers 110 000

km120 000

km130 000

km140 000

km150 000

km160 000

km

Replace fuel filter/water

separator unit.XX X

Flush and replace engine

coolant.X

Check front end alignment. X X X

Inspect the tie rod ends and

boot seals.XX

Inspect the brake linings. XXXXX X

Inspection and service should also be performed

anytime a malfunction is observed or suspected.

Retain all receipts.

³ Replace if there is superficial wear, bearing clear-

ance, or evident grease leakage.

WARNING: You can be badly injured working on or

around a motor vehicle. Do only that service work

for which you have the knowledge and the right

equipment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

HOISTING

STANDARD PROCEDURE - HOISTING

Refer to Owner's Manual provided with vehicle for

proper emergency jacking procedures.

WARNING: THE HOISTING AND JACK LIFTING

POINTS PROVIDED ARE FOR A COMPLETE VEHI-

CLE. WHEN THE ENGINE OR REAR SUSPENSION

IS REMOVED FROM A VEHICLE, THE CENTER OF

GRAVITY IS ALTERED MAKING SOME HOISTING

CONDITIONS UNSTABLE. PROPERLY SUPPORT OR

SECURE VEHICLE TO HOISTING DEVICE WHEN

THESE CONDITIONS EXIST.CAUTION: Do not position hoisting device on any

suspension component, including the front suspen-

sion crossmember, the rear leaf springs, and the

rear axle. Do not hoist on the front and rear

bumpers, the lower liftgate crossmember, the lower

radiator crossmember, the down standing flanges

on the sill or the front engine mount.

FOR PROPER HOIST PLACEMENT REFER

TO (Fig. 5).

The hoisting points are identified by S.A.E.

inverted triangle hoisting symbols (Fig. 5). The front

hoisting points are at the bottom of the font rail

below the hoisting symbol approximately 250 mm

behind the front suspension crossmember. When

using outboard lift hoists, verify that the hoist lift

pads have been properly adjusted to eliminate con-

tact between the hoist arm and the down standing

flange on the sill. The rear hoisting points are the

leaf spring front mounting brackets. The hoist pad

must be positioned to pick up the flanges on the

bracket, not the leaf spring.

When servicing the leaf springs or the leaf spring

mounting brackets, special provisions are required to

support the rear of the vehicle. Position the rear

hoist pads under the horizontal surface on the bot-

tom of the sill, inboard adjacent to the flange and

centered fore/aft between the jacking indicator tabs

on the lower flange.DO NOT HOIST ON THE

FLANGE.Place a soft pad between the hoist and the

painted surface on the sill to avoid scratching the fin-

ish.

0 - 24 LUBRICATION & MAINTENANCERS

MAINTENANCE SCHEDULES (Continued)

Page 238 of 2339

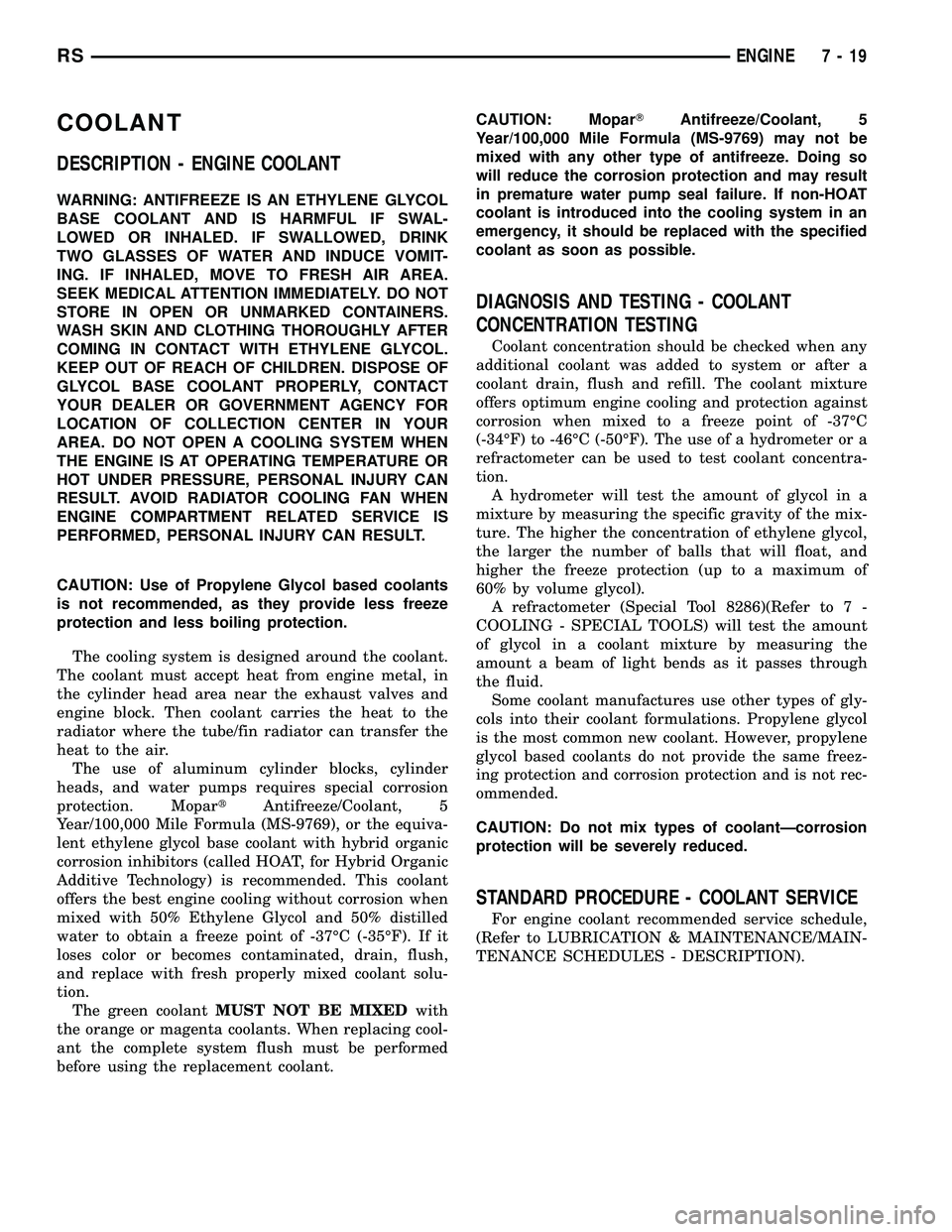

COOLANT

DESCRIPTION - ENGINE COOLANT

WARNING: ANTIFREEZE IS AN ETHYLENE GLYCOL

BASE COOLANT AND IS HARMFUL IF SWAL-

LOWED OR INHALED. IF SWALLOWED, DRINK

TWO GLASSES OF WATER AND INDUCE VOMIT-

ING. IF INHALED, MOVE TO FRESH AIR AREA.

SEEK MEDICAL ATTENTION IMMEDIATELY. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN. DISPOSE OF

GLYCOL BASE COOLANT PROPERLY, CONTACT

YOUR DEALER OR GOVERNMENT AGENCY FOR

LOCATION OF COLLECTION CENTER IN YOUR

AREA. DO NOT OPEN A COOLING SYSTEM WHEN

THE ENGINE IS AT OPERATING TEMPERATURE OR

HOT UNDER PRESSURE, PERSONAL INJURY CAN

RESULT. AVOID RADIATOR COOLING FAN WHEN

ENGINE COMPARTMENT RELATED SERVICE IS

PERFORMED, PERSONAL INJURY CAN RESULT.

CAUTION: Use of Propylene Glycol based coolants

is not recommended, as they provide less freeze

protection and less boiling protection.

The cooling system is designed around the coolant.

The coolant must accept heat from engine metal, in

the cylinder head area near the exhaust valves and

engine block. Then coolant carries the heat to the

radiator where the tube/fin radiator can transfer the

heat to the air.

The use of aluminum cylinder blocks, cylinder

heads, and water pumps requires special corrosion

protection. MopartAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769), or the equiva-

lent ethylene glycol base coolant with hybrid organic

corrosion inhibitors (called HOAT, for Hybrid Organic

Additive Technology) is recommended. This coolant

offers the best engine cooling without corrosion when

mixed with 50% Ethylene Glycol and 50% distilled

water to obtain a freeze point of -37ÉC (-35ÉF). If it

loses color or becomes contaminated, drain, flush,

and replace with fresh properly mixed coolant solu-

tion.

The green coolantMUST NOT BE MIXEDwith

the orange or magenta coolants. When replacing cool-

ant the complete system flush must be performed

before using the replacement coolant.CAUTION: MoparTAntifreeze/Coolant, 5

Year/100,000 Mile Formula (MS-9769) may not be

mixed with any other type of antifreeze. Doing so

will reduce the corrosion protection and may result

in premature water pump seal failure. If non-HOAT

coolant is introduced into the cooling system in an

emergency, it should be replaced with the specified

coolant as soon as possible.

DIAGNOSIS AND TESTING - COOLANT

CONCENTRATION TESTING

Coolant concentration should be checked when any

additional coolant was added to system or after a

coolant drain, flush and refill. The coolant mixture

offers optimum engine cooling and protection against

corrosion when mixed to a freeze point of -37ÉC

(-34ÉF) to -46ÉC (-50ÉF). The use of a hydrometer or a

refractometer can be used to test coolant concentra-

tion.

A hydrometer will test the amount of glycol in a

mixture by measuring the specific gravity of the mix-

ture. The higher the concentration of ethylene glycol,

the larger the number of balls that will float, and

higher the freeze protection (up to a maximum of

60% by volume glycol).

A refractometer (Special Tool 8286)(Refer to 7 -

COOLING - SPECIAL TOOLS) will test the amount

of glycol in a coolant mixture by measuring the

amount a beam of light bends as it passes through

the fluid.

Some coolant manufactures use other types of gly-

cols into their coolant formulations. Propylene glycol

is the most common new coolant. However, propylene

glycol based coolants do not provide the same freez-

ing protection and corrosion protection and is not rec-

ommended.

CAUTION: Do not mix types of coolantÐcorrosion

protection will be severely reduced.

STANDARD PROCEDURE - COOLANT SERVICE

For engine coolant recommended service schedule,

(Refer to LUBRICATION & MAINTENANCE/MAIN-

TENANCE SCHEDULES - DESCRIPTION).

RSENGINE7-19

Page 310 of 2339

CLEANING

The following information details the recommended

cleaning procedures for the battery and related com-

ponents. In addition to the maintenance schedules

found in this service manual and the owner's man-

ual, it is recommended that these procedures be per-

formed any time the battery or related components

must be removed for vehicle service.

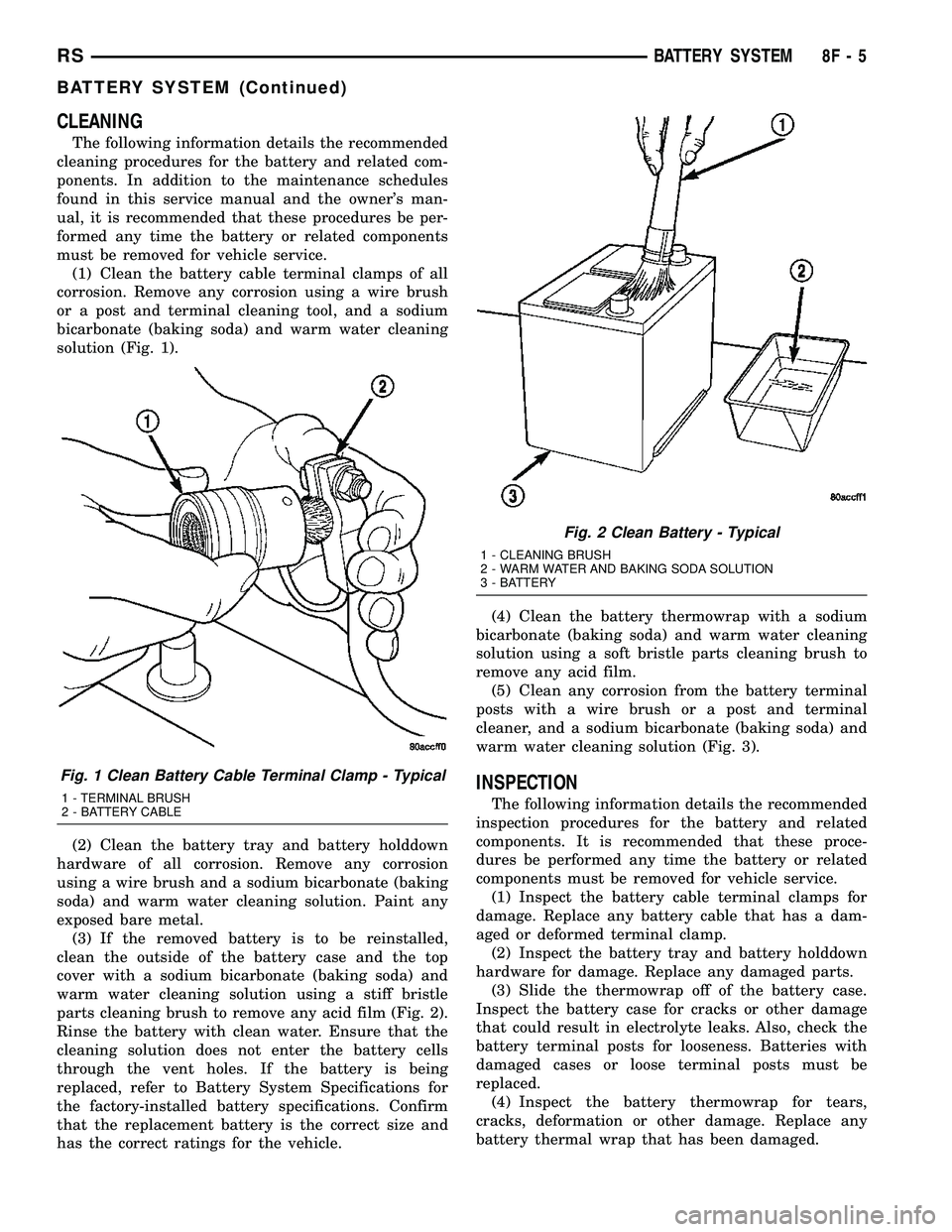

(1) Clean the battery cable terminal clamps of all

corrosion. Remove any corrosion using a wire brush

or a post and terminal cleaning tool, and a sodium

bicarbonate (baking soda) and warm water cleaning

solution (Fig. 1).

(2) Clean the battery tray and battery holddown

hardware of all corrosion. Remove any corrosion

using a wire brush and a sodium bicarbonate (baking

soda) and warm water cleaning solution. Paint any

exposed bare metal.

(3) If the removed battery is to be reinstalled,

clean the outside of the battery case and the top

cover with a sodium bicarbonate (baking soda) and

warm water cleaning solution using a stiff bristle

parts cleaning brush to remove any acid film (Fig. 2).

Rinse the battery with clean water. Ensure that the

cleaning solution does not enter the battery cells

through the vent holes. If the battery is being

replaced, refer to Battery System Specifications for

the factory-installed battery specifications. Confirm

that the replacement battery is the correct size and

has the correct ratings for the vehicle.(4) Clean the battery thermowrap with a sodium

bicarbonate (baking soda) and warm water cleaning

solution using a soft bristle parts cleaning brush to

remove any acid film.

(5) Clean any corrosion from the battery terminal

posts with a wire brush or a post and terminal

cleaner, and a sodium bicarbonate (baking soda) and

warm water cleaning solution (Fig. 3).

INSPECTION

The following information details the recommended

inspection procedures for the battery and related

components. It is recommended that these proce-

dures be performed any time the battery or related

components must be removed for vehicle service.

(1) Inspect the battery cable terminal clamps for

damage. Replace any battery cable that has a dam-

aged or deformed terminal clamp.

(2) Inspect the battery tray and battery holddown

hardware for damage. Replace any damaged parts.

(3) Slide the thermowrap off of the battery case.

Inspect the battery case for cracks or other damage

that could result in electrolyte leaks. Also, check the

battery terminal posts for looseness. Batteries with

damaged cases or loose terminal posts must be

replaced.

(4) Inspect the battery thermowrap for tears,

cracks, deformation or other damage. Replace any

battery thermal wrap that has been damaged.

Fig. 1 Clean Battery Cable Terminal Clamp - Typical

1 - TERMINAL BRUSH

2 - BATTERY CABLE

Fig. 2 Clean Battery - Typical

1 - CLEANING BRUSH

2 - WARM WATER AND BAKING SODA SOLUTION

3 - BATTERY

RSBATTERY SYSTEM8F-5

BATTERY SYSTEM (Continued)

Page 372 of 2339

(4) Lower vehicle.

(5) Connect the negative cable.

SPARK PLUG

DESCRIPTION

DESCRIPTION - STANDARD 4 CYLINDER

All engines use resistor spark plugs. They have

resistance values ranging from 6,000 to 20,000 ohms

when checked with at least a 1000 volt spark plug

tester.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.

Refer to the Specifications section for gap and type

of spark plug.

DESCRIPTION - PLATINUM PLUGS

The V6 engines use platinum resistor spark plugs.

They have resistance values of 6,000 to 20,000 ohms

when checked with at least a 1000 volt tester. For

spark plug identification and specifications, Refer to

the Specifications section.

Do not use an ohm meter to check the resis-

tance of the spark plugs. This will give an inac-

curate reading.When the spark plugs use a single or double plat-

inum tips and they have a recommended service life

of 100,000 miles for normal driving conditions per

schedule A in this manual. The spark plugs have a

recommended service life of 75,000 miles for severe

driving conditions per schedule B in this manual. A

thin platinum pad is welded to both or just the cen-

ter electrode end(s) as shown in (Fig. 13). Extreme

care must be used to prevent spark plug cross

threading, mis-gapping (Fig. 14) and ceramic insula-

tor damage during plug removal and installation.

CAUTION: Cleaning of the platinum plug may dam-

age the platinum tip.

Fig. 12 Knock Sensor

1 - GENERATOR

2 - INTAKE MANIFOLD

3 - KNOCK SENSOR

4-STARTER

Fig. 13 Platinum Pads

1 - APPLY ANTI-SEIZE COMPOUND HERE ONLY

2 - PLATINUM SPARK SURFACE

Fig. 14 Setting Spark Plug Electrode Gap

1 - TAPER GAUGE

RSIGNITION CONTROL8I-9

KNOCK SENSOR (Continued)

Page 1543 of 2339

FLUID

STANDARD PROCEDURE

FLUID LEVEL AND CONDITION CHECK

NOTE: Only transmission fluid of the type labeled

Mopar ATF+4 (Automatic Transmission Fluid)

should be used in this transaxle.

FLUID LEVEL CHECK

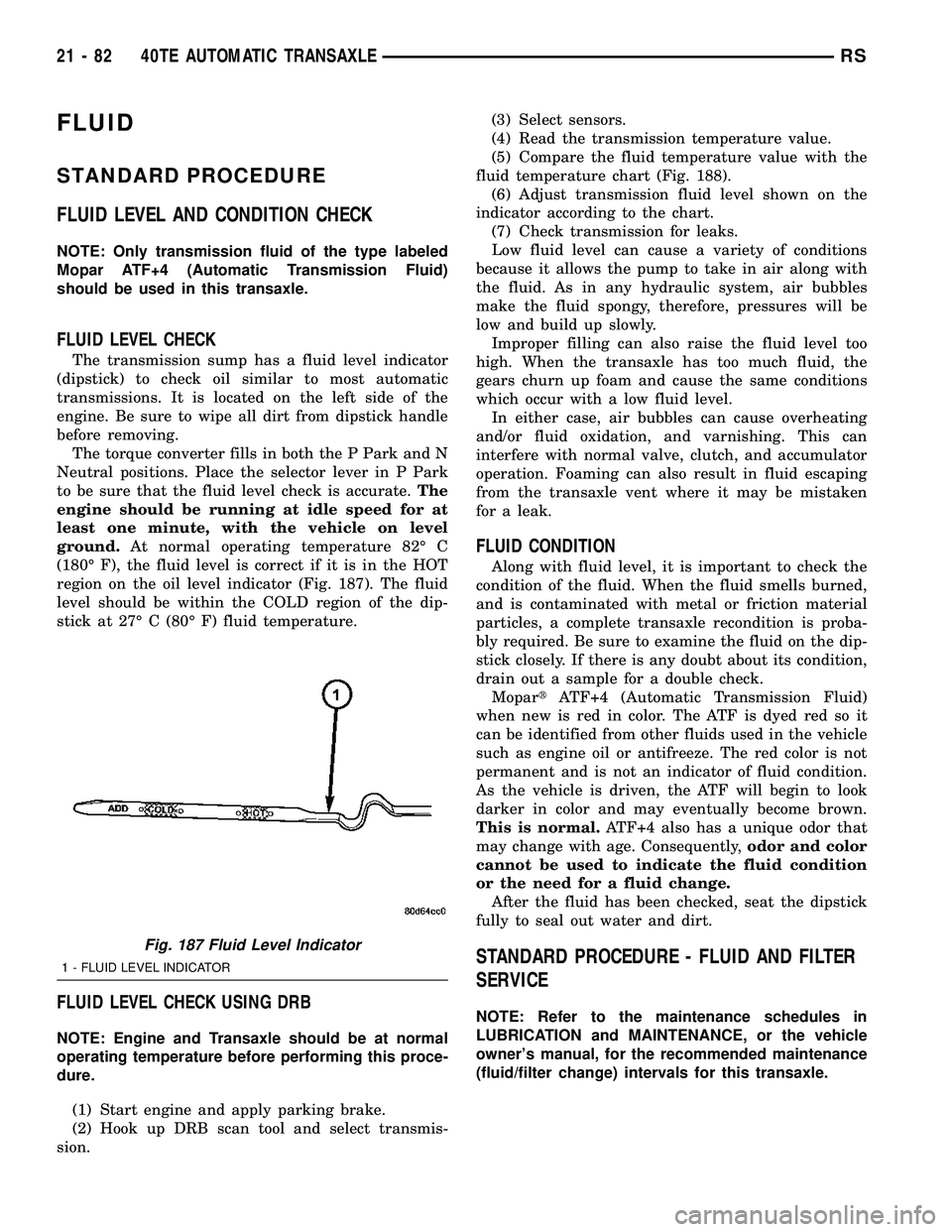

The transmission sump has a fluid level indicator

(dipstick) to check oil similar to most automatic

transmissions. It is located on the left side of the

engine. Be sure to wipe all dirt from dipstick handle

before removing.

The torque converter fills in both the P Park and N

Neutral positions. Place the selector lever in P Park

to be sure that the fluid level check is accurate.The

engine should be running at idle speed for at

least one minute, with the vehicle on level

ground.At normal operating temperature 82É C

(180É F), the fluid level is correct if it is in the HOT

region on the oil level indicator (Fig. 187). The fluid

level should be within the COLD region of the dip-

stick at 27É C (80É F) fluid temperature.

FLUID LEVEL CHECK USING DRB

NOTE: Engine and Transaxle should be at normal

operating temperature before performing this proce-

dure.

(1) Start engine and apply parking brake.

(2) Hook up DRB scan tool and select transmis-

sion.(3) Select sensors.

(4) Read the transmission temperature value.

(5) Compare the fluid temperature value with the

fluid temperature chart (Fig. 188).

(6) Adjust transmission fluid level shown on the

indicator according to the chart.

(7) Check transmission for leaks.

Low fluid level can cause a variety of conditions

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy, therefore, pressures will be

low and build up slowly.

Improper filling can also raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

which occur with a low fluid level.

In either case, air bubbles can cause overheating

and/or fluid oxidation, and varnishing. This can

interfere with normal valve, clutch, and accumulator

operation. Foaming can also result in fluid escaping

from the transaxle vent where it may be mistaken

for a leak.

FLUID CONDITION

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

and is contaminated with metal or friction material

particles, a complete transaxle recondition is proba-

bly required. Be sure to examine the fluid on the dip-

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.

STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

Fig. 187 Fluid Level Indicator

1 - FLUID LEVEL INDICATOR

21 - 82 40TE AUTOMATIC TRANSAXLERS

Page 1692 of 2339

stick closely. If there is any doubt about its condition,

drain out a sample for a double check.

MopartATF+4 (Automatic Transmission Fluid)

when new is red in color. The ATF is dyed red so it

can be identified from other fluids used in the vehicle

such as engine oil or antifreeze. The red color is not

permanent and is not an indicator of fluid condition.

As the vehicle is driven, the ATF will begin to look

darker in color and may eventually become brown.

This is normal.ATF+4 also has a unique odor that

may change with age. Consequently,odor and color

cannot be used to indicate the fluid condition

or the need for a fluid change.

After the fluid has been checked, seat the dipstick

fully to seal out water and dirt.STANDARD PROCEDURE - FLUID AND FILTER

SERVICE

NOTE: Refer to the maintenance schedules in

LUBRICATION and MAINTENANCE, or the vehicle

owner's manual, for the recommended maintenance

(fluid/filter change) intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparTATF+4

(Automatic Transmission Fluid) should be used. A

filter change should be made at the time of the

transmission oil change. The magnet (on the inside

of the oil pan) should also be cleaned with a clean,

dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

Fig. 206 Transmission Fluid Temperature Chart

1 - MAX. LEVEL2 - MIN. LEVEL

RS41TE AUTOMATIC TRANSAXLE21 - 231

FLUID (Continued)