wheel CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1215 of 2339

(6) Drain engine oil and remove oil filter.

(7) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(8) Remove engine mount support bracket.

(9) Remove front timing belt covers (Refer to 9 -

ENGINE/VALVE TIMING/TIMING BELT COVER(S)

- REMOVAL).

(10) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(11) Remove the rear timing belt cover (Refer to 9

- ENGINE/VALVE TIMING/TIMING BELT COV-

ER(S) - REMOVAL).

(12) Remove the oil pan (Refer to 9 - ENGINE/LU-

BRICATION/OIL PAN - REMOVAL).

(13) Remove oil pump pick-up tube.

(14) Remove the crankshaft sprocket and oil pump

(Refer to 9 - ENGINE/LUBRICATION/OIL PUMP -

REMOVAL).

(15) Remove balance shafts and housing assembly

(Refer to 9 - ENGINE/VALVE TIMING/BALANCE

SHAFT - REMOVAL).

(16) Remove crankshaft position sensor.

NOTE: If piston/connecting rod replacement is nec-

essary, remove cylinder head (Refer to 9 - ENGINE/

CYLINDER HEAD - REMOVAL).

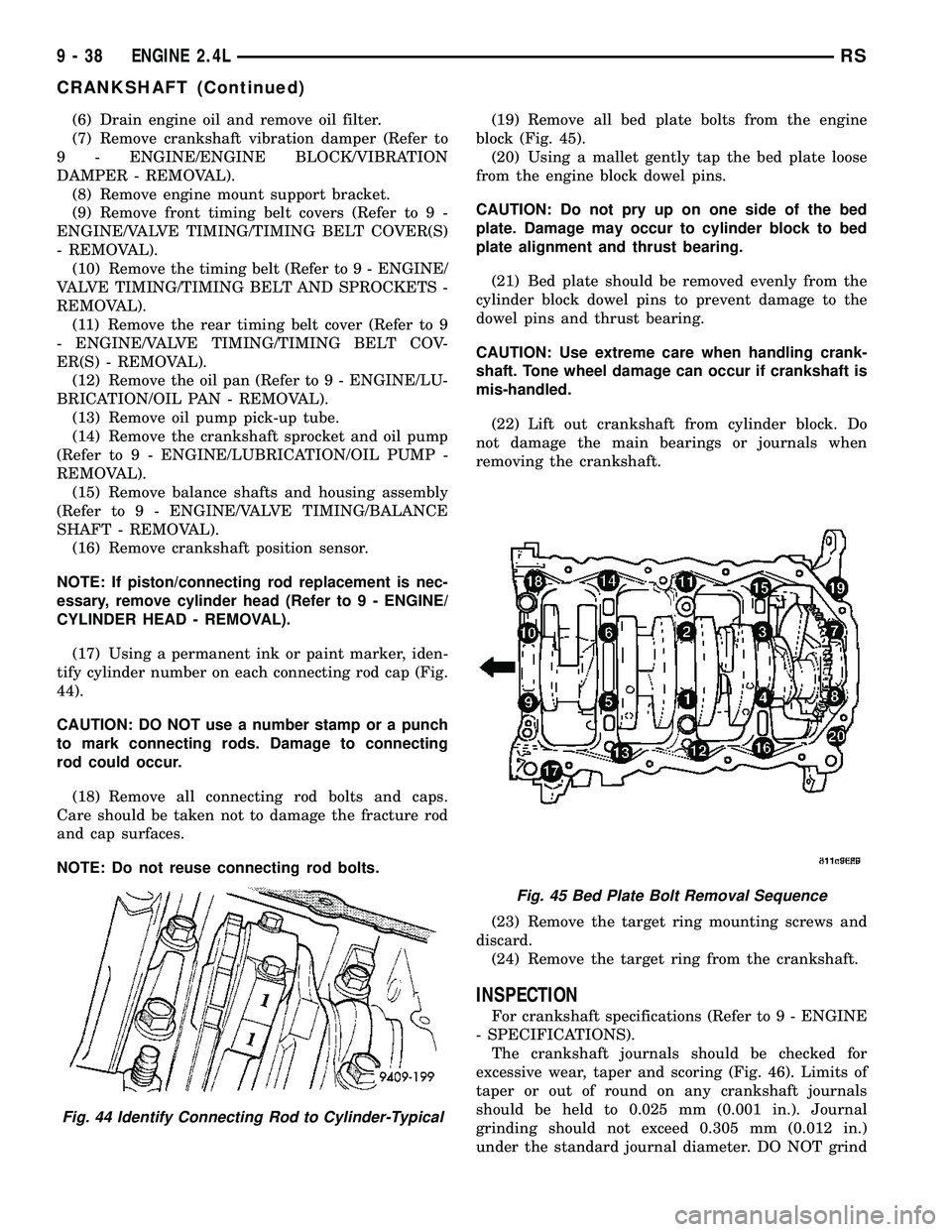

(17) Using a permanent ink or paint marker, iden-

tify cylinder number on each connecting rod cap (Fig.

44).

CAUTION: DO NOT use a number stamp or a punch

to mark connecting rods. Damage to connecting

rod could occur.

(18) Remove all connecting rod bolts and caps.

Care should be taken not to damage the fracture rod

and cap surfaces.

NOTE: Do not reuse connecting rod bolts.(19) Remove all bed plate bolts from the engine

block (Fig. 45).

(20) Using a mallet gently tap the bed plate loose

from the engine block dowel pins.

CAUTION: Do not pry up on one side of the bed

plate. Damage may occur to cylinder block to bed

plate alignment and thrust bearing.

(21) Bed plate should be removed evenly from the

cylinder block dowel pins to prevent damage to the

dowel pins and thrust bearing.

CAUTION: Use extreme care when handling crank-

shaft. Tone wheel damage can occur if crankshaft is

mis-handled.

(22) Lift out crankshaft from cylinder block. Do

not damage the main bearings or journals when

removing the crankshaft.

(23) Remove the target ring mounting screws and

discard.

(24) Remove the target ring from the crankshaft.

INSPECTION

For crankshaft specifications (Refer to 9 - ENGINE

- SPECIFICATIONS).

The crankshaft journals should be checked for

excessive wear, taper and scoring (Fig. 46). Limits of

taper or out of round on any crankshaft journals

should be held to 0.025 mm (0.001 in.). Journal

grinding should not exceed 0.305 mm (0.012 in.)

under the standard journal diameter. DO NOT grind

Fig. 44 Identify Connecting Rod to Cylinder-Typical

Fig. 45 Bed Plate Bolt Removal Sequence

9 - 38 ENGINE 2.4LRS

CRANKSHAFT (Continued)

Page 1216 of 2339

thrust faces of No. 3 main bearing. DO NOT nick

crank pin or bearing fillets. After grinding, remove

rough edges from crankshaft oil holes and clean out

all passages.

CAUTION: With the nodular cast iron crankshafts, it

is important that the final paper or cloth polish be

in the same direction as normal rotation in the

engine.

INSTALLATION - CRANKSHAFT

CRANKSHAFT MAIN BEARING LOCATION

The crankshaft is supported in five main bearings.

All upper bearing shells in the crankcase have oil

grooves and holes. All lower bearing shellsexcept

for the thrust bearing half have oil grooves and holes

(Fig. 47). Crankshaft end play is controlled by a

flanged bearing on the number three main bearing

journal.(1) Install the main bearing upper shells with the

lubrication groove and oil hole in the engine block

(Fig. 48).

(2) Make certain oil holes in block line up with oil

hole in bearings and bearing tabs seat in the block

tab slots.

NOTE: If the crankshaft is sent out for machine

work, it must be balenced as an assembly with the

target ring installed.

(3) Clean crankshaft and target ring with

MOPARtbrake parts cleaner and dry with com-

pressed air to ensure that the crankshaft mating sur-

face and target ring mounting holes are free from oil

and lock patch debris.

NOTE: Always use NEW mounting screws whether

installing original or new target ring.

(4) InstallNEWmounting screws finger tight

starting with the #1 location. (Fig. 49) Make sure

engagment occurs with the shoulder of the screw and

mounting hole before starting all other screws.

(5) Torque all mounting screws with T30 torx bit

to 13 Nm (110 in-lbs) following the torque sequence.

CAUTION: Use extreme care when handling crank-

shaft. Tone wheel damage can occur if crankshaft is

mis-handled.

CAUTION: Do not get oil on the bed plate mating

surface. It will affect the ability of the sealer to seal

the bed plate to cylinder block.

Fig. 46 Crankshaft Journal Measurements - Typical

Fig. 47 Main Bearing Identification

1 - OIL GROOVE

2 - MAIN BEARINGS

3 - OIL HOLE

4 - LOWER THRUST BEARING PLAIN (NO OIL HOLE OR

GROOVE)

Fig. 48 Installing Main Bearing Upper Shell

1 - LUBRICATION GROOVES

2 - OIL HOLES

RSENGINE 2.4L9-39

CRANKSHAFT (Continued)

Page 1227 of 2339

ENGINE MOUNTING

DESCRIPTION

The engine mounting system consist of four

mounts; right and a left side support the powertrain,

and a front and a rear mount control powertrain

torque. The right side mount is a hydro-type (Fig.

78), all others are of molded rubber material.

FRONT MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the front engine mount through bolt

from the insulator (Fig. 79).

(3) Remove the engine front mount bolts and

remove the insulator assembly (Fig. 79).

(4) Remove the front mounting bracket from

engine, if necessary (Fig. 79).

INSTALLATION

(1) Install the front mount bracket to engine, if

removed (Fig. 79).

(2) Install the insulator mount assembly (Fig. 79).

(3) Install the front engine mount through bolt to

the insulator (Fig. 79).

(4) Lower the vehicle.

LEFT MOUNT

REMOVAL

(1) Raise the vehicle on hoist.

(2) Remove the left front wheel.

(3) Remove the left mount through bolt access

cover.

(4) Support the transaxle with a suitable jack.

(5) Remove the engine front mount through bolt to

allow left mount removal clearance (Fig. 79).

(6) Remove the left mount through frame rail bolt

(Fig. 80).

(7) Lower transaxle for access to horizontal bolts.

(8) Remove the horizontal bolts from the mount to

the transaxle (Fig. 81).

NOTE: To remove mount, additional lowering of

transaxle may be required.

(9) Remove left mount.

INSTALLATION

(1) Install left mount on transaxle (Fig. 81).

(2) Raise transaxle with jack until left mount is in

position.

(3) Install left mount through bolt (Fig. 80).

Fig. 78 Engine Hydro-type Mount - Right Side

1 - BOLT

2 - BOLT

3 - FRAME RAIL

4 - RIGHT MOUNT - 2.4L ENGINE

5 - RIGHT MOUNT - 3.3/3.8L ENGINE

Fig. 79 Front Mount and Bracket

1 - BRACKET - FRONT MOUNT

2 - NUT - 68 N´m (50 ft. lbs.)

3 - BOLT - 54 N´m (40 ft. lbs.)

4 - MOUNT - FRONT INSULATOR

5 - BOLT - 68 N´m (50 ft. lbs.)

6 - BOLT - 68 N´m (50 ft. lbs.)

7 - FRONT CROSSMEMBER

9 - 50 ENGINE 2.4LRS

Page 1228 of 2339

(4) Install left mount through bolt access cover.

(5) Install front mount through bolt (Fig. 79).

(6) Install left front wheel.

(7) Lower vehicle.

REAR MOUNT

REMOVAL

(1) Raise vehicle on hoist.

(2) Remove the rear mount heat shield (Fig. 82).

(3) Remove the through bolt from the mount and

rear mount bracket (Fig. 83).

(4) Remove the mount bolts (Fig. 83).

(5) Remove the rear mount (Fig. 83).

(6) For rear mount bracket removal, remove the

bolts attaching bracket to transaxle (Fig. 84).

(7) Remove rear mount bracket.

Fig. 80 Left Mount To Bracket

1 - BOLT - BRACKET TO FRAME RAIL 68 N´m (50 ft. lbs.)

2 - BOLT - MOUNT TO RAIL THRU 75 N´m (55 ft. lbs.)

3 - BOLT - LEFT MOUNT TO TRANSAXLE 54 N´m (40 ft. lbs.)

4 - TRANSAXLE

5 - MOUNT - LEFT

6 - BRACKET - LEFT MOUNT

Fig. 81 Left Mount - 41TE Transaxle

1 - LEFT MOUNT ASSEMBLY

2 - BOLT - 54 N´m (40 ft. lbs.)

3 - TRANSAXLE - 41TE

Fig. 82 Rear Mount Heat Shield

1 - BOLT - HEAT SHIELD 11 N´m (100 in. lbs.)

2 - HEAT SHIELD

3 - CLIP

4 - REAR MOUNT

Fig. 83 Rear Mount

1 - BOLT 54 N´m (40 ft. lbs.)

2 - REAR MOUNT BRACKET

3 - THRU-BOLT 54 N´m (40 ft. lbs.)

4 - REAR MOUNT

RSENGINE 2.4L9-51

LEFT MOUNT (Continued)

Page 1242 of 2339

REAR COVER

(1) Install rear timing belt cover and fasteners.

Torque fasteners to specified values (Fig. 118).

CAUTION: Do not use an impact wrench for tighten-

ing camshaft sprocket bolt. Damage to the timing

locating pin can occur. Hand tighten using a

wrench ONLY.

(2) Install camshaft sprockets. Hold sprockets with

Special Tool 6848 and tighten center bolt to 101 N´m

(75 ft. lbs.) (Fig. 116).

(3) Install timing belt idler pulley and tighten

mounting bolt to 61 N´m (45 ft. lbs.) (Fig. 117).

(4) Install timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

INSTALLATION).

(5) Install engine mount bracket and tighten bolts

to 61 N´m (45 ft. lbs.) (Fig. 115).

(6) Install front covers.

TIMING BELT AND

SPROCKET(S)

REMOVAL

REMOVAL - TIMING BELT

(1) Remove air cleaner upper cover, housing, and

clean air tube.

(2) Remove make-up air hose from cylinder head

cover.

(3) Raise vehicle on hoist.

(4) Remove right front wheel.

(5) Remove right inner splash shield.

(6) Remove accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL).

(7) Remove crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - REMOVAL).

(8) Remove air conditioner/generator belt tensioner

and pulley assembly (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS - REMOVAL).

(9) Remove timing belt lower front cover bolts and

remove cover (Refer to 9 - ENGINE/VALVE TIMING/

TIMING BELT COVER(S) - REMOVAL).

(10) Lower vehicle.

(11) Remove bolts attaching timing belt upper

front cover and remove cover (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT COVER(S) -

REMOVAL).

(12) Remove right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

REMOVAL).

(13) Remove engine mount bracket (Fig. 119).

CAUTION: When aligning crankshaft and camshaft

timing marks always rotate engine from crankshaft.

Camshaft should not be rotated after timing belt is

removed. Damage to valve components may occur.

Always align timing marks before removing timing

belt.

(14) Before the removal of the timing belt, rotate

crankshaft until the TDC mark on oil pump housing

aligns with the TDC mark on crankshaft sprocket

(trailing edge of sprocket tooth) (Fig. 120).

NOTE: The crankshaft sprocket TDC mark is

located on the trailing edge of the sprocket tooth.

Failure to align trailing edge of sprocket tooth to

TDC mark on oil pump housing will cause the cam-

shaft timing marks to be misaligned.

(15) Loosen timing belt tensioner lock bolt (Fig.

121).

Fig. 118 Rear Timing Belt Cover Fasteners

1 - M6 BOLTS - 12 N´m (105 in. lbs.)

2 - M8 BOLTS - 28 N´m (250 in. lbs.)

3 - TIMING BELT TENSIONER

RSENGINE 2.4L9-65

TIMING BELT COVER(S) (Continued)

Page 1246 of 2339

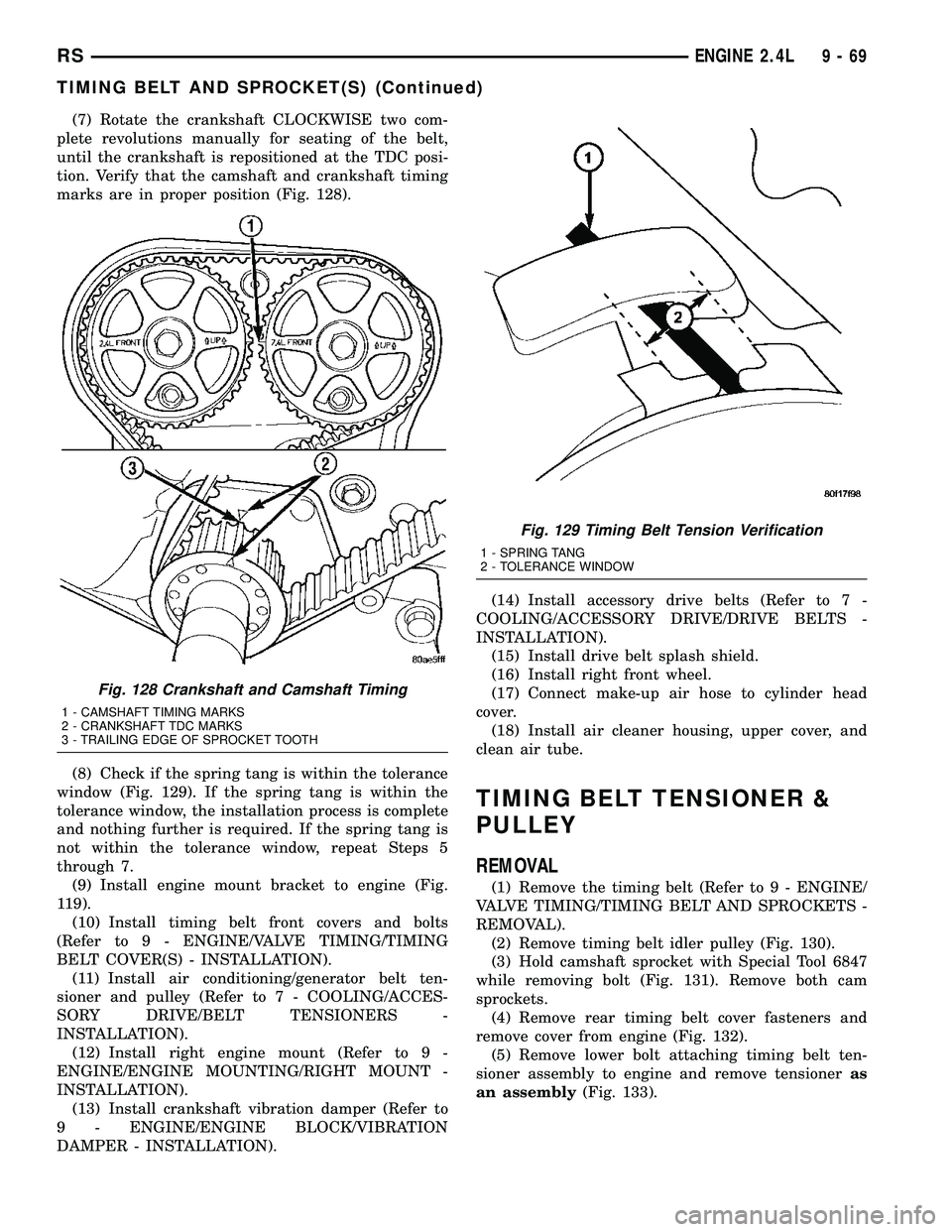

(7) Rotate the crankshaft CLOCKWISE two com-

plete revolutions manually for seating of the belt,

until the crankshaft is repositioned at the TDC posi-

tion. Verify that the camshaft and crankshaft timing

marks are in proper position (Fig. 128).

(8) Check if the spring tang is within the tolerance

window (Fig. 129). If the spring tang is within the

tolerance window, the installation process is complete

and nothing further is required. If the spring tang is

not within the tolerance window, repeat Steps 5

through 7.

(9) Install engine mount bracket to engine (Fig.

119).

(10) Install timing belt front covers and bolts

(Refer to 9 - ENGINE/VALVE TIMING/TIMING

BELT COVER(S) - INSTALLATION).

(11) Install air conditioning/generator belt ten-

sioner and pulley (Refer to 7 - COOLING/ACCES-

SORY DRIVE/BELT TENSIONERS -

INSTALLATION).

(12) Install right engine mount (Refer to 9 -

ENGINE/ENGINE MOUNTING/RIGHT MOUNT -

INSTALLATION).

(13) Install crankshaft vibration damper (Refer to

9 - ENGINE/ENGINE BLOCK/VIBRATION

DAMPER - INSTALLATION).(14) Install accessory drive belts (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

INSTALLATION).

(15) Install drive belt splash shield.

(16) Install right front wheel.

(17) Connect make-up air hose to cylinder head

cover.

(18) Install air cleaner housing, upper cover, and

clean air tube.

TIMING BELT TENSIONER &

PULLEY

REMOVAL

(1) Remove the timing belt (Refer to 9 - ENGINE/

VALVE TIMING/TIMING BELT AND SPROCKETS -

REMOVAL).

(2) Remove timing belt idler pulley (Fig. 130).

(3) Hold camshaft sprocket with Special Tool 6847

while removing bolt (Fig. 131). Remove both cam

sprockets.

(4) Remove rear timing belt cover fasteners and

remove cover from engine (Fig. 132).

(5) Remove lower bolt attaching timing belt ten-

sioner assembly to engine and remove tensioneras

an assembly(Fig. 133).

Fig. 128 Crankshaft and Camshaft Timing

1 - CAMSHAFT TIMING MARKS

2 - CRANKSHAFT TDC MARKS

3 - TRAILING EDGE OF SPROCKET TOOTH

Fig. 129 Timing Belt Tension Verification

1 - SPRING TANG

2 - TOLERANCE WINDOW

RSENGINE 2.4L9-69

TIMING BELT AND SPROCKET(S) (Continued)

Page 1255 of 2339

INSPECTION.........................145

ASSEMBLY...........................146

INSTALLATION........................146

INTAKE MANIFOLD

DESCRIPTION........................147

DIAGNOSIS AND TESTING - INTAKE

MANIFOLD LEAKS....................147

INTAKE MANIFOLD - UPPER

STANDARD PROCEDURE

STANDARD PROCEDURE - MANIFOLD

STRIPPED THREAD REPAIR............147

STANDARD PROCEDURE - INTAKE

MANIFOLD VACUUM PORT REPAIR......148

REMOVAL - UPPER INTAKE MANIFOLD.....148

CLEANING...........................148

INSPECTION.........................149

INSTALLATION - UPPER INTAKE MANIFOLD . 149

INTAKE MANIFOLD - LOWER

REMOVAL - LOWER INTAKE MANIFOLD....150

CLEANING...........................151

INSPECTION.........................151

INSTALLATION - LOWER INTAKE MANIFOLD . 151

EXHAUST MANIFOLD - RIGHT

REMOVAL............................152

CLEANING...........................153

INSPECTION.........................153INSTALLATION........................153

EXHAUST MANIFOLD - LEFT

REMOVAL............................154

CLEANING...........................154

INSPECTION.........................155

INSTALLATION........................155

VALVE TIMING

STANDARD PROCEDURE

STANDARD PROCEDURE - VALVE TIMING

VERIFICATION.......................155

STANDARD PROCEDURE - MEASURING

TIMING CHAIN WEAR.................155

TIMING CHAIN COVER

REMOVAL............................156

INSTALLATION........................157

TIMING CHAIN AND SPROCKETS

REMOVAL

REMOVAL - TIMING CHAIN AND

CAMSHAFT SPROCKET...............159

REMOVAL - CRANKSHAFT SPROCKET . . . 159

INSTALLATION

INSTALLATION - CRANKSHAFT

SPROCKET.........................160

INSTALLATION - TIMING CHAIN AND

CAMSHAFT SPROCKET...............160

ENGINE 3.3/3.8L

DESCRIPTION

The 3.3 Liter (201 cu. in.) and 3.8 Liter (231 cu.

in.) engines are 60É V-6 engines with cast iron cylin-

der blocks and aluminum cylinder heads (Fig. 1). The

engine uses a single, block mounted camshaft with

pushrods to actuate the valves. These engines do not

have provisions for a free wheeling valve train.

The firing order is 1±2±3±4±5±6. The cylinders are

numbered from the front of the engine to the rear.

The front cylinder bank is numbered 2, 4, and 6. The

rear cylinder bank is numbered 1, 3, and 5.

The engine identification number is located on the

rear of the cylinder block just below the cylinder

head (Fig. 2).

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - ENGINE

DIAGNOSIS - INTRODUCTION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Engine Mechanical and the Engine

Performance diagnostic charts, for possible causes

and corrections of malfunctions (Refer to 9 - ENGINE

- DIAGNOSIS AND TESTING - MECHANICAL)

(Refer to 9 - ENGINE - DIAGNOSIS AND TESTING

- PERFORMANCE).

For fuel system diagnosis, (Refer to 14 - FUEL

SYSTEM/FUEL DELIVERY - DIAGNOSIS AND

TESTING).

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

²Hydraulic Lash Adjuster Noise Diagnosis

²Engine Oil Leak Inspection

9 - 78 ENGINE 3.3/3.8LRS

Page 1260 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 3.3/3.8L9-83

ENGINE 3.3/3.8L (Continued)

Page 1307 of 2339

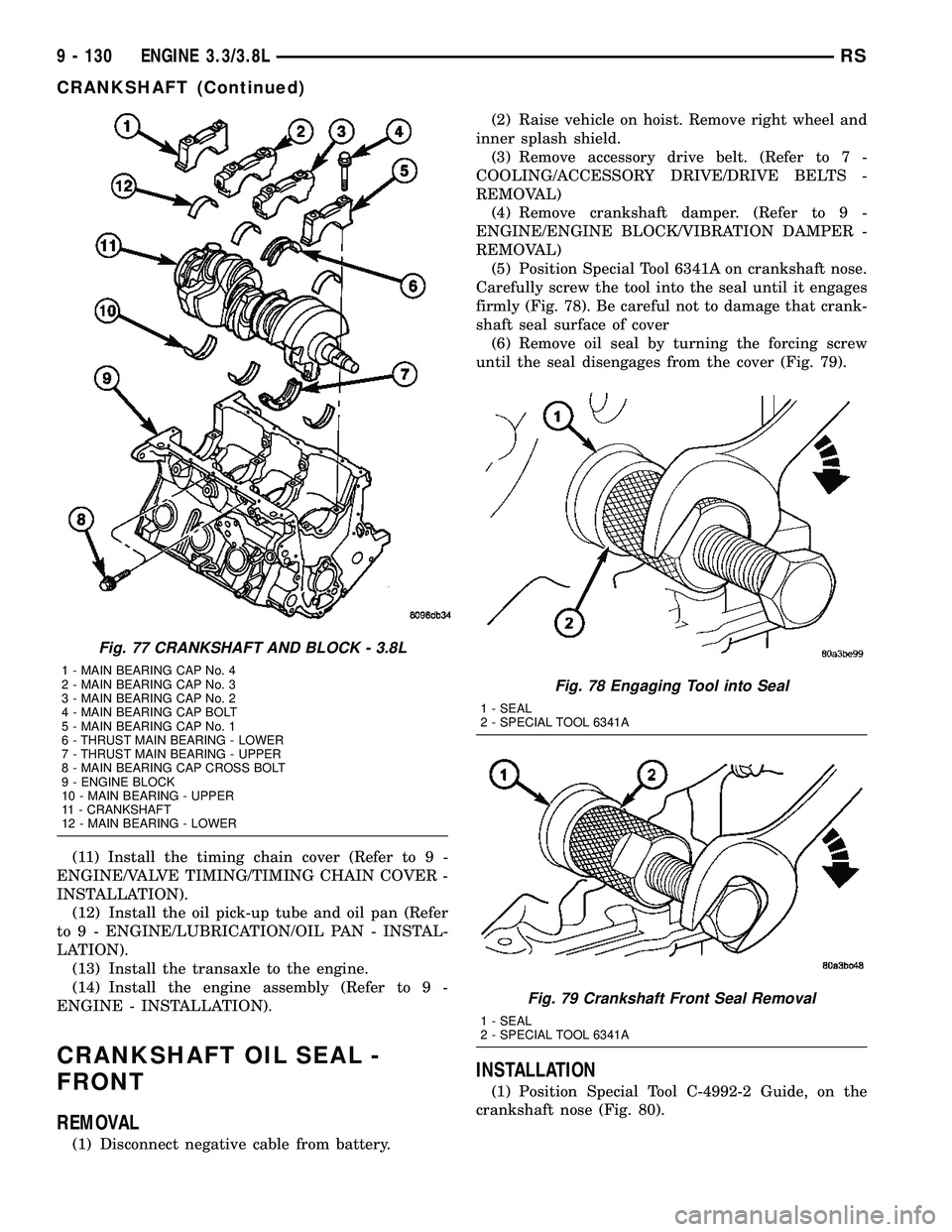

(11) Install the timing chain cover (Refer to 9 -

ENGINE/VALVE TIMING/TIMING CHAIN COVER -

INSTALLATION).

(12) Install the oil pick-up tube and oil pan (Refer

to 9 - ENGINE/LUBRICATION/OIL PAN - INSTAL-

LATION).

(13) Install the transaxle to the engine.

(14) Install the engine assembly (Refer to 9 -

ENGINE - INSTALLATION).

CRANKSHAFT OIL SEAL -

FRONT

REMOVAL

(1) Disconnect negative cable from battery.(2) Raise vehicle on hoist. Remove right wheel and

inner splash shield.

(3) Remove accessory drive belt. (Refer to 7 -

COOLING/ACCESSORY DRIVE/DRIVE BELTS -

REMOVAL)

(4) Remove crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

REMOVAL)

(5) Position Special Tool 6341A on crankshaft nose.

Carefully screw the tool into the seal until it engages

firmly (Fig. 78). Be careful not to damage that crank-

shaft seal surface of cover

(6) Remove oil seal by turning the forcing screw

until the seal disengages from the cover (Fig. 79).

INSTALLATION

(1) Position Special Tool C-4992-2 Guide, on the

crankshaft nose (Fig. 80).

Fig. 77 CRANKSHAFT AND BLOCK - 3.8L

1 - MAIN BEARING CAP No. 4

2 - MAIN BEARING CAP No. 3

3 - MAIN BEARING CAP No. 2

4 - MAIN BEARING CAP BOLT

5 - MAIN BEARING CAP No. 1

6 - THRUST MAIN BEARING - LOWER

7 - THRUST MAIN BEARING - UPPER

8 - MAIN BEARING CAP CROSS BOLT

9 - ENGINE BLOCK

10 - MAIN BEARING - UPPER

11 - CRANKSHAFT

12 - MAIN BEARING - LOWER

Fig. 78 Engaging Tool into Seal

1 - SEAL

2 - SPECIAL TOOL 6341A

Fig. 79 Crankshaft Front Seal Removal

1 - SEAL

2 - SPECIAL TOOL 6341A

9 - 130 ENGINE 3.3/3.8LRS

CRANKSHAFT (Continued)

Page 1308 of 2339

(2) Position new seal over the guide with the seal

spring in the direction of the engine front cover (Fig.

80).

(3) Install seal using Special Tool C-4992-1 until

seal is flush with cover. (Fig. 80).

(4) Install crankshaft damper. (Refer to 9 -

ENGINE/ENGINE BLOCK/VIBRATION DAMPER -

INSTALLATION)

(5) Install accessory drive belt. (Refer to 7 - COOL-

ING/ACCESSORY DRIVE/DRIVE BELTS - INSTAL-

LATION)

(6) Install inner splash shield and right front

wheel.

(7) Lower vehicle and connect negative cable to

battery.

CRANKSHAFT OIL SEAL -

REAR

REMOVAL

(1) Remove the transaxle. Refer to TRANSAXLE

AND POWER TRANSFER UNIT for procedure.

(2) Remove the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - REMOVAL)

(3) Insert a 3/16 flat bladed pry tool between the

dust lip and the metal case of the crankshaft seal.

Angle the pry tool (Fig. 81) through the dust lip

against metal case of the seal. Pry out seal.CAUTION: Do not permit the pry tool blade to con-

tact crankshaft seal surface. Contact of the pry tool

blade against crankshaft edge (chamfer) is permit-

ted.

INSTALLATION

CAUTION: If burr or scratch is present on the

crankshaft edge (chamfer), cleanup with 400 grit

sand paper to prevent seal damage during installa-

tion of new seal.

(1) Place Special Tool 6926-1 magnetic pilot tool on

crankshaft (Fig. 82).

(2) Place seal over Special Tool 6926-1 Pilot. Using

Special Tool 6926-2 Installer with C-4171 Handle,

drive seal into the retainer housing (Fig. 82).

(3) Install the flex plate. (Refer to 9 - ENGINE/

ENGINE BLOCK/FLEX PLATE - INSTALLATION)

(4) Install transaxle. Refer to TRANSAXLE AND

POWER TRANSFER UNIT for procedure.

Fig. 80 CRANKSHAFT FRONT SEAL INSTALLATION

1 - SPECIAL TOOL C-4992-1

2 - SEAL

3 - SPECIAL TOOL C-4992-2

4 - CRANKSHAFT

Fig. 81 Crankshaft Rear Oil Seal - Removal

1 - REAR CRANKSHAFT SEAL

2 - ENGINE BLOCK

3 - ENGINE BLOCK

4 - REAR CRANKSHAFT SEAL METAL CASE

5 - PRY IN THIS DIRECTION

6 - CRANKSHAFT

7 - SCREWDRIVER

8 - REAR CRANKSHAFT SEAL DUST LIP

9 - SCREWDRIVER

RSENGINE 3.3/3.8L9 - 131

CRANKSHAFT OIL SEAL - FRONT (Continued)