brake CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1779 of 2339

(8) Road test vehicle to ensure proper operation of

the brakes.

WHEEL MOUNTING STUDS -

REAR

REMOVAL

CAUTION: If a wheel attaching stud needs to be

replaced in the hub and bearing assembly the studs

MUST NOT be hammered out of the hub flange. If a

stud is removed by hammering it out of the bearing

flange, damage to the hub and bearing assembly

will occur leading to premature hub and bearing

failure.

(1) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in Lubrication

and Maintenance.

(2) Remove the rear wheel and tire assembly.

(3) Remove the brake drum or disc brake caliper

and rotor. Refer to Brakes.

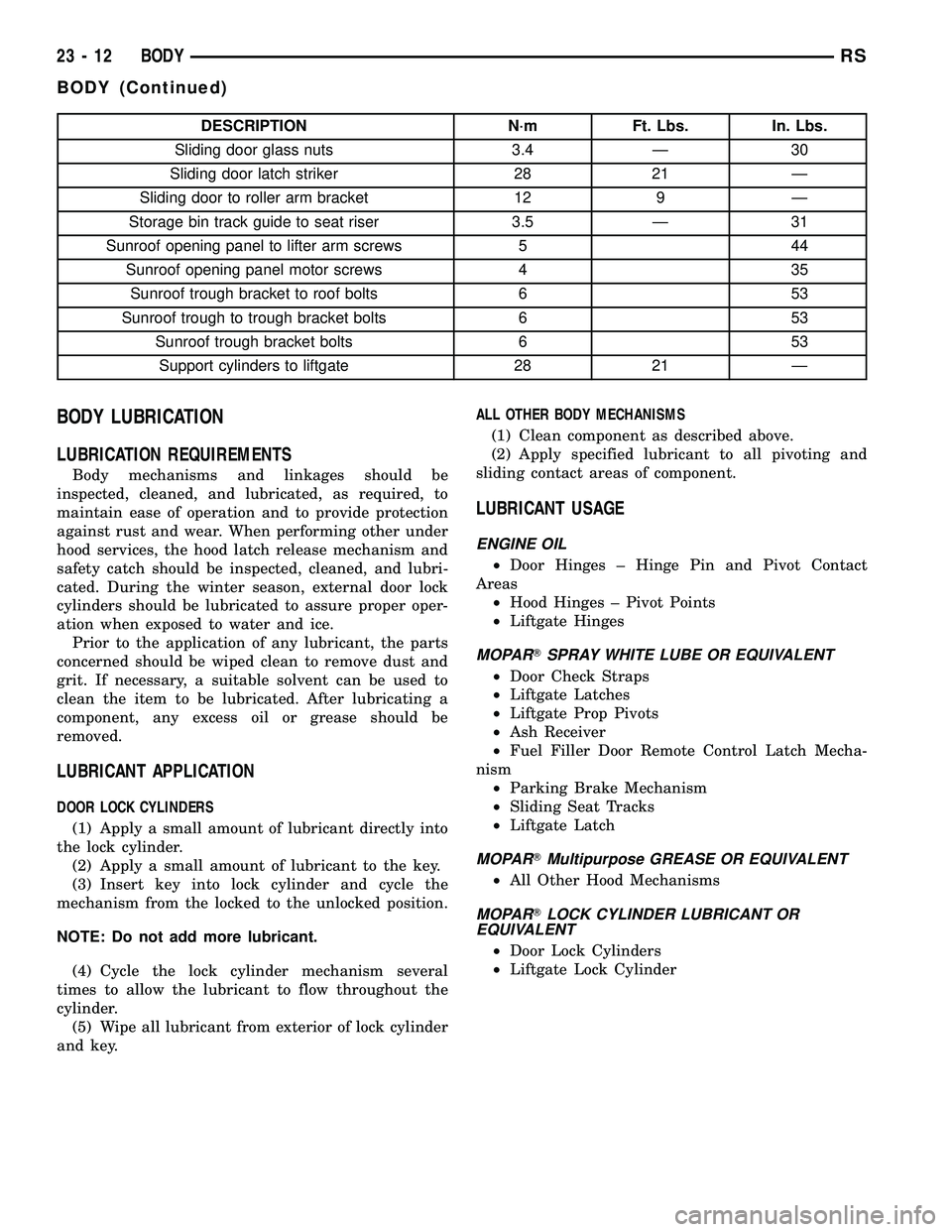

(4) Install a lug nut on the wheel stud to be

removed from the hub and bearing assembly (Fig. 36)

so the threads on stud are even with end of lug nut.

Install Remover, Special Tool C-4150A on hub and

bearing assembly flange and wheel stud (Fig. 36).

(5)

Tightening down on special tool will push wheel

stud out of the hub and bearing assembly flange.

(6) Remove lug nut from stud and remove wheel

stud from flange.

INSTALLATION

(1) Install replacement wheel stud into flange of

hub and bearing assembly. Install washers on wheelstud, then install a wheel lug nut on stud with flat

side of lug nut against washers (Fig. 37).

(2) Tighten the wheel lug nut, pulling the wheel

stud into the flange of the hub and bearing assembly.

When the head of the stud is fully seated against the

bearing flange, remove lug nut and washers from

wheel stud.

(3) Install the brake drum or disc brake rotor and

caliper on the hub and bearing assembly.

(4) Install wheel and tire assembly on vehicle.

Tighten the wheel mounting stud nuts in proper

sequence until all nuts are torqued to half specifica-

tion. Then repeat the tightening sequence to the full

specified torque of 135 N´m (100 ft. lbs.).

(5) Lower vehicle to the ground.

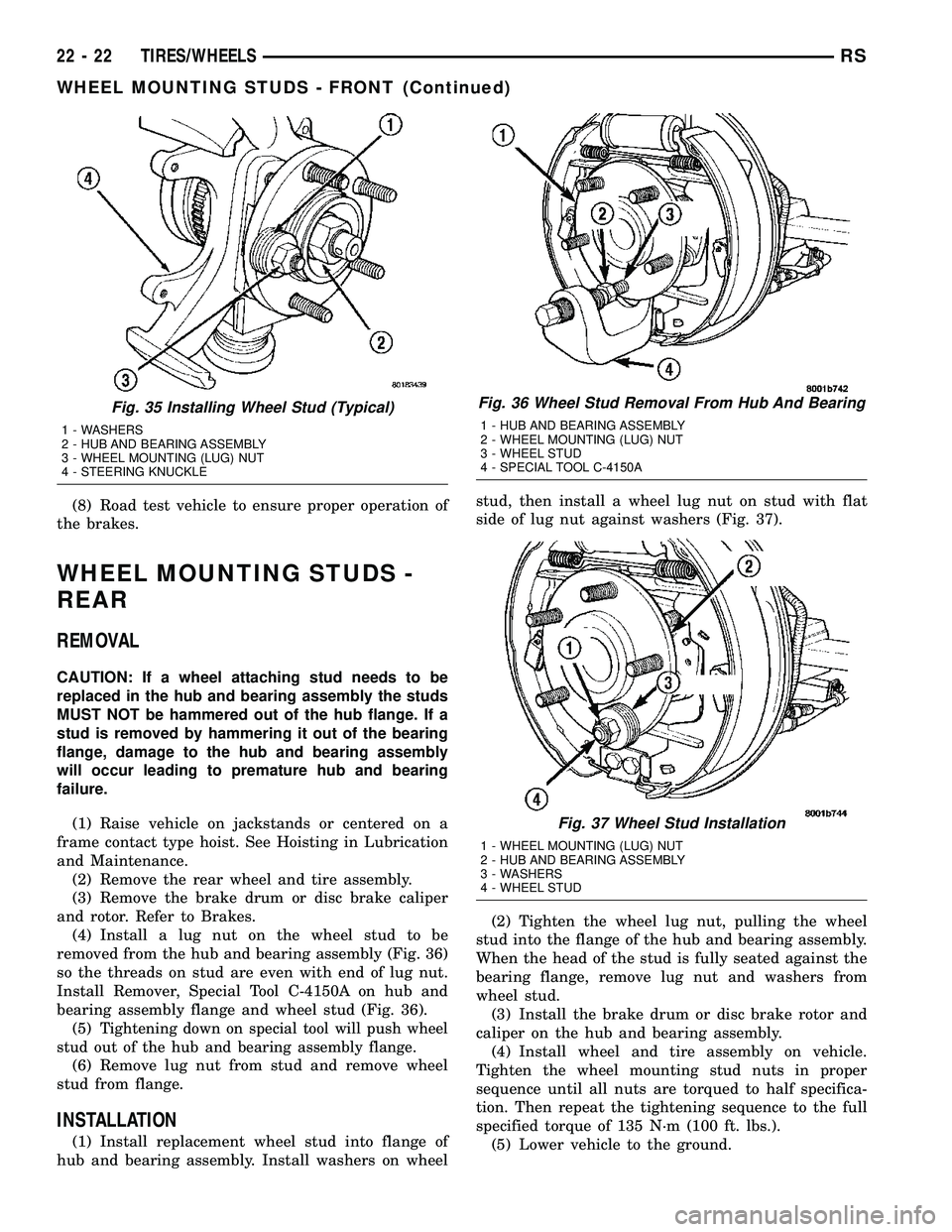

Fig. 35 Installing Wheel Stud (Typical)

1 - WASHERS

2 - HUB AND BEARING ASSEMBLY

3 - WHEEL MOUNTING (LUG) NUT

4 - STEERING KNUCKLE

Fig. 36 Wheel Stud Removal From Hub And Bearing

1 - HUB AND BEARING ASSEMBLY

2 - WHEEL MOUNTING (LUG) NUT

3 - WHEEL STUD

4 - SPECIAL TOOL C-4150A

Fig. 37 Wheel Stud Installation

1 - WHEEL MOUNTING (LUG) NUT

2 - HUB AND BEARING ASSEMBLY

3 - WASHERS

4 - WHEEL STUD

22 - 22 TIRES/WHEELSRS

WHEEL MOUNTING STUDS - FRONT (Continued)

Page 1791 of 2339

DESCRIPTION N´m Ft. Lbs. In. Lbs.

Sliding door glass nuts 3.4 Ð 30

Sliding door latch striker 28 21 Ð

Sliding door to roller arm bracket 12 9 Ð

Storage bin track guide to seat riser 3.5 Ð 31

Sunroof opening panel to lifter arm screws 5 44

Sunroof opening panel motor screws 4 35

Sunroof trough bracket to roof bolts 6 53

Sunroof trough to trough bracket bolts 6 53

Sunroof trough bracket bolts 6 53

Support cylinders to liftgate 28 21 Ð

BODY LUBRICATION

LUBRICATION REQUIREMENTS

Body mechanisms and linkages should be

inspected, cleaned, and lubricated, as required, to

maintain ease of operation and to provide protection

against rust and wear. When performing other under

hood services, the hood latch release mechanism and

safety catch should be inspected, cleaned, and lubri-

cated. During the winter season, external door lock

cylinders should be lubricated to assure proper oper-

ation when exposed to water and ice.

Prior to the application of any lubricant, the parts

concerned should be wiped clean to remove dust and

grit. If necessary, a suitable solvent can be used to

clean the item to be lubricated. After lubricating a

component, any excess oil or grease should be

removed.

LUBRICANT APPLICATION

DOOR LOCK CYLINDERS

(1) Apply a small amount of lubricant directly into

the lock cylinder.

(2) Apply a small amount of lubricant to the key.

(3) Insert key into lock cylinder and cycle the

mechanism from the locked to the unlocked position.

NOTE: Do not add more lubricant.

(4) Cycle the lock cylinder mechanism several

times to allow the lubricant to flow throughout the

cylinder.

(5) Wipe all lubricant from exterior of lock cylinder

and key.ALL OTHER BODY MECHANISMS

(1) Clean component as described above.

(2) Apply specified lubricant to all pivoting and

sliding contact areas of component.

LUBRICANT USAGE

ENGINE OIL

²Door Hinges ± Hinge Pin and Pivot Contact

Areas

²Hood Hinges ± Pivot Points

²Liftgate Hinges

MOPARTSPRAY WHITE LUBE OR EQUIVALENT

²Door Check Straps

²Liftgate Latches

²Liftgate Prop Pivots

²Ash Receiver

²Fuel Filler Door Remote Control Latch Mecha-

nism

²Parking Brake Mechanism

²Sliding Seat Tracks

²Liftgate Latch

MOPARTMultipurpose GREASE OR EQUIVALENT

²All Other Hood Mechanisms

MOPARTLOCK CYLINDER LUBRICANT OR

EQUIVALENT

²Door Lock Cylinders

²Liftgate Lock Cylinder

23 - 12 BODYRS

BODY (Continued)

Page 1843 of 2339

(8) Route cable back from latch through engine

compartment toward dash panel near power brake

booster (Fig. 5).

(9) Remove attaching clips from cable case.

(10) From inside vehicle, pull cable through dash

panel until mechanic's wire is exposed.

(11) Disconnect cable from mechanic's wire.

(12) Remove hood release cable from vehicle.

INSTALLATION

(1) Place hood release cable in position under

instrument panel.

(2) Attach latch end of hood release cable to

mechanic's wire protruding through dash panel.

(3) Route cable forward through engine compart-

ment toward latch by pulling on mechanic's wire

(Fig. 5).(4) Disconnect mechanic's wire from cable.

(5) Engage rubber grommet cable insulator into

hole in dash panel.

(6) Install hood release handle into instrument

panel.

(7) Place cable in position on latch.

(8) Slide cable case end sideways into keyhole slot

of hood latch.

(9) Engage cable end into hood latch locking mech-

anism.

(10) Install hood latch.

(11) Install attaching clips to cable case and install

clips into original holes in strut tower, fender, head-

lamp area, and radiator closure panel crossmember.

LATCH STRIKER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove bolts attaching striker to inside of

hood.

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle, aligning

with paint breaks.

(2) Install bolts attaching hood latch striker to

hood.

(3) Align hood latch striker to engage smoothly

into hood latch.

(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.Fig. 5 HOOD RELEASE CABLE ROUTING

1 - GROMMET

2 - HOOD RELEASE CABLE

3 - RADIATOR CLOSURE PANEL CROSSMEMBER

23 - 64 HOODRS

LATCH RELEASE CABLE (Continued)

Page 1847 of 2339

(13) Remove the right end cover by pulling out-

board.

(14) Remove the right side A-pillar retaining bolts

(Fig. 5). There are two 13 mm bolts and one 10 mm

bolt.

(15) Loosen the right side cowl side roll down bolt.

(16) Remove over steering column cover. (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(17) Remove the cluster bezel. (Refer to 23 -

BODY/INSTRUMENT PANEL/CLUSTER BEZEL -

REMOVAL).

(18) Remove the lower steering column cover and

end cap. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/LOWER STEERING COLUMN COVER -

REMOVAL)

(19) Remove the inflatable knee blocker. (Refer to

23 - BODY/INSTRUMENT PANEL/INFLATABLE

KNEE BLOCKER - REMOVAL)(20) Remove the two screws to the hood release

handle.

(21) Remove the two steering column fixed shroud

retaining screws (Fig. 6).

(22) Remove the four steering column shroud

retaining screws. Separate the steering column bear-

ing shroud and steering column shroud and remove

from vehicle (Fig. 6).

(23) Disconnect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(24) Disconnect the steering column wiring. There

are seven connectors and then unclip the harness

from the column.

(25) Disconnect the Occupant Restraint Controller

(ORC) harness connector.

Fig. 4 INSTRUMENT PANEL REMOVAL

1 - INSTRUMENT PANEL

2 - SIX ATTACHING SCREWS

3 - 13 mm BOLT - TWO ON EACH SIDE4 - ROLL DOWN BRACKET

5 - 10 mm BOLT - STARTING BOLT ONE EACH SIDE

23 - 68 INSTRUMENT PANELRS

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1848 of 2339

(26) Remove the three nuts retaining the steering

column to the dash panel steering column mounting

bracket and lower column to the floor (Fig. 7).(27) Remove the three nuts attaching the instru-

ment panel to the brake pedal support bracket.

(28) Remove six instrument panel steering column

cover plate attaching screws and remove cover plate

(Fig. 8).Remove the screws attaching the instrument

panel reinforcement and remove (Fig. 9).

Fig. 5 RIGHT SIDE INSTRUMENT PANEL

ATTACHING SCREWS

1 - INSTRUMENT PANEL ATTACHING SCREWS

2 - INSTRUMENT PANEL TO COWL SIDE LOCATOR SCREW

3 - COWL SIDE COWL REINFORCEMENT

4 - COWL PANEL

5 - INSTRUMENT PANEL COWL SIDE ROLL DOWN BOLT

Fig. 6 STEERING COLUMN SHROUDS

1 - FIXED SHROUD

2 - ATTACHING SCREW(S)

3 - STEERING COLUMN BEARING SHROUD

4 - TRACTION CONTROL DISABLE SWITCH

5 - MULTI-FUNCTION SWITCH AND CLOCKSPRING HOUSING

6 - STEERING COLUMN SHROUD

7 - STEERING COLUMN

Fig. 7 STEERING COLUMN MOUNTING BRACKET

1 - DASH PANEL STEERING COLUMN MOUNTING BRACKET

2 - INSTRUMENT PANEL STEERING COLUMN BRACKET

3 - ATTACHING NUT(S)

Fig. 8 LEFT SIDE I/P ATTACHING SCREWS

1 - INSTRUMENT PANEL ATTACHING SCREWS

2 - INSTRUMENT PANEL

3 - COLUMN COVER PLATE ATTACHING SCREWS

4 - INSTRUMENT PANEL COLUMN COVER PLATE

5 - INSTRUMENT PANEL COWL SIDE ROLL DOWN SCREW

6 - COWL PANEL

RSINSTRUMENT PANEL23-69

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1850 of 2339

(7) Place steering column cover plate into position

(Fig. 8).

(8) Install six instrument panel steering column

cover plate attaching screws.

(9) Install the screws attaching the instrument

panel reinforcement (Fig. 9).

(10) Place brake pedal support bracket into posi-

tion and install three nuts attaching to instrument

panel.

(11) Place steering column into position and install

four nuts retaining the steering column to the dash

panel steering column mounting bracket and lower

column to the floor (Fig. 7).

(12) Connect the Occupant Restraint Controller

(ORC) harness connector.

(13) Connect the steering column wiring. There

are seven connectors and clip the harness to the col-

umn.

(14) Connect the left side wiring:

(a) Brake switch.

(b) Main bulkhead connector.

(c) Five harness connectors.

(d) Driver airbag connector.

(15) Place steering column bearing shroud and

steering column shroud into position and install four

steering column shroud retaining screws (Fig. 6).

(16) Place fixed shroud into position and install

two steering column fixed shroud retaining screws

(Fig. 6).

(17) Install two screws to the hood release handle.

(18) Install the inflatable knee blocker. (Refer to

23 - BODY/INSTRUMENT PANEL/KNEE BLOCKER

- INSTALLATION).

(19) Install the lower steering column cover and

end cap. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/LOWER STEERING COLUMN COVER AND

END CAP - INSTALLATION).

(20) Install the cluster bezel. (Refer to 23 - BODY/

INSTRUMENT PANEL/CLUSTER BEZEL -

INSTALLATION).

(21) Install over steering column cover. (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - INSTALLATION).

(22) Install the right end cover. Position over

retaining slots and firmly snap into place.

(23) Connect the right side wire connectors to the

HVAC behind the glove box area and the two

antenna connectors behind the glove box hinge.

(24) Install the glove box:

(a) Install glove box into the vehicle. Line up the

hinges and firmly snap together.(b) Push in on sides of glove box bin and raise

door.

(25) Install two screws to each right and left cowl

trim covers.

(26) Connect the wire connectors to the Passenger

Airbag.

(27) Install the screws attaching the instrument

panel frame to the dash panel below windshield

opening.

(28) Install screws attaching instrument panel

frame to the dash panel below windshield opening

(Fig. 4).

(29) Install the instrument panel top cover and

silencer. (Refer to 23 - BODY/INSTRUMENT PAN-

EL/INSTRUMENT PANEL TOP PAD - INSTALLA-

TION).

(30) Install both left and right side A-pillar trim

covers.

(31) Install bolts attaching the lower supports to

the floor pan (Fig. 3).

(32) Install bolts attaching the lower supports to

the instrument panel frame.

(33) Install the lower console:

(a) Install lower console to vehicle.

(b) Connect the auxiliary power outlet.

(c) Install the six retaining screws.

(34) Connect the battery negative cable.

INSTRUMENT PANEL CENTER

BEZEL

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Insert the trim stick (special tool #C-4755) or

equivalent between access cover and center bezel

gently pry outward.

(3) Carefully pry the access cover from the instru-

ment panel (Fig. 10).

(4) Remove the two center bezel attaching screws.

(5) Using a trim stick or equivalent, gently pry out

on the edge of the instrument panel center bezel and

pull outward.

(6) Disconnect the wire connectors to the accessory

switches and HVAC control.

(7) Remove the instrument panel center bezel from

the vehicle.

RSINSTRUMENT PANEL23-71

INSTRUMENT PANEL ASSEMBLY (Continued)

Page 1854 of 2339

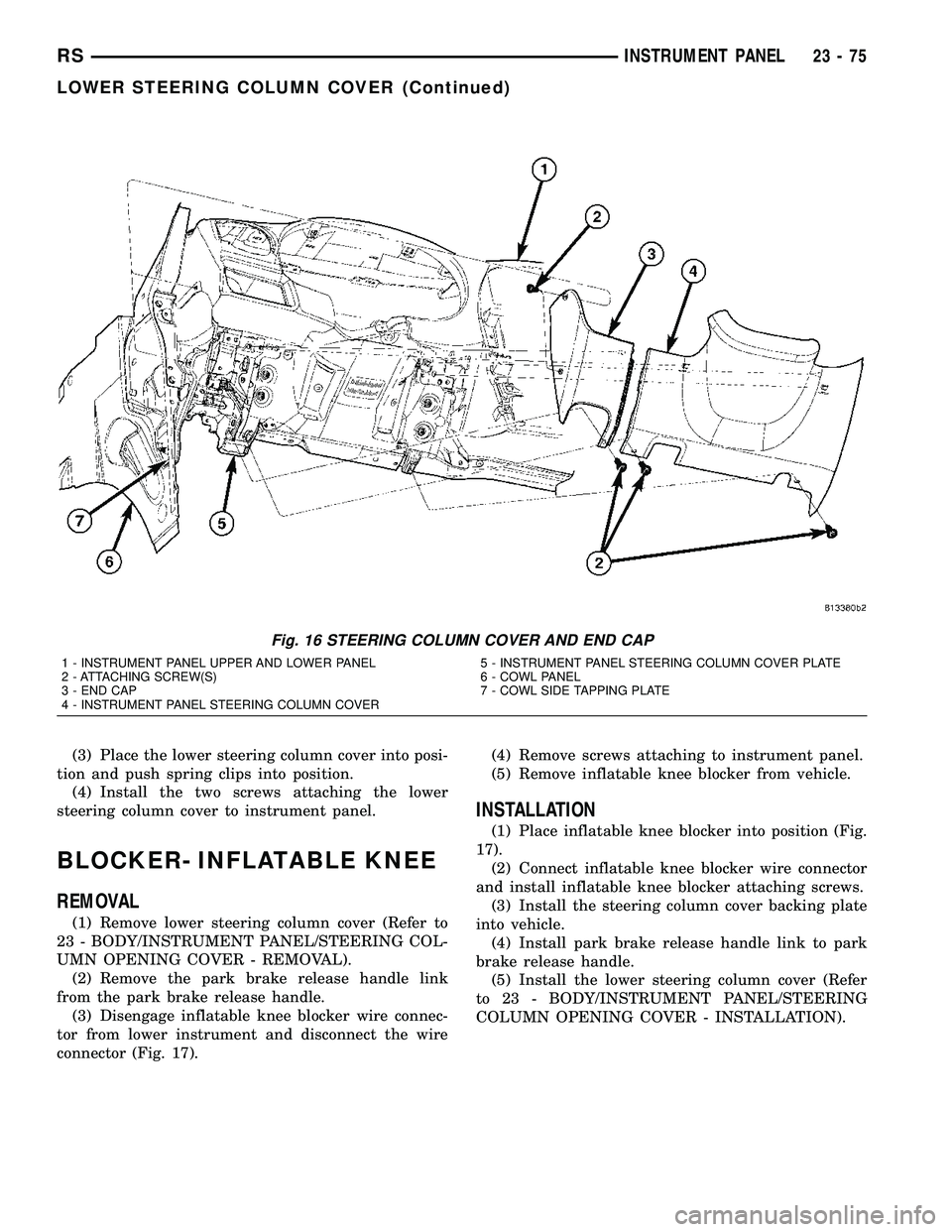

(3) Place the lower steering column cover into posi-

tion and push spring clips into position.

(4) Install the two screws attaching the lower

steering column cover to instrument panel.

BLOCKER- INFLATABLE KNEE

REMOVAL

(1) Remove lower steering column cover (Refer to

23 - BODY/INSTRUMENT PANEL/STEERING COL-

UMN OPENING COVER - REMOVAL).

(2) Remove the park brake release handle link

from the park brake release handle.

(3) Disengage inflatable knee blocker wire connec-

tor from lower instrument and disconnect the wire

connector (Fig. 17).(4) Remove screws attaching to instrument panel.

(5) Remove inflatable knee blocker from vehicle.

INSTALLATION

(1) Place inflatable knee blocker into position (Fig.

17).

(2) Connect inflatable knee blocker wire connector

and install inflatable knee blocker attaching screws.

(3) Install the steering column cover backing plate

into vehicle.

(4) Install park brake release handle link to park

brake release handle.

(5) Install the lower steering column cover (Refer

to 23 - BODY/INSTRUMENT PANEL/STEERING

COLUMN OPENING COVER - INSTALLATION).

Fig. 16 STEERING COLUMN COVER AND END CAP

1 - INSTRUMENT PANEL UPPER AND LOWER PANEL

2 - ATTACHING SCREW(S)

3 - END CAP

4 - INSTRUMENT PANEL STEERING COLUMN COVER5 - INSTRUMENT PANEL STEERING COLUMN COVER PLATE

6 - COWL PANEL

7 - COWL SIDE TAPPING PLATE

RSINSTRUMENT PANEL23-75

LOWER STEERING COLUMN COVER (Continued)

Page 2016 of 2339

DESCRIPTION FIGURE

UPPER COWL PLENUM AND REINFORCEMENT - RIGHT HAND DRIVE 201

COWL SIDE PANEL AND DASH PANEL - RIGHT HAND DRIVE 202

LOWER COWL PLENUM, SUPPORT AND DASH PANEL - RIGHT HAND DRIVE 203

STEERING COLUMN REINFORCEMENT, BELT REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE204

INSTRUMENT PANEL TAPPING PLATE AND COWL SIDE PANEL - RIGHT HAND DRIVE 205

DASH PANEL AND BELT REINFORCEMENT - RIGHT HAND DRIVE 206

UPPER SUPPORT, UPPER REINFORCEMENT AND UPPER COWL PLENUM - RIGHT

HAND DRIVE207

UPPER SUPPORT, BRAKE PEDAL BRACKET REINFORCEMENT AND DASH PANEL -

RIGHT HAND DRIVE208

REINFORCEMENT, MOUNTING BRACKETS AND DASH PANEL - RIGHT HAND DRIVE 209

STRUT TOWER, COWL SIDE PANEL - RIGHT HAND DRIVE 210

REINFORCEMENTS, SIDE RAILS, COWL SIDE PANELS AND DASH PANEL - RIGHT

HAND DRIVE211

UPPER COWL PLENUM, GUSSETS, SIDE SHIELDS AND BODY SIDE APERTURE -

RIGHT HAND DRIVE212

SIDE GLASS ANTENNA TAPPING PLATE AND INNER BODY SIDE APERTURE - RIGHT

HAND DRIVE213

Fig. 85 FRONT FENDER SHIELD - RIGHT

RSBODY STRUCTURE23 - 237

WELD LOCATIONS (Continued)

Page 2124 of 2339

Fig. 208 UPPER SUPPORT, BRAKE PEDAL BRACKET REINFORCEMENT AND DASH PANEL - RIGHT HAND

DRIVE

RSBODY STRUCTURE23 - 345

WELD LOCATIONS (Continued)

Page 2236 of 2339

FRONT HEATER CORE

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, DISABLE THE AIRBAG SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, OR INSTRUMENT PANEL COMPONENT

DIAGNOSIS OR SERVICE. DISCONNECT AND ISO-

LATE THE BATTERY NEGATIVE (GROUND) CABLE,

THEN WAIT TWO MINUTES FOR THE AIRBAG SYS-

TEM CAPACITOR TO DISCHARGE BEFORE PER-

FORMING FURTHER DIAGNOSIS OR SERVICE. THIS

IS THE ONLY SURE WAY TO DISABLE THE AIRBAG

SYSTEM. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Remove the silencer boot fasteners located

around the base of the lower steering shaft from the

dash panel so that it may be pushed aside.

(2) Remove the brake lamp switch from its mount-

ing bracket (Refer to 8 - ELECTRICAL/LAMPS/

LIGHTING - EXTERIOR/BRAKE LAMP SWITCH -

REMOVAL).

(3) Disconnect the power brake booster input rod

(push rod) from the pin on the brake pedal arm

(Refer to 5 - BRAKES - ABS/HYDRAULIC/ME-

CHANICAL/POWER BRAKE BOOSTER -

REMOVAL).

(4) Remove the heater core tubes (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING/

HEATER CORE - REMOVAL).

(5) Remove the two screws that secure the heater

core mounting plate to the distribution housing.

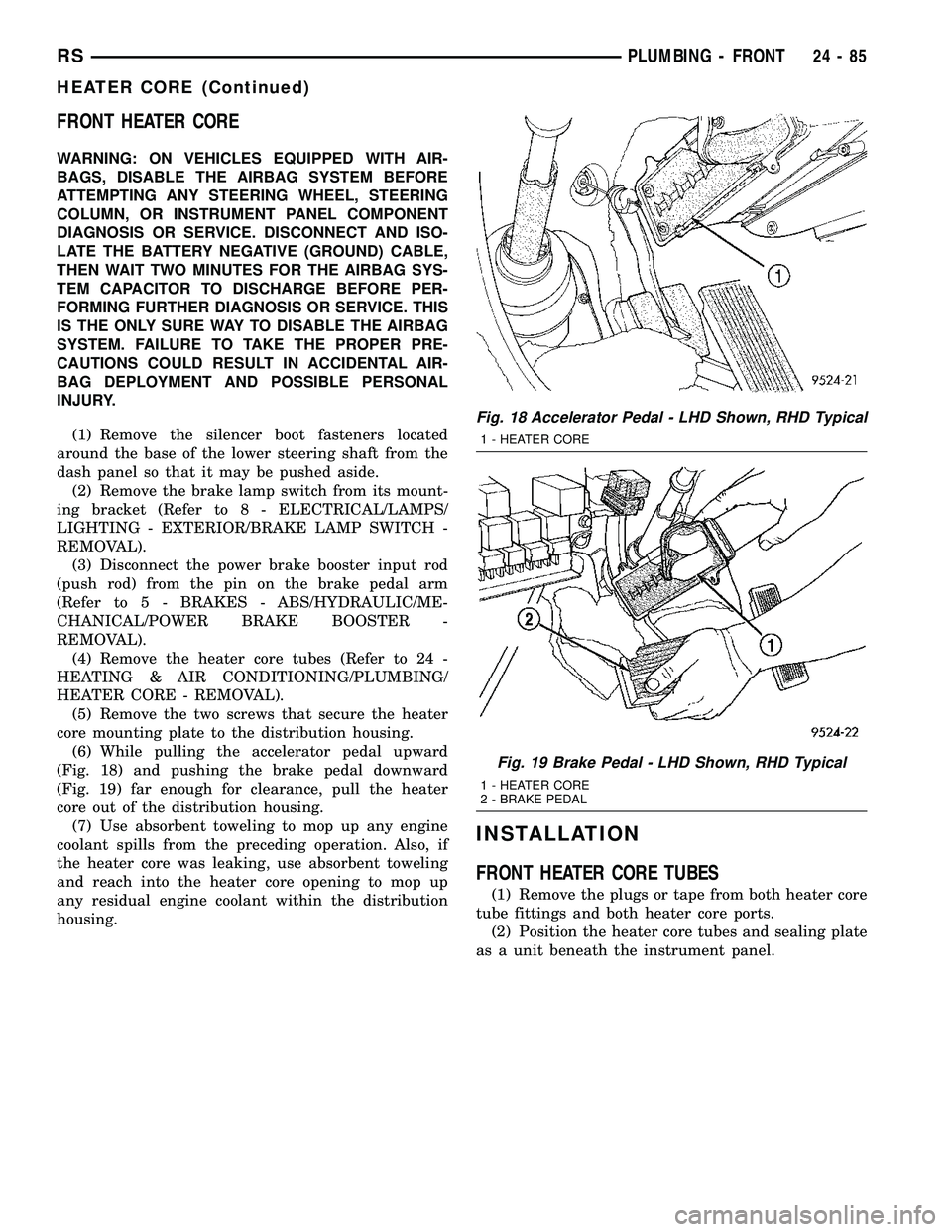

(6) While pulling the accelerator pedal upward

(Fig. 18) and pushing the brake pedal downward

(Fig. 19) far enough for clearance, pull the heater

core out of the distribution housing.

(7) Use absorbent toweling to mop up any engine

coolant spills from the preceding operation. Also, if

the heater core was leaking, use absorbent toweling

and reach into the heater core opening to mop up

any residual engine coolant within the distribution

housing.

INSTALLATION

FRONT HEATER CORE TUBES

(1) Remove the plugs or tape from both heater core

tube fittings and both heater core ports.

(2) Position the heater core tubes and sealing plate

as a unit beneath the instrument panel.

Fig. 18 Accelerator Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

Fig. 19 Brake Pedal - LHD Shown, RHD Typical

1 - HEATER CORE

2 - BRAKE PEDAL

RSPLUMBING - FRONT24-85

HEATER CORE (Continued)