display CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 374 of 2339

INSTRUMENT CLUSTER

TABLE OF CONTENTS

page page

INSTRUMENT CLUSTER

DESCRIPTION..........................1

OPERATION............................1

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS.........................2

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS...........................3REMOVAL.............................11

INSTALLATION.........................11

CLUSTER LENS

REMOVAL.............................11

INSTALLATION.........................11

INSTRUMENT CLUSTER

DESCRIPTION

The instrumentation gauges are contained in a

subdial assembly within the instrument cluster. The

individual gauges are not serviceable. If one of the

cluster gauges becomes faulty, the entire cluster

would require replacement.

The Mechanical Instrument Cluster (MIC) with a

tachometer is equipped with a electronic vacuum flu-

orescent transmission range indicator (PRND3L),

odometer, and trip odometer display.

The MIC without a tachometer is equipped with a

Light Emitting Diode (LED) transmission range indi-

cator (PRND3L) and a vacuum fluorescent odometer

display.

The MIC is equipped with the following warning

lamps.

²Lift Gate Ajar

²Low Fuel Level

²Low Windshield Washer Fluid Level

²Cruise

²Battery Voltage

²Fasten Seat Belt

²Door Ajar

²Coolant Temperature

²Anti-Lock Brake

²Brake

²Oil Pressure

²MIL (Malfunction Indicator Lamp)

²VTSS/SKIS Indicator

²Airbag

²Traction Control

²Autostick

Export Only- uses a message center that displays

the following telltales:

²Turns Signals

²High Beam

²Tire Pressure Monitoring (TPM)²Glow Plug (Export Only)

²Supplemental Cabin Heater (Export Only)WATER IN FUEL LAMP - EXPORT

The Water In Fuel Lamp is located in the message

center. When moisture is found within the fuel sys-

tem, the sensor sends a message via the PCI data

bus to the instrument cluster. The MIC illuminates

the bulb in the message center, The sensor is located

underneath the vehicle, directly above the rear axle.

The sensor is housed within the fuel filter/water sep-

arator assembly cover. The sensor is not serviced sep-

arately. If found defective, the entire assembly cover

must be replaced.

OPERATION

Refer to the vehicle Owner's Manual for operation

instructions and conditions for the Instrument Clus-

ter Gauges.

WATER IN FUEL LAMP/SENSOR - EXPORT

The Water In Fuel Sensor is a resistive type

switch. It is calibrated to sense the different resis-

tance between diesel fuel and water. When water

enters the fuel system, it is caught in the bottom of

the fuel filter/water separator assembly, where the

sensor is located. Water has less resistance than die-

sel fuel. The sensor then sends a PCI data bus mes-

sage to the instrument cluster to illuminate the

lamp.

If the lamp is inoperative, perform the self diag-

nostic test on the instrument cluster to check the

lamp operation before continuing diagnosis.

RSINSTRUMENT CLUSTER8J-1

Page 375 of 2339

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - SELF-

DIAGNOSTICS

The instrument clusters are equipped with a self

diagnostic test feature to help identify electronic

problems. Prior to any test, perform the Self-Diag-

nostic Test. The self diagnostic system displays

instrument cluster stored fault codes in the odometer

display, sweeps the gauges to the calibration points,

and bulb checks the warning indicators. When the

key is in the ON position with the engine not run-

ning, the MIL will remain illuminated for regulatory

purposes.

To activate the Self-Diagnostic program:

(1) With the ignition switch in the OFF position,

depress the TRIP ODOMETER RESET button.

(2) Continue to hold the TRIP ODOMETER

RESET button untilSofand a number (software ver-

sion number (i.e.Sof 3.2) appears in the odometer

window then release the button. If a fault code is

present, the cluster will display it in the odometer

display. When all fault codes have been displayed,

the cluster will displayªendºin the odometer dis-

play. Refer to the INSTRUMENT CLUSTER DTC'S

table to determine what each trouble code means.

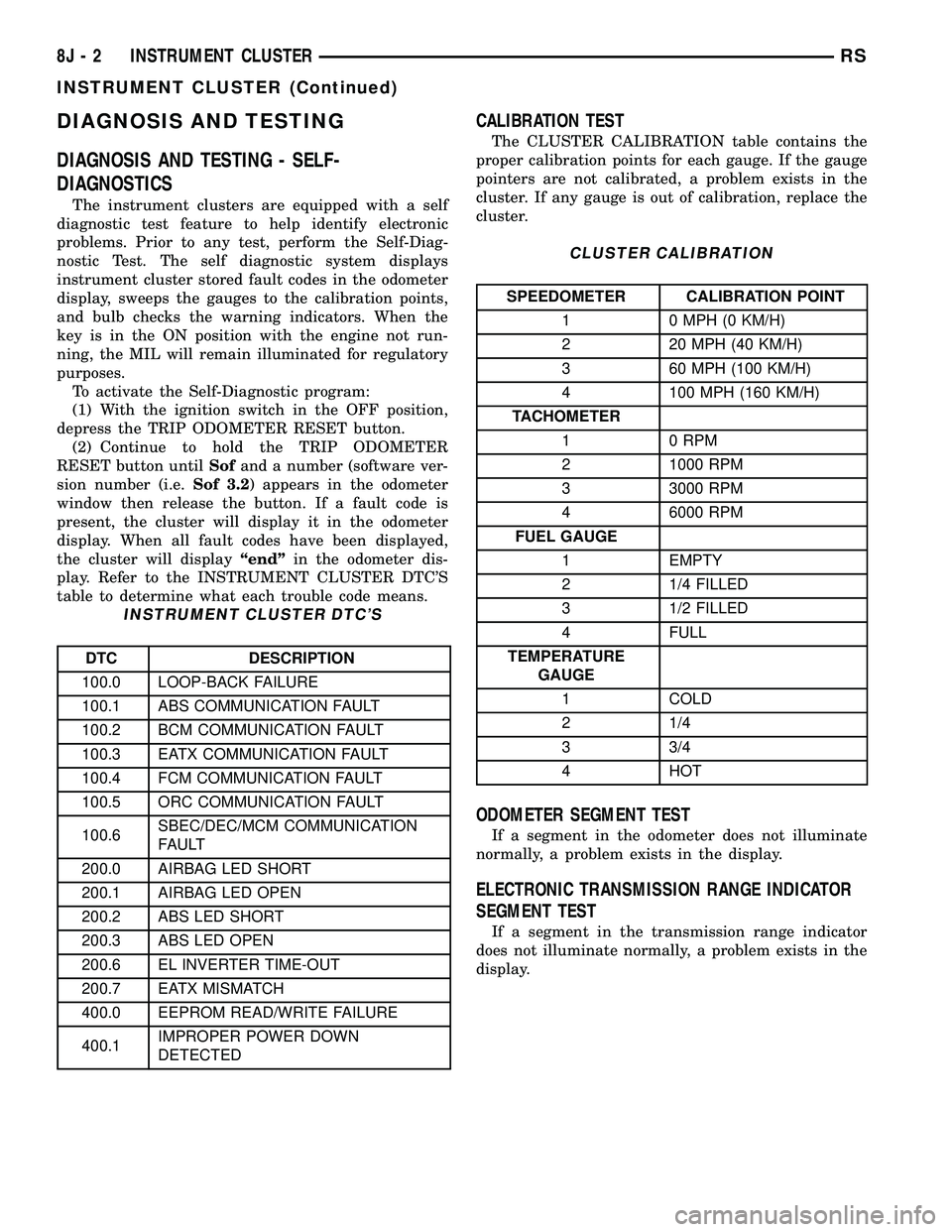

INSTRUMENT CLUSTER DTC'S

DTC DESCRIPTION

100.0 LOOP-BACK FAILURE

100.1 ABS COMMUNICATION FAULT

100.2 BCM COMMUNICATION FAULT

100.3 EATX COMMUNICATION FAULT

100.4 FCM COMMUNICATION FAULT

100.5 ORC COMMUNICATION FAULT

100.6SBEC/DEC/MCM COMMUNICATION

FAULT

200.0 AIRBAG LED SHORT

200.1 AIRBAG LED OPEN

200.2 ABS LED SHORT

200.3 ABS LED OPEN

200.6 EL INVERTER TIME-OUT

200.7 EATX MISMATCH

400.0 EEPROM READ/WRITE FAILURE

400.1IMPROPER POWER DOWN

DETECTED

CALIBRATION TEST

The CLUSTER CALIBRATION table contains the

proper calibration points for each gauge. If the gauge

pointers are not calibrated, a problem exists in the

cluster. If any gauge is out of calibration, replace the

cluster.

CLUSTER CALIBRATION

SPEEDOMETER CALIBRATION POINT

1 0 MPH (0 KM/H)

2 20 MPH (40 KM/H)

3 60 MPH (100 KM/H)

4 100 MPH (160 KM/H)

TACHOMETER

1 0 RPM

2 1000 RPM

3 3000 RPM

4 6000 RPM

FUEL GAUGE

1 EMPTY

2 1/4 FILLED

3 1/2 FILLED

4 FULL

TEMPERATURE

GAUGE

1 COLD

2 1/4

3 3/4

4 HOT

ODOMETER SEGMENT TEST

If a segment in the odometer does not illuminate

normally, a problem exists in the display.

ELECTRONIC TRANSMISSION RANGE INDICATOR

SEGMENT TEST

If a segment in the transmission range indicator

does not illuminate normally, a problem exists in the

display.

8J - 2 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 376 of 2339

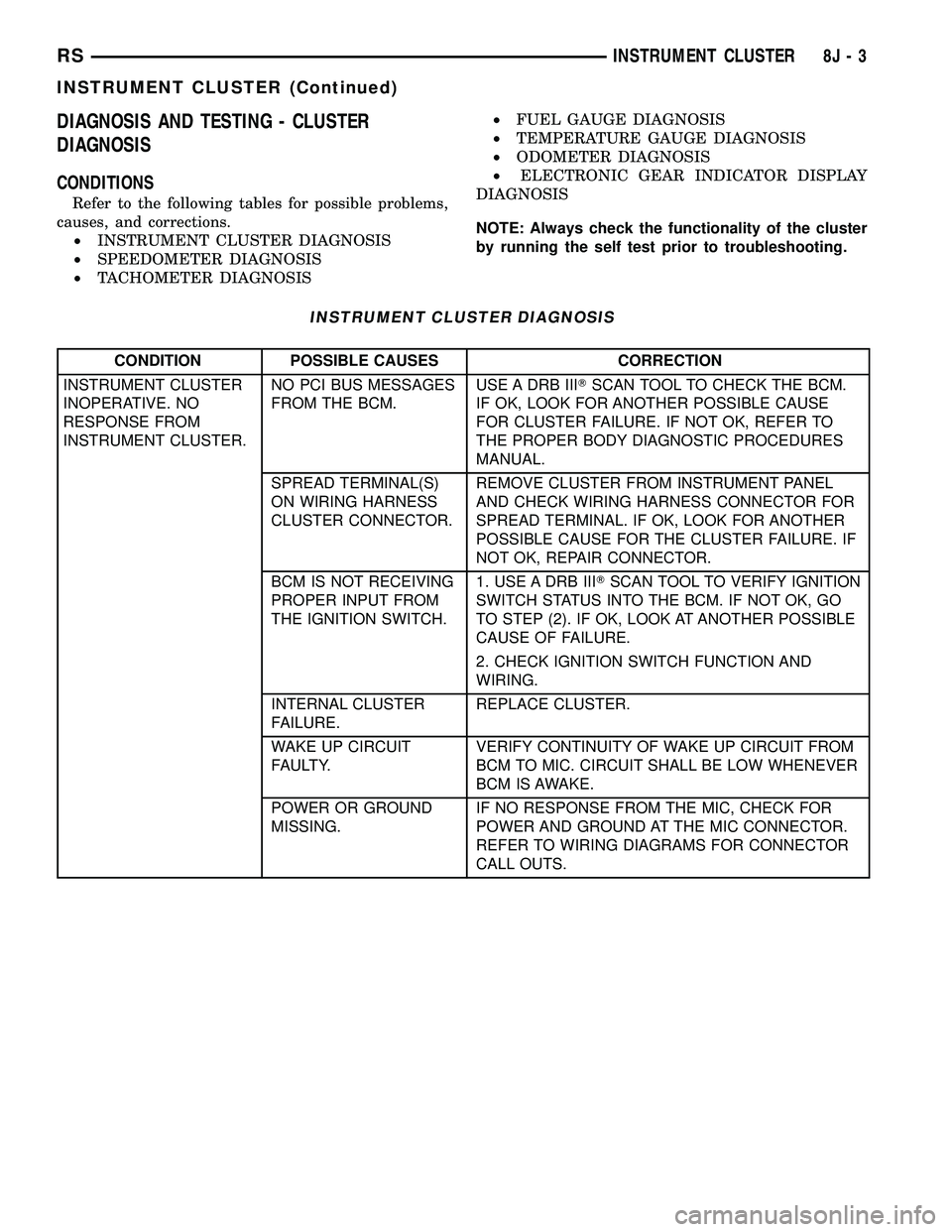

DIAGNOSIS AND TESTING - CLUSTER

DIAGNOSIS

CONDITIONS

Refer to the following tables for possible problems,

causes, and corrections.

²INSTRUMENT CLUSTER DIAGNOSIS

²SPEEDOMETER DIAGNOSIS

²TACHOMETER DIAGNOSIS²FUEL GAUGE DIAGNOSIS

²TEMPERATURE GAUGE DIAGNOSIS

²ODOMETER DIAGNOSIS

²ELECTRONIC GEAR INDICATOR DISPLAY

DIAGNOSIS

NOTE: Always check the functionality of the cluster

by running the self test prior to troubleshooting.

INSTRUMENT CLUSTER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

INSTRUMENT CLUSTER

INOPERATIVE. NO

RESPONSE FROM

INSTRUMENT CLUSTER.NO PCI BUS MESSAGES

FROM THE BCM.USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

IF OK, LOOK FOR ANOTHER POSSIBLE CAUSE

FOR CLUSTER FAILURE. IF NOT OK, REFER TO

THE PROPER BODY DIAGNOSTIC PROCEDURES

MANUAL.

SPREAD TERMINAL(S)

ON WIRING HARNESS

CLUSTER CONNECTOR.REMOVE CLUSTER FROM INSTRUMENT PANEL

AND CHECK WIRING HARNESS CONNECTOR FOR

SPREAD TERMINAL. IF OK, LOOK FOR ANOTHER

POSSIBLE CAUSE FOR THE CLUSTER FAILURE. IF

NOT OK, REPAIR CONNECTOR.

BCM IS NOT RECEIVING

PROPER INPUT FROM

THE IGNITION SWITCH.1. USE A DRB IIITSCAN TOOL TO VERIFY IGNITION

SWITCH STATUS INTO THE BCM. IF NOT OK, GO

TO STEP (2). IF OK, LOOK AT ANOTHER POSSIBLE

CAUSE OF FAILURE.

2. CHECK IGNITION SWITCH FUNCTION AND

WIRING.

INTERNAL CLUSTER

FAILURE.REPLACE CLUSTER.

WAKE UP CIRCUIT

FAULTY.VERIFY CONTINUITY OF WAKE UP CIRCUIT FROM

BCM TO MIC. CIRCUIT SHALL BE LOW WHENEVER

BCM IS AWAKE.

POWER OR GROUND

MISSING.IF NO RESPONSE FROM THE MIC, CHECK FOR

POWER AND GROUND AT THE MIC CONNECTOR.

REFER TO WIRING DIAGRAMS FOR CONNECTOR

CALL OUTS.

RSINSTRUMENT CLUSTER8J-3

INSTRUMENT CLUSTER (Continued)

Page 382 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC POINTER

MOVEMENT.1. BAD PCI BUS

MESSAGE FROM THE

POWERTRAIN CONTROL

MODULE.1.A. CHECK PCM FAULT CODES USING A DRB IIIT

SCAN TOOL. IF THERE ARE NO FAULTS, GO TO

STEP 1.B. IF THERE ARE FAULTS, REFER TO THE

PROPER POWERTRAIN DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

1.B. REFER TO FUEL, COOLANT TEMPERATURE

SENSOR, DIAGNOSIS AND TESTING. REPAIR

SENSOR AS NEEDED.

2. INTERNAL CLUSTER

FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF THE POINTER MOVES DURING TEST BUT

STILL APPEARS ERRATIC, REPLACE CLUSTER

ASSEMBLY.

TEMPERATURE GAUGE

INACCURATE.1. TEMPERATURE

GAUGE OUT OF

CALIBRATION.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST.

²IF POINTER IS ACCURATE TO THE CALIBRATION

POINTS LOOK FOR ANOTHER POSSIBLE CAUSE

OF FAILURE.

²IF POINTER IS INACCURATE TO THE

CALIBRATION POINTS, REPLACE CLUSTER

ASSEMBLY.

2. COOLANT SENSOR

OUT OF CALIBRATION.2. REFER TO FUEL, COOLANT TEMPERATURE

SENSOR FOR TEST AND REPAIR PROCEDURE.

ODOMETER DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY. 1. NO PCI BUS

ODOMETER MESSAGE

FROM BCM.1. USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

REFER TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

2. INTERNAL CLUSTER

FAILURE.2. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF ODOMETER PASSES THE SEGMENT CHECK,

LOOK FOR ANOTHER POSSIBLE CAUSE OF

FAILURE. IF IT FAILS VERIFY POWER AND

GROUND ARE BEING PROVIDED TO THE

CLUSTER. IF YES, REPLACE CLUSTER. IF NO,

DETERMINE CAUSE OF NO POWER OR GROUND.

RSINSTRUMENT CLUSTER8J-9

INSTRUMENT CLUSTER (Continued)

Page 383 of 2339

CONDITION POSSIBLE CAUSES CORRECTION

ERRATIC DISPLAY 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF ODOMETER PASSES THE SEGMENT TEST,

FAILURE MAY NOT BE IN THE CLUSTER. LOOK

FOR ANOTHER POSSIBLE CAUSE OF FAILURE.

2. VERIFY GOOD POWER AND GROUND

CONNECTIONS. IF CONNECTIONS ARE GOOD AND

NO OTHER PROBLEMS ARE FOUND, REPLACE

CLUSTER ASSEMBLY.

2. BAD PCI BUS

MESSAGE FROM THE

BCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE BCM.

REFER TO THE PROPER BODY DIAGNOSTIC

PROCEDURES MANUAL TO PROPERLY DIAGNOSE

AND REPAIR.

ODOMETER WON'T GO

INTO TRIP MODE.TRIP SWITCH DOESN'T

WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND CANNOT TOGGLE BETWEEN

ODOMETER AND TRIP ODOMETER, REPLACE

CLUSTER.

TRIP ODOMETER WON'T

RESET.RESET SWITCH

DOESN'T WORK.IF CLUSTER WILL NOT GO INTO SELF DIAGNOSTIC

MODE AND TRIP ODOMETER WILL NOT RESET,

REPLACE CLUSTER.

ELECTRONIC GEAR INDICATOR DISPLAY DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

NO DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES THE SEGMENT CHECK, THEN FAILURE

MAY NOT BE IN THE CLUSTER. LOOK FOR

ANOTHER POSSIBLE CAUSE OF FAILURE. IF IT

FAILS, REPLACE CLUSTER ASSEMBLY.

ERRATIC DISPLAY. 1. INTERNAL CLUSTER

FAILURE.1. PERFORM CLUSTER SELF-DIAGNOSTIC TEST

AND CHECK FOR FAULT CODES.

²IF PRND3L (PRND1234 IF AUTOSTICK EQUIPPED)

PASSES THE SEGMENT CHECK, THEN FAILURE

MAY NOT BE IN THE CLUSTER. LOOK FOR

ANOTHER POSSIBLE CAUSE OF FAILURE.

2. BAD PCI BUS

MESSAGE FROM THE

TCM.2. USE A DRB IIITSCAN TOOL TO CHECK THE TCM.

REFER TO THE PROPER TRANSMISSION

DIAGNOSTIC PROCEDURES MANUAL TO

PROPERLY DIAGNOSE AND REPAIR.

8J - 10 INSTRUMENT CLUSTERRS

INSTRUMENT CLUSTER (Continued)

Page 405 of 2339

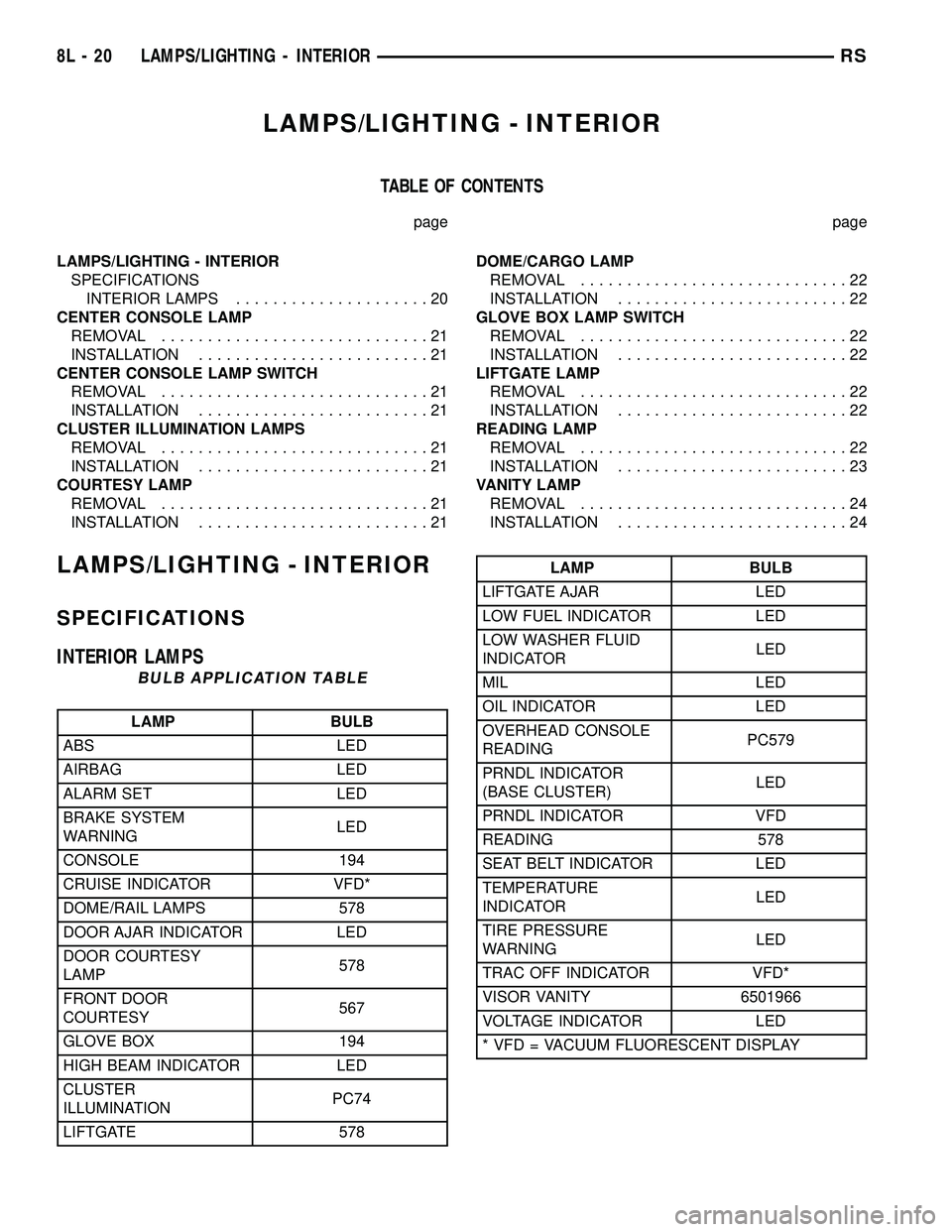

LAMPS/LIGHTING - INTERIOR

TABLE OF CONTENTS

page page

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS.....................20

CENTER CONSOLE LAMP

REMOVAL.............................21

INSTALLATION.........................21

CENTER CONSOLE LAMP SWITCH

REMOVAL.............................21

INSTALLATION.........................21

CLUSTER ILLUMINATION LAMPS

REMOVAL.............................21

INSTALLATION.........................21

COURTESY LAMP

REMOVAL.............................21

INSTALLATION.........................21DOME/CARGO LAMP

REMOVAL.............................22

INSTALLATION.........................22

GLOVE BOX LAMP SWITCH

REMOVAL.............................22

INSTALLATION.........................22

LIFTGATE LAMP

REMOVAL.............................22

INSTALLATION.........................22

READING LAMP

REMOVAL.............................22

INSTALLATION.........................23

VANITY LAMP

REMOVAL.............................24

INSTALLATION.........................24

LAMPS/LIGHTING - INTERIOR

SPECIFICATIONS

INTERIOR LAMPS

BULB APPLICATION TABLE

LAMP BULB

ABS LED

AIRBAG LED

ALARM SET LED

BRAKE SYSTEM

WARNINGLED

CONSOLE 194

CRUISE INDICATOR VFD*

DOME/RAIL LAMPS 578

DOOR AJAR INDICATOR LED

DOOR COURTESY

LAMP578

FRONT DOOR

COURTESY567

GLOVE BOX 194

HIGH BEAM INDICATOR LED

CLUSTER

ILLUMINATIONPC74

LIFTGATE 578

LAMP BULB

LIFTGATE AJAR LED

LOW FUEL INDICATOR LED

LOW WASHER FLUID

INDICATORLED

MIL LED

OIL INDICATOR LED

OVERHEAD CONSOLE

READINGPC579

PRNDL INDICATOR

(BASE CLUSTER)LED

PRNDL INDICATOR VFD

READING 578

SEAT BELT INDICATOR LED

TEMPERATURE

INDICATORLED

TIRE PRESSURE

WARNINGLED

TRAC OFF INDICATOR VFD*

VISOR VANITY 6501966

VOLTAGE INDICATOR LED

* VFD = VACUUM FLUORESCENT DISPLAY

8L - 20 LAMPS/LIGHTING - INTERIORRS

Page 411 of 2339

OVERHEAD CONSOLE

TABLE OF CONTENTS

page page

OVERHEAD CONSOLE

DESCRIPTION..........................2

DIAGNOSIS AND TESTING

OVERHEAD CONSOLE..................3

STANDARD PROCEDURE

COMPASS CALIBRATION................4

COMPASS DEMAGNETIZING.............5

COMPASS VARIATION ADJUSTMENT.......5

REMOVAL.............................6

INSTALLATION..........................6

SPECIAL TOOLS

OVERHEAD CONSOLE..................7

ELECTRONIC VEHICLE INFO CENTER

DESCRIPTION..........................7

OPERATION............................7

DIAGNOSIS AND TESTING

ELECTRONIC VEHICLE INFORMATION

CENTER.............................8

STANDARD PROCEDURE

ELECTRONIC VEHICLE INFORMATION

CENTER PROGRAMMING................8

REMOVAL.............................9

INSTALLATION.........................10

COMPASS/MINI-TRIP COMPUTER

DESCRIPTION.........................10OPERATION...........................10

DIAGNOSIS AND TESTING

COMPASS MINI-TRIP COMPUTER........10

REMOVAL.............................10

INSTALLATION.........................10

UNIVERSAL TRANSMITTER

DESCRIPTION.........................11

DIAGNOSIS AND TESTING

UNIVERSAL TRANSMITTER.............11

STANDARD PROCEDURE

SETTING TRANSMITTER CODES.........12

ERASING TRANSMITTER CODES.........12

REMOVAL.............................12

AMBIENT TEMP SENSOR

DESCRIPTION.........................12

OPERATION...........................12

DIAGNOSIS AND TESTING

AMBIENT TEMPERATURE SENSOR.......12

AMBIENT TEMPERATURE SENSOR

CIRCUIT............................12

REMOVAL.............................13

INSTALLATION.........................13

OVERHEAD CONSOLE

DESCRIPTION

Three overhead consoles options are available on

this vehicle. These options are:

²The Electronic Vehicle Information Center

(EVIC)

²The Compass Mini-Trip Computer (CMTC)

All consoles are equipped with two reading/cour-

tesy lamps and if the vehicle is equipped with a

power liftgate or power sliding door(s) the overhead

console will also include switches for these features.

The overhead console is mounted with one screw and

two snap clips to a molded plastic retainer bracket

located above the headliner.

DESCRIPTION - COMPASS

All overhead consoles include compass information.

While in the compass/temperature mode, the com-

pass will display the direction in which the vehicle is

pointed using the eight major compass headings

(Examples: north is N, northeast is NE). The self-cal-

ibrating compass unit requires no adjusting in nor-

mal use. The only calibration that may be necessary

is to drive the vehicle in three complete circles at 5

to 8 kilometers-per-hour (3 to 5 miles-per-hour), on

level ground, for a minimum of forty-eight seconds.

This will reorient the compass unit to its vehicle.

8M - 2 OVERHEAD CONSOLERS

Page 412 of 2339

The compass unit will also compensate for magne-

tism the vehicle may acquire during normal use.

However, avoid placing anything magnetic directly on

the roof of the vehicle. Magnetic mounts for an

antenna, a repair order hat, or a funeral procession

flag can exceed the compensating ability of the com-

pass unit if placed on the roof panel. The use of mag-

netic tools on the fasteners that hold the overhead

console assembly to the roof header can also affect

compass operation. If the compass operation is

erratic and roof magnetization is suspected (Refer to

8 - ELECTRICAL/OVERHEAD CONSOLE - STAN-

DARD PROCEDURE - COMPASS DEMAGNETIZ-

ING).

DESCRIPTION - TEMPERATURE

All overhead consoles include temperature informa-

tion. The temperature displays the outside ambient

temperature in whole degrees. The temperature dis-

play can be toggled from Fahrenheit to Celsius by

selecting the desired U.S./Metric option from the cus-

tomer programmable features. The displayed temper-

ature is not an instant reading of conditions, but an

average temperature. It may take the temperature

display several minutes to respond to a major tem-

perature change, such as driving out of a heated

garage into winter temperatures.

When the ignition switch is turned to the Off posi-

tion, the last displayed temperature reading stays in

the electronic control modules (CMTC, EVIC) mem-

ory. When the ignition switch is turned to the On

position again, the electronic module will display the

memory temperature for one minute; then update the

display to the current average temperature reading

within five minutes.

The temperature function is supported by an ambi-

ent temperature sensor. The sensor is mounted near

the front and center of the vehicle, and is hard wired

to the Powertrain Control Module (PCM). The PCM

sends temperature status messages to the module

over the Programmable Communication Interface

(PCI) data bus circuit.

DIAGNOSIS AND TESTING

OVERHEAD CONSOLE

Any diagnosis of the overhead console should

begin with the use of the DRB IIItdiagnostic

tool. For information on the use of the DRB

IIIt, refer to the appropriate Diagnostic Proce-

dures information.If the problem with the overhead console is an

inaccurate or dashed (- -) display, refer to SELF-DI-

AGNOSTIC TEST. If the problem with the overhead

console is incorrect Vacuum Fluorescent Display

(VFD) dimming levels, use a DRB IIItscan tool and

the proper diagnostic procedures information to test

for the correct dimming message inputs being

received from the Body Control Module (BCM) or

Front Control Module (FCM) over the Programmable

Communications Interface (PCI) data bus circuit. If

the problem is a no-display condition, use the follow-

ing procedures.

Inspect the related wiring harness connectors for

broken, bent, pushed out, or corroded terminals.

Refer to the appropriate wiring information.

(1) Check the fused B(+) fuse in the integrated

power module. If OK, go to Step 2. If not OK, repair

the shorted circuit or component as required and

replace the faulty fuse.

(2) Check for battery voltage at the fused B(+) fuse

in the integrated power module. If OK, go to Step 3.

If not OK, repair the open fused B(+) circuit to the

fused B(+) fuse in the integrated power module as

required.

(3) Check the fused ignition switch output (run/

start) fuse in the integrated power module. If OK, go

to Step 4. If not OK, repair the shorted circuit or

component as required and replace the faulty fuse.

(4) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) fuse in the integrated power mod-

ule. If OK, go to Step 5. If not OK, repair the open

fused ignition switch output (run/start) circuit to the

ignition switch as required.

(5) Turn the ignition switch to the Off position.

Disconnect and isolate the battery negative cable.

Remove the overhead console. Check for continuity

between the ground circuit cavity of the roof wire

harness connector for the electronics module and a

good ground. There should be continuity. If OK, go to

Step 6. If not OK, repair the open ground circuit as

required.

(6) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

roof wire harness connector for the electronics mod-

ule. If OK, go to Step 7. If not OK, repair the open

fused B(+) circuit to the fused B(+) fuse in the inte-

grated power module as required.

(7) Turn the ignition switch to the On position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the roof wire har-

ness connector for the electronics module. If OK,

refer to SELF-DIAGNOSTIC TEST. If not OK, repair

the open fused ignition switch output (run/start) cir-

cuit to the fuse in the integrated power module as

required.

RSOVERHEAD CONSOLE8M-3

OVERHEAD CONSOLE (Continued)

Page 413 of 2339

SELF-DIAGNOSTIC TEST

A self-diagnostic test is used to determine that the

electronics module is operating properly, and that all

the PCI data bus messages are being received for ini-

tial operation. Initiate the self-diagnostic test as fol-

lows:

(1) With the ignition switch in the Off position, on

Electronic Vehicle Information Center (EVIC) and

Compass Mini-Trip Computer (CMTC) equipped vehi-

cles simultaneously depress and hold theSTEPand

theRESETbuttons. On Compass Temperature Mod-

ule (CT) equipped vehicles depress theC/Tand the

US/Mpush buttons.

(2) Turn the ignition switch to the On position.

(3) Following completion of these tests, the elec-

tronics module will display one of the following mes-

sages:

a.Pass Self Test (EVIC only), PASS (CT,

CMTC)- The electronics module is working properly.

b.Failed Self Test (EVIC only), FAIL (CT,

CMTC)- The electronics module has an internal fail-

ure. The electronics module is faulty and must be

replaced.

NOTE: If the compass functions, but accuracy is

suspect, it may be necessary to perform a variation

adjustment. This procedure allows the compass

unit to accommodate variations in the earth's mag-

netic field strength, based on geographic location.

(Refer to 8 - ELECTRICAL/OVERHEAD CONSOLE -

STANDARD PROCEDURE - COMPASS VARIATION

ADJUSTMENT).

NOTE: If the compass reading display is blank and

only ªCALº appears in the display, demagnetizing

may be necessary to remove excessive residual

magnetic fields from the vehicle. (Refer to 8 - ELEC-

TRICAL/OVERHEAD CONSOLE - STANDARD PRO-

CEDURE - COMPASS DEMAGNETIZING).

STANDARD PROCEDURE

COMPASS CALIBRATION

CAUTION: Do not place any external magnets, such

as magnetic roof mount antennas, in the vicinity of

the compass. Do not use magnetic tools when ser-

vicing the overhead console.The electronic compass unit features a self-cali-

brating design, which simplifies the calibration pro-

cedure. This feature automatically updates the

compass calibration while the vehicle is being driven.

This allows the compass unit to compensate for small

changes in the residual magnetism the vehicle may

acquire during normal use. If the compass readings

appear to be erratic or out of calibration, perform the

following calibration procedure. Also, new service

replacement Electronic Modules (EVIC, CMTC, CT)

must have their compass calibrated using this proce-

dure. Do not attempt to calibrate the compass near

large metal objects such as other vehicles, large

buildings, or bridges; or, near overhead or under-

ground power lines.

NOTE: Whenever the compass is calibrated manu-

ally, the variance number must also be reset. (Refer

to 8 - ELECTRICAL/OVERHEAD CONSOLE - STAN-

DARD PROCEDURE - COMPASS VARIATION

ADJUSTMENT).

Calibrate the compass manually as follows:

(1) Turn the ignition switch to the On position. If

the compass/thermometer data is not currently being

displayed, momentarily depress and release the C/T

push button to reach the compass/thermometer dis-

play.

(2) On Electronic Vehicle Information Center

(EVIC) and Compass Mini-Trip Computer (CMTC)

equipped vehicles depress the Reset push button and

hold the button until ªCALº appears in the display.

This takes about ten seconds, and appears about five

seconds after ªVAR = XXº is displayed. On Compass

Temperature Module (CT) equipped vehicles depress

the C/T push button and US/M push button down

until ªCALº appears in the display. This takes about

ten seconds, and appears about five seconds after

ªVAR = XXº is displayed.

(3) Release the push button(s).

(4) Drive the vehicle on a level surface, away from

large metal objects and power lines, through three or

more complete circles at between five and eight kilo-

meters-per-hour (three and five miles-per-hour) for a

minimum of 48 seconds. The ªCALº message will dis-

appear from the display to indicate that the compass

is now calibrated.

NOTE: If the ªCALº message remains in the display,

either there is excessive magnetism near the com-

pass, or the unit is faulty. Repeat the calibration

procedure one more time.

8M - 4 OVERHEAD CONSOLERS

OVERHEAD CONSOLE (Continued)

Page 414 of 2339

NOTE: If the wrong direction is still indicated in the

compass display, the area selected for calibration

may be too close to a strong magnetic field. Repeat

the calibration procedure in another location.

COMPASS DEMAGNETIZING

A degaussing tool (Special Tool 6029) is used to

demagnetize, or degauss, the overhead console for-

ward mounting screw and the roof panel above the

overhead console. Equivalent units must be rated as

continuous duty for 110/115 volts and 60 Hz. They

must also have a field strength of over 350 gauss at 7

millimeters (0.25 inch) beyond the tip of the probe.

To demagnetize the roof panel and the overhead

console forward mounting screw, proceed as follows:

(1) Be certain that the ignition switch is in the Off

position, before you begin the demagnetizing proce-

dure.

(2) Connect the degaussing tool (Fig. 1) to an elec-

trical outlet, while keeping the tool at least 61 centi-

meters (2 feet) away from the compass unit.

(3) Slowly approach the head of the overhead con-

sole forward mounting screw with the degaussing

tool connected.

(4) Contact the head of the screw with the plastic

coated tip of the degaussing tool for about two sec-

onds.

(5) With the degaussing tool still energized, slowly

back it away from the screw. When the tip of the tool

is at least 61 centimeters (2 feet) from the screw

head, disconnect the tool.

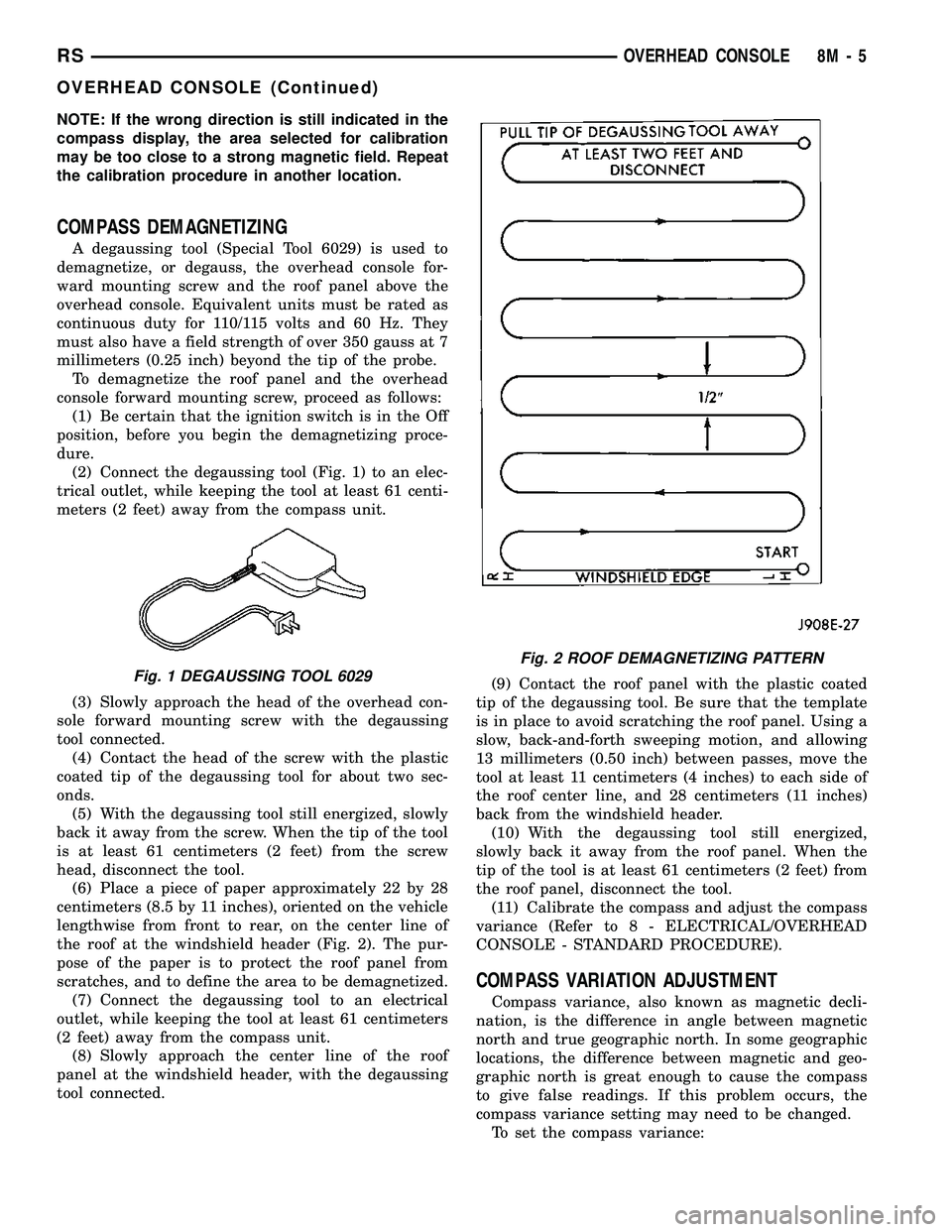

(6) Place a piece of paper approximately 22 by 28

centimeters (8.5 by 11 inches), oriented on the vehicle

lengthwise from front to rear, on the center line of

the roof at the windshield header (Fig. 2). The pur-

pose of the paper is to protect the roof panel from

scratches, and to define the area to be demagnetized.

(7) Connect the degaussing tool to an electrical

outlet, while keeping the tool at least 61 centimeters

(2 feet) away from the compass unit.

(8) Slowly approach the center line of the roof

panel at the windshield header, with the degaussing

tool connected.(9) Contact the roof panel with the plastic coated

tip of the degaussing tool. Be sure that the template

is in place to avoid scratching the roof panel. Using a

slow, back-and-forth sweeping motion, and allowing

13 millimeters (0.50 inch) between passes, move the

tool at least 11 centimeters (4 inches) to each side of

the roof center line, and 28 centimeters (11 inches)

back from the windshield header.

(10) With the degaussing tool still energized,

slowly back it away from the roof panel. When the

tip of the tool is at least 61 centimeters (2 feet) from

the roof panel, disconnect the tool.

(11) Calibrate the compass and adjust the compass

variance (Refer to 8 - ELECTRICAL/OVERHEAD

CONSOLE - STANDARD PROCEDURE).

COMPASS VARIATION ADJUSTMENT

Compass variance, also known as magnetic decli-

nation, is the difference in angle between magnetic

north and true geographic north. In some geographic

locations, the difference between magnetic and geo-

graphic north is great enough to cause the compass

to give false readings. If this problem occurs, the

compass variance setting may need to be changed.

To set the compass variance:

Fig. 1 DEGAUSSING TOOL 6029

Fig. 2 ROOF DEMAGNETIZING PATTERN

RSOVERHEAD CONSOLE8M-5

OVERHEAD CONSOLE (Continued)