key CHRYSLER CARAVAN 2005 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 435 of 2339

LATCH

DESCRIPTION

The power cinch/release latch performs the same

features as a manual liftgate latch as well as the

power cinch and / or release capability. A second type

of power latch can also be found on some vehicles,

this latch is designed to perform a power release

only. The power cinch and release capability is

accomplished by an actuator mounted to the leading

edge of the latch assembly. The latch is located in the

lower center of the power liftgate assembly (Fig. 8)

and contains integral pawl and ratchet switches. The

ratchet switch also acts as a liftgate ajar switch. The

power latch assembly can be serviced as a complete

assembly, latch without actuator or just the actuator.

OPERATION

On the power cinch/release latch, the latch

mounted actuator provides the torque required to

close the power liftgate from the secondary to the pri-mary closed and latched position. On the power

cinch/release latch and the power release only latch,

the actuator releases the liftgate from the primary

closed and latched position to the fully unlatched and

movable position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Open the liftgate and remove the liftgate trim

panel, (Refer to 23 - BODY/DECKLID/HATCH/LIFT-

GATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Disconnect the power latch electrical connector

(Fig. 9).

(4) Remove the power latch retaining bolts.

(5) Disconnect the liftgate lock cylinder link rod

(Fig. 9) from the key cylinder or latch assembly. To

disconnect from latch, rotate the plastic retaining clip

90 É to unsnap clip from linkrod. Then pull link rod

straight out of latch arm.

(6) Remove the power latch from the vehicle.

Fig. 8 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 9 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

8N - 12 POWER LIFTGATE SYSTEMRS

Page 436 of 2339

INSTALLATION

(1) Position the power latch in the vehicle.

(2) Connect the liftgate lock cylinder link rod (Fig.

10) on the cinch latch assembly. Rotate the plastic

retaining clip 90 É to lock retaining clip onto the link

rod.

(3) Connect the link rod on the lock cylinder.

(4) Install three new power latch retaining bolts.

Torque to 10 N´m (90 in. lbs.).

(5) Connect the power latch electrical connector

and secure push pin retainers.

(6) Connect the battery negative cable.

(7) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the power latch.

(8) Verify power liftgate system and power cinch /

release latch operation. Cycle the power liftgate

through one complete open and close cycle, this will

allow the power liftgate control module to relearn its

cycle with the new components.

(9) Verify power liftgate manual operation. Using

liftgate key rotate the lock cylinder to verify door

operation. Pull door open using exterior liftgate han-

dle / switch.

(10) Install the liftgate trim panel, (Refer to 23 -

BODY/DECKLID/HATCH/LIFTGATE/TAILGATE/

TRIM PANEL - INSTALLATION).

LATCH ACTUATOR

DESCRIPTION

The power cinch and/or power release latch (Fig.

11) is made possible by a latch actuator attached to

the leading edge of the power latch assembly. This 12

volt latch actuator contains a small drive gear that

meshes with the latch assemblies internal gears to

perform the power cinch close / power release opera-

tions. (Refer to 8 - ELECTRICAL/POWER DOORS/

LATCH - DESCRIPTION) for additional information.

The power cinch/release actuator is serviceable com-

ponent.

OPERATION

During a power close cycle, the power cinch actua-

tor provides the torque required to close the power

liftgate from the secondary to the primary closed and

latched position. During a power open cycle, the

power release actuator releases the liftgate from the

primary closed and latched position to the fully

unlatched and movable position.

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

Fig. 10 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 11 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

RSPOWER LIFTGATE SYSTEM8N-13

LATCH (Continued)

Page 437 of 2339

(2) Open the liftgate and remove the lower liftgate

trim panel. (Refer to 23 - BODY/DECKLID/HATCH/

LIFTGATE/TAILGATE/TRIM PANEL - REMOVAL).

(3) Disconnect the power latch electrical connector

(Fig. 12).

(4) Remove the three latch retaining bolts.

(5) Grab the latch assembly and unhook the key

cylinder link rod from the key cylinder (Fig. 12).

(6) Place the latch assembly on a bench and locate

the three wires leading from the actuator portion of

the latch assembly.

(7) Disengage the main connector retaining push

pins from the latch actuator housing.

(8) Back the three wires out of the main latch elec-

trical connector.

(9) Flip the latch assembly over and remove the

latch actuator retaining screw(s).

(10) Remove the latch actuator from the latch

assembly.

INSTALLATION

(1) Install the latch actuator onto the latch assem-

bly.

(2) Install the three latch actuator retaining

screws.

(3) Install the three wires in the main latch elec-

trical connector.NOTE: Be certain wires are reinstalled in the correct

wire cavities. Failure to do so could result in dam-

age to the latch actuator. Refer to the appropriate

wiring information for complete circuit schematic or

connector pin-out information.

(4) Secure the main connector retaining push pins

on the latch actuator housing.

(5) Grab the latch assembly and hook the key cyl-

inder link rod on the key cylinder (Fig. 13).

(6) Position the latch and install three new latch

retaining bolts. Torque to 10 N´m (90 in. lbs.).

(7) Connect the power latch electrical connector

(Fig. 13).

(8) Install the lower liftgate trim panel, (Refer to

23 - BODY/DECKLID/HATCH/LIFTGATE/TAIL-

GATE/TRIM PANEL - INSTALLATION).

(9) Connect the battery negative cable.

(10) Using an appropriate scan tool, check and

erase any power liftgate control module diagnostic

trouble codes related to the power latch.

(11) Verify power liftgate system and power cinch /

release latch operation. Cycle the power liftgate

through one complete open and close cycle, this will

allow the power liftgate control module to relearn its

cycle with the new components.

(12) Verify power liftgate manual operation. Using

liftgate key rotate the lock cylinder to verify door

operation. Pull door open using exterior liftgate han-

dle / switch.

Fig. 12 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

Fig. 13 POWER LATCH ORIENTATION

1 - LATCH & ACTUATOR ASSEMBLY

2 - LATCH ELECTRICAL CONNECTOR

3 - LOCK CYLINDER LINK ROD

4 - LIFTGATE LOCK CYLINDER

8N - 14 POWER LIFTGATE SYSTEMRS

LATCH ACTUATOR (Continued)

Page 443 of 2339

POWER LOCKS

TABLE OF CONTENTS

page page

POWER LOCKS

DESCRIPTION.........................20

OPERATION...........................21

DOOR CYLINDER LOCK SWITCH - EXPORT

DESCRIPTION.........................22

OPERATION...........................22

DIAGNOSIS AND TESTING

DOOR CYLINDER LOCK SWITCH -

EXPORT............................22

REMOVAL.............................22

INSTALLATION.........................22

DOOR LOCK MOTOR

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR..................23

DOOR LOCK SWITCH

DIAGNOSIS AND TESTING

DOOR LOCK SWITCH..................23

REMOVAL.............................23INSTALLATION.........................23

KEYLESS ENTRY TRANSMITTER

DIAGNOSIS AND TESTING

KEYLESS ENTRY TRANSMITTER.........24

STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE........................24

STANDARD PROCEDURE - BATTERY

REPLACEMENT.......................24

STANDARD PROCEDURE - REMOTE

KEYLESS ENTRY TRANSMITTER

PROGRAMMING......................24

SPECIFICATIONS

SPECIFICATIONS - TRANSMITTER RANGE . 24

SPECIFICATIONS - BATTERY............24

SLIDING DOOR LOCK MOTOR

REMOVAL.............................25

INSTALLATION.........................25

POWER LOCKS

DESCRIPTION

POWER LOCKS

The power lock system allows all of the doors to be

locked or unlocked electrically by operating a switch

on either front door trim panel. The power lock sys-

tem receives non-switched battery current through a

fuse in the Integrated Power Module (IPM), so that

the power locks remain operational, regardless of the

ignition switch position.

The Body Control Module (BCM) locks the doors

automatically when the vehicle is driven beyond the

speed of 25.7 Km/h (15 mph), all doors are closed, the

accelerator pedal is depressed and the door lock actu-

ation had not been previously activated. The rolling

door lock feature is customer programmable.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences.

The power lock system for this vehicle can also be

operated remotely using the available Remote Key-

less Entry (RKE) system radio frequency transmit-

ters, if equipped.

AUTOMATIC DOOR LOCKS

When enabled, this feature will lock all of the door

locks if all of the doors are closed and the vehicle

speed goes above 25.7 km/h (15 mph). If a door

unlock has occurred, then the BCM will perform

another auto lock, if the doors did not electrically

unlock, another auto lock will not occur.

DOOR LOCK INHIBIT

When the key is in the ignition (in any switch posi-

tion) and either front door is opened, the door lock

switches LOCK functions are disabled. The

UN-LOCK functions are still functional. This protects

against locking the vehicle with the key still in the

ignition. The RKE key fob will still lock the doors.

After the key is removed from the ignition or the

doors are closed, the power door locks will operate

normally.

REMOTE KEYLESS ENTRY

The Remote Keyless Entry (RKE) system allows

the use of a remote battery-powered radio transmit-

ter to communicate with the BCM to actuate the

power lock system.

The RKE transmitters are also equipped with a

Panic button. If the Panic button on the RKE trans-

mitter is depressed, the horn will sound and the

exterior lights will flash on the vehicle for about

three minutes, or until the Panic button is depressed

8N - 20 POWER LOCKSRS

Page 444 of 2339

a second time. Pressing the Panic button also acti-

vates the courtesy lamps. Pressing the Panic button

again stops the exterior lamps from flashing and the

horn from sounding. However, the courtesy lamps

will remain illuminated until either the BCM times

out lamp operation or until the turning of the igni-

tion. The panic feature will operate if the ignition is

ON, but only if the Panic button is pressed prior to

starting the vehicle. A vehicle speed of about 25.7

km/h (15 miles-per-hour) will also cancel the panic

event.

The RKE system can also perform other functions

on this vehicle. If the vehicle is equipped with the

optional Vehicle Theft Security System (VTSS), the

RKE transmitter will arm the VTSS when the Lock

button is depressed, and disarm the VTSS when the

Unlock button is depressed.

The RKE system includes two transmitters when

the vehicle is shipped from the factory, but the sys-

tem can retain the vehicle access codes of up to a

total of eight transmitters. If an RKE transmitter is

inoperative or lost, new transmitter vehicle access

codes can be programmed into the system using a

DRB IIItscan tool.

This vehicle also offers several customer program-

mable features, which allows the selection of several

optional electronic features to suit individual prefer-

ences. Customer programmable feature options

affecting the RKE system include:

²Automatic Door Lock- Customer programma-

ble feature that allows the BCM to perform an auto-

matic door lock if the vehicle speed is above 25.7

km/h (15 miles-per-hour).

²Automatic Door Unlock On Exit- Customer

programmable feature that allows the BCM to per-

form an automatic door unlock if the vehicle speed is

0, vehicle in park and driver door is opened.

²Flash Lights with Lock and Unlock- Allows

the option of having the park lamps flash as an opti-

cal verification that the RKE system received a valid

Lock request or Unlock request from the RKE trans-

mitter, or having no optical verification.

²Programming Additional Transmitters-

Allows up to a total of four transmitter vehicle access

codes to be stored.

²Remote Unlock Sequence- Allows the option

of having only the driver side front door unlock when

the RKE transmitter Unlock button is depressed the

first time. The remaining doors unlock when the but-

ton is depressed a second time within 5 seconds of

the first unlock press. Another option is having all

doors unlock upon the first depression of the RKE

transmitter Unlock button.

²Sound Horn on Lock- Allows the option of

having the horn sound a short chirp as an audible

verification that the RKE system received a validLock request from the RKE transmitter, or having no

audible verification.

OPERATION

POWER LOCKS

The Body Control Module (BCM) locks or unlocks

the doors when an actuation input signal from a door

lock switch, Central Lock key cylinder or Remote

Keyless Entry (RKE) is received. The BCM turns on

the output drivers and provides a voltage level to the

door lock motor for a specified time.

REMOTE KEYLESS ENTRY

The RKE transmitter uses radio frequency signals

to communicate with the SKREEM module. The

SKREEM is on the PCI bus. When the operator

presses a button on the transmitter, it sends a spe-

cific request to the SKREEM. In turn, the SKREEM

sends the appropriate request over the PCI bus to

the following:

²Integrated Power Module (IPM)- to activate

the park lamps, the headlamps and the horn for the

horn chirp.

²Power Liftgate Module (PLGM)- to control

the liftgate lock and unlock functions.

After pressing the lock button on the RKE trans-

mitter, all of the door locks will lock, the illuminated

entry will turn off (if all doors are closed) and the

vehicle theft security system (if equipped) will arm.

Pressing the unlock button one time will unlock

the driver door, or all doors based on the customer

programmable feature enabled, the illuminated entry

will turn on the courtesy lamps and the vehicle theft

security system (if equipped) will disarm. Pressing

the unlock button a second time, the remaining door

locks will unlock.

If the vehicle is equipped with the memory system,

the memory message will identify which transmitter

(1 or 2) sent the signal.

ROLLING CODE

The rolling code feature changes part of the trans-

mitter message each time that it is used. The trans-

mitter message and the receiver message increment

together. Under certain conditions with a rolling code

system, such as pressing a button on the RKE trans-

mitter over 255 times outside of receiver range or

replacing the battery, the receiver and transmitter

can fall out of synchronization. To re-synchronize,

press and release the UNLOCK button on the RKE

transmitter repeatedly (it may take up to eight

cycles) while listening carefully for the power door

locks in the vehicle to cycle, indicating that resyn-

chronization has occurred.

RSPOWER LOCKS8N-21

POWER LOCKS (Continued)

Page 445 of 2339

The lock function works from the RKE transmitter

even in an out of synchronization condition, therefore

it could be verified by pressing the LOCK button on

the RKE key fob.

DOOR CYLINDER LOCK

SWITCH - EXPORT

DESCRIPTION

The Door Cylinder Lock Switch (If equipped) is

used to:

²Unlock/Lock all the doors via the Central Lock-

ing feature.

²Arm/Disarm the Vehicle Theft Security System.

²Trigger the Illuminated Entry feature.

The door cylinder lock switch is mounted to the

rear of the driver door lock cylinder. When installed

on the rear of the cylinder, there is a tab on the lock

cylinder that aligns with the switch to prevent it

from turning. An anti-rotating device. The door cylin-

der lock switch is a one time use switch. Once it is

removed from the rear of the door lock cylinder, it

may not be reinstalled and a new switch must be

used.

OPERATION

When the Door Cylinder Lock Switch is turned

either way using the door key cylinder, the BCM

reads a direct message signal from the switch.

If turning the key cylinder once, toward the front

of the vehicle, this will:

(1) Mechanically unlock the door lock.

(2) Disarm the Vehicle Theft Security System (if

equipped).

(3) Turn on the Illuminated Entry (if equipped) for

approximately 30 seconds.

If the key cylinder is turned to the unlock position

(toward the front of vehicle) twice within two sec-

onds, all the doors and liftgate will unlock (if

equipped with the central locking feature).

To lock the vehicle using the door cylinder lock

switch, turn the key cylinder toward the rear of the

vehicle once. This will lock the door that you are

using the key on. If equipped with the central locking

feature, this will lock all the other doors and liftgate.

Furthermore, this will arm the vehicle theft security

system and turn off the illuminated entry.

DIAGNOSIS AND TESTING

DOOR CYLINDER LOCK SWITCH - EXPORT

Any diagnosis of the power lock system

should begin with the use of the DRB IIItdiag-

nostic tool. For information on the use of theDRB IIIt, refer to the appropriate Diagnostic

Service Manual.

For complete circuit diagrams, refer to the appro-

priate wiring information.

(1) Visually inspect the switch for proper installa-

tion. Make sure it is seated on the rear of the key

cylinder, with the tab of the door key cylinder prop-

erly aligned with the slot on the door cylinder lock

switch.

(2) Disconnect the switch at the harness connector

and check the resistance in each switch position.

CAUTION: Do not disconnect the switch from the

rear of the door key cylinder. This switch is a one

time use switch. Once it is removed from the rear of

the switch, it is not reusable and must be replaced.

Test the switch at the harness connector.

DOOR CYLINDER LOCK SWITCH RESISTANCE

SWITCH POSITION RESISTANCE VALUE

COUNTERCLOCKWISE 5.4K OHMS

NEUTRAL 18.4K OHMS

CLOCKWISE 2K OHMS

REMOVAL

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the door trim panel of the effected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - REMOVAL).

(3) Close the door window.

(4) Disconnect the door cylinder lock switch wire

connector from the door harness, and wiring clip

from the impact beam.

(5) Remove the outer door handle from the door.

(6) Remove the switch from the key cylinder in the

door handle and remove from vehicle.

INSTALLATION

(1) Install the switch on the key cylinder in the

door handle.

(2) Install the door handle.

(3) Connect the door cylinder lock switch wire con-

nector to the door harness, and the wiring clip to the

impact beam.

(4) Install the door trim panel of the affected door

cylinder lock switch (Refer to 23 - BODY/DOOR -

FRONT/TRIM PANEL - INSTALLATION).

(5) Connect the battery negative cable.

(6) Verify system operation.

8N - 22 POWER LOCKSRS

POWER LOCKS (Continued)

Page 447 of 2339

KEYLESS ENTRY

TRANSMITTER

DIAGNOSIS AND TESTING

KEYLESS ENTRY TRANSMITTER

Using special tool 9001, first test to ensure that

the transmitter is functioning. Typical testing dis-

tance is 2.5 centimeters (1 inch) for Asian transmit-

ters and 30.5 centimeters (12 inches) for all others.

To test, position the transmitter as shown (Fig. 2).

Press any transmitter button, then test each button

individually. The tool will beep if a radio signal

strength that lights five or more LED's is detected.

Repeat this test three times. If transmitter fails any

of the test, refer to the Diagnostic Procedures man-

ual.

STANDARD PROCEDURE

STANDARD PROCEDURE - HORN CHIRP

PREFERENCE

DISABLING

The horn chirp can be toggled using a DRB IIItor

by using a programmed Remote Keyless Entry (RKE)

transmitter.

To DISABLE (cancelling) the horn chirp feature,

press and hold the transmitter LOCK button for a

minimum of five seconds. While pressing the LOCK

button in, press the PANIC button. The horn chirp

feature will not function until the above procedure is

repeated.

ENABLING

The horn chirp can be toggled using a DRB IIItor

by using the Remote Keyless Entry (RKE) transmit-

ter.

To ENABLE (reinstate) the horn chirp feature, use

any one of the four programmed integrated key/key

fob transmitters and reverse the above procedures. It

will ENABLE the horn chirp feature for all transmit-

ters.

STANDARD PROCEDURE - BATTERY

REPLACEMENT

(1) With the transmitter buttons facing down, use

a coin to pry the two halves of the transmitter apart.

Make sure not to damage the rubber gasket during

separation of the housing halves.

(2) Remove the battery from the transmitter back

housing holder.

(3) Replace the batteries. Avoid touching the new

batteries with your fingers, Skin oils may cause bat-

tery deterioration. If you touch a battery, clean it off

with rubbing alcohol.

(4) To assemble the transmitter case, snap the two

halves together.

STANDARD PROCEDURE - REMOTE KEYLESS

ENTRY TRANSMITTER PROGRAMMING

(Refer to 8 - ELECTRICAL/VEHICLE THEFT

SECURITY/TRANSPONDER KEY - STANDARD

PROCEDURE) for programming procedures.

SPECIFICATIONS

SPECIFICATIONS - TRANSMITTER RANGE

Normal operation range is up to a distance of 7

meters (23 ft.) of the vehicle. Range may be better or

worse depending on the environment around the

vehicle.

SPECIFICATIONS - BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiva-

lent, TWO cells are required. Battery life is about

three years minimum.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

Fig. 2 TRANSMITTER DIAGNOSIS - TYPICAL

8N - 24 POWER LOCKSRS

Page 455 of 2339

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for more information on the heated

seat option. (Refer to 8 - ELECTRICAL/POWER

SEATS - DESCRIPTION - MEMORY SEAT SYS-

TEM) for more information on the memory seat sys-

tem.

The power seat system includes the following com-

ponents:

²Power seat recliners

²Power seat switches

²Power seat tracks

²Circuit breaker

The power seat system with memory and heated

seat options includes the following components:

²Power seat recliner

²Power seat switch

²Power seat track.

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Heated Seat Module (HSM)

²Heated seat switch

²Electronic Vehicle Information Center (EVIC)

MEMORY SYSTEM

The memory system is able to store and recall the

driver side power seat positions (including the power

recliner position), power adjustable pedal positions

and the driver outside mirror position for two driv-

ers. On vehicles equipped with a factory radio, the

memory system is also able to store and recall radio

station presets for two drivers. The memory system

also will store and recall the last station listened to

for each driver, even if it is not one of the preset sta-

tions.

The memory system will automatically return to

its preset settings when the corresponding numbered

button of the memory switch is depressed, or when

the doors are unlocked using the corresponding

Remote Keyless Entry (RKE) transmitter. A customer

programmable feature of the memory system allows

the RKE recall of memory features to be disabled, if

desired. This programmable feature is internal in the

Electronic Vehicle Information Center (EVIC) mod-

ule, which is located in the overhead console.

A Memory Seat Mirror Module (MSMM) is used to

control and integrate the many electronic functions

and features included in the memory seat and mirror

systems.

The memory system includes the following compo-

nents:

²Memory Seat Mirror Module (MSMM)

²Memory set switch

²Position potentiometers on the driver outside

side view mirror

²Position potentiometers on the power adjustable

pedal motor²Position potentiometers on the driver side power

seat track and power seat recliner motors

²Electronic Vehicle Information Center (EVIC)

²Radio receiver (if PCI data bus capable)

Certain functions of the memory system rely upon

resources shared with other electronic modules in the

vehicle over the Programmable Communications

Interface (PCI) data bus network. Initial diagnosis of

these electronic modules or the PCI data bus network

requires the use of a DRBIIItor equivalent scan tool

and the proper Diagnostic Procedures information. If

this method does not prove conclusive, the proper

wiring schematics and the service manual diagnostic

information are required.

The other electronic modules that may affect mem-

ory system operation are:

²Body Control Module (BCM)- (Refer to 8 -

ELECTRICAL/ELECTRONIC CONTROL MOD-

ULES/BODY CONTROL/CENTRAL TIMER MODUL

- DESCRIPTION) for additional information.

²Powertrain Control Module (PCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/POWERTRAIN CONTROL MODULE -

DESCRIPTION) for additional information.

²Transmission Control Module (TCM)- (Refer

to 8 - ELECTRICAL/ELECTRONIC CONTROL

MODULES/TRANSMISSION CONTROL MODULE -

DESCRIPTION) for additional information.

(Refer to 8 - ELECTRICAL/HEATED SEATS -

DESCRIPTION) for additional information on the

heated seat system. (Refer to 8 - ELECTRICAL/

POWER LOCKS - DESCRIPTION) for additional

information on the RKE system.

OPERATION

POWER SEAT SYSTEM

The power seat system receives battery current

through fuse #22 in the Integrated Power Module

(IPM) and a circuit breaker under the front seats,

regardless of the ignition switch position.

When a power seat switch control knob or knobs

are actuated, a battery feed and a ground path are

applied through the switch contacts to the appropri-

ate power seat track adjuster motor. The selected

adjuster motor operates to move the seat track

through its drive unit in the selected direction until

the switch is released, or until the travel limit of the

seat track is reached. When the switch is moved in

the opposite direction, the battery feed and ground

path to the motor are reversed through the switch

contacts. This causes the adjuster motor to run in the

opposite direction.

No power seat switch should be held applied in any

direction after the seat track has reached its travel

limit. The power seat adjuster motor each contain a

8N - 32 POWER SEAT SYSTEMRS

POWER SEAT SYSTEM (Continued)

Page 463 of 2339

POWER SLIDING DOOR SYSTEM

TABLE OF CONTENTS

page page

POWER SLIDING DOOR SYSTEM

DESCRIPTION.........................40

OPERATION...........................41

DIAGNOSIS AND TESTING

POWER SLIDING DOOR SYSTEM........42

STANDARD PROCEDURE

POWER SLIDING DOOR LEARN CYCLE....48

PUSH-PIN GROMMET REPLACEMENT.....48

POWER SLIDING DOOR ADJUSTMENT....49

LATCH

DESCRIPTION.........................49

OPERATION...........................49

REMOVAL.............................49

INSTALLATION.........................50

SLIDING DOOR MOTOR

DESCRIPTION.........................51

OPERATION...........................51

REMOVAL.............................51

INSTALLATION.........................51

FULL OPEN SWITCH

DESCRIPTION.........................52

OPERATION...........................52

B-PILLAR SWITCH

DESCRIPTION.........................52OPERATION...........................52

REMOVAL.............................52

INSTALLATION.........................52

LOWER DRIVE UNIT

DESCRIPTION.........................53

OPERATION...........................53

REMOVAL.............................53

INSTALLATION.........................54

FLEX DRIVE

DESCRIPTION.........................55

OPERATION...........................55

REMOVAL.............................55

INSTALLATION.........................56

LOWER DRIVE UNIT TRACK & RACK

DESCRIPTION.........................57

OPERATION...........................57

REMOVAL.............................57

INSTALLATION.........................58

WIRING HARNESS

DESCRIPTION.........................59

OPERATION...........................59

REMOVAL.............................59

INSTALLATION.........................59

POWER SLIDING DOOR

SYSTEM

DESCRIPTION

Some vehicles are equipped with a power sliding

door system. Vehicles may be equipped with only a

right side power sliding door or a right and left side

power sliding doors. The components of the power

sliding door system are:

²Door motor assembly

²Latch assembly

²Sliding door control module

²Lower drive unit assembly

²Flex drive assembly

²Wire harness and track

²Lower drive unit track and rack assembly

²Full open switch

²B-pillar switch

²Overhead console switch

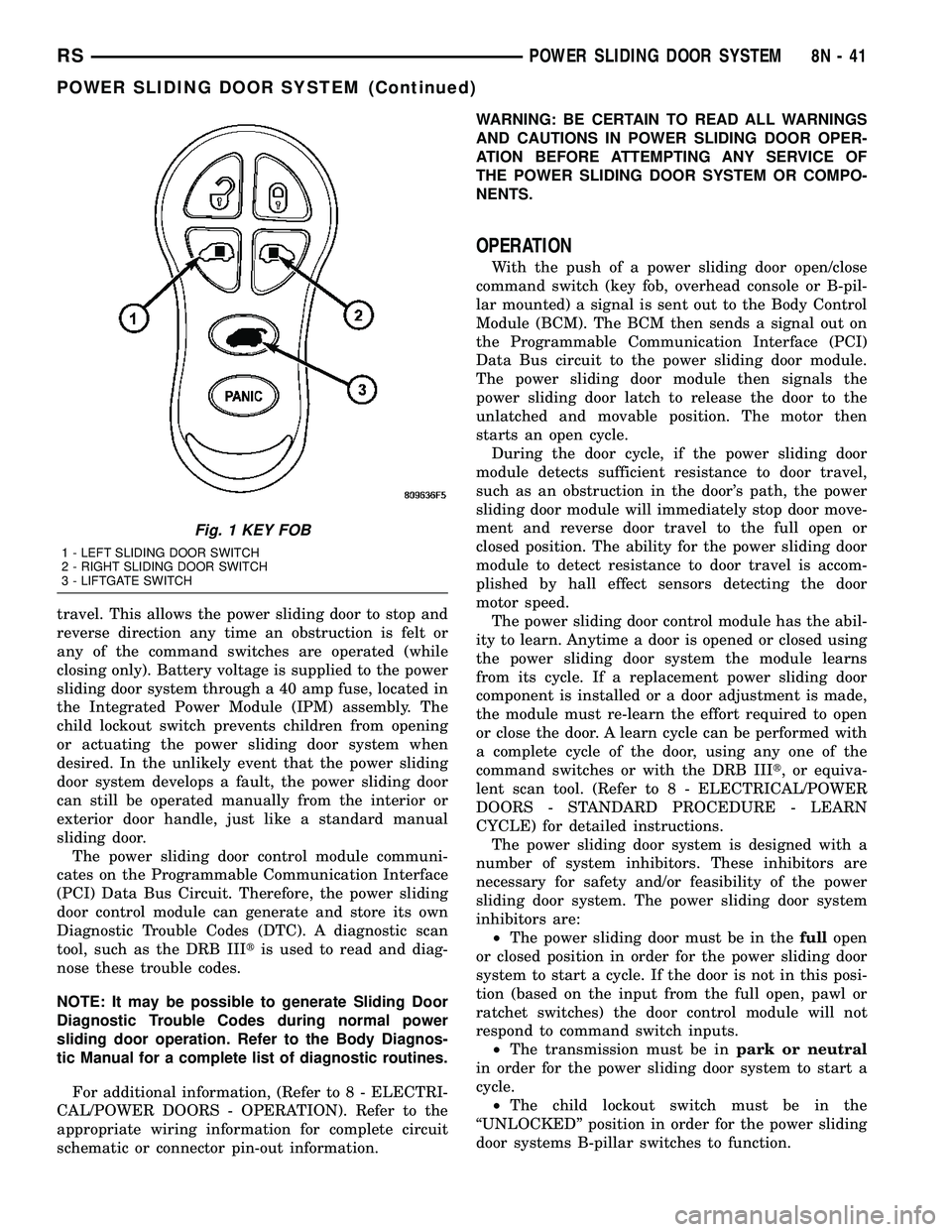

²Key fob switches (Fig. 1)

²Pawl switch

²Ratchet switch

²Child lockout and handle switchesEach power sliding door has its own door control

module, located in the center of the door behind the

door trim panel. (Refer to 8 - ELECTRICAL/ELEC-

TRONIC CONTROL MODULES/DOOR CONTROL

MODULE - DESCRIPTION) The power sliding door

motor is located in the front portion of the door, on

the inner door panel sheet metal. The latch assembly

is located in the rear of the power sliding door, near

the body line. The lower drive unit is attached to the

lower door hinge. The flex drive assembly connects

the door motor to the lower drive unit. The wire har-

ness and track and the lower drive unit track are vis-

ible with the door open in the lower door sill area.

The power sliding door full open switch is located

under the lower drive unit and is part of the hold

open latch assembly. The pawl, ratchet, handle and

child lockout switches are all located on the power

sliding door latch assembly. The B-pillar switch is an

open and close command switch located on the inte-

rior B-pillar trim. The overhead console switch, is an

open and close command switch located in the vehi-

cle's overhead console.

Software technology has enabled the power sliding

door control module to detect resistance to door

8N - 40 POWER SLIDING DOOR SYSTEMRS

Page 464 of 2339

travel. This allows the power sliding door to stop and

reverse direction any time an obstruction is felt or

any of the command switches are operated (while

closing only). Battery voltage is supplied to the power

sliding door system through a 40 amp fuse, located in

the Integrated Power Module (IPM) assembly. The

child lockout switch prevents children from opening

or actuating the power sliding door system when

desired. In the unlikely event that the power sliding

door system develops a fault, the power sliding door

can still be operated manually from the interior or

exterior door handle, just like a standard manual

sliding door.

The power sliding door control module communi-

cates on the Programmable Communication Interface

(PCI) Data Bus Circuit. Therefore, the power sliding

door control module can generate and store its own

Diagnostic Trouble Codes (DTC). A diagnostic scan

tool, such as the DRB IIItis used to read and diag-

nose these trouble codes.

NOTE: It may be possible to generate Sliding Door

Diagnostic Trouble Codes during normal power

sliding door operation. Refer to the Body Diagnos-

tic Manual for a complete list of diagnostic routines.

For additional information, (Refer to 8 - ELECTRI-

CAL/POWER DOORS - OPERATION). Refer to the

appropriate wiring information for complete circuit

schematic or connector pin-out information.WARNING: BE CERTAIN TO READ ALL WARNINGS

AND CAUTIONS IN POWER SLIDING DOOR OPER-

ATION BEFORE ATTEMPTING ANY SERVICE OF

THE POWER SLIDING DOOR SYSTEM OR COMPO-

NENTS.

OPERATION

With the push of a power sliding door open/close

command switch (key fob, overhead console or B-pil-

lar mounted) a signal is sent out to the Body Control

Module (BCM). The BCM then sends a signal out on

the Programmable Communication Interface (PCI)

Data Bus circuit to the power sliding door module.

The power sliding door module then signals the

power sliding door latch to release the door to the

unlatched and movable position. The motor then

starts an open cycle.

During the door cycle, if the power sliding door

module detects sufficient resistance to door travel,

such as an obstruction in the door's path, the power

sliding door module will immediately stop door move-

ment and reverse door travel to the full open or

closed position. The ability for the power sliding door

module to detect resistance to door travel is accom-

plished by hall effect sensors detecting the door

motor speed.

The power sliding door control module has the abil-

ity to learn. Anytime a door is opened or closed using

the power sliding door system the module learns

from its cycle. If a replacement power sliding door

component is installed or a door adjustment is made,

the module must re-learn the effort required to open

or close the door. A learn cycle can be performed with

a complete cycle of the door, using any one of the

command switches or with the DRB IIIt, or equiva-

lent scan tool. (Refer to 8 - ELECTRICAL/POWER

DOORS - STANDARD PROCEDURE - LEARN

CYCLE) for detailed instructions.

The power sliding door system is designed with a

number of system inhibitors. These inhibitors are

necessary for safety and/or feasibility of the power

sliding door system. The power sliding door system

inhibitors are:

²The power sliding door must be in thefullopen

or closed position in order for the power sliding door

system to start a cycle. If the door is not in this posi-

tion (based on the input from the full open, pawl or

ratchet switches) the door control module will not

respond to command switch inputs.

²The transmission must be inpark or neutral

in order for the power sliding door system to start a

cycle.

²The child lockout switch must be in the

ªUNLOCKEDº position in order for the power sliding

door systems B-pillar switches to function.

Fig. 1 KEY FOB

1 - LEFT SLIDING DOOR SWITCH

2 - RIGHT SLIDING DOOR SWITCH

3 - LIFTGATE SWITCH

RSPOWER SLIDING DOOR SYSTEM8N-41

POWER SLIDING DOOR SYSTEM (Continued)