wheel torque CHRYSLER CARAVAN 2005 Workshop Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 338 of 2339

CONDITION POSSIBLE CAUSE CORRECTION

2. STARTING CIRCUIT

WIRING FAULTY.2. REFER TO THE FEED CIRCUIT RESISTANCE TEST AND

THE FEED CIRCUIT TEST IN THIS SECTION. REPAIR AS

NECESSARY.

3. STARTER ASSEMBLY

FAULTY.3. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

4. ENGINE SEIZED. 4. REFER TO THE ENGINE SECTION, FOR DIAGNOSTIC AND

SERVICE PROCEDURES.

5. LOOSE

CONNECTION AT

BATTERY, PDC,

STARTER, OR ENGINE

GROUND.5. INSPECT FOR LOOSE CONNECTIONS.

6. FAULTY TEETH ON

RING GEAR.6. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

STARTER

ENGAGES,

SPINS OUT

BEFORE

ENGINE

STARTS.1. BROKEN TEETH ON

STARTER RING GEAR.1. REMOVE STARTER. INSPECT RING GEAR AND REPLACE

IF NECESSARY.

2. STARTER ASSEMBLY

FAULTY.2. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

STARTER DOES

NOT

DISENGAGE.1. STARTER

IMPROPERLY

INSTALLED.1. INSTALL STARTER. TIGHTEN STARTER MOUNTING

HARDWARE TO CORRECT TORQUE SPECIFICATIONS.

2. STARTER RELAY

FAULTY.2. REFER TO RELAY TEST, IN THIS SECTION. REPLACE

RELAY, IF NECESSARY.

3. IGNITION SWITCH

FAULTY.3. REFER TO IGNITION SWITCH TEST, IN THE STEERING

SECTION. REPLACE SWITCH, IF NECESSARY.

4. STARTER ASSEMBLY

FAULTY.4. IF ALL OTHER STARTING SYSTEM COMPONENTS AND

CIRCUITS CHECK OK, REPLACE STARTER ASSEMBLY.

5. FAULTY TEETH ON

RING GEAR.5. ROTATE FLYWHEEL 360É, AND INSPECT TEETH AND RING

GEAR REPLACED IF DAMAGED.

DIAGNOSIS AND TESTING - CONTROL

CIRCUIT TEST

The starter control circuit has:

²Starter motor with integral solenoid

²Starter relay

²Transmission range sensor, or Park/Neutral

Position switch with automatic transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Powertrain Control Module (PCM)

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for the proper relay location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED. THIS MAY RESULT IN

PERSONAL INJURY OR DEATH.

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

RSSTARTING8F-33

STARTING (Continued)

Page 371 of 2339

INSTALLATION - 3.3/3.8L

(1) Install coil over studs on bracket.

(2) Install 2 nuts to the ignition coil studs. Tighten

nuts and bolts.

(3) Connect the electrical connector to the ignition

coil.

(4) Install the ignition cables to the ignition coil.

(5) Reposition the Power steering reservoir. Slide

bracket over the mounting stud (Fig. 11).

(6) Install 2 bolts to the Power steering reservoir

to intake manifold.

(7) Tighten the lower nut to stud on ignition coil

bracket.

(8) Install the throttle and speed control cables to

clip.

(9) Connect the negative battery cable.

KNOCK SENSOR

DESCRIPTION

The knock sensor threads into the cylinder block.

The knock sensor is designed to detect engine vibra-

tion that is caused by detonation.

OPERATION

When the knock sensor detects a knock in one of

the cylinders, it sends an input signal to the PCM. In

response, the PCM retards ignition timing for all cyl-

inders by a scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increases, the

knock sensor output voltage also increases.

The voltage signal produced by the knock sensor

increases with the amplitude of vibration. The PCM

receives as an input the knock sensor voltage signal.

If the signal rises above a predetermined level, the

PCM will store that value in memory and retard

ignition timing to reduce engine knock. If the knock

sensor voltage exceeds a preset value, the PCM

retards ignition timing for all cylinders. It is not a

selective cylinder retard.

The PCM ignores knock sensor input during engine

idle conditions. Once the engine speed exceeds a

specified value, knock retard is allowed.

Knock retard uses its own short term and long

term memory program.

Long term memory stores previous detonation

information in its battery-backed RAM. The maxi-

mum authority that long term memory has over tim-

ing retard can be calibrated.

Short term memory is allowed to retard timing up

to a preset amount under all operating conditions (as

long as rpm is above the minimum rpm) except WOT.The PCM, using short term memory, can respond

quickly to retard timing when engine knock is

detected. Short term memory is lost any time the

ignition key is turned off.

NOTE: Over or under tightening affects knock sen-

sor performance, possibly causing improper spark

control.

REMOVAL

REMOVAL - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Disconnect electrical connector from knock sen-

sor.

(2) Use a crow foot socket to remove the knock

sensors.

REMOVAL - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Disconnect the negative battery cable.

(2) Raise vehicle and support.

(3) On All Wheel Drive vehicles remove the PTU

(Power Transfer Unit), refer to the Transmission sec-

tion for more information.

(4) Disconnect electrical connector from knock sen-

sor.

(5) Use a crow foot socket to remove the knock

sensor.

INSTALLATION

INSTALLATION - 2.4L

The knock sensor threads into the side of the cyl-

inder block in front of the starter (Fig. 12).

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

INSTALLATION - 3.8L

The knock sensor threads into the side of the cyl-

inder block in the rear.

(1) Install knock sensor. Tighten knock sensor to

10 N´m (7 ft. lbs.) torque.Over or under tighten-

ing effects knock sensor performance, possibly

causing improper spark control.

(2) Attach electrical connector to knock sensor.

(3) On All Wheel Drive vehicles install the PTU

(Power Transfer Unit) for the rear wheels, refer to

the Transmission section for more information.

8I - 8 IGNITION CONTROLRS

IGNITION COIL (Continued)

Page 499 of 2339

(12) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(13) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(14) Connect the 2±way connector to the remote

radio control harness.

(15) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING). Personal injury or

death may result if the system test is not performed

properly.

REMOVAL

(1) Position steering wheel and front wheels

straight ahead.

(2) Release hood latch and open hood.

(3) Disconnect and isolate the battery negative

cable.

(4)

WARNING: Wait two minutes for the airbag system

reserve capacitor to discharge before beginning

any airbag system or component service. Failure to

do so may result in accidental airbag deployment,

personal injury or death.

(5) Remove driver airbag from steering wheel

(Refer to 8 - ELECTRICAL/RESTRAINTS/DRIVER

AIRBAG - REMOVAL).

(6) Disconnect wire connectors from back of driver

airbag.

(7) Disconnect the 2±way connector from remote

radio control harness.

(8) Disconnect the 4±way harness connector from

the speed control/horn harness to the clockspring.

(9) Remove steering wheel (Refer to 19 - STEER-

ING/COLUMN/STEERING WHEEL - REMOVAL).

(10) Remove steering column shrouds and discon-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - REMOVAL).

(11) Disconnect 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(12) Remove clockspring from column assembly by

removing the two retaining screws that attach the

clock spring to the column.

INSTALLATION

(1) Install the clockspring on the column.

(2) Connect the 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(3) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(4) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(5) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(6) Connect the 2±way connector to the remote

radio control harness (if equipped).

(7) Install the driver airbag (Refer to 8 - ELEC-

TRICAL/RESTRAINTS/DRIVER AIRBAG - INSTAL-

LATION). Torque the two screws to 10 N´m (90 in.

lbs.).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

CURTAIN AIRBAG

DESCRIPTION

Curtain Airbags (Fig. 11) are available when it is

also equipped with dual front airbags. These airbags

are passive and inflatable, Supplemental Restraint

System (SRS) components, and vehicles with this

equipment can be readily identified by a molded

identification trim button with the ªSRS - AIRBAGº

logo (Fig. 12) located on the B-pillar and C-pillar

upper trim panels. This system is designed to reduce

injuries to the vehicle occupants in the event of a

side impact collision.

Curtain airbags have two individually controlled

curtain airbag units. These airbag units are con-

cealed and mounted above the headliner where they

are each secured to one of the roof side rails (Fig.

13). Each airbag cushion is contained within a fabric

wrap that extends along the roof rail from the A-pil-

lar at the front of the vehicle to just behind the

D-pillar at the rear of the vehicle. One tether extends

down the A-pillar from the front of the airbag cush-

ion, and a second tether extends to the roof rail at

the D-pillar. The end of the A-pillar tether is secured

to a slot in the sheet metal with a metal hook

retained by a bolt. The D-pillar tether is attached to

the d-pillar.

8O - 12 RESTRAINTSRS

CLOCKSPRING (Continued)

Page 505 of 2339

INSTALLATION

DEPLOYED AIRBAG

(1) Perform clean up procedure (Refer to 8 - ELEC-

TRICAL/RESTRAINTS - STANDARD PROCEDURE

- SERVICE AFTER AN AIRBAG DEPLOYMENT).

(2) Install a new steering column assembly and

lower steering column coupler (Refer to 19 - STEER-

ING/COLUMN - INSTALLATION).

(3) Install the new clockspring.

(4) Connect the 4-way and 6-way connectors

between the clockspring and the instrument panel

wiring harness.

(5) Install the steering column shrouds and con-

nect traction control wire connector (if equipped)

(Refer to 19 - STEERING/COLUMN/LOWER

SHROUD - INSTALLATION).

(6) Install the steering wheel (Refer to 19 -

STEERING/COLUMN/STEERING WHEEL -

INSTALLATION).

(7) Connect the 4±way harness connector to the

speed control/horn harness to the clockspring.

(8) Connect the 2±way connector to the remote

radio control harness.

(9) Install the driver airbag and the two screws

retaining the airbag. Tighten screws to 10 N´m (90

in. lbs.)

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

UNDEPLOYED AIRBAG

(1) Connect the harness connector on the driver

airbag trim cover (horn, speed controls) to the clock-

spring.

(2) Connect the squib connectors to the driver air-

bag.

(3) Position the driver airbag into the steering

wheel.

(4) Install the two screws retaining the airbag.

Tighten screws to 10 N´m (90 in. lbs.)

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

IMPACT SENSOR

DESCRIPTION

FRONT IMPACT SENSORS

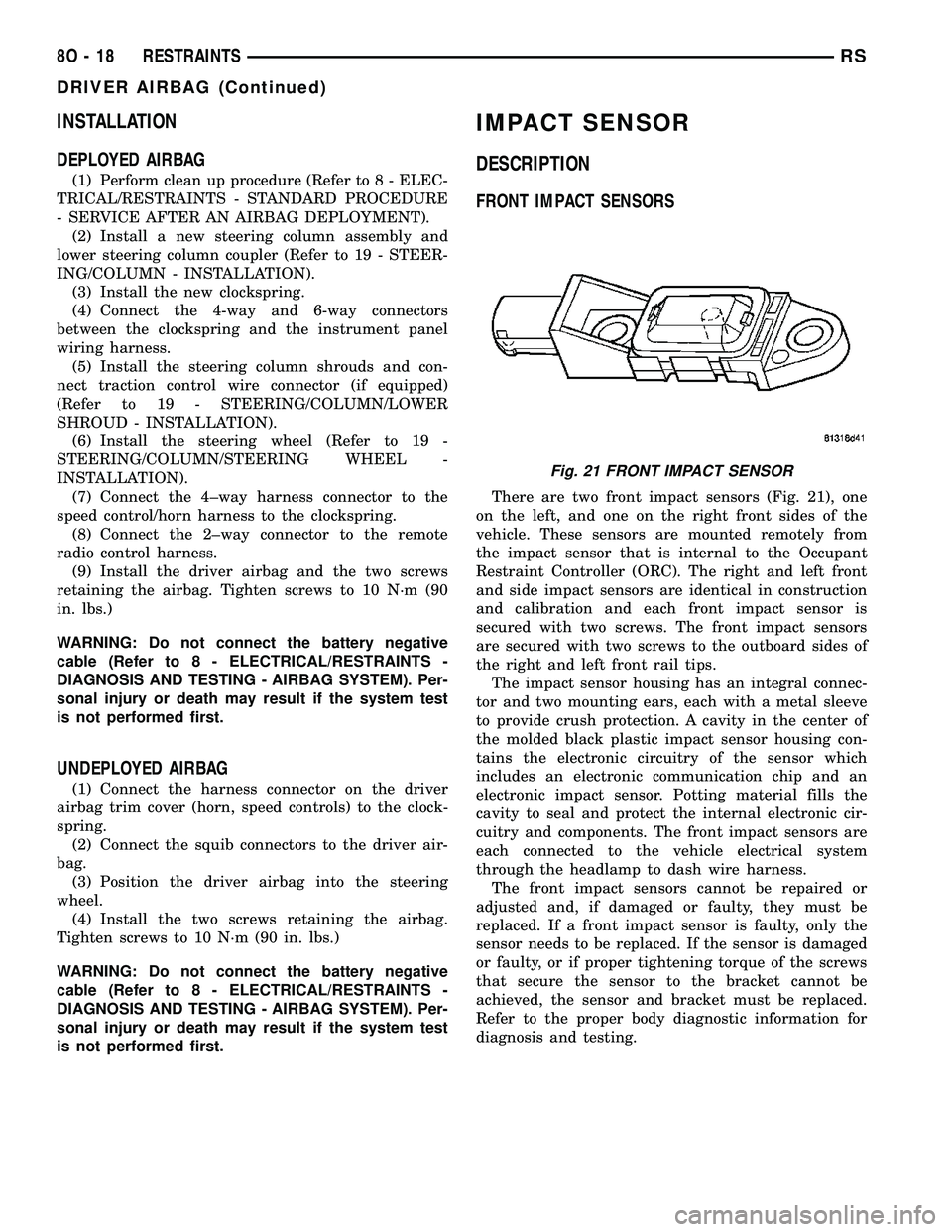

There are two front impact sensors (Fig. 21), one

on the left, and one on the right front sides of the

vehicle. These sensors are mounted remotely from

the impact sensor that is internal to the Occupant

Restraint Controller (ORC). The right and left front

and side impact sensors are identical in construction

and calibration and each front impact sensor is

secured with two screws. The front impact sensors

are secured with two screws to the outboard sides of

the right and left front rail tips.

The impact sensor housing has an integral connec-

tor and two mounting ears, each with a metal sleeve

to provide crush protection. A cavity in the center of

the molded black plastic impact sensor housing con-

tains the electronic circuitry of the sensor which

includes an electronic communication chip and an

electronic impact sensor. Potting material fills the

cavity to seal and protect the internal electronic cir-

cuitry and components. The front impact sensors are

each connected to the vehicle electrical system

through the headlamp to dash wire harness.

The front impact sensors cannot be repaired or

adjusted and, if damaged or faulty, they must be

replaced. If a front impact sensor is faulty, only the

sensor needs to be replaced. If the sensor is damaged

or faulty, or if proper tightening torque of the screws

that secure the sensor to the bracket cannot be

achieved, the sensor and bracket must be replaced.

Refer to the proper body diagnostic information for

diagnosis and testing.

Fig. 21 FRONT IMPACT SENSOR

8O - 18 RESTRAINTSRS

DRIVER AIRBAG (Continued)

Page 508 of 2339

WARNING: Wait two minutes for the system reserve

capacitor to discharge before beginning any airbag

component service. Personal injury or death may

result.

(3) Open sliding door to the fullest open position.

(4) Remove the two retaining screws to the impact

sensor (Fig. 27).

(5) Disconnect the electrical connector from the

impact sensor and remove from vehicle (Fig. 27).

QUARTER PANEL MOUNTED

(1) Open hood, disconnect and isolate the battery

negative cable.

(2)

WARNING: Wait two minutes for the system reserve

capacitor to discharge before beginning any airbag

component service. Personal injury or death may

result.

(3) Remove the quarter trim panel for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/QUARTER

TRIM PANEL - REMOVAL).

(4) Remove the two retaining screws to the impact

sensor (Fig. 28).

(5) Disconnect the electrical connector from the

impact sensor and remove from vehicle (Fig. 28).

INSTALLATION

FRONT IMPACT SENSOR

(1) Position sensor in vehicle (Fig. 24).

(2) Install the two retaining screws to the impact

sensor (Fig. 24). Torque screws to 7 N´m (62 in. lbs.).

(3) Connect electrical connector (Fig. 24).

(4) Lower vehicle from hoist.

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

SIDE IMPACT SENSORS

B-PILLAR MOUNTED

(1) Position sensor bracket in vehicle (Fig. 25).

(2) Install the four retaining screws to the impact

sensor bracket (Fig. 25). Torque screws to 7 N´m (62

in. lbs.).

(3) Connect the electrical connector (Fig. 25).

(4) Install the B-pillar lower trim for the side of

the vehicle that you are replacing the side impact

sensor (Refer to 23 - BODY/INTERIOR/B-PILLAR

LOWER TRIM - INSTALLATION).

Fig. 27 2ND ROW SIDE IMPACT SENSOR

1 - 2ND ROW SIDE IMPACT SENSOR ELECTRICAL CONNECTOR

2 - 2ND ROW SIDE IMPACT SENSOR RETAINING SCREWS

3 - SLIDING DOOR LOWER ROLLER ARM

Fig. 28 3RD ROW SIDE IMPACT SENSOR

1 - 3RD ROW SIDE IMPACT SENSOR

2 - 3RD ROW SIDE IMPACT SENSOR MOUNTING SCREWS

3 - REAR SPEAKER

4 - REAR WHEEL WELL

RSRESTRAINTS8O-21

IMPACT SENSOR (Continued)

Page 517 of 2339

WARNING: Never replace both the Occupant

Restraint Controller (ORC) and the Occupant Clas-

sification Module (OCM) at the same time. If both

require replacement, replace one, then perform the

Airbag System test (Refer to 8 - ELECTRICAL/RE-

STRAINTS - DIAGNOSIS AND TESTING - AIRBAG

SYSTEM) before replacing the other. Both the ORC

and the OCM store Occupant Classification System

(OCS) calibration data, which they transfer to one

another when one of them is replaced. If both are

replaced at the same time, an irreversible fault will

be set in both modules and the OCS may malfunc-

tion and result in personal injury or death.

(1) Install the ORC into vehicle (Fig. 39).

(2) Connect the wire connector to the ORC (Fig.

39).

(3) Install three bolts holding ORC to floor bracket

(Fig. 39). Torque bolts to 7.3 - 9.6 N´m (65 to 85 in.

lbs.)

(4) Install the storage bin onto the instrument

panel (Refer to 23 - BODY/INSTRUMENT PANEL/

STORAGE BIN - INSTALLATION).

WARNING: Do not connect the battery negative

cable (Refer to 8 - ELECTRICAL/RESTRAINTS -

DIAGNOSIS AND TESTING - AIRBAG SYSTEM). Per-

sonal injury or death may result if the system test

is not performed first.

(5) Verify vehicle and system operation.

(6) Close hood.

PASSENGER AIRBAG

DESCRIPTION

WARNING: Never disassemble the passenger air-

bag. The passenger airbag has no serviceable

parts. If tampered with internally, the airbag could

deploy and result in personal injury or death.

The Passenger Airbag is located beneath the

instrument panel and pad assembly. The airbag is

mounted to the back side of the instrument panel

reinforcement.

The instrument panel top pad is the most visible

part of the passenger airbag system. Located under

the instrument panel top pad are the airbag door, the

passenger airbag cushion and the airbag cushion

supporting components.

The passenger airbag includes a magnesium hous-

ing within which the cushion and inflator are

mounted and sealed.

Following a passenger airbag deployment, the pas-

senger airbag and the instrument panel must bereplaced. The passenger airbag cannot be repaired,

and must be replaced if deployed or damaged in any

way.

OPERATION

The passenger airbag is equipped with two infla-

tors, each with three levels of pressure output. The

inflators seal the hole in the airbag cushion so it can

discharge the gas it produces directly into the cush-

ion when supplied with the proper electrical signal.

Following an airbag deployment, the airbag cushion

quickly deflates by venting this gas through the

cushion material towards the instrument panel.

The passenger airbag is secured with screws to the

instrument panel beneath the instrument panel top

pad and above the glove box opening. The instrument

panel top pad above the glove box opening conceals

the airbag door and a predetermined hinge line

beneath its decorative cover. Upon airbag deploy-

ment, the top pad will bend at the hinge line and the

door will fold back out of the way onto the top of the

instrument panel.

When the front airbag system is deployed, the fol-

lowingMUSTbe replaced:

²Complete Steering Column Assembly.

²Lower Steering Column Coupler.

²Steering Wheel.

²Clock Spring.

²Driver Airbag.

²Passenger Airbag.

²Upper Instrument Panel with Pad.

CARE OF UNDEPLOYED AIRBAGS

Airbags must be stored in their original special

container until used for service. At no time should a

source of electricity be permitted near the inflator on

the back of an airbag. When carrying or handling an

undeployed airbag, the trim side of the airbag should

be pointing away from the body to minimize possibil-

ity of injury if accidental deployment occurs. Do not

place undeployed airbag face down on a solid surface,

the airbag will propel into the air if accidental

deployment occurs.

REMOVAL

DEPLOYED AIRBAG

(1) Open hood.

(2) Disconnect and isolate the battery negative

cable.

(3)

8O - 30 RESTRAINTSRS

OCCUPANT RESTRAINT CONTROLLER (Continued)

Page 532 of 2339

SPEED CONTROL

TABLE OF CONTENTS

page page

SPEED CONTROL

DESCRIPTION..........................1

OPERATION

OPERATION..........................1

OPERATION - INTERACTIVE SPEED

CONTROL (4 Speed EATX Only)...........2

DIAGNOSIS AND TESTING - ROAD TEST.....3

SPECIFICATIONS - TORQUE...............3

CABLE

DESCRIPTION..........................4

OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SERVO

DESCRIPTION..........................4OPERATION............................4

REMOVAL.............................4

INSTALLATION..........................4

SWITCH

DESCRIPTION..........................5

OPERATION............................5

REMOVAL.............................5

INSTALLATION..........................6

VACUUM RESERVOIR

DESCRIPTION..........................6

OPERATION............................6

REMOVAL.............................6

INSTALLATION..........................6

SPEED CONTROL

DESCRIPTION

The speed control system is electronically con-

trolled and vacuum operated. The electronic control

is integrated into the Powertrain Control Module.

The controls are located on the steering wheel. The

ON/OFF, and SET buttons are located on the left side

of the airbag module. The RESUME/ACCEL, CAN-

CEL and COAST buttons are located on the right

side of the airbag module (Fig. 1).The system is designed to operate at speeds above

30 mph (48 km/h).

WARNING: THE USE OF SPEED CONTROL IS NOT

RECOMMENDED WHEN DRIVING CONDITIONS DO

NOT PERMIT MAINTAINING A CONSTANT SPEED,

SUCH AS IN HEAVY TRAFFIC OR ON ROADS THAT

ARE WINDING, ICY, SNOW COVERED, OR SLIP-

PERY.

OPERATION

OPERATION

When speed control is activated by depressing the

ON switch, the PCM allows a set speed to be stored

in RAM for speed control. To store a set speed,

depress and release the SET switch while the vehicle

is moving at a speed between 25 and 85 mph. In

order for the speed control to engage, the brakes can-

not be applied, nor can the gear selector be indicat-

ing the transmission is in Park or Neutral (ATX) or

1st/2nd gear (MTX). The speed control can be disen-

gaged manually by:

²Stepping on the brake pedal

²Depressing the OFF switch

²Depressing the CANCEL switch.

²Depressing the clutch pedal

²Operating in 1st or 2nd gear (autostick, if

equipped)

Fig. 1 SPEED CONTROL SWITCHES - Typical

RSSPEED CONTROL8P-1

Page 558 of 2339

INSTALLATION

(1) Push filler neck and front washer hose through

the opening in the front fender side shield. Connect

the reservoir to the body mount by lowering the res-

ervoir down.

(2) Install the two reservoir mounting screws.

Torque screws to 8.5 - 11.3 N´m (75 - 100 in. lbs.).

(3) Connect the electrical body harness connectors

to the washer pump motor and the fluid level sensor.

Slide the red lock on the connector to the closed or

locked position.

(4) Assure that washer is properly routed to pre-

vent pinching and possible inoperative washers.

(5) Install the left right front wheelhouse splash

shield (Refer to 23 - BODY/EXTERIOR/WHEEL-

HOUSE SPLASH SHIELD - INSTALLATION).

(6) Install the right front wheel and tire assembly

(Refer to 22 - TIRES/WHEELS - INSTALLATION).

(7) lower vehicle from hoist or jack stands.

(8) Install the filler tube screw. Torque screw to 8.5

- 11.3 N´m (75 - 100 in. lbs.).

(9) Connect the washer hose to the hose clip

located on the front fender side shield.

(10) Connect the washer hose at the in-line con-

nector forward of the cowl grille.

(11) Install the engine fresh air housing inside the

engine compartment (Refer to 9 - ENGINE/AIR

INTAKE SYSTEM/AIR CLEANER HOUSING -

INSTALLATION).

(12) Connect the battery negative cable.

(13) Verify system operation.

WIPER BLADES

REMOVAL

(1) Lift the wiper arm away from the glass.

(2) Disengage the release tab holding the wiper

blade to the wiper arm and remove the wiper blade

from the wiper arm (Fig. 5) and (Fig. 6).

CLEANING

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, (refer to 8 -

ELECTRICAL/WIPERS/WASHERS/WIPER ARMS -

ADJUSTMENTS).

INSTALLATION

(1) Position the blade onto the arm.

(2) Engage the blade to the retainer by pulling up

on the blade until the tabs snap into position (Fig. 5).

WIPER LINKAGE

REMOVAL

(1) Remove the front windshield wiper unit from

vehicle (Refer to 8 - ELECTRICAL/WIPERS/WASH-

ERS/WIPER MODULE - REMOVAL).

(2) Place the wiper unit on a suitable work sur-

face.

(3) Remove nuts holding the cowl cover brackets to

the wiper unit.

(4) Remove cowl cover brackets from the wiper

unit.

(5) Remove nuts holding linkage to the wiper unit.

(6) Remove the wiper linkage from the wiper unit.

Fig. 5 WINDSHIELD WIPER BLADE

1 - RELEASE TAB

Fig. 6 REAR WIPER

1 - WIPER ARM

2 - BLADE LATCH

RSWIPERS/WASHERS8R-13

WASHER RESERVOIR (Continued)

Page 561 of 2339

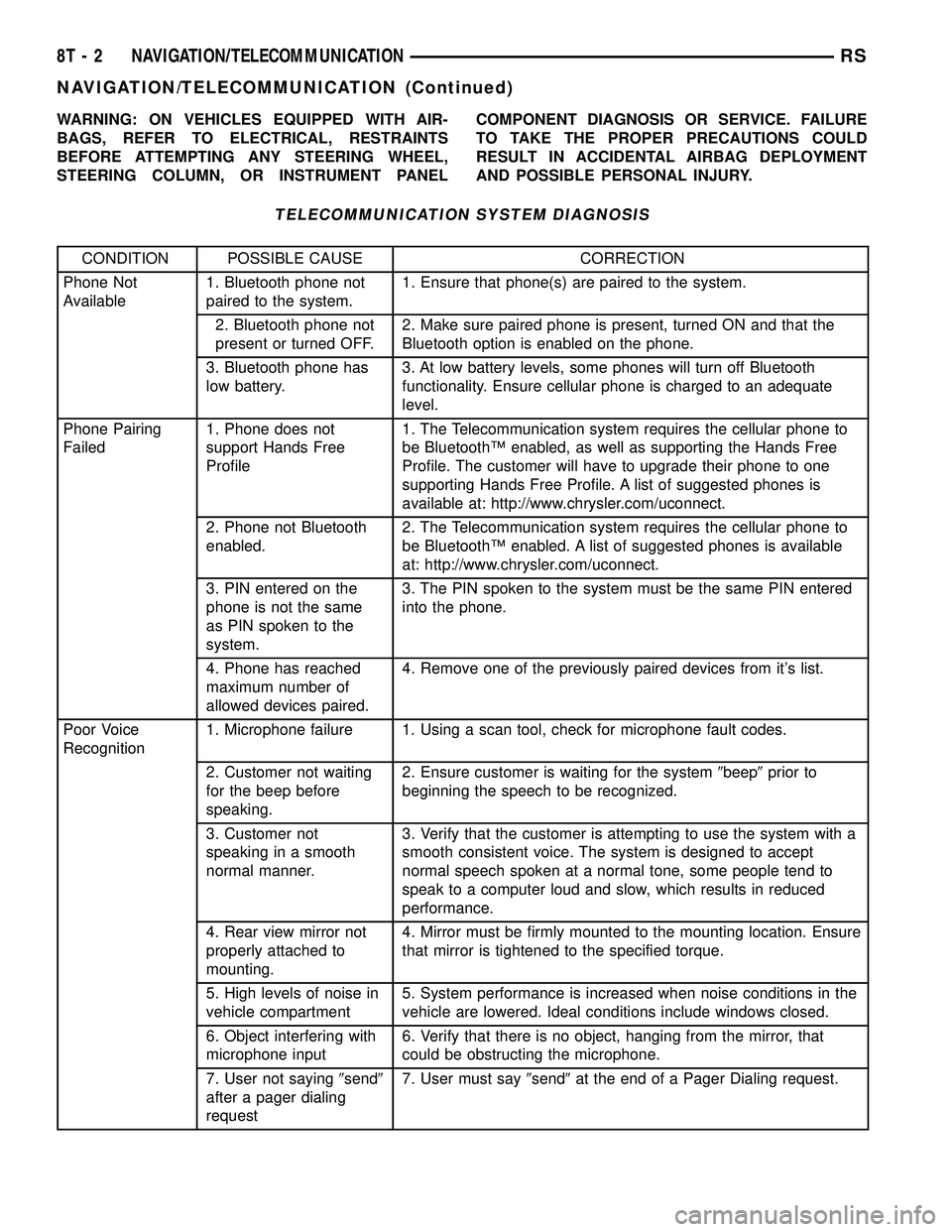

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO ELECTRICAL, RESTRAINTS

BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANELCOMPONENT DIAGNOSIS OR SERVICE. FAILURE

TO TAKE THE PROPER PRECAUTIONS COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

TELECOMMUNICATION SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

Phone Not

Available1. Bluetooth phone not

paired to the system.1. Ensure that phone(s) are paired to the system.

2. Bluetooth phone not

present or turned OFF.2. Make sure paired phone is present, turned ON and that the

Bluetooth option is enabled on the phone.

3. Bluetooth phone has

low battery.3. At low battery levels, some phones will turn off Bluetooth

functionality. Ensure cellular phone is charged to an adequate

level.

Phone Pairing

Failed1. Phone does not

support Hands Free

Profile1. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled, as well as supporting the Hands Free

Profile. The customer will have to upgrade their phone to one

supporting Hands Free Profile. A list of suggested phones is

available at: http://www.chrysler.com/uconnect.

2. Phone not Bluetooth

enabled.2. The Telecommunication system requires the cellular phone to

be BluetoothŸ enabled. A list of suggested phones is available

at: http://www.chrysler.com/uconnect.

3. PIN entered on the

phone is not the same

as PIN spoken to the

system.3. The PIN spoken to the system must be the same PIN entered

into the phone.

4. Phone has reached

maximum number of

allowed devices paired.4. Remove one of the previously paired devices from it's list.

Poor Voice

Recognition1. Microphone failure 1. Using a scan tool, check for microphone fault codes.

2. Customer not waiting

for the beep before

speaking.2. Ensure customer is waiting for the system9beep9prior to

beginning the speech to be recognized.

3. Customer not

speaking in a smooth

normal manner.3. Verify that the customer is attempting to use the system with a

smooth consistent voice. The system is designed to accept

normal speech spoken at a normal tone, some people tend to

speak to a computer loud and slow, which results in reduced

performance.

4. Rear view mirror not

properly attached to

mounting.4. Mirror must be firmly mounted to the mounting location. Ensure

that mirror is tightened to the specified torque.

5. High levels of noise in

vehicle compartment5. System performance is increased when noise conditions in the

vehicle are lowered. Ideal conditions include windows closed.

6. Object interfering with

microphone input6. Verify that there is no object, hanging from the mirror, that

could be obstructing the microphone.

7. User not saying9send9

after a pager dialing

request7. User must say9send9at the end of a Pager Dialing request.

8T - 2 NAVIGATION/TELECOMMUNICATIONRS

NAVIGATION/TELECOMMUNICATION (Continued)

Page 1184 of 2339

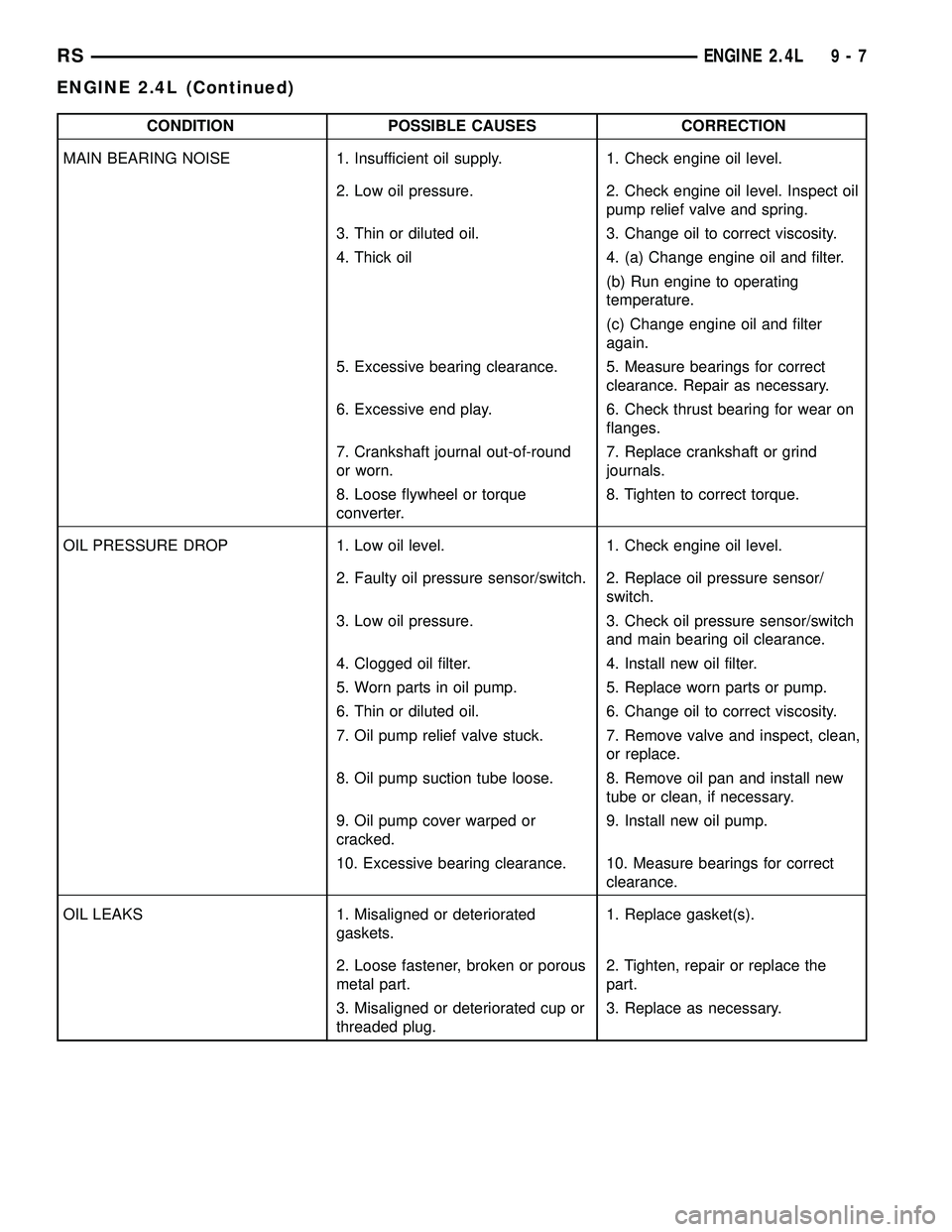

CONDITION POSSIBLE CAUSES CORRECTION

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Thick oil 4. (a) Change engine oil and filter.

(b) Run engine to operating

temperature.

(c) Change engine oil and filter

again.

5. Excessive bearing clearance. 5. Measure bearings for correct

clearance. Repair as necessary.

6. Excessive end play. 6. Check thrust bearing for wear on

flanges.

7. Crankshaft journal out-of-round

or worn.7. Replace crankshaft or grind

journals.

8. Loose flywheel or torque

converter.8. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sensor/switch. 2. Replace oil pressure sensor/

switch.

3. Low oil pressure. 3. Check oil pressure sensor/switch

and main bearing oil clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Oil pump relief valve stuck. 7. Remove valve and inspect, clean,

or replace.

8. Oil pump suction tube loose. 8. Remove oil pan and install new

tube or clean, if necessary.

9. Oil pump cover warped or

cracked.9. Install new oil pump.

10. Excessive bearing clearance. 10. Measure bearings for correct

clearance.

OIL LEAKS 1. Misaligned or deteriorated

gaskets.1. Replace gasket(s).

2. Loose fastener, broken or porous

metal part.2. Tighten, repair or replace the

part.

3. Misaligned or deteriorated cup or

threaded plug.3. Replace as necessary.

RSENGINE 2.4L9-7

ENGINE 2.4L (Continued)