body CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 2261 of 2339

(5) Using spring tension clamp pliers, compress

and slide the clamps off of the rubber hoses at the

front of the underbody heater tubes (Fig. 15).

CAUTION:

DO NOT apply excessive pressure on heater tubes

or connections when removing heater hoses.

Excessive pressure may damage or deform the

tubes, causing an engine coolant leak.

(6) Disconnect the heater hoses by carefully twist-

ing the hoses back and forth on the rear heater

extension tubes, while gently pulling them away

from the end of the tubes.

(7) If necessary, carefully cut the hose ends and

peel the hoses off of the tubes.NOTE:

Replacement of the heater hoses will be required if

the hose ends are cut for removal.

(8) Remove the screws that secure the underbody

line retaining straps to the vehicle underbody.

(9) Remove the underbody heater tubes from the

retaining straps.

(10) Remove the underbody heater tubes from the

vehicle.

UNDERBODY REFRIGERANT LINES

WARNING: REFER TO THE APPLICABLE WARN-

INGS AND CAUTIONS FOR THIS SYSTEM BEFORE

PERFORMING THE FOLLOWING OPERATION (Refer

to 24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - WARNING - A/C PLUMBING) and (Refer to

24 - HEATING & AIR CONDITIONING/PLUMBING -

FRONT - CAUTION - A/C PLUMBING).

(1) Recover the refrigerant from the refrigerant

system (Refer to 24 - HEATING & AIR CONDITION-

ING/PLUMBING - FRONT - STANDARD PROCE-

DURE - REFRIGERANT RECOVERY).

(2) Raise and support vehicle.

(3) Disconnect the exhaust system from the

exhaust hanger rubber isolators and position the

exhaust system out of the way (Refer to 11 -

EXHAUST SYSTEM - DESCRIPTION).

(4) Disconnect the underbody refrigerant lines

from the front liquid and suction line extension tubes

and remove and discard the O-ring seals. (Fig. 16).

Fig. 15 Underbody Connections

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

Fig. 16 Underbody A/C Line Front Connections ±

Typical

1 - SUCTION LINE EXTENSION TUBE

2 - LIQUID LINE EXTENSION TUBE

3 - RETAINING STRAP

4 - REAR HEATER EXTENSION TUBES

5 - UNDERBODY REFRIGERANT LINES

Fig. 14 Underbody Heater Tube Quick Connect

Fittings

1 - INSERT

2 - QUICK CONNECT FITTING

3 - COMPRESS INSERT FOR REMOVAL

24 - 110 PLUMBING - REARRS

UNDERBODY LINES (Continued)

Page 2262 of 2339

(5) Install plugs in, or tape over the opened refrig-

erant line fittings.

(6) Remove the screws that secure the underbody

line retaining straps to the vehicle underbody.

(7) Remove the underbody refrigerant lines from

the retaining straps.

(8) Remove the bolt or nut (depending on applica-

tion) that secures the underbody refrigerant lines to

the rear evaporator extension line tapping plate,

located behind the right rear wheel housing (Fig. 17)

and (Fig. 18).

(9) Disconnect the underbody refrigerant lines

from the rear evaporator extension line tapping plate

and remove and discard the O-ring seals.

(10) Install plugs in, or tape over the opened

underbody refrigerant line fittings and the rear evap-

orator extension line ports.

(11) Remove the underbody refrigerant lines from

the vehicle.

(12) If required, place the underbody refrigerant

lines on a workbench, remove the nylon wedges that

secure the underbody refrigerant lines to the under-

body refrigerant line sealing plate and remove the

lines from the sealing plate. (Fig. 19).

Fig. 17 Underbody A/C Line Rear Connections ±

with New Seating Element

1 - UNDERBODY LIQUID LINE

2 - NUT

3 - SEALING PLATE

4 - UNDERBODY SUCTION LINE

5 - EXTENSION LINE TAPPING PLATE

Fig. 18 Underbody A/C Line Rear Connections ±

without New Seating Element

1 - UNDERBODY LIQUID LINE

2 - BOLT

3 - EXTENSION LINE TAPPING PLATE

4 - UNDERBODY SUCTION LINE

5 - SEALING PLATE

Fig. 19 Underbody A/C Line Sealing Plate ± Typical

1 - O-RING (2)

2 - UNDERBODY LIQUID LINE

3 - NYLON WEDGE (2)

4 - SEALING PLATE

5 - VISE

6 - UNDERBODY SUCTION LINE

RSPLUMBING - REAR24 - 111

UNDERBODY LINES (Continued)

Page 2263 of 2339

INSTALLATION

UNDERBODY HEATER TUBES

(1) Position the underbody heater tubes onto the

vehicle underbody.

(2) Install the underbody heater tubes into the

underbody line retaining straps.

(3) Install the bolts that secure the retaining

straps to the vehicle underbody. Tighten the screws

securely.

(4) Connect the rubber hoses at the front of the

underbody heater tubes to the rear heater extension

tubes.

(5) Using spring tension clamp pliers, compress

and slide the clamps that secure the heater hoses

over the extension tubes. Release the clamp when it

is correctly positioned over the tube.

(6) Connect the rear underbody heater tube quick

connections to the rear heater core extension tubes.

(7) Lower the vehicle.

(8) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE - COOLING

SYSTEM REFILL).

UNDERBODY REFRIGERANT LINES

(1) If removed, install the underbody refigerant

lines into the underbody refrigerant line sealing plate

and install the nylon wedges that secure the refrig-

erant lines to the sealing plate.

(2) Position the underbody refrigerant lines onto

the vehicle underbody.

(3) Install the underbody refrigerant lines into the

underbody line retaining straps.

(4) Install the bolts that secure the retaining

straps to the vehicle underbody. Tighten the screws

securely.(5) Remove the tape or plugs from the rear under-

body refrigerant line fittings and the rear evaporator

extension line ports.

(6) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them onto the underbody

refrigerant line fittings.

(7) Connect the underbody refrigerant lines to the

rear evaporator extension line tapping plate.

(8) Install the bolt or nut (depending on applica-

tion) that secures the underbody refrigerant line

sealing plate to the rear evaporator extension line

tapping plate. Tighten the bolt or nut to 23 N´m (17

ft. lbs.).

(9) Remove the tape or plugs from the front liquid

and suction line extension tubes and the underbody

refrigerant line fittings.

(10) Lubricate new rubber O-ring seals with clean

refrigerant oil and install them onto the underbody

refrigerant line fittings.

(11) Connect the underbody refrigerant line fit-

tings to the front liquid and suction line extension

tubes. Tighten the fittings to 23 N´m (17 ft. lbs.).

(12) Position the exhaust system and install it to

the exhaust hanger rubber isolators (Refer to 11 -

EXHAUST SYSTEM - DESCRIPTION).

(13) Lower the vehicle.

(14) Evacuate the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT - STANDARD PROCEDURE - REFRIGER-

ANT SYSTEM EVACUATE).

(15) Charge the refrigerant system (Refer to 24 -

HEATING & AIR CONDITIONING/PLUMBING -

FRONT - STANDARD PROCEDURE - REFRIGER-

ANT SYSTEM CHARGE).

24 - 112 PLUMBING - REARRS

UNDERBODY LINES (Continued)

Page 2267 of 2339

(6) Refill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(7) Verify function of the cabin heater.

EXHAUST TUBE

REMOVAL

WARNING: THERE IS A POTENTIAL DANGER OF

SKIN BURNS AS THE SUPPLEMENTAL CABIN

HEATER AND ITS COMPONENTS MAY BE VERY

HOT. MAKE SURE THE CABIN HEATER IS

ALLOWED TO COOL DOWN BEFORE ANY SERVICE

WORK ON THE CABIN HEATER SYSTEM IS

ATTEMPTED.

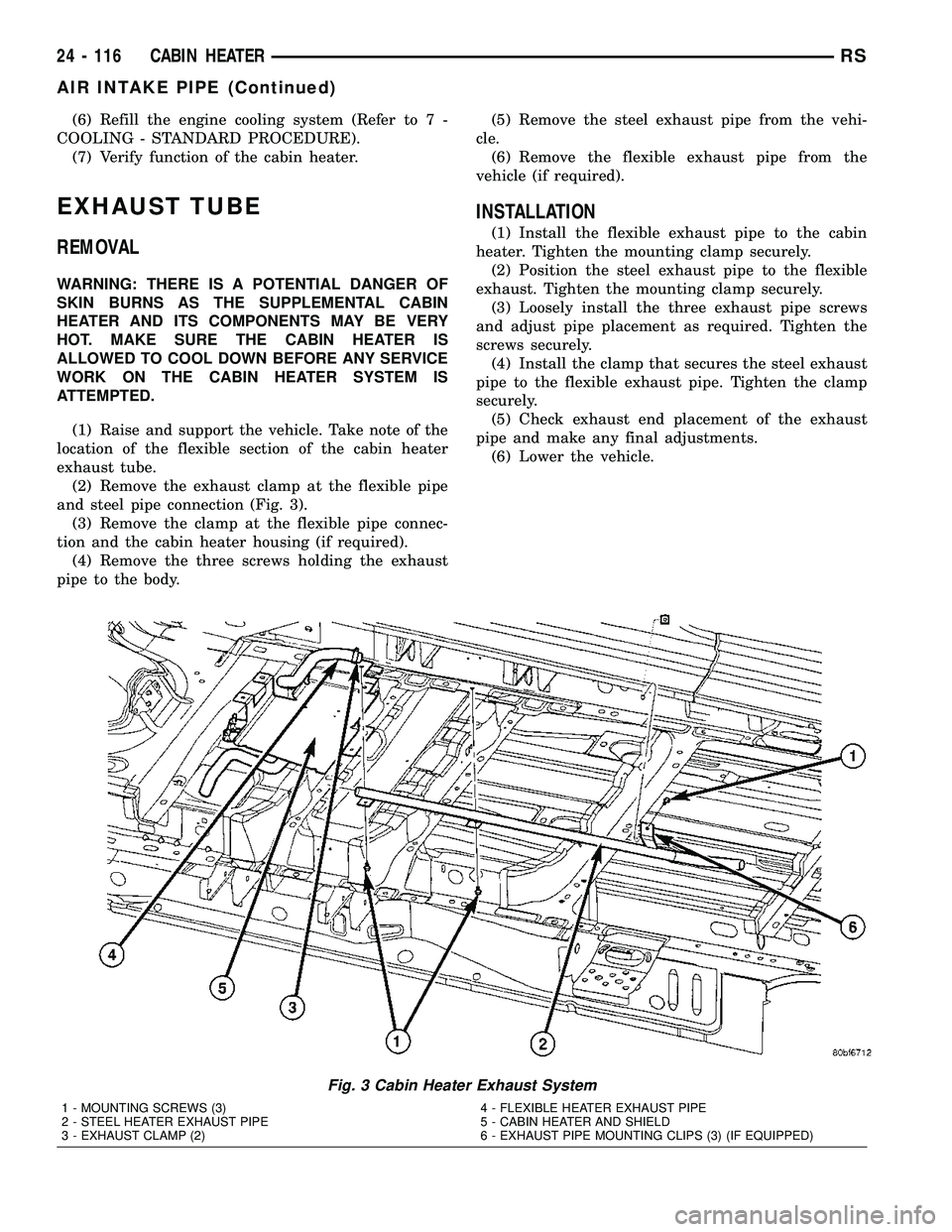

(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Remove the exhaust clamp at the flexible pipe

and steel pipe connection (Fig. 3).

(3) Remove the clamp at the flexible pipe connec-

tion and the cabin heater housing (if required).

(4) Remove the three screws holding the exhaust

pipe to the body.(5) Remove the steel exhaust pipe from the vehi-

cle.

(6) Remove the flexible exhaust pipe from the

vehicle (if required).

INSTALLATION

(1) Install the flexible exhaust pipe to the cabin

heater. Tighten the mounting clamp securely.

(2) Position the steel exhaust pipe to the flexible

exhaust. Tighten the mounting clamp securely.

(3) Loosely install the three exhaust pipe screws

and adjust pipe placement as required. Tighten the

screws securely.

(4) Install the clamp that secures the steel exhaust

pipe to the flexible exhaust pipe. Tighten the clamp

securely.

(5) Check exhaust end placement of the exhaust

pipe and make any final adjustments.

(6) Lower the vehicle.

Fig. 3 Cabin Heater Exhaust System

1 - MOUNTING SCREWS (3)

2 - STEEL HEATER EXHAUST PIPE

3 - EXHAUST CLAMP (2)4 - FLEXIBLE HEATER EXHAUST PIPE

5 - CABIN HEATER AND SHIELD

6 - EXHAUST PIPE MOUNTING CLIPS (3) (IF EQUIPPED)

24 - 116 CABIN HEATERRS

AIR INTAKE PIPE (Continued)

Page 2269 of 2339

FUEL LINE

STANDARD PROCEDURE

CLEANING

(1) Remove the cabin heater fuel line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - REMOVAL).

(2) With the cabin heater fuel line removed from

the vehicle, place a shop cloth on the fuel tank end of

the fuel line to catch any residue, then apply a small

amount of air pressure to the other end of the fuel

line.

(3) Check to see if air pressure is coming from the

tank end of the line. If pressure is flowing unre-

stricted the line is clean.

(4) If the fuel line shows any signs of being

restricted after air pressure is applied, the fuel line

should be replaced.

(5) Install the cabin heater fuel line (Refer to 24 -

HEATING & AIR CONDITIONING/CABIN HEAT-

ER/FUEL LINE - INSTALLATION).

(6) Verify function of the cabin heater.

REMOVAL

CAUTION: Make sure that the hoist is properly posi-

tioned under the vehicle to prevent damage to the

flexible section of the cabin heater exhaust tube.

(1) Raise and support the vehicle.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel that may drain from the

heater fuel hose or the dosing pump.

(2) Remove the two clamps that secure the heater

fuel hose to the dosing pump and the heater fuel line

(Fig. 5).

(3) Disconnect the heater fuel hose from the dosing

pump and the heater fuel line.

(4) Remove the clamp that secures the heater fuel

line to the fuel tank.

(5) Disconnect the heater fuel line from the fuel

tank.

(6) Disconnect the fuel line from the body retain-

ing clips and remove the fuel line from vehicle.

INSTALLATION

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTIONS MAY

RESULT IN PERSONAL INJURY OR DEATH.

(1) Position the cabin heater fuel line to the vehi-

cle and connect the body retaining clips.

(2) Connect the heater fuel line to the fuel tank.

(3) Install the clamp that secure the heater fuel

line to the fuel tank. Tighten the clamp securely.

(4) Connect the heater fuel hose to the dosing

pump and the heater fuel line.

(5) Install the clamps that secure the heater fuel

hose to the dosing pump and the heater fuel line.

Tighten the clamps securely.

(6) Lower the vehicle.

Fig. 5 Dosing Pump Fuel Line

1 - HEATER FUEL LINE

2 - HEATER FUEL HOSE

3 - HEATER AIR INTAKE PIPE

4 - RETAINING CLAMP (2)

5 - DOSING PUMP

24 - 118 CABIN HEATERRS

Page 2272 of 2339

(7) Connect the heater lines to the heater hoses at

the heater core and EGR port. Position spring clamps

onto the hoses.

(8) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

HEATER UNIT

REMOVAL

WARNING: DO NOT OPERATE THE DIESEL SUP-

PLEMENTAL CABIN HEATER IN AN ENCLOSED

AREA SUCH AS A GARAGE THAT DOES NOT HAVE

EXHAUST VENTILATION FACILITIES. ALWAYS VENT

THE CABIN HEATER EXHAUST WHEN OPERATING

THE CABIN HEATER. ALLOW THE DIESEL SUPPLE-

MENTAL CABIN HEATER TO COOL BEFORE PER-

FORMING ANY SERVICE PROCEDURES TO THE

CABIN HEATER. VERIFY THAT ALL DIESEL SUP-

PLEMENTAL CABIN HEATER FUEL LINES ARE

SECURELY FASTENED TO THEIR RESPECTIVE

COMPONENTS BEFORE PERFORMING ANY SER-

VICE PROCEDURES TO THE CABIN HEATER. FAIL-

URE TO FOLLOW THESE INSTRUCTION MAY

RESULT IN PERSONAL INJURY OR DEATH.(1) Raise and support the vehicle. Take note of the

location of the flexible section of the cabin heater

exhaust tube.

(2) Drain the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(3) Carefully open one hose to the underbody tube

assembly and drain the remaining coolant. A salvage

hose is a good idea to control the residual coolant, as

flow will occur from both the cabin heater and the

hose and tube assemblies.

(4) Remove the second hose from the underbody

hose and tube assembly.

(5) Loosen the hose and tube assembly from the

toe-board crossmember at two locations.

(6) Disconnect the electrical connector from the

body harness near the toe-board crossmember and

rail.

(7) Remove the wiring harness from the toe-board

crossmember (Refer to 24 - HEATING & AIR CON-

DITIONING/CABIN HEATER/HEATER UNIT -

REMOVAL).

(8) Open the fuel filler cap. Disconnect the rubber

fuel hose between the body tube assembly and the

fuel pump nipple at the body tube joint. A minimal

amount of fuel may flow from the open port.

NOTE: Utilize an approved fuel storage container to

catch any residual fuel.

(9) Loosen the two fasteners at the rail. Take care

to notice that the exhaust tube bracket tab is on top

of the heater bracket and that there are two spacer

washers installed between the rubber grommets.

(10) Remove the flexible section of the cabin

heater exhaust tube from the exhaust tube by loos-

ening the clamp. Remove the hose from the exhaust

tube. Removal of the rail tube assembly may aid in

this service operation (Refer to 24 - HEATING & AIR

CONDITIONING/CABIN HEATER/EXHAUST TUBE

- REMOVAL).

(11) Remove seat hex nut at the heater mounting

flange to crossmember.

(12) Loosen the remaining fasteners which mount

the exhaust tube assembly to the vehicle.

(a) Install a suitable support device under the

cabin heater and secure the cabin heater to the

support.

(13) Loosen the remaining three fasteners to the

crossmembers.

(14) Remove the loosened fasteners that support

the cabin heater while supporting the weight of the

heater.

(15) Swing the cabin heater mounting bracket

from between the exhaust bracket and rail mounting

location. Drain any residual coolant from the cabin

heater.

Fig. 7 Cabin Heater Air Intake And Heater Pipe

Assembly

1 - INTAKE TUBE AIR INTAKE

2 - INTAKE PIPE

3 - RETAINING SCREWS

4 - INTAKE HEATER LINE

5 - RETURN HEATER LINE

RSCABIN HEATER24 - 121

HEATER PIPES (Continued)

Page 2273 of 2339

(16) Remove the cabin heater from the vehicle.

INSTALLATION

(1) Install the cabin heater mounting bracket

between the exhaust bracket and the rail mounting

location.

(2) Support the cabin heater and install the fasten-

ers that secure the cabin heater to the mounting

bracket.

(3) Install the three fasteners to the crossmem-

bers. Tighten the M6 fasteners to 7 N´m (62 in. lbs.).

(4) Position the two spacer washers between the

body and the rubber grommets for the two mounting

points on the rail.

(5) Tighten the remaining M6 fasteners to 7 N´m

(62 in. lbs.) and the M8 fasteners to 23 N´m (17 ft.

lbs.) which mount the exhaust tube assembly to the

vehicle.

(6) Install the seat hex nut at the heater mounting

flange to the crossmembers. Tighten the nut to 60

N´m (44 ft. lbs.)

(7) Install the flexible section of the cabin heater

exhaust tube to the exhaust tube. Tighten the M6

bolt of the clamp securley. Install the hose to the

exhaust tube.

(8) Tighten the two M8 fasteners at the rail to 23

N´m (17 ft. lbs.). Taking care so that the exhaust

tube bracket tab is on the top of the heater bracket.

(9) Install the wiring harness (Refer to 24 - HEAT-

ING & AIR CONDITIONING/CABIN HEATER/

HEATER UNIT - INSTALLATION).

(10) Tighten the hose and tube assembly to the

toe-board crossmember at two locations.

(11) Install the second hose to the underbody hose

and tube assembly.

(12) Connect the rubber fuel hose between the

body tube assembly and the fuel pump nipple at the

body tube joint. Close the fuel fill cap.

(13) Remove the cabin heater support device from

under the vehicle.

(14) Lower the vehicle.(15) Fill the engine cooling system (Refer to 7 -

COOLING - STANDARD PROCEDURE).

(16) Verify function of the cabin heater.

HEATER WIRING

REMOVAL

(1) Elevate vehicle on a lift taking note of the

exhaust tube flexible section.

(2) Unplug connector from vehicle wiring harness

to cabin heater harness.

(3) Unplug connector from cabin heater harness to

dosing pump connector.

(4) Unplug two connectors from cabin heater har-

ness to cabin heater controller connectors.

(5) Remove two wiring harness connectors from

underbody.

(6) Remove two wiring harness connectors from

cabin heater shield.

(7) Carefully route the cabin heater harness to the

left side between the cabin heater unit and the cabin

heater shield.

INSTALLATION

(1) Carefully route the cabin heater harness from

the left side of the cabin heater between the cabin

heater unit and the cabin heater shield.

(2) Install the two wiring harness retaining con-

nectors to the cabin heater shield.

(3) Route the wiring harness along the underside

of the vehicle and install the two wiring harness

retaining connectors.

(4) Plug the two connectors from the cabin heater

harness to the cabin heater controller.

(5) Plug the connector to the cabin heater harness

to the dosing pump connector.

(6) Plug the connector from the vehicle wiring har-

ness to the cabin heater harness.

(7) Lower the vehicle.

(8) Verify function of the cabin heater.

24 - 122 CABIN HEATERRS

HEATER UNIT (Continued)

Page 2279 of 2339

The major non-monitored circuits are listed below

along with examples of failures modes that do not

directly cause the PCM to set a DTC, but for a sys-

tem that is monitored.

FUEL PRESSURE

The fuel pressure regulator controls fuel system

pressure. The PCM cannot detect a clogged fuel

pump inlet filter, clogged in-line fuel filter, or a

pinched fuel supply or return line. However, these

could result in a rich or lean condition causing the

PCM to store an oxygen sensor, fuel system, or mis-

fire diagnostic trouble code.

SECONDARY IGNITION CIRCUIT

The PCM cannot detect an inoperative ignition coil,

fouled or worn spark plugs, ignition cross firing, or

open spark plug cables. The misfire will however,

increase the oxygen content in the exhaust, deceiving

the PCM in to thinking the fuel system is too lean.

Also see misfire detection. There are DTC's that can

detect misfire and Ionization shorts in the secondary

ignition circuit, refer to the Powertrain Diagnostic

manual for more information

CYLINDER COMPRESSION

The PCM cannot detect uneven, low, or high engine

cylinder compression. Low compression lowers O2

content in the exhaust. Leading to fuel system, oxy-

gen sensor, or misfire detection fault.

EXHAUST SYSTEM

The PCM cannot detect a plugged, restricted or

leaking exhaust system. It may set a EGR (if

equipped) or Fuel system or O2S fault.

FUEL INJECTOR MECHANICAL MALFUNCTIONS

The PCM cannot determine if a fuel injector is

clogged, the needle is sticking or if the wrong injector

is installed. However, these could result in a rich or

lean condition causing the PCM to store a diagnostic

trouble code for either misfire, an oxygen sensor, or

the fuel system.

EXCESSIVE OIL CONSUMPTION

Although the PCM monitors engine exhaust oxygen

content when the system is in closed loop, it cannot

determine excessive oil consumption.

THROTTLE BODY AIR FLOW

The PCM cannot detect a clogged or restricted air

cleaner inlet or filter element.

VACUUM ASSIST

The PCM cannot detect leaks or restrictions in the

vacuum circuits of vacuum assisted engine control

system devices. However, these could cause the PCMto store a MAP sensor diagnostic trouble code and

cause a high idle condition.

PCM SYSTEM GROUND

The PCM cannot determine a poor system ground.

However, one or more diagnostic trouble codes may

be generated as a result of this condition. The mod-

ule should be mounted to the body at all times,

including when diagnostics are performed.

PCM CONNECTOR ENGAGEMENT

The PCM may not be able to determine spread or

damaged connector pins. However, it might store

diagnostic trouble codes as a result of spread connec-

tor pins.

DESCRIPTION - MONITORED SYSTEMS

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the a scan tool.

The following is a list of the system monitors:

²EGR Monitor (if equipped)

²Misfire Monitor

²Fuel System Monitor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Catalyst Monitor

²Evaporative System Leak Detection Monitor (if

equipped)

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

OXYGEN SENSOR (O2S) MONITOR

Effective control of exhaust emissions is achieved

by an oxygen feedback system. The most important

element of the feedback system is the O2S. The O2S

is located in the exhaust path. Once it reaches oper-

ating temperatures of 300É to 350ÉC (572É to 662ÉF),

the sensor generates a voltage that is inversely pro-

portional to the amount of oxygen in the exhaust.

25 - 6 EMISSIONS CONTROLRS

EMISSIONS CONTROL (Continued)

Page 2286 of 2339

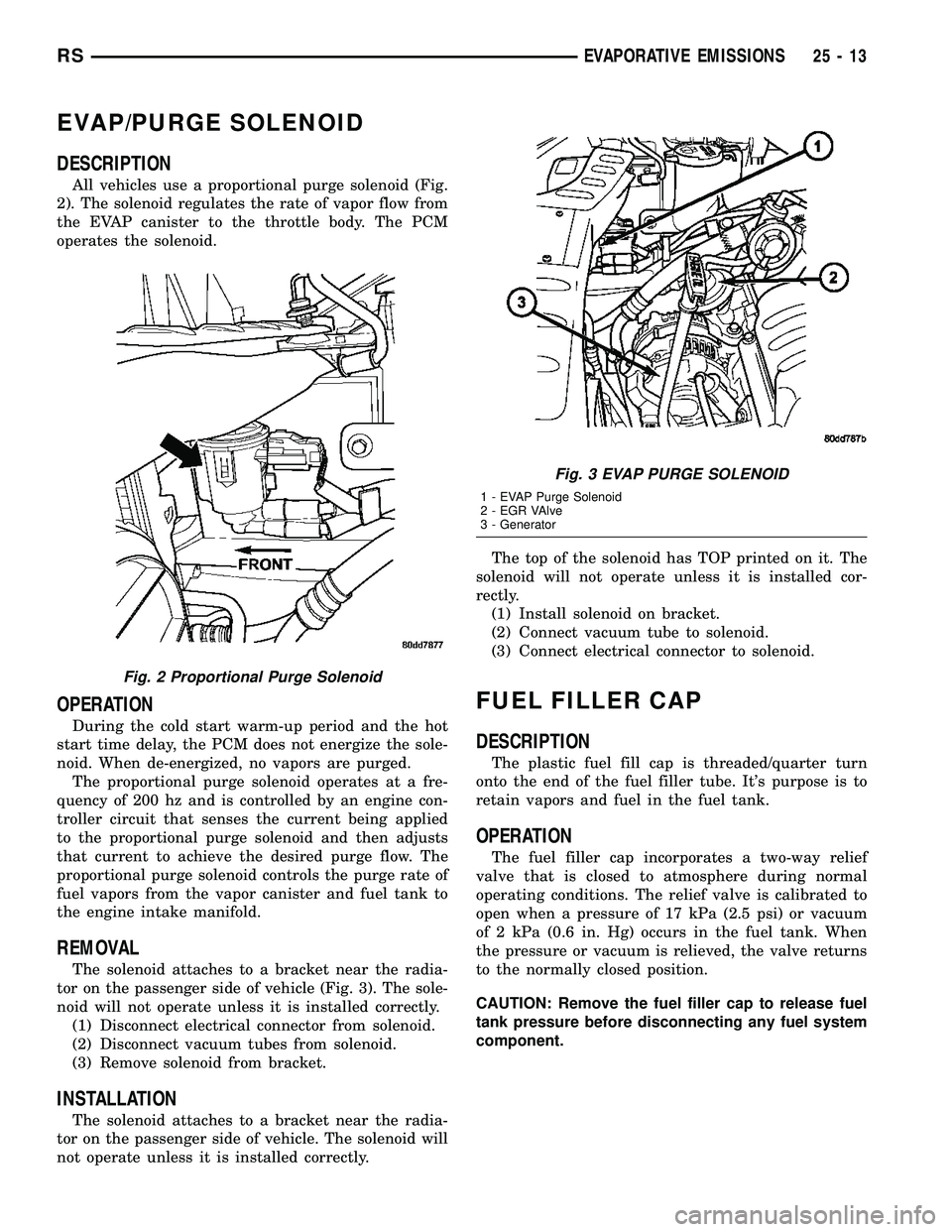

EVAP/PURGE SOLENOID

DESCRIPTION

All vehicles use a proportional purge solenoid (Fig.

2). The solenoid regulates the rate of vapor flow from

the EVAP canister to the throttle body. The PCM

operates the solenoid.

OPERATION

During the cold start warm-up period and the hot

start time delay, the PCM does not energize the sole-

noid. When de-energized, no vapors are purged.

The proportional purge solenoid operates at a fre-

quency of 200 hz and is controlled by an engine con-

troller circuit that senses the current being applied

to the proportional purge solenoid and then adjusts

that current to achieve the desired purge flow. The

proportional purge solenoid controls the purge rate of

fuel vapors from the vapor canister and fuel tank to

the engine intake manifold.

REMOVAL

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle (Fig. 3). The sole-

noid will not operate unless it is installed correctly.

(1) Disconnect electrical connector from solenoid.

(2) Disconnect vacuum tubes from solenoid.

(3) Remove solenoid from bracket.

INSTALLATION

The solenoid attaches to a bracket near the radia-

tor on the passenger side of vehicle. The solenoid will

not operate unless it is installed correctly.The top of the solenoid has TOP printed on it. The

solenoid will not operate unless it is installed cor-

rectly.

(1) Install solenoid on bracket.

(2) Connect vacuum tube to solenoid.

(3) Connect electrical connector to solenoid.

FUEL FILLER CAP

DESCRIPTION

The plastic fuel fill cap is threaded/quarter turn

onto the end of the fuel filler tube. It's purpose is to

retain vapors and fuel in the fuel tank.

OPERATION

The fuel filler cap incorporates a two-way relief

valve that is closed to atmosphere during normal

operating conditions. The relief valve is calibrated to

open when a pressure of 17 kPa (2.5 psi) or vacuum

of 2 kPa (0.6 in. Hg) occurs in the fuel tank. When

the pressure or vacuum is relieved, the valve returns

to the normally closed position.

CAUTION: Remove the fuel filler cap to release fuel

tank pressure before disconnecting any fuel system

component.

Fig. 2 Proportional Purge Solenoid

Fig. 3 EVAP PURGE SOLENOID

1 - EVAP Purge Solenoid

2 - EGR VAlve

3 - Generator

RSEVAPORATIVE EMISSIONS25-13

Page 2303 of 2339

AJAR SWITCH - EXPORT -INSTALLATION, HOOD .................8Q-3

AJAR SWITCH - EXPORT - REMOVAL, HOOD .............................. 8Q-3

ALIGNMENT - DESCRIPTION, WHEEL ......2-47

ALIGNMENT - EXPORT - STANDARD PROCEDURE, FRONT FOG LAMP UNIT .....8L-9

ALIGNMENT - EXPORT - STANDARD PROCEDURE, HEADLAMP UNIT .........8L-15

ALIGNMENT - STANDARD PROCEDURE, FRONT FOG LAMP UNIT ................8L-9

ALIGNMENT - STANDARD PROCEDURE, FRONT WIPER ARM ................... 8R-9

ALIGNMENT - STANDARD PROCEDURE, HEADLAMP UNIT ..................... 8L-14

ALIGNMENT - STANDARD PROCEDURE, WHEEL ............................. 2-52

ALIGNMENT, SPECIFICATIONS - WHEEL ....2-56

AMBIENT TEMP SENSOR - DESCRIPTION . 8M-12

AMBIENT TEMP SENSOR - OPERATION . . 8M-12

AMBIENT TEMPERATURE SENSOR CIRCUIT, DIAGNOSIS AND TESTING .....8M-12

AMBIENT TEMPERATURE SENSOR, DIAGNOSIS AND TESTING .............8M-12

AMPLIFIER - INSTALLATION .............8A-7

AMPLIFIER - REMOVAL ................8A-7

AN AIRBAG DEPLOYMENT - STANDARD PROCEDURE, SERVICE AFTER ...........8O-7

ANCHOR - DESCRIPTION, CHILD RESTRAINT .......................... 8O-9

ANCHOR - OPERATION, CHILD RESTRAINT .......................... 8O-10

ANTENNA - EXPORT - DESCRIPTION, QUARTER GLASS INTEGRAL ............8A-13

ANTENNA - EXPORT - OPERATION, QUARTER GLASS INTEGRAL ............8A-13

ANTENNA - NAVIGATION RADIO - INSTALLATION ....................... 8A-11

ANTENNA - NAVIGATION RADIO - REMOVAL .......................... 8A-11

ANTENNA BODY AND CABLE - DESCRIPTION ........................ 8A-7

ANTENNA BODY AND CABLE - OPERATION .......................... 8A-7

ANTENNA BODY AND CABLE, DIAGNOSIS AND TESTING ..............8A-8

ANTENNA CABLE - INSTALLATION, INSTRUMENT PANEL .................8A-12

ANTENNA CABLE - REMOVAL, INSTRUMENT PANEL .................8A-12

ANTENNA, EXPORT - QUARTER GLASS INTEGRAL .......................... 8A-13

ANTENNA MODULE - EXPORT - DESCRIPTION ....................... 8A-10

ANTENNA MODULE - EXPORT - OPERATION ......................... 8A-10

ANTENNA MODULE, EXPORT ...........8A-10

ANTILOCK BRAKE - DESCRIPTION, CONTROLLER ........................ 8E-4

ANTILOCK BRAKE - INSTALLATION, CONTROLLER ........................ 8E-6

ANTILOCK BRAKE - OPERATION, CONTROLLER ........................ 8E-5

ANTILOCK BRAKE - REMOVAL, CONTROLLER ........................ 8E-5

ANTILOCK BRAKE SYSTEM - DESCRIPTION ........................ 5-87

ANTILOCK BRAKE SYSTEM - OPERATION . . 5-88

ANTILOCK BRAKE SYSTEM BLEEDING - STANDARD PROCEDURE ................5-90

ANTILOCK BRAKE SYSTEM (EXPORT) - DESCRIPTION ........................ 5-87

A-PILLAR LOWER EXTENSION TRIM - INSTALLATION ....................... 23-79

A-PILLAR LOWER EXTENSION TRIM - REMOVAL .......................... 23-79

A-PILLAR TRIM - INSTALLATION ........23-79

A-PILLAR TRIM - REMOVAL ............23-79

A-PILLAR-HEADER, OR B-PILLAR - INSTALLATION ....................... 23-17

A-PILLAR-HEADER, OR B-PILLAR - REMOVAL .......................... 23-17

APPLIQUE - INSTALLATION .............23-14

APPLIQUE - REMOVAL ................23-14

ARM - DESCRIPTION, LOWER CONTROL . . . 2-12

ARM - INSPECTION, LOWER CONTROL ....2-14

ARM - INSTALLATION, LOWER CONTROL . . 2-15

ARM - INSTALLATION, REAR WIPER .....8R-10 ARM - OPERATION, LOWER CONTROL

.....2-12

ARM - REMOVAL, LOWER CONTROL ......2-12

ARM - REMOVAL, REAR WIPER .........8R-10

ARM ALIGNMENT - STANDARD PROCEDURE, FRONT WIPER ............8R-9

ARM (REAR BUSHING - HYDRO) - ASSEMBLY, LOWER CONTROL ...........2-15

ARM (REAR BUSHING - HYDRO) - DISASSEMBLY, LOWER CONTROL ........2-13

ARM (REAR BUSHING - STANDARD) - ASSEMBLY, LOWER CONTROL ...........2-14

ARM (REAR BUSHING - STANDARD) - DISASSEMBLY, LOWER CONTROL ........2-13

ARMREST - INSTALLATION ............23-108

ARMREST - REMOVAL ...............23-108

ARMREST - SECOND ROW - FOLD-IN- FLOOR - INSTALLATION ..............23-130

ARMREST - SECOND ROW - FOLD-IN- FLOOR - REMOVAL .................. 23-130

ARMREST ROTATING ASSEMBLY - SECOND ROW - FOLD-IN-FLOOR -

INSTALLATION ...................... 23-130

ARMREST ROTATING ASSEMBLY - SECOND ROW - FOLD-IN-FLOOR -

REMOVAL ......................... 23-130

ARMS - DESCRIPTION, ROCKER ........9-112

ARMS - INSPECTION, ROCKER ...........9-35

ARMS - INSTALLATION, FRONT WIPER ....8R-9

ARMS - INSTALLATION, ROCKER .........9-35

ARMS - OPERATION, ROCKER ..........9-112

ARMS - REMOVAL, FRONT WIPER .........8R-9

ARMS - REMOVAL, ROCKER .............9-35

ARMS AND SHAFT - ASSEMBLY, ROCKER ............................ 9-113

ARMS AND SHAFT - DISASSEMBLY, ROCKER ............................ 9-113

ARMS AND SHAFT - INSTALLATION, ROCKER ............................ 9-113

ARMS AND SHAFT - REMOVAL, ROCKER . . 9-112

ASSIST DISPLAY - DESCRIPTION, PARK . . . 8B-3

ASSIST DISPLAY - INSTALLATION, PARK . . . 8B-4

ASSIST DISPLAY - OPERATION, PARK .....8B-3

ASSIST DISPLAY - REMOVAL, PARK ......8B-4

ASSIST HANDLE - INSTALLATION ........23-79

ASSIST HANDLE - REMOVAL ...........23-79

ASSIST MODULE - DESCRIPTION, PARK . . . 8B-4

ASSIST MODULE - INSTALLATION, PARK . . 8B-6

ASSIST MODULE - OPERATION, PARK .....8B-5

ASSIST MODULE - REMOVAL, PARK ......8B-5

ASSIST SENSOR - DESCRIPTION, PARK . . . 8B-6

ASSIST SENSOR - INSTALLATION, PARK . . . 8B-6

ASSIST SENSOR - OPERATION, PARK .....8B-6

ASSIST SENSOR - REMOVAL, PARK ......8B-6

ASSIST STRAP - INSTALLATION, FRONT SEAT BACK ........................ 23-112

ASSIST STRAP - REMOVAL, FRONT SEAT BACK ........................ 23-112

ATTACHED - INSTALLATION, EXTERIOR NAME PLATES - ADHESIVE .............23-51

ATTACHED - INSTALLATION, EXTERIOR NAME PLATES - TAPE .................23-51

ATTACHED - REMOVAL, EXTERIOR NAME PLATES - ADHESIVE .................. 23-51

ATTACHED - REMOVAL, EXTERIOR NAME PLATES - TAPE ...................... 23-51

AUDIO/VIDEO - DESCRIPTION ...........8A-1

AUDIO/VIDEO, DIAGNOSIS AND TESTING . . 8A-2

AUTO SHUT DOWN RELAY - DESCRIPTION ......................... 8I-3

AUTO SHUT DOWN RELAY - OPERATION . . . 8I-3

AUTOMATIC ADJUSTER - DIAGNOSIS AND TESTING, DRUM BRAKE ............5-14

AUTOMATIC ADJUSTER TENSION RELEASE - STANDARD PROCEDURE,

PARKING BRAKE ...................... 5-63

AUTOMATIC ADJUSTER TENSION RESET - STANDARD PROCEDURE, PARKING

BRAKE .............................. 5-64

AUTOMATIC DAY / NIGHT MIRROR - DESCRIPTION ....................... 8N-28

AUTOMATIC DAY / NIGHT MIRROR - OPERATION ......................... 8N-28

AUTOMATIC DAY / NIGHT MIRROR, DIAGNOSIS AND TESTING .............8N-28

AUTOMATIC TEMPERATURE CONTROL, DESCRIPTION ........................ 24-3

AUTOMATIC TEMPERATURE CONTROL, OPERATION .......................... 24-5AUTOMATIC TEMPERATURE CONTROL

SYSTEM, OPERATION ................24-114

AUTOMATIC TRANSAXLE - DESCRIPTION, 40TE ................... 21-2

AUTOMATIC TRANSAXLE - DESCRIPTION, 41TE .................21-147

AUTOMATIC TRANSAXLE - OPERATION, 40TE ............................... 21-4

AUTOMATIC TRANSAXLE - OPERATION, 41TE ............................. 21-149

AUTOMATIC TRANSAXLE, SPECIAL TOOLS - 41TE ...................... 21-213

AUTOMATIC/MANUAL TRANSAXLE FLUID - DESCRIPTION ........................0-4

AWD - INSTALLATION ..................2-45

AWD - INSTALLATION, REAR WHEEL SPEED SENSOR ....................... 5-92

AWD - INSTALLATION, SPRING ..........2-39

AWD - REMOVAL ..................... 2-44

AWD - REMOVAL, REAR WHEEL SPEED SENSOR ............................ 5-92

AWD - REMOVAL, SPRING ..............2-38

AWD, HEAVY DUTY, CARGO - INSTALLATION ........................ 2-36

AWD, HEAVY DUTY, CARGO - REMOVAL . . . 2-36

AWD POWER TRANSFER UNIT FLUID - DESCRIPTION .........................0-6

AWD REAR DRIVELINE MODULE FLUIDS - DESCRIPTION ........................0-6

B OR C-PILLAR - INSTALLATION, SEAT BELT HEIGHT ADJUSTER ..............8O-38

B OR C-PILLAR - REMOVAL, SEAT BELT HEIGHT ADJUSTER ................... 8O-38

BACK - INSTALLATION, BENCH SEAT ....23-147

BACK - INSTALLATION, FRONT SEAT ....23-111

BACK - QUAD BUCKET - INSTALLATION, BUCKET SEAT ...................... 23-141

BACK - QUAD BUCKET - REMOVAL, BUCKET SEAT ...................... 23-140

BACK - REMOVAL, BENCH SEAT ........23-147

BACK - REMOVAL, FRONT SEAT ........23-111

BACK ASSIST STRAP - INSTALLATION, FRONT SEAT ....................... 23-112

BACK ASSIST STRAP - REMOVAL, FRONT SEAT ....................... 23-112

BACK COVER - INSTALLATION, BENCH SEAT ............................. 23-148

BACK COVER - INSTALLATION, FRONT SEAT ............................. 23-116

BACK COVER - REMOVAL, BENCH SEAT . . 23-148

BACK COVER - REMOVAL, FRONT SEAT . . 23-113

BACK COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-133

BACK COVER/FOAM - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-133

BACK COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-156

BACK COVER/FOAM - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-155

BACK FRAME - SECOND ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-134

BACK FRAME - SECOND ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-134

BACK FRAME - THIRD ROW - FOLD-IN-FLOOR - INSTALLATION, SEAT . . 23-157

BACK FRAME - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, SEAT ......23-156

BACK HINGE - REMOVAL, BENCH SEAT . . 23-146

BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - INSTALLATION,

SEAT ............................. 23-146

BACK HINGE COVERS - QUAD BUCKET, 50/50 SPLIT, BENCH - REMOVAL, SEAT . . 23-146

BACK PANEL - INSTALLATION, BENCH SEAT ............................. 23-144

BACK PANEL - INSTALLATION, FRONT SEAT ............................. 23-113

BACK PANEL - REMOVAL, BENCH SEAT . . 23-143

BACK PANEL - REMOVAL, FRONT SEAT . . 23-112

BACK PANEL - SECOND ROW -FOLD-IN-FLOOR - INSTALLATION,

SEAT ............................. 23-134

BACK PANEL - SECOND ROW -FOLD-IN-FLOOR - REMOVAL, SEAT .....23-134

BACK PANEL - THIRD ROW -FOLD-IN- FLOOR - INSTALLATION, SEAT .........23-158

BACK PANEL - THIRD ROW -FOLD-IN- FLOOR - REMOVAL, SEAT .............23-158

2 INDEXRS

Description Group-Page Description Group-Page Description Group-Page