spare tire CHRYSLER CARAVAN 2005 Service Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2005, Model line: CARAVAN, Model: CHRYSLER CARAVAN 2005Pages: 2339, PDF Size: 59.69 MB

Page 1758 of 2339

TIRES/WHEELS

TABLE OF CONTENTS

page page

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND

WHEEL VIBRATION.....................1

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE AND

WHEEL BALANCE......................5

STANDARD PROCEDURE - TIRE AND

WHEEL MATCH MOUNTING..............7

STANDARD PROCEDURE - TIRE AND

WHEEL ROTATION.....................7

REMOVAL

REMOVAL - TIRE AND WHEEL ASSEMBLY

(ALUMINUM WHEEL)....................8

REMOVAL - TIRE AND WHEEL ASSEMBLY

(STEEL WHEEL).......................8

INSTALLATION

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (ALUMINUM WHEEL)..........8

INSTALLATION - TIRE AND WHEEL

ASSEMBLY (STEEL WHEEL)..............8

TIRE PRESSURE MONITORING

DESCRIPTION..........................9

OPERATION...........................10

SENSOR - TPM

DESCRIPTION.........................10

OPERATION...........................10

CAUTION.............................11

DIAGNOSIS AND TESTING - TIRE PRESSURE

SENSOR............................11

REMOVAL.............................11

INSTALLATION.........................11

TIRES

DESCRIPTION

DESCRIPTION - TIRE..................13

DESCRIPTION - RADIAL-PLY TIRES.......13

DESCRIPTION - REPLACEMENT TIRES....14

DESCRIPTION - SPARE TIRE

(TEMPORARY).......................14DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE . . . 14

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD...............................14

DIAGNOSIS AND TESTING - TIRE WEAR

PATTERNS..........................16

DIAGNOSIS AND TESTING - TREAD WEAR

INDICATORS.........................16

STANDARD PROCEDURE

STANDARD PROCEDURE - TIRE INFLATION

PRESSURES.........................16

STANDARD PROCEDURE - TIRE

PRESSURE FOR HIGH SPEED

OPERATION.........................17

STANDARD PROCEDURE - TIRE LEAK

REPAIRING..........................17

CLEANING - TIRES.....................18

WHEELS

DESCRIPTION - WHEEL..................18

DIAGNOSIS AND TESTING - WHEEL

INSPECTION.........................19

CLEANING

WHEEL AND WHEEL TRIM CARE.........19

SPECIFICATIONS

WHEEL.............................19

WHEEL COVER

DESCRIPTION.........................19

REMOVAL.............................19

INSTALLATION.........................20

WHEEL MOUNTING STUDS - FRONT

REMOVAL.............................21

INSTALLATION.........................21

WHEEL MOUNTING STUDS - REAR

REMOVAL.............................22

INSTALLATION.........................22

TIRES/WHEELS

DIAGNOSIS AND TESTING - TIRE AND WHEEL

VIBRATION

Tire and wheel imbalance, runout and force varia-

tion can cause vehicles to exhibit steering wheel

vibration.

VISUAL INSPECTION

Visual inspection of the vehicle is recommended

prior to road testing or performing any other proce-

dure. Raise vehicle on a suitable hoist. (Refer to

LUBRICATION & MAINTENANCE/HOISTING -

STANDARD PROCEDURE)

Inspect for the following:

²Verify correct (OEM) wheel and tire, as well as

correct wheel weights. Aluminum wheels require

RSTIRES/WHEELS22-1

Page 1764 of 2339

If difficult to balance, break down the wheel and

tire assembly and check for loose debris inside tire.

Prior to disassembly, mark (index) the tire at the

valve stem. Use this mark in order to remount the

tire in its original orientation with respect to the

wheel.

STANDARD PROCEDURE - TIRE AND WHEEL

MATCH MOUNTING

Wheels and tires are match mounted at the factory.

This means that the high spot of the tire is matched

to the low spot on the wheel rim. This technique is

used to reduce runout in the wheel and tire assem-

bly. The high spot on the tire is marked with a paint

mark or a bright colored adhesive label on the out-

board sidewall. The low spot on the wheel is identi-

fied with a label on the outside of the rim and a dot

or line in the drop well area of the rim (inside where

the tire mounts). If the outside label has been

removed, the tire will have to be removed to locate

the dot or line on the inside of the rim. The tire can

then be match mounted to the tire.

Information on match mounting the tire to the

wheel can be found in Tire and Wheel Runout/Match

Mounting, items (2) through (5), within Diagnosis

And Testing - Tire And Wheel Vibration. (Refer to 22

- TIRES/WHEELS - DIAGNOSIS AND TESTING)

STANDARD PROCEDURE - TIRE AND WHEEL

ROTATION

NON-DIRECTIONAL TREAD PATTERN TIRES

Tires on the front and rear axles operate at differ-

ent loads and perform different functions. For these

reasons, they wear at unequal rates, and tend to

develop irregular wear patterns. These effects can bereduced by timely rotation of tires. The benefits of

rotation are especially worthwhile. Rotation will

increase tread life, help to maintain mud, snow, and

wet traction levels, and contribute to a smooth, quiet

ride.

The suggested rotation method is the forward-cross

tire rotation method (Fig. 11). This method takes

advantage of current tire industry practice which

allows rotation of radial-ply tires. Other rotation

methods may be used, but may not have all the ben-

efits of the recommended method.

NOTE: Only the 4 tire rotation method may be used

if the vehicle is equipped with a low mileage or tem-

porary spare tire.

DIRECTIONAL TREAD PATTERN TIRES

Some vehicles are fitted with special high-perfor-

mance tires having a directional tread pattern. These

tires are designed to improve traction on wet pave-

ment. To obtain the full benefits of this design, the

tires must be installed so that they rotate in the cor-

rect direction. This is indicated by arrows on the tire

sidewalls.

When wheels and tires are being installed, extra

care is needed to ensure that this direction of rota-

tion is maintained.

Refer to Owner's Manual for rotation schedule.

Fig. 10 Aluminum Wheel Weight

1 - TIRE

2 - WHEEL

3 - WHEEL WEIGHT

Fig. 11 Forward-Cross Tire Rotation Method

RSTIRES/WHEELS22-7

TIRES/WHEELS (Continued)

Page 1766 of 2339

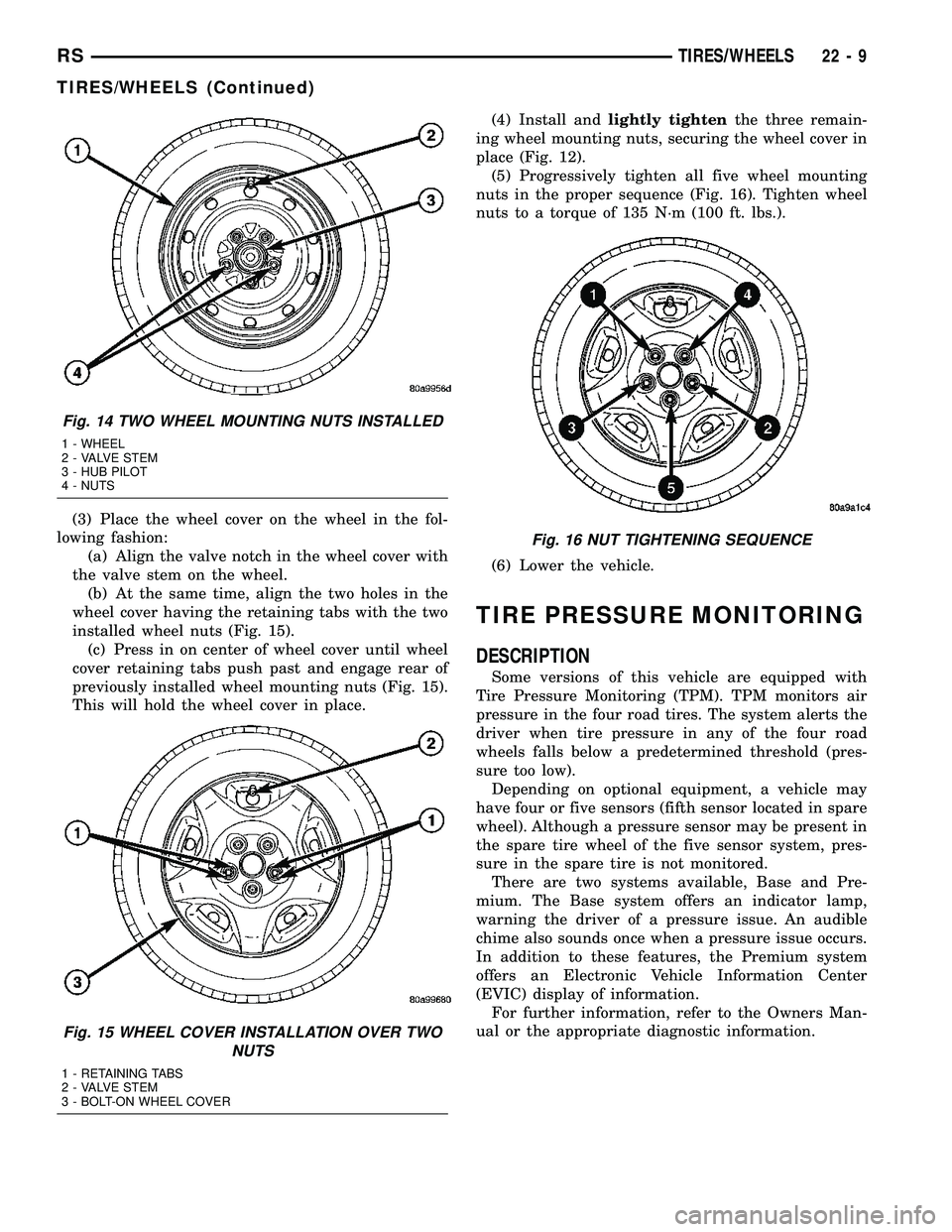

(3) Place the wheel cover on the wheel in the fol-

lowing fashion:

(a) Align the valve notch in the wheel cover with

the valve stem on the wheel.

(b) At the same time, align the two holes in the

wheel cover having the retaining tabs with the two

installed wheel nuts (Fig. 15).

(c) Press in on center of wheel cover until wheel

cover retaining tabs push past and engage rear of

previously installed wheel mounting nuts (Fig. 15).

This will hold the wheel cover in place.(4) Install andlightly tightenthe three remain-

ing wheel mounting nuts, securing the wheel cover in

place (Fig. 12).

(5) Progressively tighten all five wheel mounting

nuts in the proper sequence (Fig. 16). Tighten wheel

nuts to a torque of 135 N´m (100 ft. lbs.).

(6) Lower the vehicle.

TIRE PRESSURE MONITORING

DESCRIPTION

Some versions of this vehicle are equipped with

Tire Pressure Monitoring (TPM). TPM monitors air

pressure in the four road tires. The system alerts the

driver when tire pressure in any of the four road

wheels falls below a predetermined threshold (pres-

sure too low).

Depending on optional equipment, a vehicle may

have four or five sensors (fifth sensor located in spare

wheel). Although a pressure sensor may be present in

the spare tire wheel of the five sensor system, pres-

sure in the spare tire is not monitored.

There are two systems available, Base and Pre-

mium. The Base system offers an indicator lamp,

warning the driver of a pressure issue. An audible

chime also sounds once when a pressure issue occurs.

In addition to these features, the Premium system

offers an Electronic Vehicle Information Center

(EVIC) display of information.

For further information, refer to the Owners Man-

ual or the appropriate diagnostic information.

Fig. 14 TWO WHEEL MOUNTING NUTS INSTALLED

1 - WHEEL

2 - VALVE STEM

3 - HUB PILOT

4 - NUTS

Fig. 15 WHEEL COVER INSTALLATION OVER TWO

NUTS

1 - RETAINING TABS

2 - VALVE STEM

3 - BOLT-ON WHEEL COVER

Fig. 16 NUT TIGHTENING SEQUENCE

RSTIRES/WHEELS22-9

TIRES/WHEELS (Continued)

Page 1767 of 2339

OPERATION

The Tire Pressure Monitoring (TPM) system uses

radio and sensor technology to monitor tire air pres-

sure levels. Sensors, mounted to each road wheel as

part of the valve stem, transmit a low frequency indi-

cating their individual pressure to a receiver located

in the Wireless Control Module (WCM) portion of the

Sentry Key Remote Electronic Entry Module

(SKREEM). These transmissions occur approximately

once every minute at speeds over 20 mph (32 km/h).

The Tire Pressure Monitoring system remains active

even if no tire pressure related message is displayed.

The sensors lay dormant (Park Mode), then wake

and start transmitting (Drive Mode) when the vehicle

first reaches speeds over 20 mph (32 km/h). Once the

wheels stop rotating for a period of approximately 30

minutes, the sensors shut down until again awaken.

Although not transmitting as when in Drive Mode,

while in Park Mode, the sensors still transmit

approximately once every 13 hours to let the receiver

know air pressure status at that time.

The receiver only receives information from the

four rotating tires. A fifth sensor may be located in

the spare tire wheel, depending on vehicle options.

Although this fifth sensor may be present, it does not

broadcast any information because it does not rotate.

When the system detects that a tire is going low,

below the Low Pressure (lamp) ON Threshold (See

following table), the driver is alerted to the situation.

The Base system illuminates an indicator lamp,

warning the driver of a pressure issue and sounds an

audible chime. In equipped with the Premium sys-

tem, the information is also displayed on the Elec-

tronic Vehicle Information Center (EVIC).

Once pressure in the suspect tire raises above the

Low Pressure (lamp) OFF Threshold, the lamp will

go out and the system returns to normal.

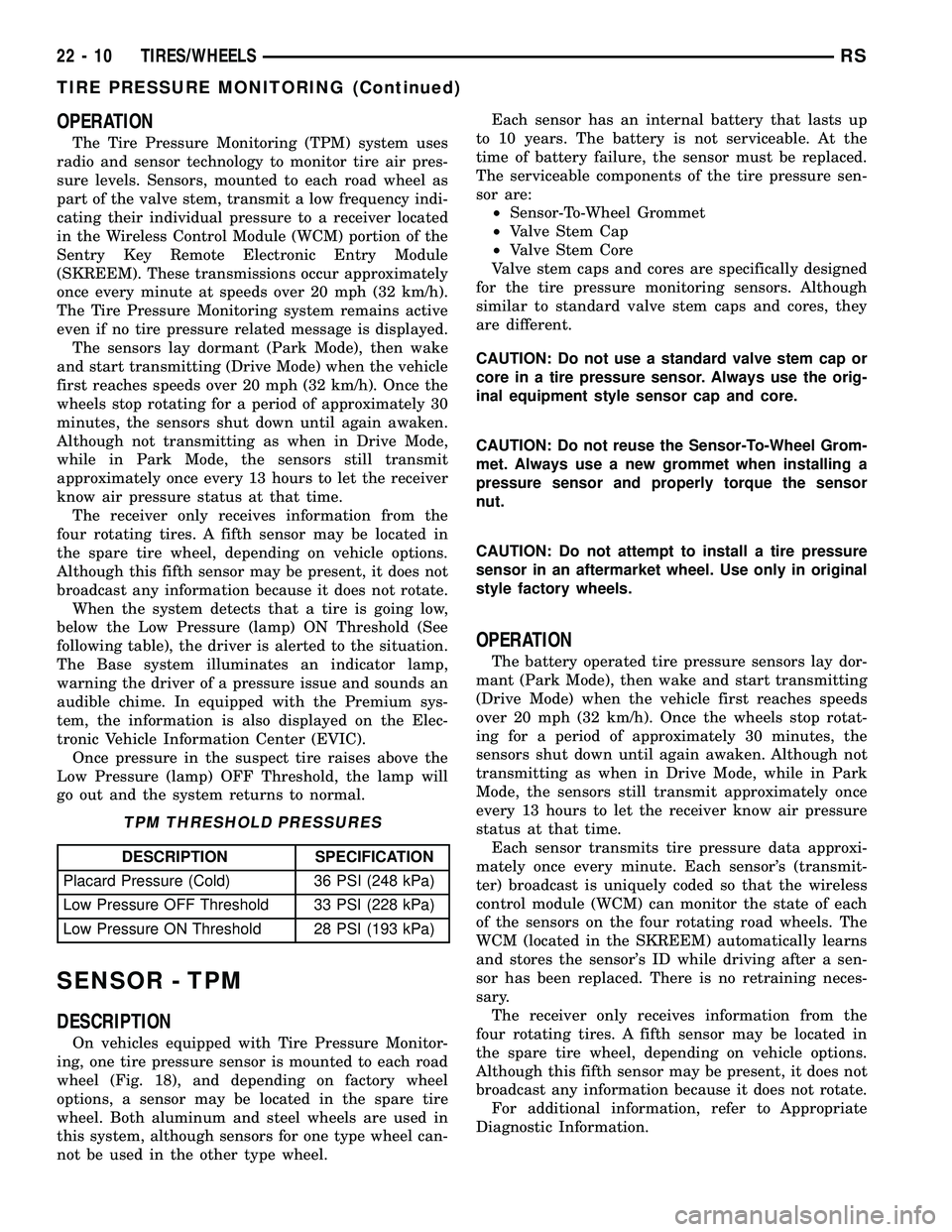

TPM THRESHOLD PRESSURES

DESCRIPTION SPECIFICATION

Placard Pressure (Cold) 36 PSI (248 kPa)

Low Pressure OFF Threshold 33 PSI (228 kPa)

Low Pressure ON Threshold 28 PSI (193 kPa)

SENSOR - TPM

DESCRIPTION

On vehicles equipped with Tire Pressure Monitor-

ing, one tire pressure sensor is mounted to each road

wheel (Fig. 18), and depending on factory wheel

options, a sensor may be located in the spare tire

wheel. Both aluminum and steel wheels are used in

this system, although sensors for one type wheel can-

not be used in the other type wheel.Each sensor has an internal battery that lasts up

to 10 years. The battery is not serviceable. At the

time of battery failure, the sensor must be replaced.

The serviceable components of the tire pressure sen-

sor are:

²Sensor-To-Wheel Grommet

²Valve Stem Cap

²Valve Stem Core

Valve stem caps and cores are specifically designed

for the tire pressure monitoring sensors. Although

similar to standard valve stem caps and cores, they

are different.

CAUTION: Do not use a standard valve stem cap or

core in a tire pressure sensor. Always use the orig-

inal equipment style sensor cap and core.

CAUTION: Do not reuse the Sensor-To-Wheel Grom-

met. Always use a new grommet when installing a

pressure sensor and properly torque the sensor

nut.

CAUTION: Do not attempt to install a tire pressure

sensor in an aftermarket wheel. Use only in original

style factory wheels.

OPERATION

The battery operated tire pressure sensors lay dor-

mant (Park Mode), then wake and start transmitting

(Drive Mode) when the vehicle first reaches speeds

over 20 mph (32 km/h). Once the wheels stop rotat-

ing for a period of approximately 30 minutes, the

sensors shut down until again awaken. Although not

transmitting as when in Drive Mode, while in Park

Mode, the sensors still transmit approximately once

every 13 hours to let the receiver know air pressure

status at that time.

Each sensor transmits tire pressure data approxi-

mately once every minute. Each sensor's (transmit-

ter) broadcast is uniquely coded so that the wireless

control module (WCM) can monitor the state of each

of the sensors on the four rotating road wheels. The

WCM (located in the SKREEM) automatically learns

and stores the sensor's ID while driving after a sen-

sor has been replaced. There is no retraining neces-

sary.

The receiver only receives information from the

four rotating tires. A fifth sensor may be located in

the spare tire wheel, depending on vehicle options.

Although this fifth sensor may be present, it does not

broadcast any information because it does not rotate.

For additional information, refer to Appropriate

Diagnostic Information.

22 - 10 TIRES/WHEELSRS

TIRE PRESSURE MONITORING (Continued)

Page 1771 of 2339

Radial-ply tires must always be used in sets of four

and under no circumstances should they be used on

the front only. It is recommended that tires from dif-

ferent manufacturers NOT be mixed. They may be

mixed with a temporary spare tire when necessary. A

maximum speed of 80 km/h (50 mph) is recom-

mended while a temporary spare is in use.

Radial-ply tires have the same load-carrying capac-

ity as other types of tires of the same size. They also

use the same recommended inflation pressures.

DESCRIPTION - REPLACEMENT TIRES

WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

WARNING: IN ORDER TO MAINTAIN THE SPEED

CAPABILITY OF THE VEHICLE, REPLACEMENT

TIRES MUST HAVE SPEED RATINGS EQUAL TO OR

HIGHER THAN THOSE FITTED TO THE VEHICLE AS

ORIGINAL EQUIPMENT. IF TIRES WITH LOWER

SPEED RATINGS ARE FITTED, THE VEHICLE'S

HANDLING MAY BE AFFECTED AND THE SPEED

CAPABILITY OF THE VEHICLE MAY BE LOWERED

TO THE MAXIMUM SPEED CAPABILITY OF THE

REPLACEMENT TIRES. TO AVOID AN ACCIDENT

RESULTING IN SEVERE OR FATAL INJURY, CON-

SULT THE TIRE MANUFACTURER IN REGARDS TO

MAXIMUM SPEED RATINGS.

It is recommended that tires equivalent to the orig-

inal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The original equipment tires provide a proper com-

bination of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life²Traction

²Rolling resistance

²Speed capability

The use of tires smaller than the minimum tire

size approved for the vehicle can result in tire over-

loading and failure.

Use tires that have the approved load rating for

the vehicle and never overload them. Failure to equip

the vehicle with tires having adequate speed capabil-

ity can result in sudden tire failure and loss of vehi-

cle control.

The use of oversize tires may cause interference

with vehicle components. Under extremes of suspen-

sion and steering travel, interference with vehicle

components may cause tire damage.

DESCRIPTION - SPARE TIRE (TEMPORARY)

The temporary (convenience) spare tire is designed

for emergency use only. The original tire should be

repaired and reinstalled, or replaced with a new, at

the first opportunity.

The temporary (convenience) spare tire should be

inflated to the pressure listed on its sidewall. Do not

exceed speeds of 80 km/h (50 mph) when the tempo-

rary spare tire is in use on the vehicle. Refer to the

Owner's Manual for more details.

DIAGNOSIS AND TESTING

DIAGNOSIS AND TESTING - TIRE NOISE

Unusual tire noise can be associated with tire and

wheel vibration or irregular tire wear. For vibration,

(Refer to 22 - TIRES/WHEELS - DIAGNOSIS AND

TESTING). For irregular tire wear, (Refer to 22 -

TIRES/WHEELS/TIRES - DIAGNOSIS AND TEST-

ING).

DIAGNOSIS AND TESTING - TIRE/VEHICLE

LEAD

Use the following Vehicle Lead Diagnosis And Cor-

rection Chart to diagnose and correct a vehicle lead

or drift problem.

22 - 14 TIRES/WHEELSRS

TIRES (Continued)

Page 1861 of 2339

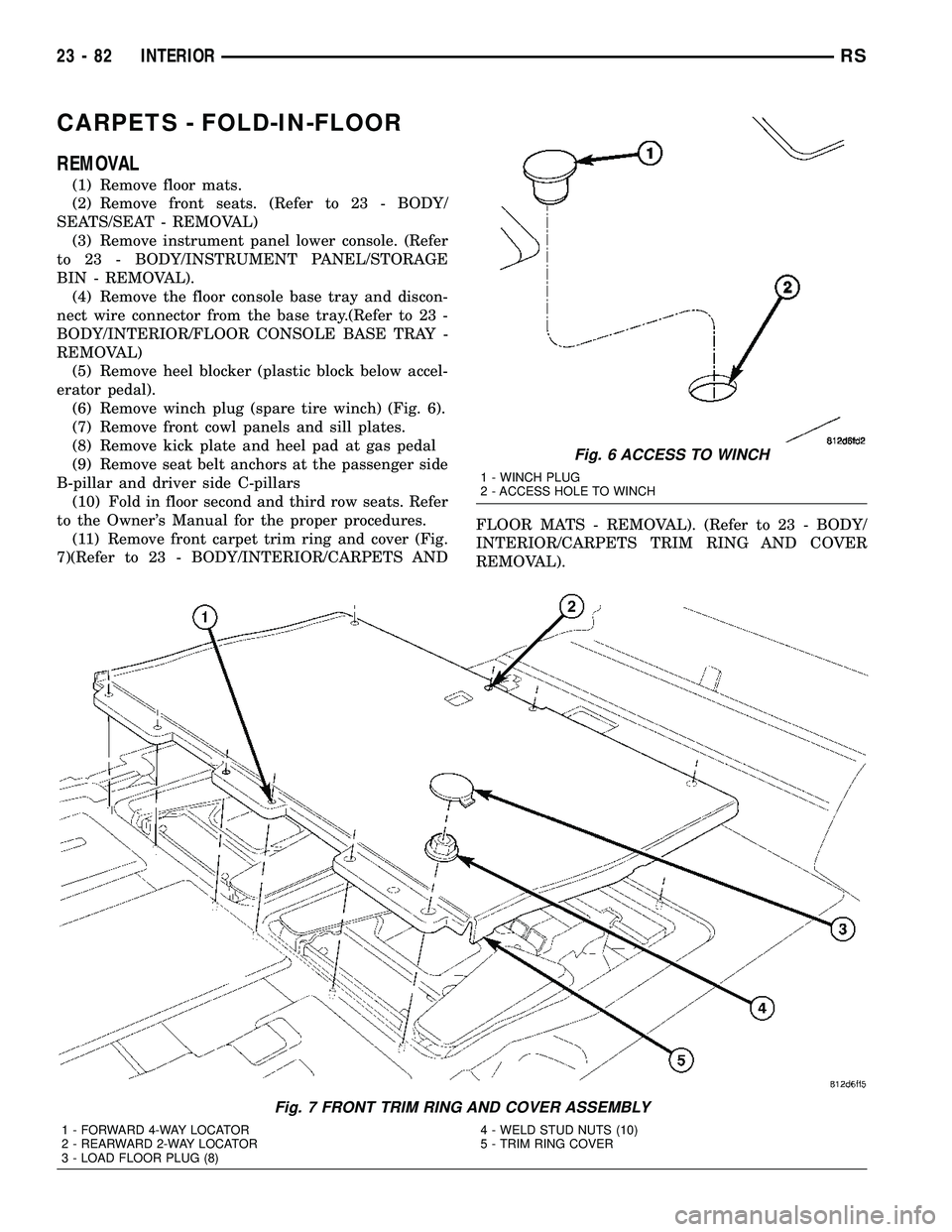

CARPETS - FOLD-IN-FLOOR

REMOVAL

(1) Remove floor mats.

(2) Remove front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL)

(3) Remove instrument panel lower console. (Refer

to 23 - BODY/INSTRUMENT PANEL/STORAGE

BIN - REMOVAL).

(4) Remove the floor console base tray and discon-

nect wire connector from the base tray.(Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE BASE TRAY -

REMOVAL)

(5) Remove heel blocker (plastic block below accel-

erator pedal).

(6) Remove winch plug (spare tire winch) (Fig. 6).

(7) Remove front cowl panels and sill plates.

(8) Remove kick plate and heel pad at gas pedal

(9) Remove seat belt anchors at the passenger side

B-pillar and driver side C-pillars

(10) Fold in floor second and third row seats. Refer

to the Owner's Manual for the proper procedures.

(11) Remove front carpet trim ring and cover (Fig.

7)(Refer to 23 - BODY/INTERIOR/CARPETS ANDFLOOR MATS - REMOVAL). (Refer to 23 - BODY/

INTERIOR/CARPETS TRIM RING AND COVER

REMOVAL).

Fig. 6 ACCESS TO WINCH

1 - WINCH PLUG

2 - ACCESS HOLE TO WINCH

Fig. 7 FRONT TRIM RING AND COVER ASSEMBLY

1 - FORWARD 4-WAY LOCATOR

2 - REARWARD 2-WAY LOCATOR

3 - LOAD FLOOR PLUG (8)4 - WELD STUD NUTS (10)

5 - TRIM RING COVER

23 - 82 INTERIORRS

Page 1863 of 2339

(3) Roll carpet forward under instrument panel

(Fig. 8).

(4) Install push pins fasteners through carpet and

grommet into floor to attach carpet to floor in front

seat area.

(5) Pull wire harnesses through the carpet as

needed.

(6) Smooth out the carpet and allowing weld studs

to go all the way through the carpet.

(7) Install rear push pins fasteners attaching rear

of carpet.

(8) Place third row carpet cover into position and

press clips into position (Fig. 9).

(9) Slide the carpet under the quarter trim panel

into position.

(10) Install lower B-pillar trim covers.

(11) Install sliding door sill plates. (Refer to 23 -

BODY/INTERIOR/SLIDING DOOR SILL PLATE -

INSTALLATION).

(12) Install front carpet trim ring and cover (Fig.

7). (Refer to 23 - BODY/INTERIOR/CARPETS TRIM

RING AND COVER - INSTALLATION)

(13) Install seat belt anchors at the passenger side

B-pillar and driver side C-pillars

(14) Install kick plate and heel pad at the gas

pedal

(15) Install winch plug (spare tire winch) (Fig. 6).

(16) Install front cowl panels and sill plates.

(17) Install heel blocker (plastic block below accel-

erator pedal).

(18) Install the floor console base tray and discon-

nect wire connector from the base tray. (Refer to 23 -

BODY/INTERIOR/FLOOR CONSOLE BASE TRAY -

INSTALLATION).

(19) Install instrument panel lower console. (Refer

to 23 - BODY/INSTRUMENT PANEL/STORAGE

BIN - INSTALLATION).

(20) Install front seats. (Refer to 23 - BODY/

SEATS/SEAT - REMOVAL).

(21) Install floor mats.CARPET TRIM RING AND

COVER - FOLD-IN-FLOOR

REMOVAL

(1) Move front seats to the full forward position.

(2) Fold the second row seats into the floor.

(3) Remove the load floor plugs (Fig. 10).

(4) Remove the ten weld nuts.

(5) Open door covers (Fig. 11).

(6) Remove the four inter weld nuts (Fig. 12).

(7) Raise the front trim ring and cover up off of

the weld studs and remove from vehicle.

INSTALLATION

(1) Place front trim ring and cover assembly into

position.

(2) Open door covers (Fig. 11).

(3) Install the four inter weld nuts (Fig. 12).

(4) Close door covers.

(5) Install the ten weld nuts (Fig. 10).

(6) Install the eight load floor plugs.

(7) Open the second row seats into position.

(8) Move front seats to the position.

23 - 84 INTERIORRS

CARPETS - FOLD-IN-FLOOR (Continued)

Page 1888 of 2339

If any of the remaining OCS components of the

passenger side front seat cushion require replace-

ment, they are serviced only as a factory-calibrated,

assembled, and tamper-evident service replacement

package. This package includes the assembled frame,

springs, pad, bladder, sensor, foam, wiring and a cal-

ibrated OCM. When installing this package, always

replace all of the existing components with the new

components as a unit. Do not attempt to separate or

disconnect any of the new OCS components con-

tained in the service replacement package from each

other, and do not attempt to reuse any of the

replaced components in this or any other vehicle.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

ger side front seat cushion unit with another com-

plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR

DEATH, ON VEHICLES EQUIPPED WITH AIRBAGS,

DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM BEFORE ATTEMPTING ANY STEERING

WHEEL, STEERING COLUMN, AIRBAG, OCCUPANT

CLASSIFICATION SYSTEM, SEAT BELT TEN-

SIONER, IMPACT SENSOR, OR INSTRUMENT

PANEL COMPONENT DIAGNOSIS OR SERVICE.

DISCONNECT AND ISOLATE THE BATTERY NEGA-

TIVE (GROUND) CABLE, THEN WAIT TWO MINUTES

FOR THE SYSTEM CAPACITOR TO DISCHARGE

BEFORE PERFORMING FURTHER DIAGNOSIS OR

SERVICE. THIS IS THE ONLY SURE WAY TO DIS-

ABLE THE SUPPLEMENTAL RESTRAINT SYSTEM.

FAILURE TO TAKE THE PROPER PRECAUTIONS

COULD RESULT IN ACCIDENTAL AIRBAG DEPLOY-

MENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECTANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

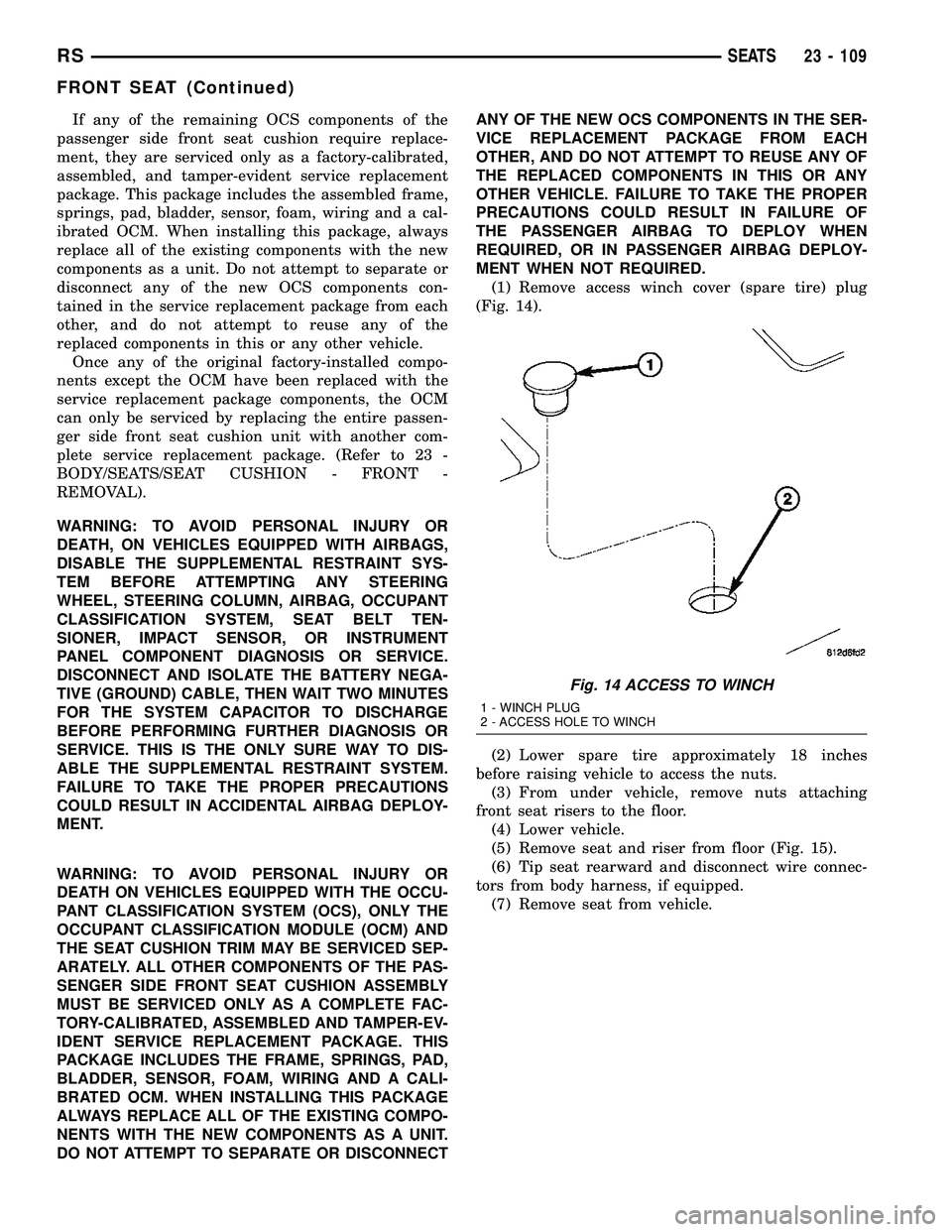

(1) Remove access winch cover (spare tire) plug

(Fig. 14).

(2) Lower spare tire approximately 18 inches

before raising vehicle to access the nuts.

(3) From under vehicle, remove nuts attaching

front seat risers to the floor.

(4) Lower vehicle.

(5) Remove seat and riser from floor (Fig. 15).

(6) Tip seat rearward and disconnect wire connec-

tors from body harness, if equipped.

(7) Remove seat from vehicle.

Fig. 14 ACCESS TO WINCH

1 - WINCH PLUG

2 - ACCESS HOLE TO WINCH

RSSEATS23 - 109

FRONT SEAT (Continued)

Page 1889 of 2339

INSTALLATION

A non-calibrated Occupant Classification Module

(OCM) is the only component of the Occupant Clas-

sification System (OCS) that is available for separate

service replacement, as outlined in the procedures

that follow. The OCS components of the passenger

side front seat cushion including the cushion frame,

springs, pad, occupant detection bladder, pressure

sensor, seat cushion foam and the OCM are a factory-

calibrated and assembled unit. Once this unit is con-

nected to a vehicle electrically, the calibration

settings are uploaded from the OCM and stored in

the memory of the Airbag Control Module (ACM). If

only the OCM is subsequently replaced, the new,

non-calibrated OCM learns the proper calibration

settings from the ACM after it is connected to the

vehicle electrically.

If any of the remaining OCS components of the

passenger side front seat cushion require replace-

ment, they are serviced only as a factory-calibrated,

assembled, and tamper-evident service replacement

package. This package includes the assembled frame,

springs, pad, bladder, sensor, foam, wiring and a cal-

ibrated OCM. When installing this package, always

replace all of the existing components with the new

components as a unit. Do not attempt to separate or

disconnect any of the new OCS components con-

tained in the service replacement package from each

other, and do not attempt to reuse any of the

replaced components in this or any other vehicle.

Once any of the original factory-installed compo-

nents except the OCM have been replaced with the

service replacement package components, the OCM

can only be serviced by replacing the entire passen-

ger side front seat cushion unit with another com-plete service replacement package. (Refer to 23 -

BODY/SEATS/SEAT CUSHION - FRONT -

REMOVAL).

WARNING: TO AVOID PERSONAL INJURY OR DEATH,

ON VEHICLES EQUIPPED WITH AIRBAGS, DISABLE

THE SUPPLEMENTAL RESTRAINT SYSTEM BEFORE

ATTEMPTING ANY STEERING WHEEL, STEERING

COLUMN, AIRBAG, OCCUPANT CLASSIFICATION

SYSTEM, SEAT BELT TENSIONER, IMPACT SENSOR,

OR INSTRUMENT PANEL COMPONENT DIAGNOSIS

OR SERVICE. DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE, THEN WAIT

TWO MINUTES FOR THE SYSTEM CAPACITOR TO

DISCHARGE BEFORE PERFORMING FURTHER DIAG-

NOSIS OR SERVICE. THIS IS THE ONLY SURE WAY

TO DISABLE THE SUPPLEMENTAL RESTRAINT SYS-

TEM. FAILURE TO TAKE THE PROPER PRECAU-

TIONS COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT.

WARNING: TO AVOID PERSONAL INJURY OR

DEATH ON VEHICLES EQUIPPED WITH THE OCCU-

PANT CLASSIFICATION SYSTEM (OCS), ONLY THE

OCCUPANT CLASSIFICATION MODULE (OCM) AND

THE SEAT CUSHION TRIM MAY BE SERVICED SEP-

ARATELY. ALL OTHER COMPONENTS OF THE PAS-

SENGER SIDE FRONT SEAT CUSHION ASSEMBLY

MUST BE SERVICED ONLY AS A COMPLETE FAC-

TORY-CALIBRATED, ASSEMBLED AND TAMPER-EV-

IDENT SERVICE REPLACEMENT PACKAGE. THIS

PACKAGE INCLUDES THE FRAME, SPRINGS, PAD,

BLADDER, SENSOR, FOAM, WIRING AND A CALI-

BRATED OCM. WHEN INSTALLING THIS PACKAGE

ALWAYS REPLACE ALL OF THE EXISTING COMPO-

NENTS WITH THE NEW COMPONENTS AS A UNIT.

DO NOT ATTEMPT TO SEPARATE OR DISCONNECT

ANY OF THE NEW OCS COMPONENTS IN THE SER-

VICE REPLACEMENT PACKAGE FROM EACH

OTHER, AND DO NOT ATTEMPT TO REUSE ANY OF

THE REPLACED COMPONENTS IN THIS OR ANY

OTHER VEHICLE. FAILURE TO TAKE THE PROPER

PRECAUTIONS COULD RESULT IN FAILURE OF

THE PASSENGER AIRBAG TO DEPLOY WHEN

REQUIRED, OR IN PASSENGER AIRBAG DEPLOY-

MENT WHEN NOT REQUIRED.

(1) Place seat into position (Fig. 15).

(2) Tip seat rearward and connect wire connectors

to body harness, if equipped.

(3) Place seat riser studs into openings in the floor.

(4) From under vehicle, install nuts attaching

front seat risers to the floor. Tighten nuts to 88 N´m

(65 ft. lbs.) torque.

(5) Crank winch to raise spare tire into position,

and install winch plug (Fig. 14).

Fig. 15 FRONT SEAT

1 - FRONT SEAT

2 - CONNECTORS

3 - B-PILLAR

23 - 110 SEATSRS

FRONT SEAT (Continued)

Page 2331 of 2339

SLEEVE - THIRD ROW - FOLD-IN-FLOOR- INSTALLATION, HEADREST ...........23-153

SLEEVE - THIRD ROW - FOLD-IN-FLOOR - REMOVAL, HEADREST ..............23-152

SLIDING DOOR - INSTALLATION .........23-29

SLIDING DOOR - REMOVAL ............23-29

SLIDING DOOR ADJUSTMENT, STANDARD PROCEDURE - POWER ......8N-49

SLIDING DOOR ADJUSTMENTS, ADJUSTMENTS ...................... 23-30

SLIDING DOOR CONTROL MODULE - DESCRIPTION ....................... 8E-18

SLIDING DOOR CONTROL MODULE - OPERATION ......................... 8E-18

SLIDING DOOR CONTROL MODULE, DIAGNOSIS AND TESTING .............8E-18

SLIDING DOOR GLASS - INSTALLATION . . 23-163

SLIDING DOOR GLASS - REMOVAL .....23-163

SLIDING DOOR LEARN CYCLE, STANDARD PROCEDURE - POWER ......8N-48

SLIDING DOOR LOCK MOTOR - INSTALLATION ...................... 8N-25

SLIDING DOOR LOCK MOTOR - REMOVAL .......................... 8N-25

SLIDING DOOR MOTOR - DESCRIPTION . . 8N-51

SLIDING DOOR MOTOR - INSTALLATION . . 8N-51

SLIDING DOOR MOTOR - OPERATION ....8N-51

SLIDING DOOR MOTOR - REMOVAL .....8N-51

SLIDING DOOR SILL PLATE - INSTALLATION ....................... 23-99

SLIDING DOOR SILL PLATE - REMOVAL ....23-98

SLIDING DOOR STOP BUMPER BEZEL - INSTALLATION ....................... 23-25

SLIDING DOOR STOP BUMPER BEZEL - REMOVAL .......................... 23-25

SLIDING DOOR SYSTEM - DESCRIPTION, POWER ............................ 8N-40

SLIDING DOOR SYSTEM - OPERATION, POWER ............................ 8N-41

SLIDING DOOR SYSTEM, DIAGNOSIS AND TESTING - POWER ...............8N-42

SLIDING DOOR WEATHERSTRIP - INSTALLATION ...................... 23-168

SLIDING DOOR WEATHERSTRIP - REMOVAL ......................... 23-168

SOCKET - INSTALLATION, STABILIZER ....23-33

SOCKET - REMOVAL, STABILIZER .......23-33

SOLENOID - DESCRIPTION, EVAP/PURGE . 25-13

SOLENOID - DESCRIPTION, SHIFT INTERLOCK .................. 21-113,21-264

SOLENOID - DIAGNOSIS AND TESTING, BRAKE/TRANSMISSION SHIFT

INTERLOCK .................. 21-115,21-266

SOLENOID - INSTALLATION, EVAP/ PURGE ............................. 25-13

SOLENOID - INSTALLATION, SHIFT INTERLOCK .................. 21-116,21-267

SOLENOID - OPERATION, EVAP/PURGE . . . 25-13

SOLENOID - OPERATION, SHIFT INTERLOCK .................. 21-114,21-265

SOLENOID - REMOVAL, EVAP/PURGE .....25-13

SOLENOID - REMOVAL, SHIFT INTERLOCK .................. 21-115,21-266

SOLENOID/PRESSURE SWITCH ASSY - DESCRIPTION ................ 21-117,21-268

SOLENOID/PRESSURE SWITCH ASSY - INSTALLATION ................ 21-119,21-270

SOLENOID/PRESSURE SWITCH ASSY - OPERATION .................. 21-118,21-268

SOLENOID/PRESSURE SWITCH ASSY - REMOVAL ................... 21-118,21-269

SPARE TIRE (TEMPORARY) - DESCRIPTION ....................... 22-14

SPARK PLUG CABLE - DESCRIPTION .....8I-10

SPARK PLUG CABLE RESISTANCE, SPECIFICATIONS ...................... 8I-2

SPARK PLUG, SPECIFICATIONS ...........8I-2

SPEAKER, DIAGNOSIS AND TESTING .....8A-18

SPEED CONTROL - DESCRIPTION ........8P-1

SPEED CONTROL (4 SPEED EATX ONLY) - OPERATION, INTERACTIVE .............8P-2

SPEED OPERATION - STANDARD PROCEDURE, TIRE PRESSURE FOR

HIGH .............................. 22-17

SPEED SENSOR - AWD - INSTALLATION, REAR WHEEL ........................ 5-92

SPEED SENSOR - AWD - REMOVAL, REAR WHEEL ........................ 5-92SPEED SENSOR - DESCRIPTION, ENGINE . 14-30

SPEED SENSOR - FWD - INSTALLATION,

REAR WHEEL ........................ 5-93

SPEED SENSOR - FWD - REMOVAL, REAR WHEEL ........................ 5-93

SPEED SENSOR - INPUT - DESCRIPTION ................ 21-120,21-271

SPEED SENSOR - INPUT - INSTALLATION ................ 21-121,21-272

SPEED SENSOR - INPUT - OPERATION . . 21-120, 21-271

SPEED SENSOR - INPUT - REMOVAL . . . 21-121, 21-272

SPEED SENSOR - INSTALLATION, FRONT WHEEL ............................. 5-92

SPEED SENSOR - OPERATION, ENGINE . . . 14-30

SPEED SENSOR - OUTPUT - DESCRIPTION ................ 21-122,21-273

SPEED SENSOR - OUTPUT - INSTALLATION ................ 21-123,21-274

SPEED SENSOR - OUTPUT - OPERATION .................. 21-122,21-273

SPEED SENSOR - OUTPUT - REMOVAL . . 21-123, 21-274

SPEED SENSOR - REMOVAL, FRONT WHEEL ............................. 5-91

SPEED SENSOR AIR GAP, SPECIFICATIONS - WHEEL ..............5-91

SPIRAL PLATE BATTERY CHARGING, STANDARD PROCEDURE ...............8F-10

SPLASH SHIELD - INSTALLATION, FRONT WHEELHOUSE .................23-57

SPLASH SHIELD - REMOVAL, FRONT WHEELHOUSE ....................... 23-57

SPLICE INFORMATION - DESCRIPTION, CONNECTOR, GROUND ..............8W-01-7

SPLICING - STANDARD PROCEDURE, WIRE ...........................8W -01-15

SPLIT - INSTALLATION, BENCH SEAT RISER - 50/50 ...................... 23-145

SPLIT - REMOVAL, BENCH SEAT RISER - 50/50 ............................. 23-145

SPLIT, BENCH - INSTALLATION, SEAT BACK HINGE COVERS - QUAD BUCKET,

50/50 ............................. 23-146

SPLIT, BENCH - INSTALLATION, SEAT CUSHION COVER - QUAD BUCKET,

50/50 ............................. 23-144

SPLIT, BENCH - REMOVAL, SEAT BACK HINGE COVERS - QUAD BUCKET, 50/50 . . 23-146

SPLIT, BENCH - REMOVAL, SEAT CUSHION COVER - QUAD BUCKET,

50/50 ............................. 23-144

SPRING - AWD - INSTALLATION ..........2-39

SPRING - AWD - REMOVAL .............2-38

SPRING - CARGO - INSTALLATION ........2-40

SPRING - CARGO - REMOVAL ...........2-40

SPRING - FWD - INSTALLATION ..........2-42

SPRING - FWD - REMOVAL .............2-40

SPRING ASSEMBLY - INSTALLATION, QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER - FLAP ..................... 23-151

SPRING ASSEMBLY - REMOVAL, QUAD BUCKET SEAT SIDE SHIELD/CUP

HOLDER - FLAP ..................... 23-151

SPRING FRONT - INSTALLATION, BUSHING - LEAF ...................... 2-30

SPRING FRONT - REMOVAL, BUSHING - LEAF ............................... 2-29

SPRING MOUNTS - FRONT - INSTALLATION ........................ 2-43

SPRING MOUNTS - FRONT - REMOVAL ....2-42

SPRING MOUNTS - REAR - INSTALLATION ........................ 2-43

SPRING MOUNTS - REAR - REMOVAL .....2-43

SPRING SHACKLE - INSTALLATION .......2-44

SPRING SHACKLE - REMOVAL ...........2-44

SPRINGS - DESCRIPTION, VALVE ........9-109

SPRINGS - OPERATION, VALVE .........9-109

SPROCKET - INSTALLATION, CRANKSHAFT ................... 9-160,9-67

SPROCKET - INSTALLATION, TIMING CHAIN AND CAMSHAFT ...............9-160

SPROCKET - REMOVAL, CRANKSHAFT . . . 9-159,

9-66

SPROCKET - REMOVAL, TIMING CHAIN AND CAMSHAFT ..................... 9-159SPROCKETS - INSTALLATION,

CAMSHAFT .......................... 9-67

SPROCKETS - REMOVAL, CAMSHAFT ......9-66

STABILIZER - INSTALLATION ...........23-33

STABILIZER - REMOVAL ...............23-33

STABILIZER BAR - DESCRIPTION .....2-16,2-44

STABILIZER BAR - INSPECTION ..........2-17

STABILIZER BAR - INSTALLATION ........2-17

STABILIZER BAR - OPERATION .......2-16,2-44

STABILIZER BAR - REMOVAL ............2-17

STABILIZER BAR CUSHION - INSTALLATION .........................2-4

STABILIZER BAR CUSHION - REMOVAL .....2-4

STABILIZER SOCKET - INSTALLATION ....23-33

STABILIZER SOCKET - REMOVAL ........23-33

STAKING - STANDARD PROCEDURE, HEAT ............................... 23-9

STANDARD 4 CYLINDER - DESCRIPTION . . . 8I-9

STARTER, SPECIFICATIONS .............8F-37

STARTING - DESCRIPTION .............8F-31

STARTING - OPERATION ...............8F-31

STARTING - STANDARD PROCEDURE, JUMP ............................... 0-25

STARTING SYSTEM TEST - DIAGNOSIS AND TESTING ....................... 8F-31

STATE DISPLAY TEST MODE, OPERATION - DRB III T................ 25-10

STEERING - DIAGNOSIS AND TESTING, SUSPENSION .......................... 2-50

STEERING BELT TENSION - STANDARD PROCEDURE, CHECKING POWER ..........7-8

STEERING COLUMN - DESCRIPTION .....19-10

STEERING COLUMN - DIAGNOSIS AND TESTING ........................... 19-11

STEERING COLUMN COVER - INSTALLATION, LOWER ................23-74

STEERING COLUMN COVER - INSTALLATION, OVER .................23-76

STEERING COLUMN COVER - REMOVAL, LOWER ............................ 23-74

STEERING COLUMN COVER - REMOVAL, OVER .............................. 23-76

STEERING FASTENER TORQUE, SPECIFICATIONS - POWER ..............19-9

STEERING FLUID LEVEL CHECKING - STANDARD PROCEDURE, POWER .......19-44

STEERING GEAR, SPECIAL TOOLS - POWER ............................ 19-34

STEERING KNUCKLE - INSPECTION ........2-9

STEERING KNUCKLE - INSTALLATION ......2-9

STEERING KNUCKLE - REMOVAL ..........2-7

STEERING PUMP INITIAL OPERATION - STANDARD PROCEDURE, POWER .......19-37

STEERING PUMP, SPECIAL TOOLS - POWER ............................ 19-44

STEERING, SPECIAL TOOLS - POWER .....19-9

STEERING SYSTEM - DESCRIPTION, POWER ............................. 19-1

STEERING SYSTEM - OPERATION, POWER ............................. 19-1

STEERING SYSTEM DIAGNOSIS CHARTS - DIAGNOSIS AND TESTING .............19-3

STEERING SYSTEM FLOW AND PRESSURE TEST - DIAGNOSIS AND

TESTING, POWER ..................... 19-1

STEERING WHEEL - INSTALLATION ......19-24

STEERING WHEEL - REMOVAL ..........19-23

STEM SEALS - DESCRIPTION, VALVE .....9-114

STEM SEALS - INSTALLATION, VALVE ....9-115

STEM SEALS - REMOVAL, VALVE ........9-115

STOP BUMPER - INSTALLATION .........23-25

STOP BUMPER - REMOVAL ............23-25

STOP BUMPER BEZEL - INSTALLATION, SLIDING DOOR ...................... 23-25

STOP BUMPER BEZEL - REMOVAL, SLIDING DOOR ...................... 23-25

STOP LAMP - INSTALLATION, CENTER HIGH MOUNTED ...................... 8L-6

STOP LAMP - REMOVAL, CENTER HIGH MOUNTED ........................... 8L-6

STOP LAMP UNIT - INSTALLATION, CENTER HIGH MOUNTED ...............8L-6

STOP LAMP UNIT - REMOVAL, CENTER HIGH MOUNTED ...................... 8L-6

STORAGE BIN - INSTALLATION, UNDER SEAT ............................. 23-149

STORAGE BIN - REMOVAL, UNDER SEAT . 23-149

30 INDEXRS

Description Group-Page Description Group-Page Description Group-Page