flat tire CHRYSLER CROSSFIRE 2006 1.G User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2006, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2006 1.GPages: 296, PDF Size: 1.6 MB

Page 163 of 296

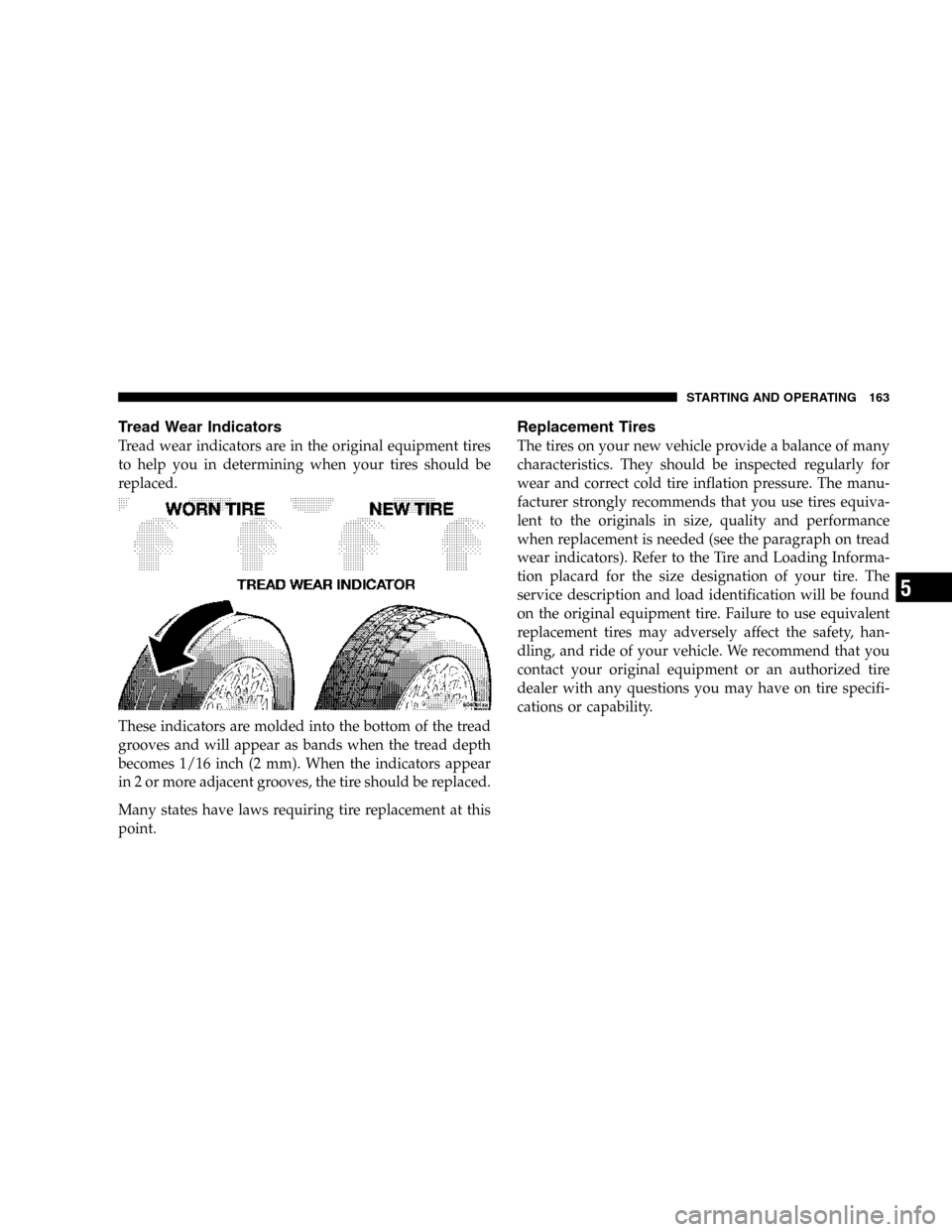

Tread Wear Indicators

Tread wear indicators are in the original equipment tires

to help you in determining when your tires should be

replaced.

These indicators are molded into the bottom of the tread

grooves and will appear as bands when the tread depth

becomes 1/16 inch (2 mm). When the indicators appear

in 2 or more adjacent grooves, the tire should be replaced.

Many states have laws requiring tire replacement at this

point.

Replacement Tires

The tires on your new vehicle provide a balance of many

characteristics. They should be inspected regularly for

wear and correct cold tire inflation pressure. The manu-

facturer strongly recommends that you use tires equiva-

lent to the originals in size, quality and performance

when replacement is needed (see the paragraph on tread

wear indicators). Refer to the Tire and Loading Informa-

tion placard for the size designation of your tire. The

service description and load identification will be found

on the original equipment tire. Failure to use equivalent

replacement tires may adversely affect the safety, han-

dling, and ride of your vehicle. We recommend that you

contact your original equipment or an authorized tire

dealer with any questions you may have on tire specifi-

cations or capability.

STARTING AND OPERATING 163

5

Page 164 of 296

Recommended Tire Inflation Pressures

Sport Performance (Y speed rating) tires and All-Season

Performance (W speed rating) tires

Front 225/40 ZR18............... 32psi(221 kPa)

Rear 255/35 ZR19................ 33psi(227 kPa)

Sport Performance (Y speed rating) tires and All-Season

Performance (W speed rating) tires above 100 mph (161

km/h)

Front 225/40 ZR18............... 36psi(248 kPa)

Rear 255/35 ZR19................ 36psi(248 kPa)

Winter tires

Front 225/40 VR18 M+S........... 33psi(227 kPa)

Rear 225/40 VR18 M+S............ 36psi(248 kPa)WARNING!

•When obtaining replacement tires, assure that the

tires are specified for replacement on the Cross-

fire. Tires with the same size, speed, or load

ratings that are specified for replacement on other

vehicles may not properly fit on the original

equipment wheels of your vehicle.

•Do not use a tire, wheel size or rating other than

that specified for your vehicle. Some combina-

tions of unapproved tires and wheels may change

suspension dimensions and performance charac-

teristics, resulting in changes to steering, han-

dling, and braking of your vehicle. This can cause

unpredictable handling and stress to steering and

suspension components. You could lose control

and have an accident resulting in serious injury or

death. Use only the tire and wheel sizes with load

ratings approved for your vehicle.

•Never use a tire with a smaller load index or

capacity, other than what was originally equipped

on your vehicle. Using a tire with a smaller load

index could result in tire overloading and failure.

You could lose control and have an accident.

•Failure to equip your vehicle with tires having

adequate speed capability can result in sudden

tire failure and loss of vehicle control.

164 STARTING AND OPERATING

Page 165 of 296

CAUTION!

Replacing original tires with tires of a different size

may result in false speedometer and odometer read-

ings. Check with your authorized dealer before

replacing tires with a different size.

Alignment And Balance

The suspension components of your vehicle should be

inspected and aligned when needed to obtain full tire

tread mileage

Poor suspension alignment may result in:

•Fast tire wear.

•Uneven tire wear, such as feathering and one-sided

wear.

•Vehicle pull to right or left.

Tires may also cause the vehicle to pull to the left or right.

Alignment will not correct this condition. See your dealer

for proper diagnosis.Improper alignment will not cause vehicle vibration.

Vibration may be a result of tire and wheel out-of-

balance. Proper balancing will reduce vibration and

avoid tire cupping and spotty wear.

TIRE PRESSURE MONITOR SYSTEM (If

Equipped)

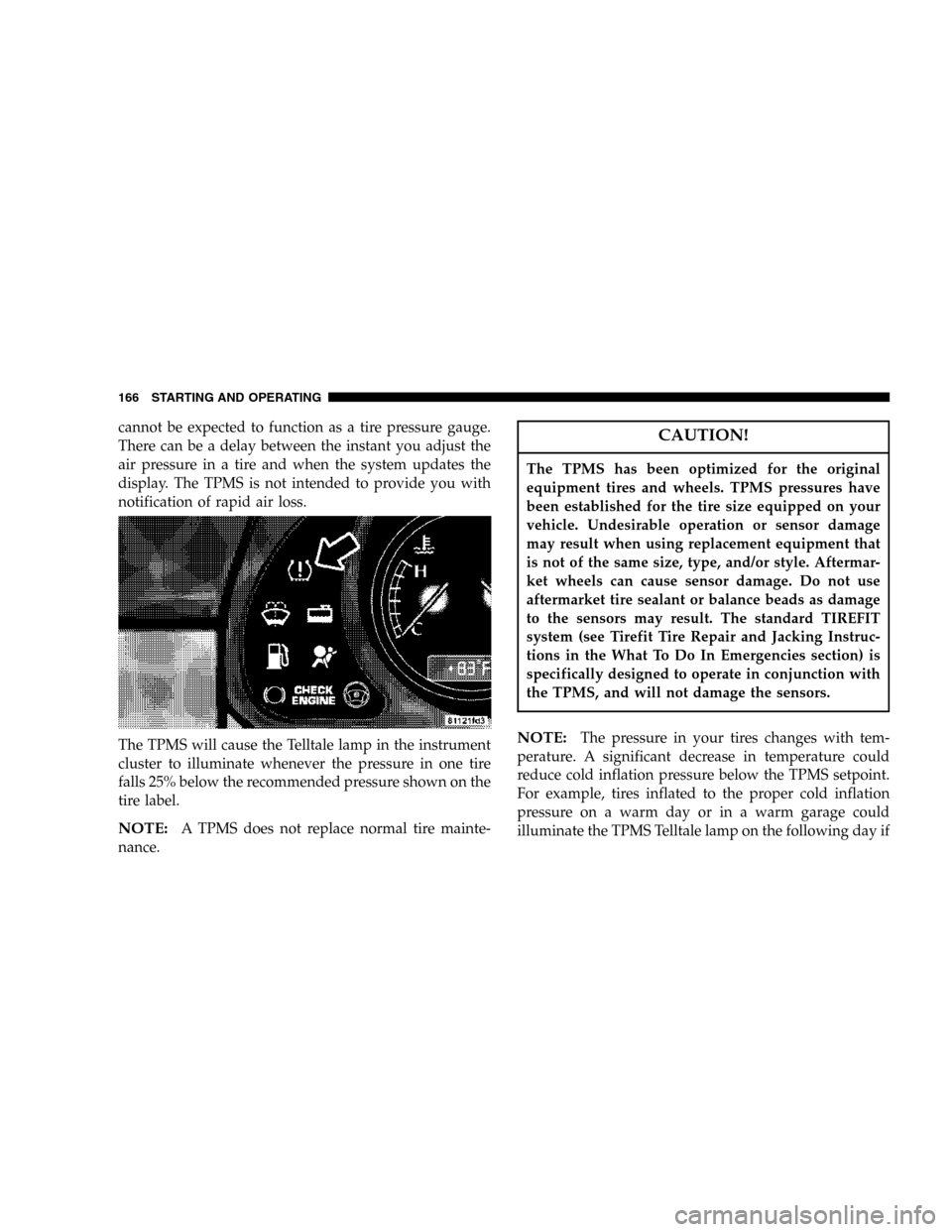

The Tire Pressure Monitor System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to a computer which monitors for low pressure.

If low pressure is measured, the TPMS Telltale Lamp will

illuminate.

NOTE:It is particularly important, for you to check the

tire pressure in all of your tires regularly and to maintain

the proper pressure.

The TPMS informs you of a low tire pressure condition.

If this occurs, correct your tire inflation pressure as soon

as possible, and inspect all of your tires. Be sure to use a

high quality gauge when adjusting pressure. The TPMS

is designed to periodically monitor your tire pressure but

STARTING AND OPERATING 165

5

Page 166 of 296

cannot be expected to function as a tire pressure gauge.

There can be a delay between the instant you adjust the

air pressure in a tire and when the system updates the

display. The TPMS is not intended to provide you with

notification of rapid air loss.

The TPMS will cause the Telltale lamp in the instrument

cluster to illuminate whenever the pressure in one tire

falls 25% below the recommended pressure shown on the

tire label.

NOTE:A TPMS does not replace normal tire mainte-

nance.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures have

been established for the tire size equipped on your

vehicle. Undesirable operation or sensor damage

may result when using replacement equipment that

is not of the same size, type, and/or style. Aftermar-

ket wheels can cause sensor damage. Do not use

aftermarket tire sealant or balance beads as damage

to the sensors may result. The standard TIREFIT

system (see Tirefit Tire Repair and Jacking Instruc-

tions in the What To Do In Emergencies section) is

specifically designed to operate in conjunction with

the TPMS, and will not damage the sensors.

NOTE:The pressure in your tires changes with tem-

perature. A significant decrease in temperature could

reduce cold inflation pressure below the TPMS setpoint.

For example, tires inflated to the proper cold inflation

pressure on a warm day or in a warm garage could

illuminate the TPMS Telltale lamp on the following day if

166 STARTING AND OPERATING

Page 181 of 296

WARNING!

Cuts or punctures larger than approximately 0.16 in. (4

mm), tire damage caused by driving with extremely

low tire pressure or on a flat tire, or a damaged wheel

can pose a hazard while driving. TIREFIT should not

be used in such circumstances. Do not drive the

vehicle under such circumstances. Contact your near-

est authorized dealer for assistance.

Take care not to allow the contents of TIREFIT to come

in contact with hair, eyes or clothing. TIREFIT is

harmful if inhaled, swallowed or absorbed through the

skin: It causes skin, eye and respiratory irritation. Any

contact with eyes or skin should be flushed immedi-

ately with plenty of water. If clothing comes in contact

with TIREFIT, change clothing as soon as possible.

In case of allergic reaction or rash, consult a physician

immediately. Keep TIREFIT out of reach of children. If

swallowed, rinse mouth immediately with plenty of

water and drink plenty of water. Do not induce

vomiting! Consult a physician immediately.

Keep away from open flame or heat source.

Sealing tire with TIREFIT

1. Set the parking brake and turn on the hazard warning

flashers.

2. Move the transmission selector lever to the PARK

position (manual transmission to FIRST or REVERSE

gear) and turn off the engine.

3. Remove the TIREFIT kit and electric air pump from

the area below the cargo compartment carpet.

4. Open flap (2) on the electric air pump.

5. Pull the power plug (4) and air hose (5) along with the

pressure gauge out of the air pump housing.

6. Screw the air hose (5) onto the hose connection on the

TIREFIT sealant bottle (1).

7. Holding the sealant bottle by the top, insert it down-

wards into the recess (3) on the air pump.

8. Unscrew the valve cap from the valve on the deflated

tire.

9. Screw the filler hose from the sealant bottle on the tire

valve.

10. Insert the power plug (4) into the power point on the

instrument panel.

WHAT TO DO IN EMERGENCIES 181

6

Page 182 of 296

11. Turn the ignition key to the ON/RUN position.

12. Press the switch on the air pump to 1. The air pump

should start to inflate the tire.

13. After five minutes, the tire should be inflated to at

least 26 psi (180 kPa) on the pressure gauge.

14. If the tire doesn’t inflate to this level, press the air

pump switch to 0, disconnect the TIREFIT system from

the tire, and drive the vehicle back and forth approxi-

mately 30 feet (9 m) to distribute the sealant more evenly

within the tire.

15. Attach the air pump hose directly to the tire, press the

switch to 1, and inflate the tire again.NOTE:If a tire

pressure of 26 psi (180 kPa) is not reached after five

minutes, the tire is too badly damaged. Do not attempt to

drive the vehicle further, and call for assistance.

16.

If a tire pressure of 26 psi (180 kPa) is obtained, press

the air pump switch to 0, turn the ignition switch to the

OFF/LOCK position, and disconnect the TIREFIT system.

17. Drive the vehicle for about 10 minutes to ensure

optimum distribution of the tire sealant within the tire.18. Check the pressure in the tire. If the pressure is above

19 psi (130 kPa), inflate the tire to the pressure indicated

on the tire pressure label on the driver side latch pillar.

19. Have the tire inspected at the earliest opportunity at

an authorized dealer or tire service center.

NOTE:Do not exceed 50 mph (80 km/h) until the tire

has been inspected.

NOTE:If a pressure of at least 19 psi (130 kPa) cannot

be maintained in the tire, the tire is too badly damaged.

Do not attempt to drive the vehicle further, and call for

assistance.

NOTE:Do not operate the electric air pump for more

than eight minutes to avoid overheating. The air pump

may be used again once it has cooled down.

NOTE:Replace the TIREFIT sealant bottle once every

four years to assure optimum operation of the system.

NOTE:If TIREFIT is liquid, clean water and a damp

cloth will remove the material from the vehicle or tire and

wheel components. Once TIREFIT sealing material has

dried, it can easily be peeled off and properly discarded.

182 WHAT TO DO IN EMERGENCIES

Page 184 of 296

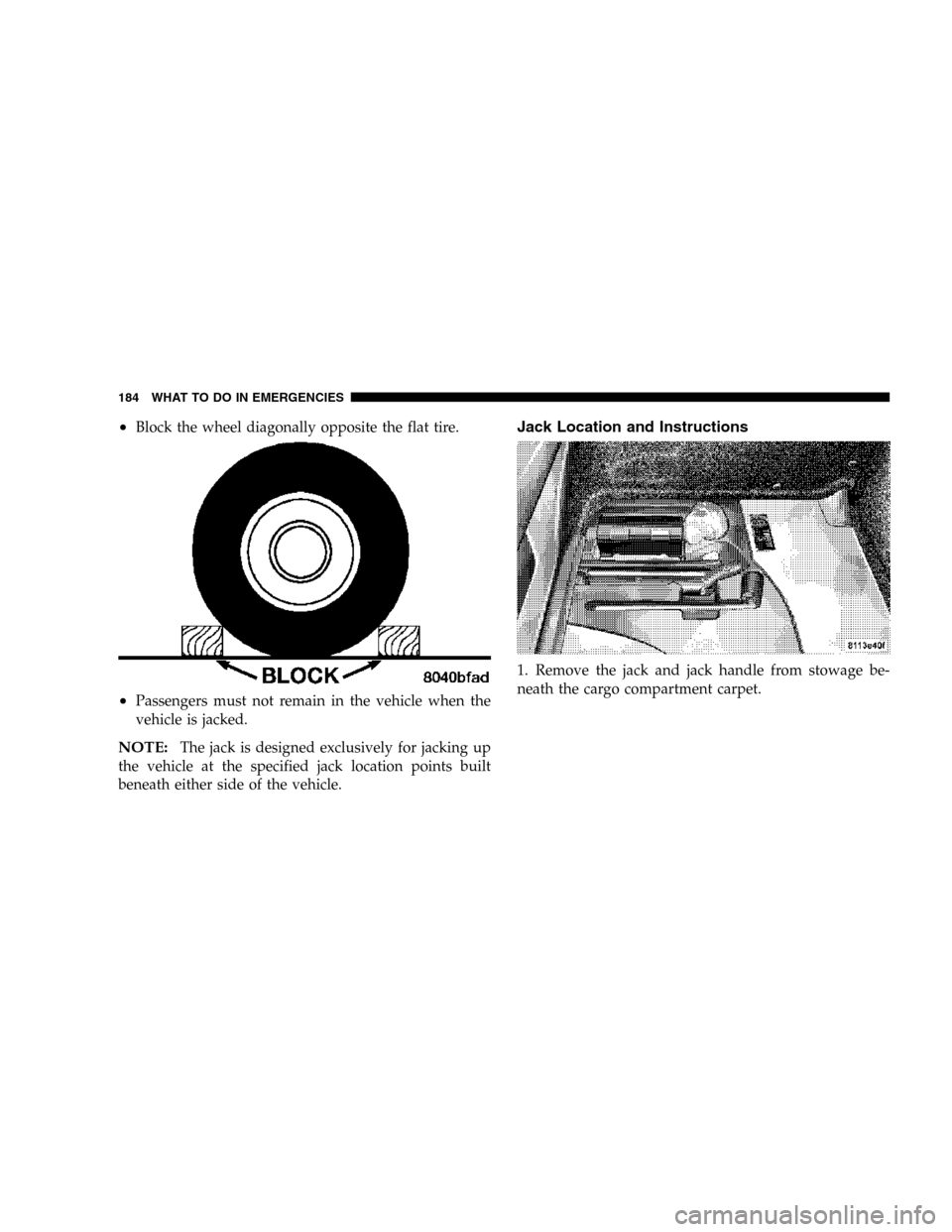

•Block the wheel diagonally opposite the flat tire.

•Passengers must not remain in the vehicle when the

vehicle is jacked.

NOTE:The jack is designed exclusively for jacking up

the vehicle at the specified jack location points built

beneath either side of the vehicle.

Jack Location and Instructions

1. Remove the jack and jack handle from stowage be-

neath the cargo compartment carpet.

184 WHAT TO DO IN EMERGENCIES

Page 190 of 296

Traction

When driving on wet or slushy roads, it is possible for a

wedge of water to build up between the tire and road

surface. This is hydroplaning and may cause partial or

complete loss of vehicle control and stopping ability. To

reduce this possibility, the following precautions should

be observed:

1. Slow down during rainstorms or when roads are

slushy.

2. Slow down if the road has standing water or puddles.

3. Replace tires when tread wear indicators first become

visible.

4. Keep tires properly inflated.

5. Maintain enough distance between your vehicle and

the vehicle in front to avoid a collision in a sudden stop.

FREEING A STUCK VEHICLE

In order to free a stuck vehicle you must turn off the

Electronic Stability Program (ESP) before attempting to

“rock” the vehicle.

If your vehicle becomes stuck in mud, sand or snow, it

can often be moved by a rocking motion. Turn your

steering wheel right and left to clear the area around the

front wheels. Then shift back and forth between Reverse

and Drive. Usually the least accelerator pedal pressure to

maintain the rocking motion without spinning the

wheels is most effective.

NOTE:ESP should be turned on again after freeing the

vehicle from a stuck condition.

CAUTION!

Racing the engine or spinning the wheels too fast

may lead to transmission/axle overheating and fail-

ure. It can also damage the tires. Do not spin the

wheels above 35 mph (55 km/h).

190 WHAT TO DO IN EMERGENCIES

Page 248 of 296

Check the battery every four to six weeks to ensure that

the voltage is above 12.40. Voltage will drop more rapidly

in hot temperatures. If battery voltage drops below 12.40,

follow the battery recharge procedure in the Service

Manual.

•Check that the radiator coolant level of protection is to

at least -20°F (-29°C).

•Block the wheels. Do not apply the parking brake.

•Make sure that all tires are inflated to the optimum

pressure.

•Cut blocks of plywood about the same size of the tires.

Cover each block with indoor/outdoor carpeting and

place them between the tires and concrete. This will

prevent tire flat spotting.

•For long term storage, remove the tires and put the

vehicle up on blocks. Stack the tires on plywood and

cover with a tarp to prevent flat spotting.

•Move the wiper blades away from the windshield.

NOTE:To help prevent the battery from discharging

during shorter periods of inactivity, perform the follow-

ing:

1. Make sure that the rear liftgate/decklid, hood, and

doors are completely closed.

2. Make sure that the remote transmitter is operating and

that the battery is good.

3. Make sure that the hood, rear liftgate and door

switches are in adjustment.

4. Use the remote transmitter to set the alarm.

248 MAINTAINING YOUR VEHICLE

Page 258 of 296

Your Flexible Service System (FSS) — see Understanding

Your Instrument Panel section — should give you an

exact indication of when your vehicle should be sched-

uled for service and which schedule to follow.

Additional Periodic Maintenanceitems should also be

performed beyond the items listed in the following charts

to assure the optimum performance of your Crossfire.

SCOPE OF WORK FOR “A” SCHEDULE

MAINTENANCE SERVICE

Oil Change

•Change oil and replace filter

Maintenance

•Lubricate hood hinges, latch, and secondary latch

•Reset FSS Display

Function Check

•Horn, hazard warning flashers, turn signals, and indi-

cator lamps

•Headlamps and exterior lighting

•Windshield wipers and washer system

Inspection

•Check front and rear brake pads for lining thickness

•Check tires for damage and general condition

•Check tire inflation pressures and correct if necessary

Fluid Levels

Check fluid levels for the following systems and correct if

necessary. Should there be a loss of fluid that cannot be

explained by regular use, trace and eliminate the cause.

•Engine cooling system (check corrosion inhibitor/

antifreeze)

•Hydraulic brake system

•Power steering system

•Windshield washer system

258 MAINTENANCE SCHEDULES

8

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S