check oil CHRYSLER CROSSFIRE 2007 1.G Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2007, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2007 1.GPages: 299, PDF Size: 8.26 MB

Page 55 of 299

ENGINE BREAK-IN RECOMMENDATIONS

The engine in your new Crossfire does not require a long

break-in period. Following these few simple guidelines is

all that is necessary for a good break-in.

²Drive your vehicle at moderate vehicle and engine

speeds during the first 1,000 miles (1,600 km).

²Do not make any full throttle starts and avoid full

throttle acceleration.

²Use the proper transmission gear for your speed

range.

²Avoid excessive idling.

²Check the engine oil level at every fuel fill.

NOTE:A new engine may consume some oil during the

first few thousand miles of operation. This should be

considered as a normal part of the break-in and not an

indication of a problem.

SAFETY TIPS

Exhaust Gas

WARNING!

Exhaust gases can injure or kill. They contain carbon

monoxide (CO) which is colorless and odorless.

Breathing it can make you unconscious and can

eventually poison you. To avoid breathing (CO)

follow the safety tips below.

²Do not run the engine in a closed garage or in confined

areas any longer than needed to move your vehicle in

or out of the area.

²If it is necessary to sit in a parked vehicle with the

engine running, adjust your heating or cooling con-

trols to force outside air into the vehicle. Set the blower

at high speed.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 55

2

Page 57 of 299

Fluid Leaks

Check area under vehicle after overnight parking for fuel,

water, oil, or other fluid leaks. Also, if gasoline fumes are

present, the cause should be corrected immediately.

NOTE:Use of the air conditioning may cause puddles

of water to form under the vehicle.

THINGS TO KNOW BEFORE STARTING YOUR VEHICLE 57

2

Page 125 of 299

28. Oil Level Indicator Light

With the key in the ignition switch turned to

the ON/RUN position, the oil level indicator

light comes on. It should go out immediately

when the engine is running. If the light does

not go out, or comes on while driving, the engine oil

level has dropped to approximately the minimum

mark on the dipstick.

CHECKING ENGINE OIL LEVEL

A sensor in the oil pan allows oil level to be checked

without opening the hood. It provides an accurate mea-

surement of oil level, whereas the low engine oil level

indicator warns that oil level is definitely too low. With

the vehicle parked on a level surface, the engine is

warmed up and shut off for approximately five minutes.

When the ignition switch is turned to the ON/RUN

position, press the knob to the left of the speedometer

once and wait 7 seconds. An ISO oil level icon appears in

the trip odometer window and a ªclockº icon in the

cumulative odometer display. Pressing the knob to the

left of the speedometer twice within one second displays

one of the following messages:²OK

²-1.0 Q (-1.0L)

²-1.5 Q (-1.5L)

²-2.0 Q (-2.0L)

²HI

The indicated amount of oil must be added to the engine

if the message -2.0 Q (-2.0L) blinks and a signal sounds.

The HI message indicates that the excess oil must be

removed from the pan to avoid possible engine or

catalytic converter damage. If the ISO oil level icon and

ªclockº icon remain on when attempting to check oil

level and no message follows, or if the low engine oil

level warning lamp comes on, a malfunction in the

engine oil level system is indicated. A conveniently

located dipstick allows manual checking of the oil level.

If no leaks are noted, continue to drive to the nearest

service station where the engine oil should be topped to

the ªfullº mark on the dipstick with an approved oil.

29. Low Fuel Warning Light

When the fuel level drops to about 2 gallons (7.5

liters), this symbol will light and remains lit until

fuel is added.

UNDERSTANDING YOUR INSTRUMENT PANEL 125

4

Page 225 of 299

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the proper equipment.

If you have any doubt about your ability to perform

a service job, take your vehicle to a competent

technician.

MAINTENANCE PROCEDURES

The pages that follow contain the maintenance service

recommended by the engineers who designed your ve-

hicle.

Besides the maintenance items for which there are fixed

maintenance intervals, there are other items that should

operate satisfactorily without periodic maintenance.However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance.

These items should be inspected if a malfunction is

observed or suspected.

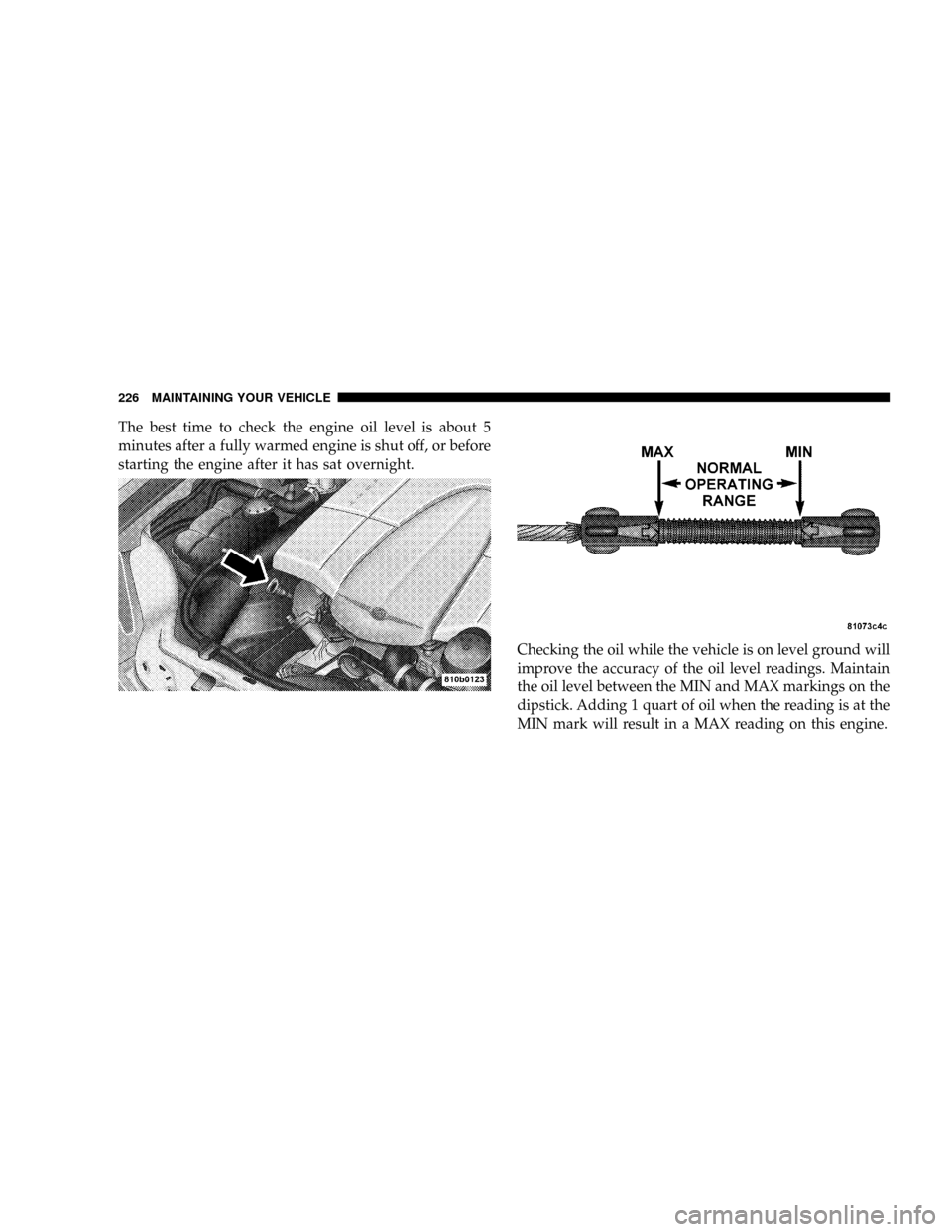

Engine Oil

Checking Oil Level

To assure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop.

You can check the oil level using the procedure described

in Checking Engine Oil Level in the Understanding Your

Instrument Panel section, or by checking the engine oil

dipstick.

MAINTAINING YOUR VEHICLE 225

7

Page 226 of 299

The best time to check the engine oil level is about 5

minutes after a fully warmed engine is shut off, or before

starting the engine after it has sat overnight.

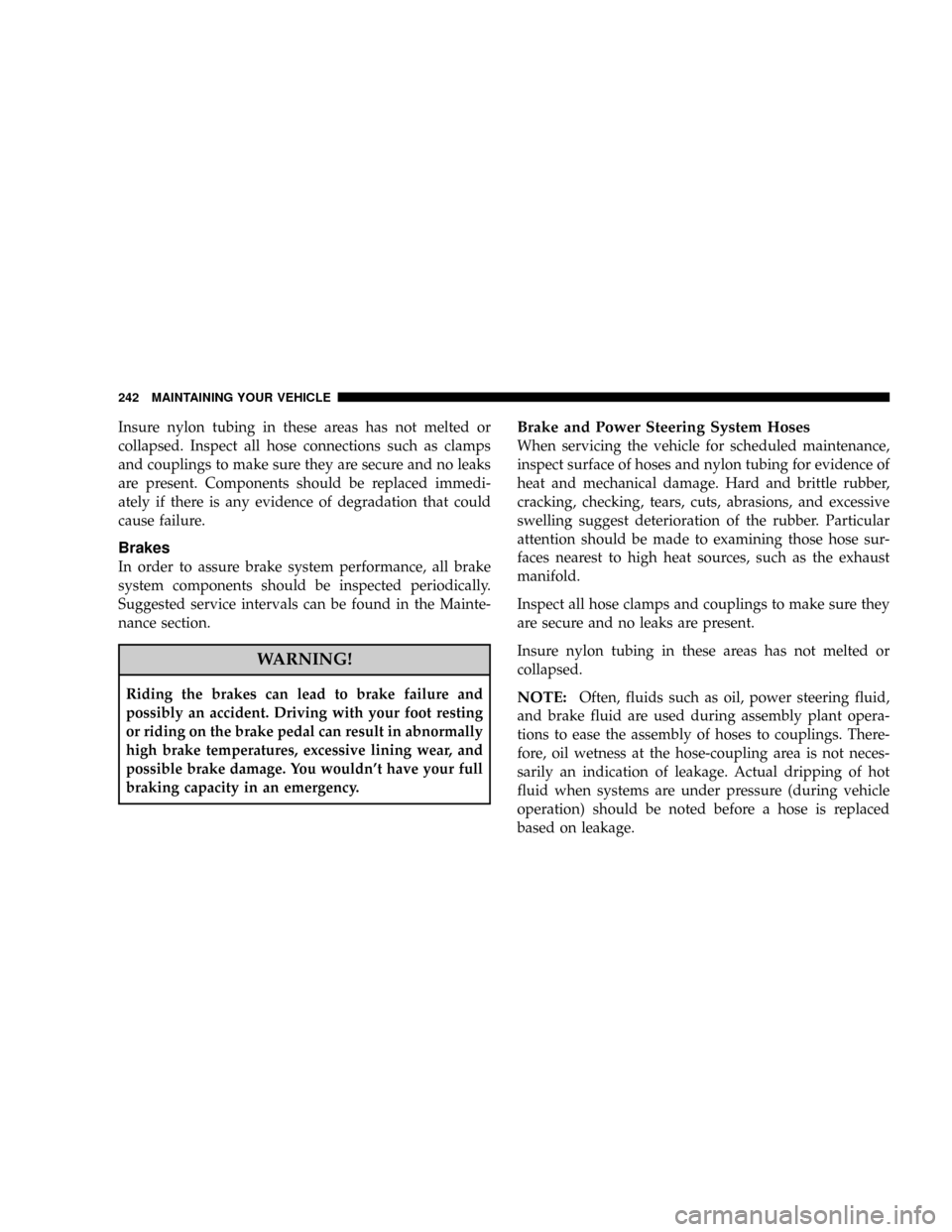

Checking the oil while the vehicle is on level ground will

improve the accuracy of the oil level readings. Maintain

the oil level between the MIN and MAX markings on the

dipstick. Adding 1 quart of oil when the reading is at the

MIN mark will result in a MAX reading on this engine.

226 MAINTAINING YOUR VEHICLE

Page 242 of 299

Insure nylon tubing in these areas has not melted or

collapsed. Inspect all hose connections such as clamps

and couplings to make sure they are secure and no leaks

are present. Components should be replaced immedi-

ately if there is any evidence of degradation that could

cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Insure nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

242 MAINTAINING YOUR VEHICLE

Page 243 of 299

NOTE:Inspection of brake hoses should be done

whenever the brake system is serviced and at every

engine oil change.

WARNING!

Worn brake hoses can burst and cause brake failure.

You could have an accident. If you see any signs of

cracking, scuffing, or worn spots, have the brake

hoses replaced immediately.

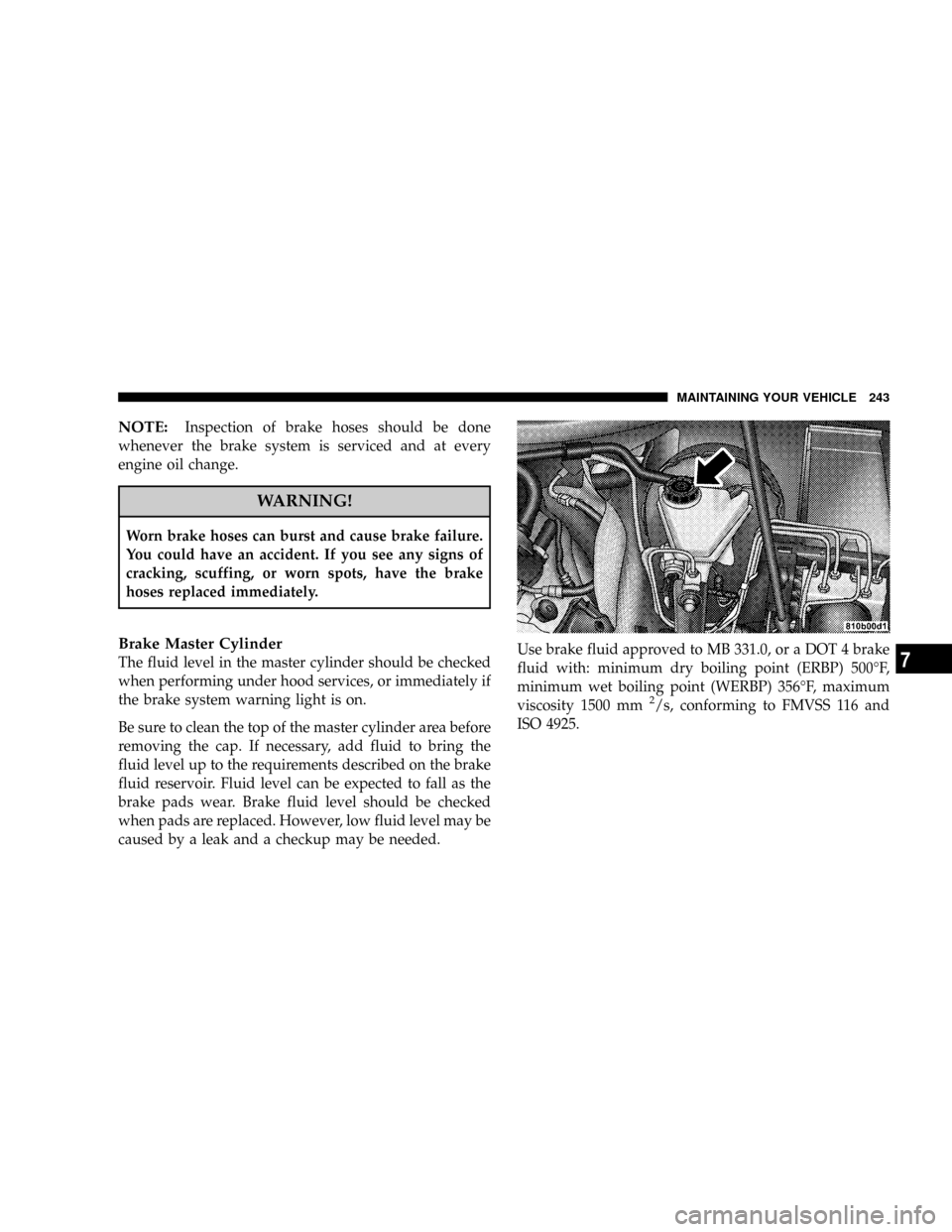

Brake Master Cylinder

The fluid level in the master cylinder should be checked

when performing under hood services, or immediately if

the brake system warning light is on.

Be sure to clean the top of the master cylinder area before

removing the cap. If necessary, add fluid to bring the

fluid level up to the requirements described on the brake

fluid reservoir. Fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be checked

when pads are replaced. However, low fluid level may be

caused by a leak and a checkup may be needed.Use brake fluid approved to MB 331.0, or a DOT 4 brake

fluid with: minimum dry boiling point (ERBP) 500ÉF,

minimum wet boiling point (WERBP) 356ÉF, maximum

viscosity 1500 mm

2/s, conforming to FMVSS 116 and

ISO 4925.

MAINTAINING YOUR VEHICLE 243

7

Page 245 of 299

CAUTION!

Using a transmission fluid other than the fluid rec-

ommended by DaimlerChrysler Corporation may

cause deterioration in transmission shift quality

and/or torque converter shudder. Using a transmis-

sion fluid other than that recommended by the

DaimlerChrysler Corporation will result in more

frequent fluid and filter changes. Refer to the Rec-

ommended Fluids, Lubricants and Genuine Parts

section for correct fluid type.

Fluid Level Check

Regular automatic transmission fluid level checks and

changes are not required. For this reason the dipstick is

omitted.

If you notice fluid loss or gear shift malfunction, have

your authorized dealer check the transmission fluid level.

Fluid and Filter Changes

Automatic transmission fluid and filter should be

changed at 80,000 miles (129,000 km). The fluid is then

filled for life.

NOTE:Refer to Section 8 of this manual for Mainte-

nance Schedules.

Manual Transmission

Selection of Lubricant

No fluid service is required. Use only fluid approved to

MB 236.2. SAE 5W-20 engine oil, meeting API SL or GF-3,

may be substituted. Refer to the Recommended Fluids,

Lubricants and Genuine Parts section for the correct fluid

type.

Fluid Level Check

Check the fluid level by removing the fill plug. The fluid

level should be between the bottom of the fill hole and a

point not more than 3/16 inch (4.76 mm) below the

bottom of the hole.

MAINTAINING YOUR VEHICLE 245

7

Page 263 of 299

the vehicle and then readjust the headlights to the

original position. If any further adjustments are neces-

sary contact your manufacturer's dealer. A detailed ser-

vice procedure is contained in the manufacturer's Service

Manual. Information on purchasing a Service Manual can

be found at the back of this Owner's Manual.

VEHICLE STORAGE

We recommend that you follow these guidelines before

storing your Crossfire for extended periods.

²Fill the gas tank. This will prevent water condensation

inside the tank. If you plan on storing your vehicle

more than two months, add an anti-oxidant fuel

stabilizer to the gas tank.

²Change the oil to remove any corrosive combustion-

related acids in the crankcase.

²Wash and wax the vehicle to protect the finish.

²Cover the vehicle whenever possible to prevent acci-

dental damage to the finish.

²Store the vehicle in a dry, well-ventilated location.

²If the vehicle will be subjected to freezing tempera-

tures, remove the battery and store it in a dry, well-

ventilated place. If the vehicle is not going to be driven

in the next three weeks, follow the battery recharge

procedure in the Service Manual, then disconnect the

battery at the negative terminal.

CAUTION!

Use care when disconnecting the remote positive

cable. It is connected to the battery and can short out

to any metal on the vehicle. Always tape or wrap the

exposed cable end to prevent electrical shorts.

Disconnecting the battery causes the engine control sys-

tem to lose memory of some ªlearnedº functions. The

engine may run rough when first started after a battery

disconnect until the control module ªrelearnsº these

functions.

Check the battery every four to six weeks to ensure that

the voltage is above 12.40. Voltage will drop more rapidly

MAINTAINING YOUR VEHICLE 263

7

Page 271 of 299

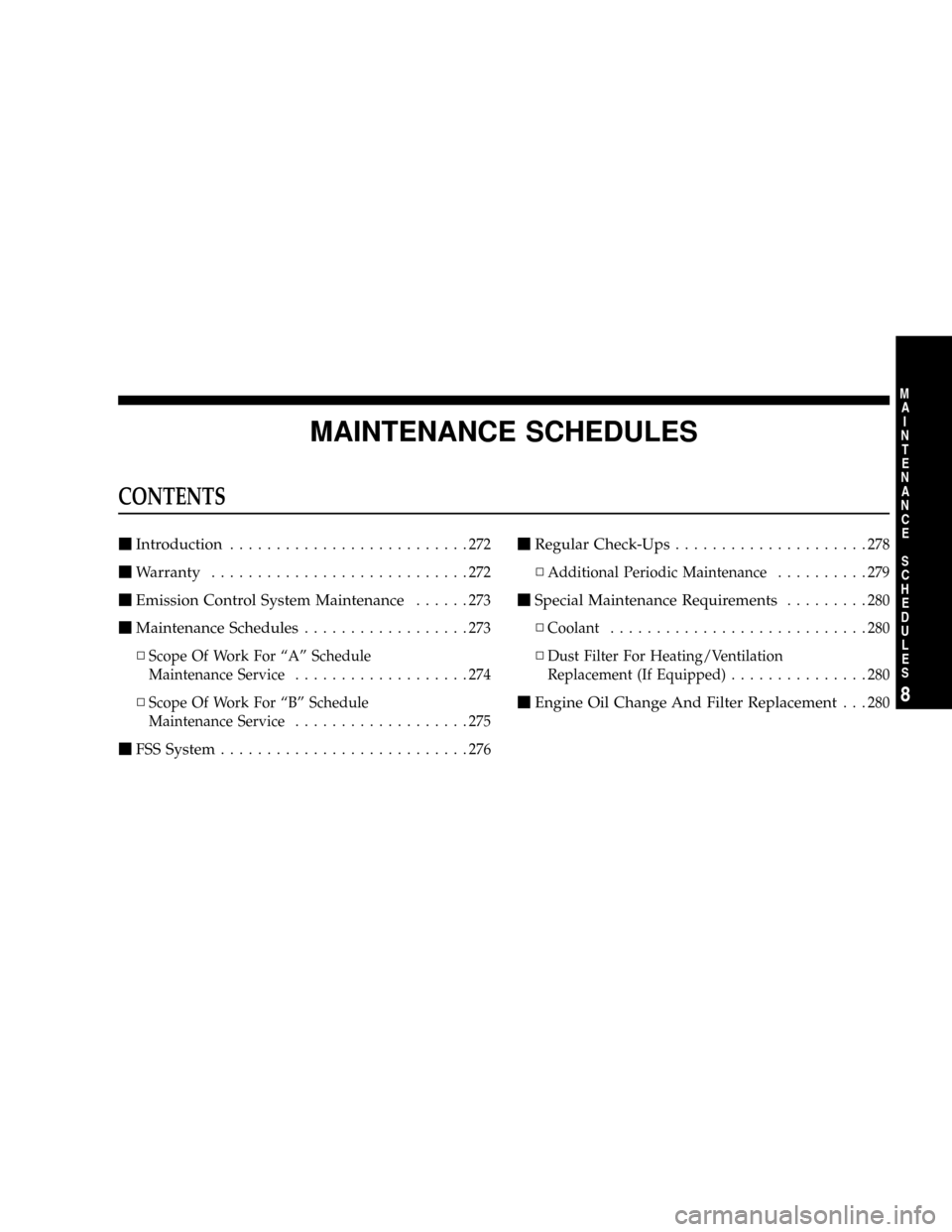

MAINTENANCE SCHEDULES

CONTENTS

mIntroduction..........................272

mWarranty............................272

mEmission Control System Maintenance......273

mMaintenance Schedules..................273

NScope Of Work For ªAº Schedule

Maintenance Service...................274

NScope Of Work For ªBº Schedule

Maintenance Service...................275

mFSS System...........................276

mRegular Check-Ups.....................278

NAdditional Periodic Maintenance..........279

mSpecial Maintenance Requirements.........280

NCoolant............................280

NDust Filter For Heating/Ventilation

Replacement (If Equipped)...............280

mEngine Oil Change And Filter Replacement...2808

M

A

I

N

T

E

N

A

N

C

E

S

C

H

E

D

U

L

E

S