maintenance CHRYSLER CROSSFIRE 2008 1.G User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: CROSSFIRE, Model: CHRYSLER CROSSFIRE 2008 1.GPages: 358, PDF Size: 4.7 MB

Page 265 of 358

until you turn OFF the ignition key or start the engine.

This means that your vehicle's OBD II system isnot

readyand you shouldnotproceed to the I/M station.

b. The CHECK ENGINE light will not flash at all and

will remain fully illuminated until you turn off the

ignition key or start the engine. This means that your

vehicle's OBD II system isreadyand you can proceed

to the I/M station.

If your OBD II system isnot ready,you should see your

authorized dealer or repair facility. If your vehicle was

recently serviced or had a battery failure or replacement,

you may need to do nothing more than drive your

vehicle as you normally would in order for your OBD II

system to update. A recheck with the above test routine

may then indicate that the system is now ready.

Regardless of whether your vehicle's OBD II system is

ready or not ready, if the CHECK ENGINE light is

illuminated during normal vehicle operation, you shouldhave your vehicle serviced before going to the I/M

station. The I/M station can fail your vehicle because the

CHECK ENGINE light is on with the engine running.

REPLACEMENT PARTS

Use of genuine Mopartparts for normal/scheduled

maintenance and repairs is highly recommended to en-

sure the designed performance. Damage or failures

caused by the use of non-Mopartparts for maintenance

and repairs will not be covered by the warranty offered

by DaimlerChrysler Corporation.

AUTHORIZED DEALER SERVICE

Your authorized dealer has the qualified service person-

nel, special tools and equipment to perform all service

operations in an expert manner. Service Manuals are

available which include detailed service information for

your vehicle. Refer to these manuals before attempting

any procedure yourself.

MAINTAINING YOUR VEHICLE 263

7

Page 266 of 358

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being assessed

against you.

WARNING!

You can be badly injured working on or around a

motor vehicle. Do only that service work for which

you have the knowledge and the proper equipment.

If you have any doubt about your ability to perform

a service job, take your vehicle to a competent

technician.

MAINTENANCE PROCEDURES

The pages that follow contain the maintenance service

recommended by the engineers who designed your ve-

hicle.

Besides the maintenance items for which there are fixed

maintenance intervals, there are other items that should

operate satisfactorily without periodic maintenance.

However, if a malfunction of these items does occur, it

could adversely affect the engine or vehicle performance.

These items should be inspected if a malfunction is

observed or suspected.

Engine Oil

Checking Oil Level

To assure proper engine lubrication, the engine oil must

be maintained at the correct level. Check the oil level at

regular intervals, such as every fuel stop.

264 MAINTAINING YOUR VEHICLE

Page 268 of 358

Change Engine Oil

The oil change interval for yourvehicle is initially set at

7,000 mi (Canada: 11 000 km).

The Flexible Service System (FSS) in your vehicle evalu-

ates engine temperature, oil level, vehicle speed, engine

speed, distance driven, and the time elapsed since your

last service. It determines when your vehicle needs

maintenance service and alerts you in advance. The next

necessary service is indicated by the FSS in your instru-

ment cluster.

NOTE:Also see the FSS system details in the Under-

standing Your Instrument Panel section of this manual.

Very light duty driving cycles (most trips more than 10

mi [16 km]) at moderate speeds in moderate temperature

conditions) can extend the service interval beyond 7,000

mi (Canada: 11 000 km).IfANYof the following apply to your driving, the oil

change interval can be reduced significantly:

²Day and night temperatures are below 32ÉF (0ÉC)

²Stop-and-go driving

²Extensive engine idling

²Driving in dusty conditions

²Short trips of less than 10 mi (16 km)

²More than 50% of your driving is at sustained high

speeds during hot weather, above 90ÉF (32ÉC)

²Taxi, Police, or delivery service (commercial service)

Observe the oil change interval indicated by your FSS

system. This system will monitor the driving conditions

seen by your vehicle, and will recommend the best

interval for servicing your vehicle to maintain it in top

condition.

266 MAINTAINING YOUR VEHICLE

Page 270 of 358

Disposing of Used Engine Oil

Care should be taken in disposing of used engine oil from

your vehicle. Used oil, indiscriminately discarded, can

present a problem to the environment. Contact your

dealer, service station, or governmental agency for advice

on how and where used oil can be safely discarded in

your area.

Engine Oil Filter

The engine oil filter should be replaced at every engine

oil change.

Engine Oil Filter Selection

All DaimlerChrysler Corporation engines have a full-

flow type disposable oil filter. Use a filter of this type for

replacement. The quality of replacement filters varies

considerably. Only high quality filters should be used to

assure most efficient service. MopartEngine Oil Filters

are high quality oil filters and are recommended.

Drive Belts - Check Condition and Tension

At the distance shown in the maintenance schedules,

check all drive belts for condition and proper tension.

Improper belt tension can cause belt slippage and failure.

Inspect the drive belts for evidence of cuts, cracks, or

glazing and replace them if there is any sign of damage

which could result in belt failure. If adjustment is re-

quired, adjust the belts according to the specifications

and procedures shown in the Service Manual.

Special tools are required to properly measure tension

and to restore belt tension to factory specifications. Also,

check belt routing to make sure there is no interference

between the belts and other engine components.

Spark Plugs

Spark plugs must fire properly to assure engine perfor-

mance and emission control. New spark plugs should be

installed at the distance specified in the appropriate

maintenance chart. The entire set should be replaced if

268 MAINTAINING YOUR VEHICLE

Page 271 of 358

there is any malfunction due to a faulty spark plug.

Check the specifications section for the proper type of

spark plug for use in your vehicle.

Engine Air Cleaner Filter

Under normal driving conditions, replace the air filter at

each interval called out by FSS.

WARNING!

The air cleaner can provide a measure of protection

in the case of engine backfire. Do not remove the air

cleaner unless such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle with

the air cleaner removed. Failure to do so can result in

serious personal injury.

Engine Fuel Filter

A plugged fuel filter can cause hard starting or limit the

speed at which a vehicle can be driven. Should an

excessive amount of dirt accumulate in the fuel tank,

frequent fuel filter replacement may be necessary. See

your authorized dealer for service.

Catalytic Converter

The catalytic converter requires the use of unleaded fuel

only. Leaded gasoline will destroy the effectiveness of the

catalyst as an emission control device.

Under normal operating conditions, the catalytic con-

verter will not require maintenance. However, it is im-

portant to keep the engine properly serviced to assure

proper catalyst operation and prevent possible catalyst

damage.

If the CHECK ENGINE light is flashing, immediate

service is required.

MAINTAINING YOUR VEHICLE 269

7

Page 273 of 358

To minimize the possibility of catalyst damage:

²Do not shut off the engine or interrupt the ignition

when the transmission is in gear and the vehicle is in

motion.

²Do not try to start the engine by pushing or towing the

vehicle.

²Do not idle the engine with any spark plug wires

disconnected for a prolonged period.

Ignition Wiring System

The ignition cables should be kept clean and properly

connected. Terminals should be fully seated. Cracked,

damaged, or faulty cables should be replaced.

Crankcase Emission Control System

Proper operation of this system depends on freedom

from sticking or plugging due to deposits.

Check the ventilation hose for indication of damage or

plugging deposits. Replace if necessary.

Maintenance-Free Battery

The top of the maintenance-free battery is permanently

sealed. You will never have to add water, nor is periodic

maintenance required.

MAINTAINING YOUR VEHICLE 271

7

Page 276 of 358

Power Steering Fluid

No power steering fluid service is required. The system is

filled at the factory with Pentosin CHF 11S. Steering noise

and reduced component life may result if an unapproved

fluid is used.During scheduled maintenance, check the power steering

fluid level at the power steering fluid reservoir. Nor-

mally, it will not be necessary to add power steering

fluid.

Before removing the reservoir cap, wipe the outside of

the cap and reservoir so that no dirt can fall into the

reservoir.

The power steering pump has a dipstick. Fluid level

should be maintained at the proper level indicated on the

dipstick. If the indicated level of power steering fluid is

low, see your authorized dealer. With a clean cloth, wipe

any spilled fluid from all surfaces.

274 MAINTAINING YOUR VEHICLE

Page 277 of 358

Chassis Lubrication

Front Suspension Ball Joints

There are two front suspension lower ball joints that are

permanently lubricated. Inspect these ball joints when-

ever under-vehicle service is done.

Steering Linkage

Inspect tie rod ends whenever the vehicle is serviced.

They are permanently lubricated and do not require

periodic lubrication.

Drive Shaft Universal Joints

Your vehicle has four constant velocity universal joints.

Periodic lubrication of these joints is not required. How-

ever, the joint boots should be inspected for external

leakage or damage when other maintenance is per-

formed.

If leakage or damage is evident, replace the universal

joint boot and grease immediately.

Continued operation could result in failure of the univer-

sal joint due to water and dirt contamination of the

grease. This would require complete replacement of the

joint assembly.

MAINTAINING YOUR VEHICLE 275

7

Page 283 of 358

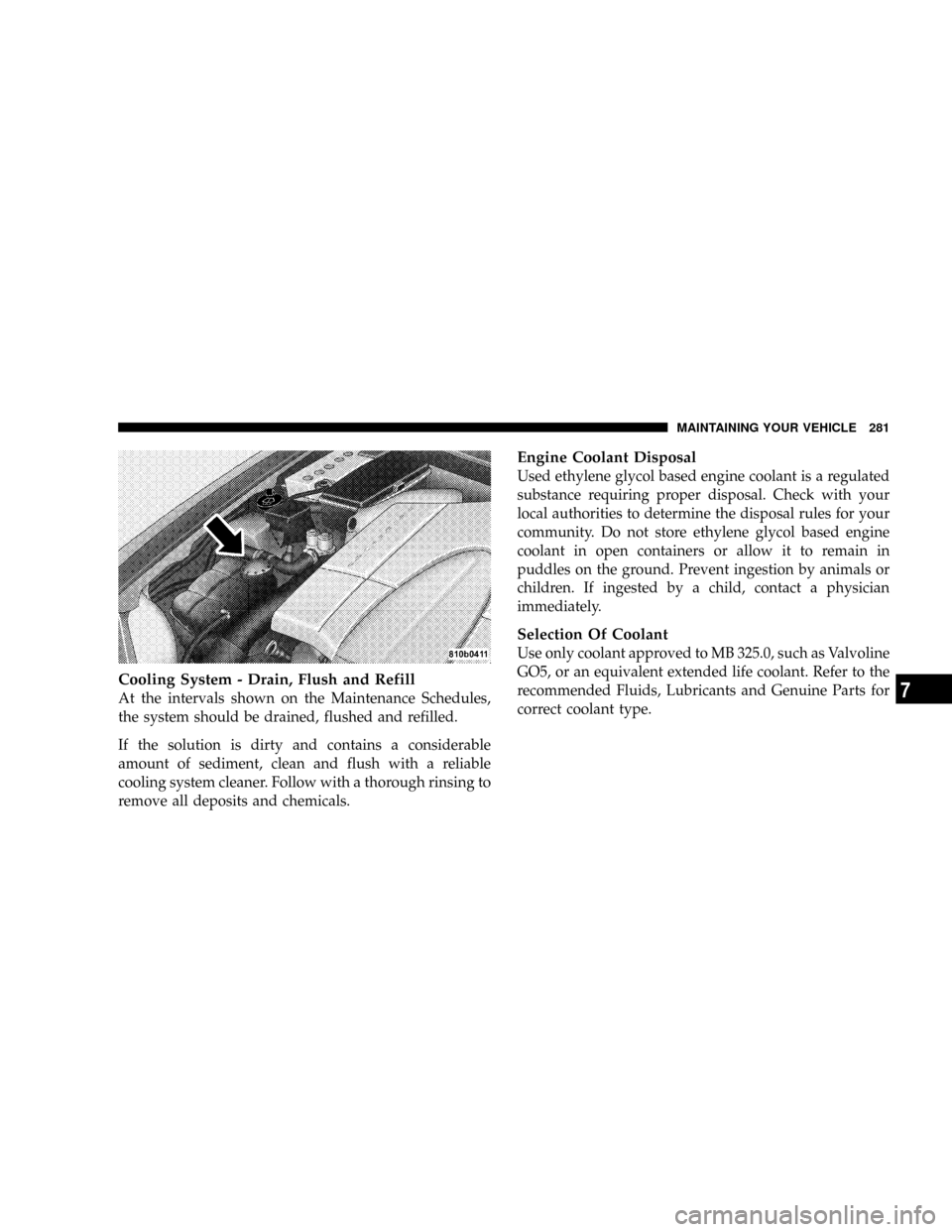

Cooling System - Drain, Flush and Refill

At the intervals shown on the Maintenance Schedules,

the system should be drained, flushed and refilled.

If the solution is dirty and contains a considerable

amount of sediment, clean and flush with a reliable

cooling system cleaner. Follow with a thorough rinsing to

remove all deposits and chemicals.

Engine Coolant Disposal

Used ethylene glycol based engine coolant is a regulated

substance requiring proper disposal. Check with your

local authorities to determine the disposal rules for your

community. Do not store ethylene glycol based engine

coolant in open containers or allow it to remain in

puddles on the ground. Prevent ingestion by animals or

children. If ingested by a child, contact a physician

immediately.

Selection Of Coolant

Use only coolant approved to MB 325.0, such as Valvoline

GO5, or an equivalent extended life coolant. Refer to the

recommended Fluids, Lubricants and Genuine Parts for

correct coolant type.

MAINTAINING YOUR VEHICLE 281

7

Page 287 of 358

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance section.

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake and Power Steering System Hoses

When servicing the vehicle for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,cracking, checking, tears, cuts, abrasions, and excessive

swelling suggest deterioration of the rubber. Particular

attention should be made to examining those hose sur-

faces nearest to high heat sources, such as the exhaust

manifold.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

Ensure the nylon tubing in these areas has not melted or

collapsed.

NOTE:Often, fluids such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to ease the assembly of hoses to couplings. There-

fore, oil wetness at the hose-coupling area is not neces-

sarily an indication of leakage. Actual dripping of hot

fluid when systems are under pressure (during vehicle

operation) should be noted before a hose is replaced

based on leakage.

MAINTAINING YOUR VEHICLE 285

7