tow CHRYSLER PACIFICA 2004 1.G User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2004, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2004 1.GPages: 361, PDF Size: 5.21 MB

Page 110 of 361

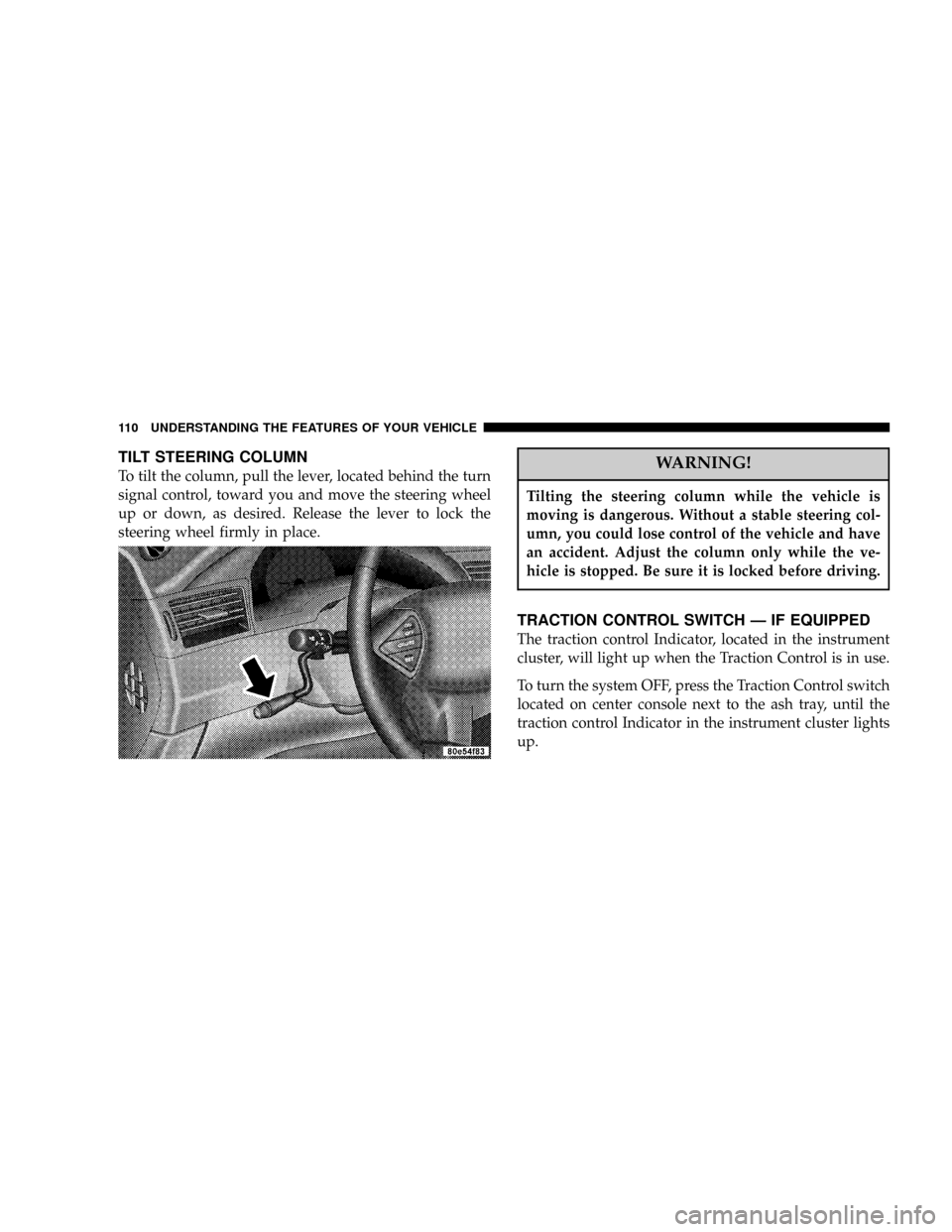

TILT STEERING COLUMN

To tilt the column, pull the lever, located behind the turn

signal control, toward you and move the steering wheel

up or down, as desired. Release the lever to lock the

steering wheel firmly in place.WARNING!

Tilting the steering column while the vehicle is

moving is dangerous. Without a stable steering col-

umn, you could lose control of the vehicle and have

an accident. Adjust the column only while the ve-

hicle is stopped. Be sure it is locked before driving.

TRACTION CONTROL SWITCH Ð IF EQUIPPED

The traction control Indicator, located in the instrument

cluster, will light up when the Traction Control is in use.

To turn the system OFF, press the Traction Control switch

located on center console next to the ash tray, until the

traction control Indicator in the instrument cluster lights

up.

110 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 128 of 361

WARNING!

In an accident a cargo cover loose in the vehicle

could cause injury. It could fly around in a sudden

stop and strike someone in the vehicle. Do not store

the cargo cover on the cargo floor or in the passenger

compartment. Remove the cover from the vehicle

when taken from its mounting. Do not store in the

vehicle.

Stowed Position

1. Fold down the third row seatbacks.

2. Fold the cargo cover extensions to their stowed posi-

tion and lock into place.3. Insert the pins on the ends of the cover into the slots

located on the trim panel behind the third row seatbacks.

4. Grasp the center portion of the cover flap. Pull it over

the cargo area.

5. Insert the pins on the ends of the cover flap into the

slots on the rear trim panel.

6. The liftgate may be opened or closed with the cargo

cover in place.

Cargo Tie-Down Hooks

The tie-downs located on cargo area floor and on the rear

trim panels should be used to safely secure loads when

vehicle is moving.

128 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 130 of 361

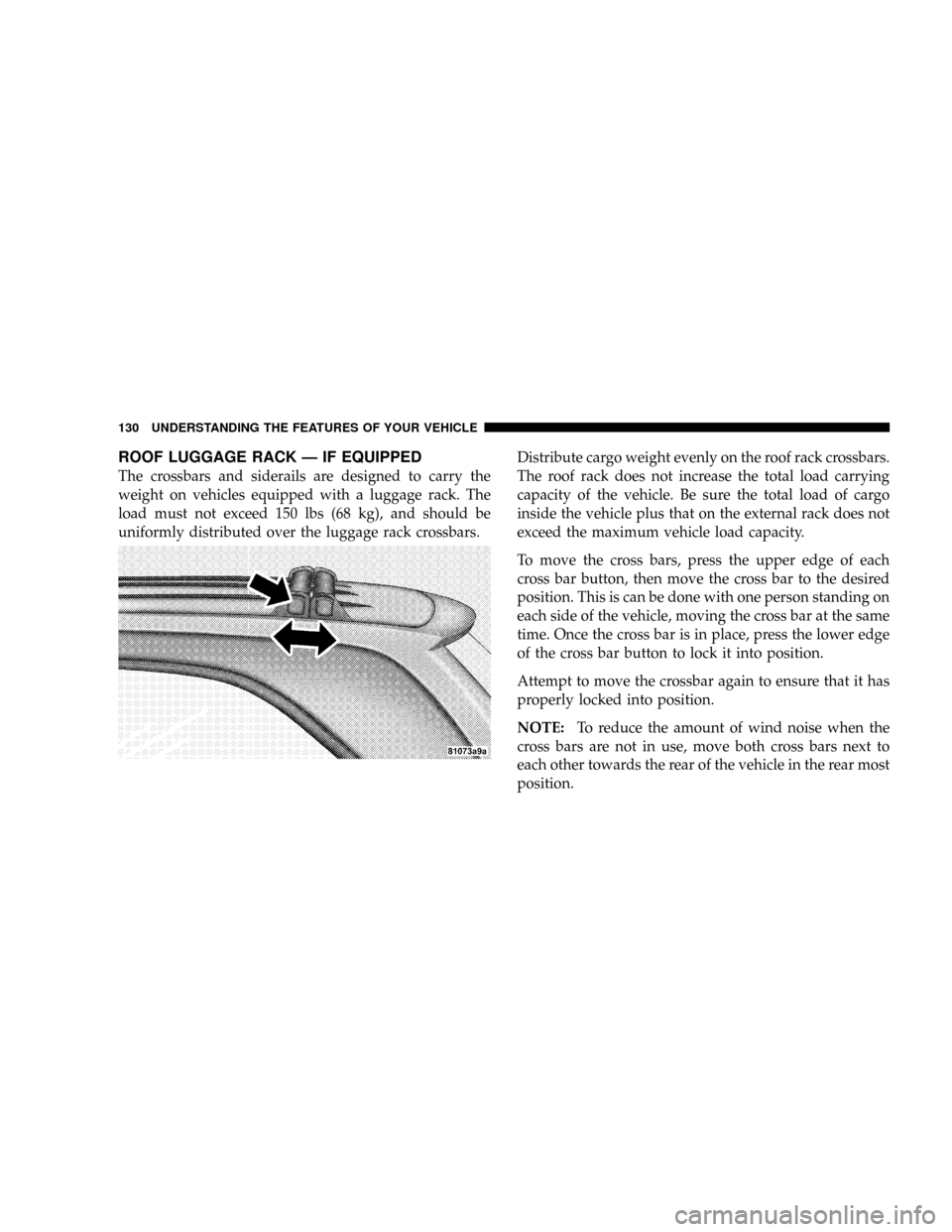

ROOF LUGGAGE RACK Ð IF EQUIPPED

The crossbars and siderails are designed to carry the

weight on vehicles equipped with a luggage rack. The

load must not exceed 150 lbs (68 kg), and should be

uniformly distributed over the luggage rack crossbars.Distribute cargo weight evenly on the roof rack crossbars.

The roof rack does not increase the total load carrying

capacity of the vehicle. Be sure the total load of cargo

inside the vehicle plus that on the external rack does not

exceed the maximum vehicle load capacity.

To move the cross bars, press the upper edge of each

cross bar button, then move the cross bar to the desired

position. This is can be done with one person standing on

each side of the vehicle, moving the cross bar at the same

time. Once the cross bar is in place, press the lower edge

of the cross bar button to lock it into position.

Attempt to move the crossbar again to ensure that it has

properly locked into position.

NOTE:To reduce the amount of wind noise when the

cross bars are not in use, move both cross bars next to

each other towards the rear of the vehicle in the rear most

position.

130 UNDERSTANDING THE FEATURES OF YOUR VEHICLE

Page 138 of 361

INSTRUMENT CLUSTER DESCRIPTIONS

1. Voltage Light

This light monitors the electrical system voltage.

The light should turn on momentarily as the

engine is started. If the light stays on or turns on while

driving, it indicates a problem with the charging system.

Immediate service should be obtained.

2. Temperature Gauge

The temperature gauge shows engine coolant tempera-

ture. Any reading within the normal range indicates that

the engine cooling system is operating satisfactorily.

The gauge pointer will likely indicate a higher tempera-

ture when driving in hot weather, up mountain grades,

or when towing a trailer. It should not be allowed to

exceed the upper limits of the normal operating range.

CAUTION!

Driving with a hot engine cooling system could

damage your vehicle. If temperature gauge reads (H),

pull over and stop the vehicle. Idle the vehicle with

the air conditioner turned off until the pointer drops

back into the normal range. If the pointer remains on

the ªHº, and you hear continuous chimes, turn the

engine off immediately, and call for service.

138 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 143 of 361

release the Trip Odometer button. To reset a trip odom-

eter, display the desired trip odometer to be reset then

push and hold the button until the display resets (ap-

proximately 2 seconds).

14. Cruise Indicator

This display indicator shows that the Speed Control

System is ON.

15. Malfunction Indicator Light

This light is part of an onboard diagnostic system

called OBD that monitors engine and automatic

transmission control systems. The light will illu-

minate when the key is in the ON position before engine

start. If the bulb does not come on when turning the key

from OFF to ON, have the condition checked promptly.

Certain conditions such as a loose or missing gas cap,

poor fuel quality, etc. may illuminate the light after

engine start. The vehicle should be serviced if the lightstays on through several of your typical driving cycles. In

most situations the vehicle will drive normally and will

not require towing.

The Malfunction Indicator Light flashes to alert you to

serious conditions that could lead to immediate loss of

power or severe catalytic converter damage. The vehicle

should be serviced as soon as possible if this occurs.

16. High Beam Light

This light shows that the headlights are on high

beam. Pull the Multi-Function lever towards the

steering wheel to switch the headlights from high or low

beam.

17. Navigation Screen Ð If Equipped

Displays the current navigation screen.

18. Front Fog Light Indicator Ð If Equipped

This light shows the front fog lights are ON.

UNDERSTANDING YOUR INSTRUMENT PANEL 143

4

Page 164 of 361

To set the clock, use a ballpoint pen or similar object to

press the hour (H) or minute (M) buttons on the radio,

The time setting will increase each time you press the

button. Press any other button to exit from the clock

setting mode.

General Information

This radio complies with Part 15 of FCC rules and with

RSS-210 of Industry Canada. Operation is subject to the

following conditions:

1. This device may not cause harmful interference,

2. This device must accept any interference received,

including interference that may cause undesired opera-

tion.

NOTE:Changes or modifications not expressively ap-

proved by the party responsible for compliance could

void the user's authority to operate the equipment.

Tape Player Operation

Insert the cassette with the exposed tape side toward the

right and the mechanical action of the player will gently

pull the cassette into the play position.

NOTE:When subjected to extremely cold temperatures,

the tape mechanism may require a few minutes to warm

up for proper operation. Sometimes poor playback may

be experienced due to a defective cassette tape. Clean and

demagnetize the tape heads at least twice a year.

Tape Side йD/PTY

Pressing the¹Dbutton during tape mode will cause the

other side of the tape to be played. The display will

confirm the selected tape play direction. The time is

always displayed.

Tape

Press the TAPE button to select the Tape mode.

164 UNDERSTANDING YOUR INSTRUMENT PANEL

Page 177 of 361

General Information

This device complies with part 15 of the FCC rules and

RSS 210 of Industry Canada. Operation is subject to the

following two conditions: (1) This device may not cause

harmful interference and (2) This device must accept any

interference received, including interference that may

cause undesired operation.

If you experience static or the headphones will not hold

a channel, check for these two conditions:

1. A weak battery in the headphones.

2. Closeness to a radio transmitter such as a radio station

tower, airport transmitter, and some mobile or CB radios.

Operating Instructions Ð MP3 Player

An MP3 player can be connected to the audio system.

Connect the cables to the RCA jacks located on the front

of the CD/DVD changer.NOTE:Follow the manufactures instructions for the

correct colors when connecting the RCA cables.

Operating Instructions Ð Video

Games/Camcorders

A video game unit or camcorder can be connected to the

rear audio/video system. Connect the cables to the RCA

jacks located on the front of the CD/DVD changer.

NOTE:To operate a video game unit a DC to AC

adapter may be required, plug the adapter into any

power outlet.

Follow the manufactures instructions for the correct

colors when connecting the RCA cables.

NOTE:MP3 player's, video game systems, camcorders

connected to the RCA jacks and CD's or DVD's inserted

into the CD/DVD changer can be heard through the

headphones.

UNDERSTANDING YOUR INSTRUMENT PANEL 177

4

Page 197 of 361

NGasoline/Oxygenate Blends..............236

NMMT In Gasoline.....................237

NSulfur In Gasoline.....................237

NMaterials Added To Fuel................238

NFuel System Cautions..................238

NCarbon Monoxide Warnings..............239

mAdding Fuel..........................240

NFuel Filler Cap (Gas Cap)...............240mVehicle Loading........................241

NVehicle Certification Label...............241

NGross Vehicle Weight Rating (GVWR).......242

NGross Axle Weight Rating (GAWR).........242

NOverloading.........................242

NLoading............................243

mTrailer Towing.........................244

NWarranty Requirements.................245

STARTING AND OPERATING 197

5

Page 199 of 361

WARNING!

²Do not attempt to push or tow your vehicle to get

it started. Vehicles equipped with an automatic

transmission cannot be started this way. Un-

burned fuel could enter the catalytic converter and

once the engine has started, ignite and damage the

converter and vehicle. If the vehicle has a dis-

charged battery, booster cables may be used to

obtain a start from a booster battery or the battery

in another vehicle. This type of start can be

dangerous if done improperly. See section 6 of

this manual for the proper jump starting proce-

dures and follow them carefully.

²Never pour fuel or other flammable liquid into

the throttle body air inlet opening in an attempt to

start the vehicle. This could result in flash fire

causing serious personal injury.

If Engine Fails to Start

If the engine fails to start after you have followed the

ªNORMAL STARTINGº procedure, it may be flooded.

Push the accelerator pedal all the way to the floor and

hold it there while cranking the engine. This should clear

any excess fuel in case the engine is flooded.

CAUTION!

To prevent damage to the starter, do not crank the

engine for more than 15 seconds at a time. Wait 10 to

15 seconds before trying again.

STARTING AND OPERATING 199

5

Page 203 of 361

NOTE:Even if the transmission can be reset, it is

recommended that you visit a dealer at your earliest

possible convenience. Your dealer has diagnostic equip-

ment to determine if the problem could recur.

If the transmission cannot be reset, dealer service is

required.

Gear Ranges

DO NOT race the engine when shifting from PARK or

NEUTRAL positions into another gear range.

ªPº Park

Supplements the parking brake by locking the transmis-

sion. The engine can be started in this range. Never

attempt to use PARK while vehicle is in motion.

Apply parking brake when leaving vehicle in this range.

ªRº Reverse

Shift into this range only after the vehicle has come to a

complete stop.ªNº Neutral

Engine may be started in this range.

ªDº Overdrive

To be used for most city and highway driving, it provides

smoothest upshifts and downshifts and best fuel

economy. When frequent transmission shifting occurs

while using the ªDº Overdrive position, such as when

operating the vehicle under heavy loading conditions,

(i.e. in hilly terrain, traveling into strong head winds or

while towing heavy trailers), use the AutoStick mode and

select the ª3º range.

NOTE:Using the ª3º range in the AutoStick mode

while operating the vehicle under heavy operating con-

ditions will improve performance and extend transmis-

sion life by reducing excessive shifting and heat build up.

STARTING AND OPERATING 203

5