ECU CHRYSLER PACIFICA 2008 1.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2008, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2008 1.GPages: 457, PDF Size: 6.7 MB

Page 281 of 457

possible convenience. Your dealer has diagnostic equip-

ment to determine if the problem could recur.

Gear Ranges

DO NOT race the engine when shifting from PARK or

NEUTRAL positions into another gear range.

ªPº Park

Supplements the parking brake by locking the transmis-

sion. The engine can be started in this range. Never

attempt to use PARK while vehicle is in motion.

Apply parking brake when leaving vehicle in this range.

WARNING!

Never use Park position on an automatic transmission

as a substitute for the parking brake. Always apply

parking brake fully when parked to guard against

vehicle movement and possible injury or damage.

ªRº Reverse

Shift into this range only after the vehicle has come to a

complete stop.

ªNº Neutral

Engine may be started in this range.

ªDº Overdrive

To be used for most city and highway driving, it provides

smoothest upshifts and downshifts and best fuel

economy. When frequent transmission shifting occurs

while using the ªDº Overdrive position, such as when

operating the vehicle under heavy loading conditions,

(i.e. in hilly terrain, traveling into strong head winds or

while towing heavy trailers), use the AutoStick mode and

select the ª3º range.

NOTE:Using the ª3º range in the AutoStick mode

while operating the vehicle under heavy operating con-

ditions will improve performance and extend transmis-

sion life by reducing excessive shifting and heat build up.

STARTING AND OPERATING 281

5

Page 333 of 457

Loading

To load your vehicle properly, first figure out its empty

weight, axle by axle and side by side. Store heavier items

down low and be sure you distribute their weight as

evenly as possible. Stow all loose items securely before

driving. If weighing the loaded vehicle shows that you

have exceeded either GAWR, but the total load is within

the specified GVWR, you must redistribute the weight.

Improper weight distribution can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.

A loaded vehicle is shown in the illustration. Note that

neither the GVWR or the GAWR capacities have been

exceeded.

STARTING AND OPERATING 333

5

Page 343 of 457

WARNING!

Improper towing can lead to an injury accident.

Follow these guidelines to make your trailer towing

as safe as possible:

Make certain that the load is secured in the trailer

and will not shift during travel. When trailering

cargo that is not fully secured, dynamic load shifts

can occur that may be difficult for the driver to

control. You could lose control of your vehicle and

have an accident.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Safety chains must always be used between your

vehicle and trailer. Always connect the chains to the

frame or hook retainers of the vehicle hitch. Cross the

chains under the trailer tongue and allow enough

slack for turning corners.

²Vehicles with trailers should not be parked on a grade.

When parking, apply the parking brake on the tow

vehicle. Put the tow vehicle automatic transmission in

P for Park. Always, block or9chock9the trailer wheels.

²GCWR must not be exceeded.

²Total weight must be distributed between the tow

vehicle and the trailer such that the following four

ratings are not exceeded:

1. GVWR

2. GTW

3. GAWR

STARTING AND OPERATING 343

5

Page 356 of 457

Jacking Instructions

WARNING!

²Getting under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on you.

You could be crushed. Never get any part of your

body under a vehicle that is on a jack. Never start

or run the engine while the vehicle is on a jack. If

you need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

²The jack is designed to use as a tool for changing

tires only. The jack should not be used to lift the

vehicle for service purposes. The vehicle should

be jacked on a firm level surface only. Avoid ice or

slippery areas.

WARNING!

Carefully follow these tire changing warnings to help pre-

vent personal injury or damage to your vehicle:

²Always park on a firm, level surface as far from the edge

of the roadway as possible before raising the vehicle.

²Block the wheel diagonally opposite the wheel to be

raised.

²Apply the parking brake firmly before jacking.

²Never start the engine with the vehicle on a jack.

²Do not let anyone sit in the vehicle when it is on a jack.

²Do not get under the vehicle when it is on a jack.

²Only use the jack in the positions indicated.

²If working on or near a roadway, be extremely careful of

motor traffic.

²To assure that spare tires, flat or inflated are securely

stowed, spares must be stowed with the value stem

facing the ground.

356 WHAT TO DO IN EMERGENCIES

Page 358 of 457

location.Do not raise the vehicle until you are sure the

jack is securely engaged. Never jack up the vehicle

using any suspension components.

6. Raise the vehicle by turning the jack screw to the right,

using the swivel wrench. Raise the vehicle only until the

tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift

provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make

the vehicle less stable. It could slip off the jack and

hurt someone near it. Raise the vehicle only enough

to remove the tire.7. Remove the wheel lug nuts, for vehicles with wheel

covers, remove the cover from the wheel by hand. Do not

pry the wheel cover off. Then pull the wheel off the hub.

8. Install the spare wheel, for vehicles with wheel covers,

align the notch in the wheel cover with the valve stem on

the wheel. Install the cover on the wheel by hand only

and install the wheel lug nuts with the cone shaped end

of the nut toward the wheel. Lightly tighten the lug nuts.

To avoid the risk of forcing the vehicle off the jack, do not

tighten the lug nuts fully until the vehicle has been

lowered.

NOTE:Do not install the wheel cover on the compact

spare.

Do not use a hammer or force to install the wheel covers.

9. Lower the vehicle by turning the jack screw to the left.

10. Finish tightening the lug nuts. Push down on the

wrench while tightening for increased leverage. Alternate

358 WHAT TO DO IN EMERGENCIES

Page 359 of 457

lug nuts until each nut has been tightened twice. Correct

wheel nut tightness is 130 N´m (95 ft. lbs). If in doubt

about the correct tightness, have them checked with a

torque wrench by your dealer or at a service station.

11. Lower the jack to its fully closed position.

WARNING!

A loose tire or jack, thrown forward in a collision or

hard stop could endanger the occupants of the ve-

hicle. Always stow the jack parts and the spare tire in

the places provided.

NOTE:The full size flat tire will not store under the

vehicle. It should be repaired /or replaced, and rein-

stalled on the vehicle as soon as possible.

12. Secure the spare tire as follows:

²Turn the wheel so that the valve-stem is down. Slide

the wheel retainer through the center of the wheel

and position it properly across the wheel opening.

²For convenience in checking the spare tire inflation,

stow with the valve-stem toward the rear of the

vehicle.

²Using the jack-handle, rotate the drive nut to the

right until the wheel is drawn into place against the

underside of the vehicle.

²Continue to rotate the nut until you hear the mecha-

nism click three times. It cannot be overtightened.

Push against the tire several times to be sure it is

securely in place.

13. Stow the jack and jack handle.

14. Check the tire pressure as soon as possible. Correct

pressure as required.

WHAT TO DO IN EMERGENCIES 359

6

Page 394 of 457

²Do not change the thermostat for summer or winter

operation. If replacement is ever necessary, install

ONLY the correct type thermostat. Other designs may

result in unsatisfactory coolant performance, poor gas

mileage, and increased emissions.

Hoses And Vacuum/Vapor Harnesses

Inspect surfaces of hoses and nylon tubing for evidence

of heat and mechanical damage. Hard or soft spots,

brittle rubber, cracking, tears, cuts, abrasions, and exces-

sive swelling indicate deterioration of the rubber.

Pay particular attention to those hoses nearest to high

heat sources such as the exhaust manifold. Inspect hose

routing to be sure hoses do not come in contact with any

heat source or moving component which may cause heat

damage or mechanical wear.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

Components should be replaced immediately if there is

any evidence of wear or damage that could cause failure.

Brakes

In order to assure brake system performance, all brake

system components should be inspected periodically.

Suggested service intervals can be found in the Mainte-

nance Schedules.

394 MAINTAINING YOUR VEHICLE

Page 395 of 457

WARNING!

Riding the brakes can lead to brake failure and

possibly an accident. Driving with your foot resting

or riding on the brake pedal can result in abnormally

high brake temperatures, excessive lining wear, and

possible brake damage. You wouldn't have your full

braking capacity in an emergency.

Brake And Power Steering Hoses

When the vehicle is serviced for scheduled maintenance,

inspect surface of hoses and nylon tubing for evidence of

heat and mechanical damage. Hard and brittle rubber,

cracking, tears, cuts, abrasion, and excessive swelling

indicate deterioration of the rubber. Particular attention

should be made to examining those hose surfaces nearest

to high heat sources, such as the exhaust manifold.Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose connections such as clamps and cou-

plings to make sure they are secure and no leaks are

present.

NOTE:Often, fluid such as oil, power steering fluid,

and brake fluid are used during assembly plant opera-

tions to facilitate the assembly of hoses to couplings.

Therefore, oil wetness at the hose-coupling area is not

necessarily an indication of leakage. Actual dripping of

hot fluid when systems are under pressure (during

vehicle operation), should be noted before a hose is

replaced based on leakage.

NOTE:Inspection of brake hoses should be performed

whenever the brake system is serviced and at every

engine oil change. Inspect hydraulic brake hoses for

surface cracking, scuffing, or worn spots. If there is any

evidence of cracking, scuffing, or worn spots, the hose

MAINTAINING YOUR VEHICLE 395

7

Page 412 of 457

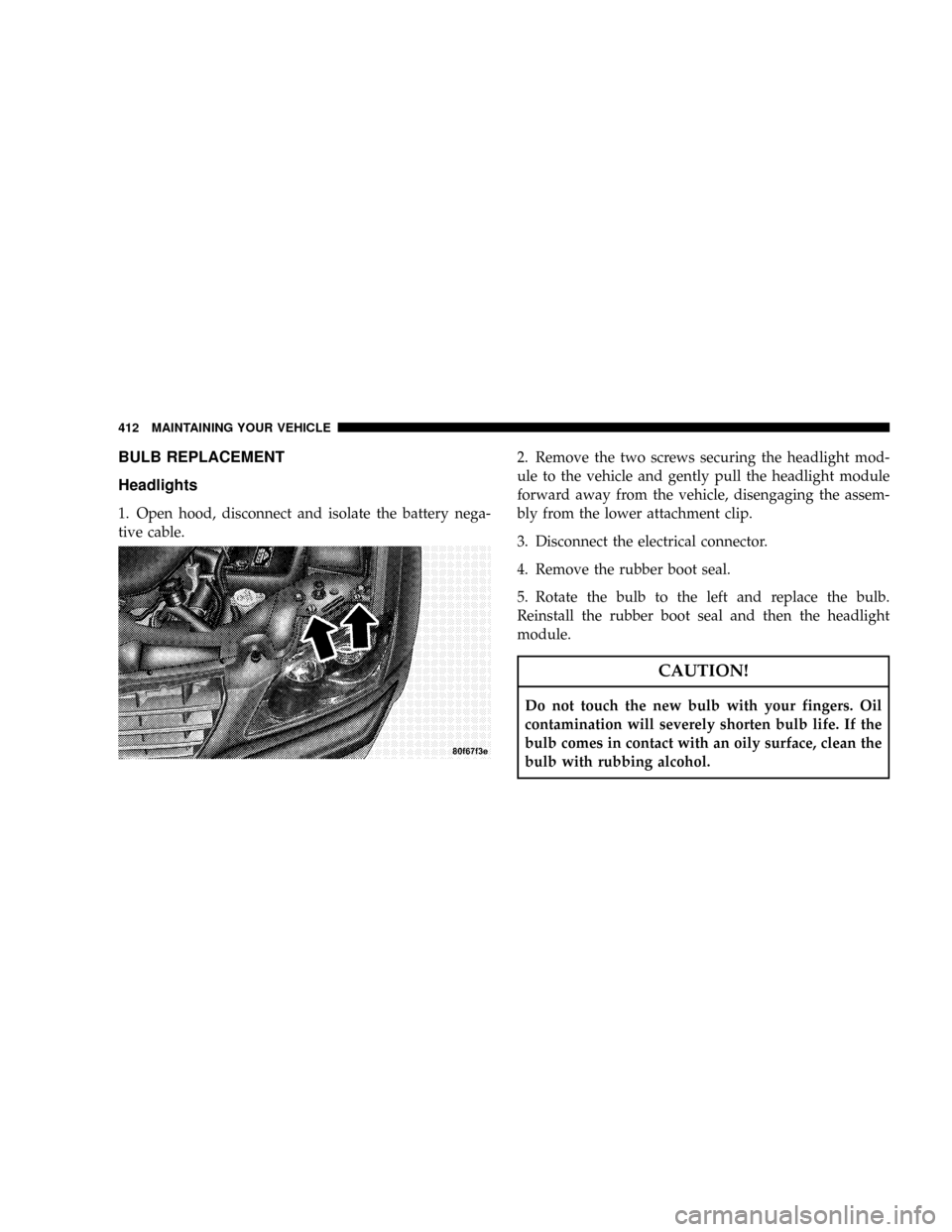

BULB REPLACEMENT

Headlights

1. Open hood, disconnect and isolate the battery nega-

tive cable.2. Remove the two screws securing the headlight mod-

ule to the vehicle and gently pull the headlight module

forward away from the vehicle, disengaging the assem-

bly from the lower attachment clip.

3. Disconnect the electrical connector.

4. Remove the rubber boot seal.

5. Rotate the bulb to the left and replace the bulb.

Reinstall the rubber boot seal and then the headlight

module.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

412 MAINTAINING YOUR VEHICLE

Page 414 of 457

2. Remove the two screws securing the headlight mod-

ule to the vehicle and pull the headlight module forward

away from the vehicle, disengaging the assembly from

the lower attachment clip.

3. Twist the bulb socket to remove from the headlight

module and pull the bulb from socket.

4. Replace the bulb, reinstall the socket and then reinstall

the headlight module.Front Fog Light

1. Reach under the front fascia and grasp the front fog

light bulb.

2. Twist the front fog light bulb to remove from the fog

light module.

3. Disconnect the electrical connector and replace the

bulb.

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with an oily surface, clean the

bulb with rubbing alcohol.

414 MAINTAINING YOUR VEHICLE