clock CHRYSLER PACIFICA 2017 2.G User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2017, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2017 2.GPages: 828, PDF Size: 7.58 MB

Page 542 of 828

WARNING!(Continued)

ON. It may cause serious electrical shock or electro-

cution if not serviced properly. See your authorized

dealer for service.

Bi-Halogen Headlamps

1. Reach behind the headlamp housing to access the

headlamp bulb cap.

2. Firmly grasp the headlamp bulb cap and rotate it counterclockwise to unlock it.

3. Firmly grasp the headlamp bulb socket assembly androtate counterclockwise to remove from the housing.

Headlamp Bulb Cap

540 IN CASE OF EMERGENCY

Page 544 of 828

5. Install the bulb and connector assembly into theheadlamp housing and rotate clockwise to lock it in

place.

6. Install the headlamp bulb cap in the headlamp hous- ing and rotate clockwise to lock it in place.

Front Turn Signal Lamp

1. Open the hood.

2. Twist the front turn signal lamp socket assemblycounterclockwise, and then remove the front turn

signal lamp assembly from the lamp housing.

3. Pull the bulb out of the socket and insert the replace-ment bulb.

4. Install the front turn signal lamp socket assembly into the housing, and rotate the front turn signal lamp

socket clockwise to lock it in place.

Front Turn Signal Lamp Socket

542 IN CASE OF EMERGENCY

Page 545 of 828

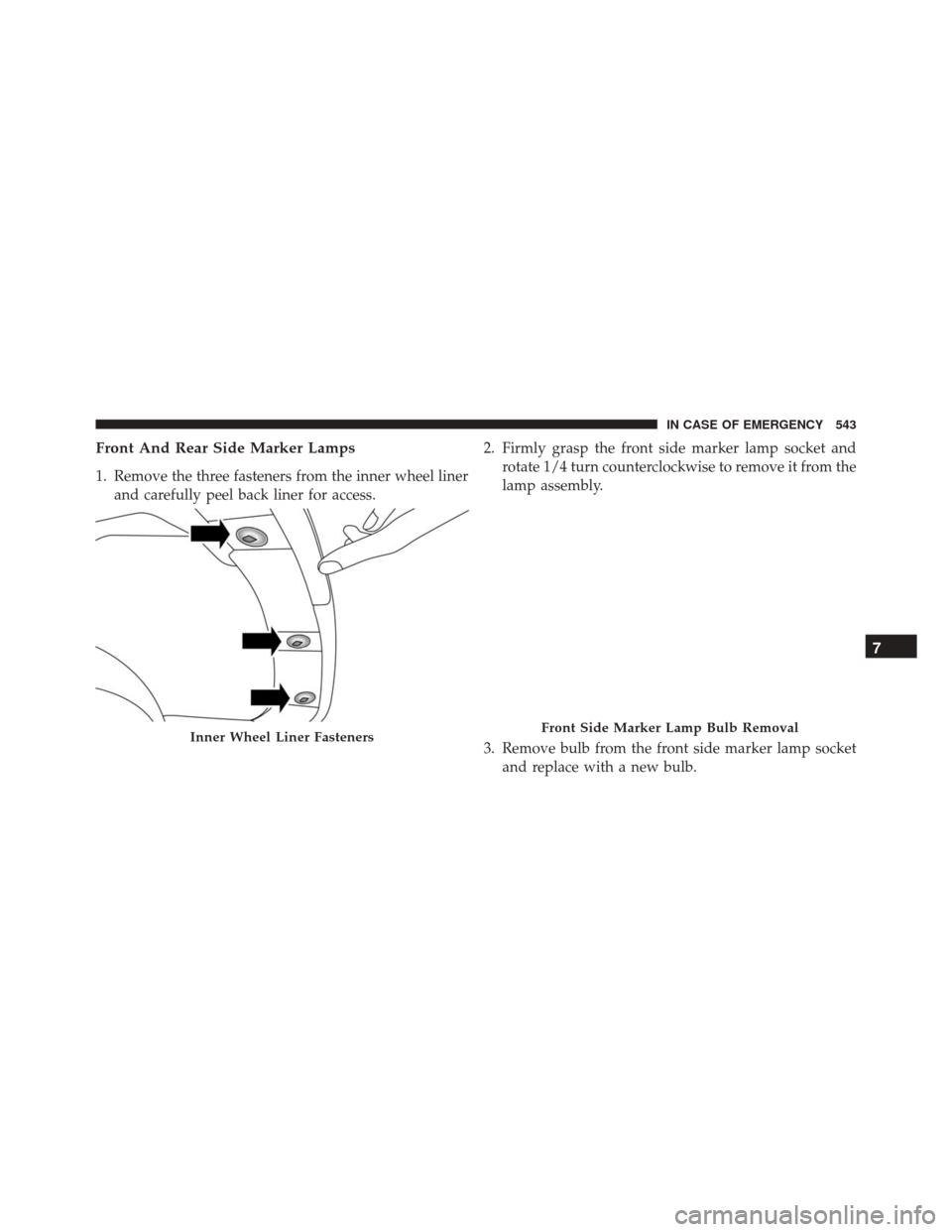

Front And Rear Side Marker Lamps

1. Remove the three fasteners from the inner wheel linerand carefully peel back liner for access. 2. Firmly grasp the front side marker lamp socket and

rotate 1/4 turn counterclockwise to remove it from the

lamp assembly.

3. Remove bulb from the front side marker lamp socket and replace with a new bulb.

Inner Wheel Liner FastenersFront Side Marker Lamp Bulb Removal

7

IN CASE OF EMERGENCY 543

Page 546 of 828

4. Install front side marker lamp socket in lamp assemblyand rotate 1/4 turn clockwise to lock into place.

5. Position the inner wheel liner in place and install the three fasteners.

Front Fog Lamp — Halogen

1. Remove fasteners from inner wheel liner and carefullypeel back liner for access.

2. Reach through the front fascia to fog lamp housing to access the bulb.

3. Rotate the front fog lamp socket counterclockwise, and remove the bulb and socket assembly from the

front fog lamp housing. 4. Pull the bulb out of the socket and insert the replace-

ment bulb.

Front Fog Lamp Socket

544 IN CASE OF EMERGENCY

Page 547 of 828

CAUTION!

Do not touch the new bulb with your fingers. Oil

contamination will severely shorten bulb life. If the

bulb comes in contact with any oily surface, clean the

bulb with rubbing alcohol.

5. Install the front fog lamp socket assembly into the into the front fog lamp housing, and rotate the connector

clockwise to lock it in place.

6. Position the inner wheel liner in place and install fasteners.

Rear Liftgate Mounted Back-Up Lamps And Tail

Lamps (If Bulb Equipped)

1. Raise the liftgate.

2. Use a fiber stick or flat blade screw driver to pry offthe bulb access cover on the lower liftgate trim. 3. Back-up lamps/tail lamp (if bulb equipped) are now

visible. Rotate socket(s) counter clockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s)

6. Reverse process to reinstall the liftgate trim.

Rear Bodyside Mounted Taillamps

1. Raise the liftgate.

2. Remove two torx head screws on bodyside lamp using a T30 screwdriver.

3. Remove lamp from vehicle body and locate bulb socket on rear of lamp. Rotate socket counter-

clockwise.

4. Remove/replace bulb(s).

5. Reinstall the socket(s)

7

IN CASE OF EMERGENCY 545

Page 563 of 828

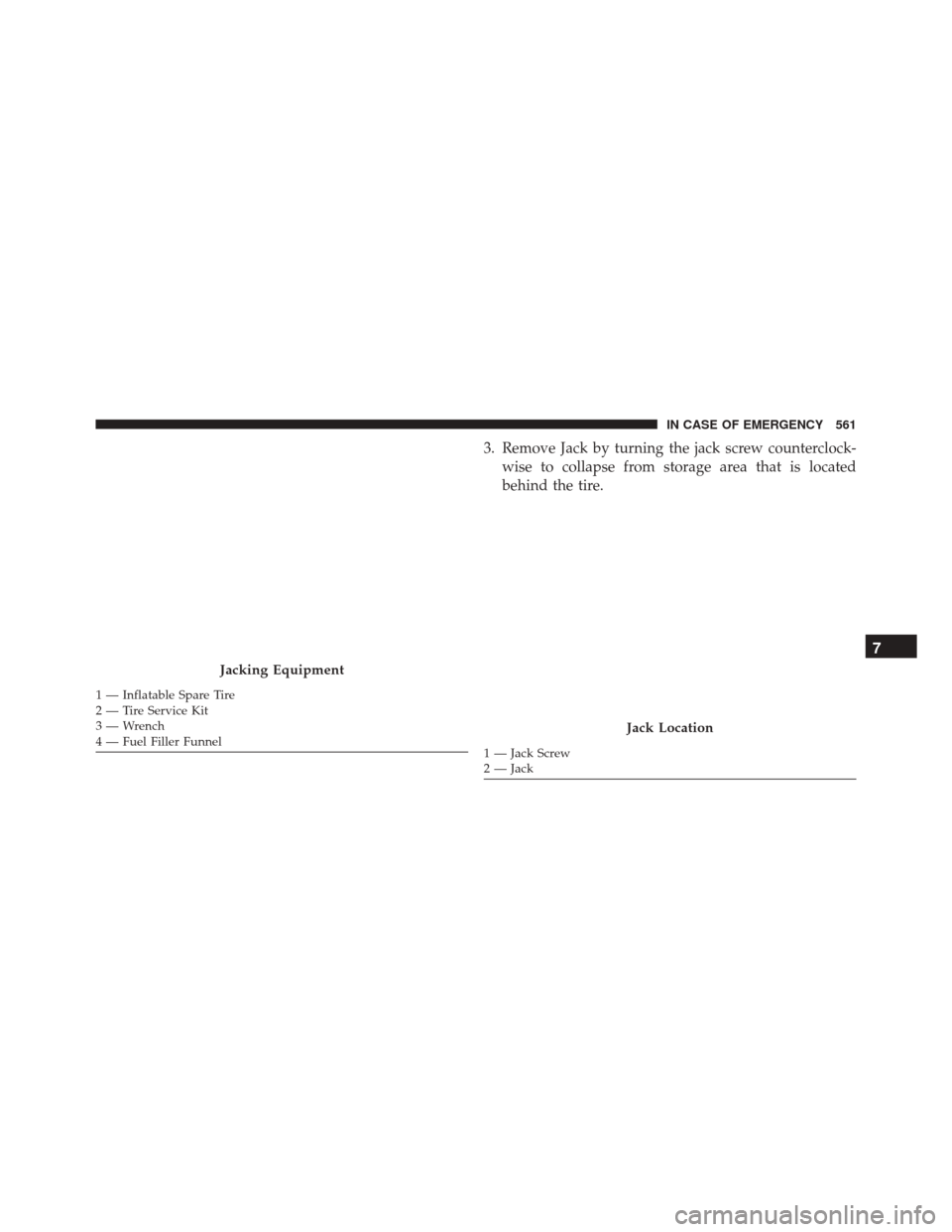

3. Remove Jack by turning the jack screw counterclock-wise to collapse from storage area that is located

behind the tire.

Jacking Equipment

1 — Inflatable Spare Tire

2 — Tire Service Kit

3 — Wrench

4 — Fuel Filler Funnel

Jack Location

1 — Jack Screw

2 — Jack

7

IN CASE OF EMERGENCY 561

Page 572 of 828

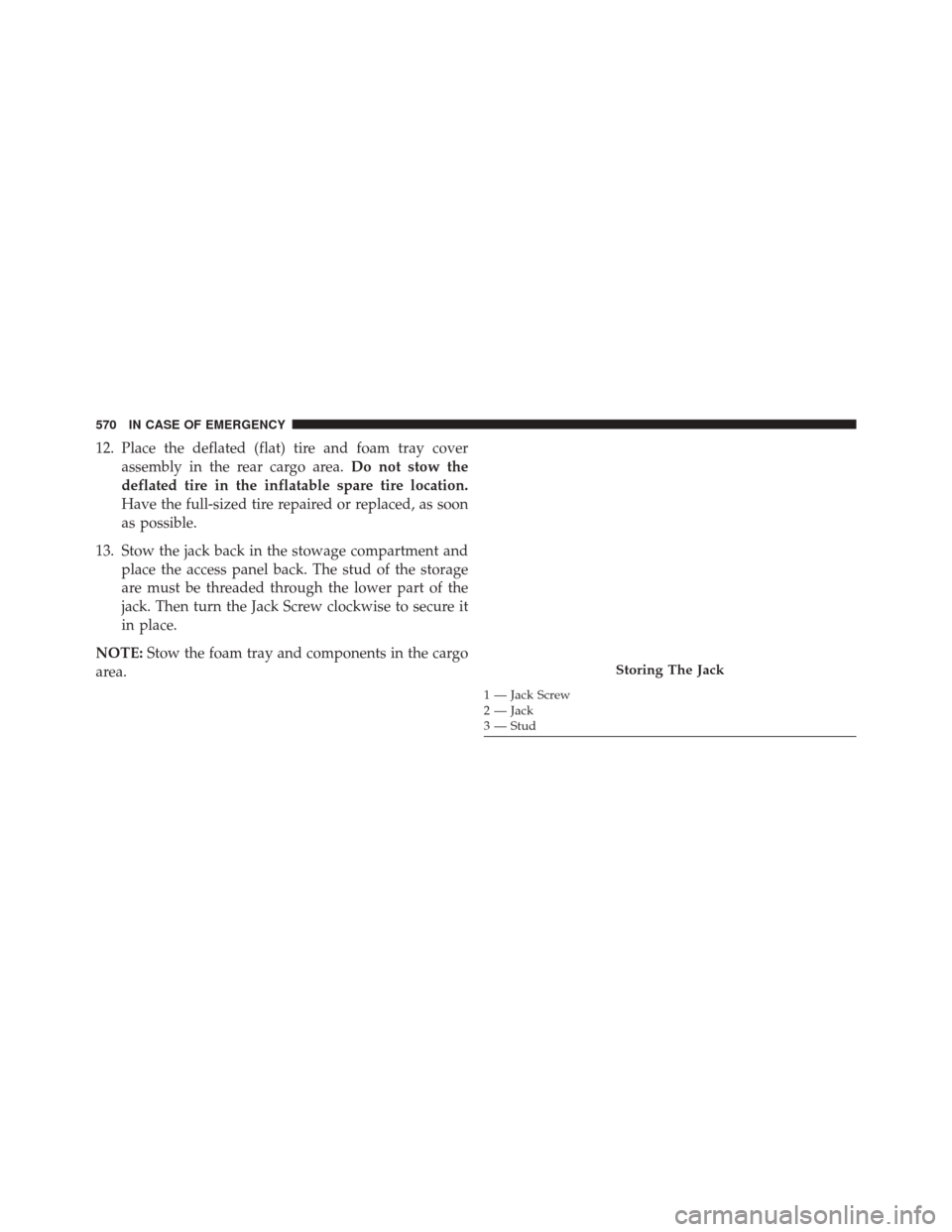

12. Place the deflated (flat) tire and foam tray coverassembly in the rear cargo area. Do not stow the

deflated tire in the inflatable spare tire location.

Have the full-sized tire repaired or replaced, as soon

as possible.

13. Stow the jack back in the stowage compartment and place the access panel back. The stud of the storage

are must be threaded through the lower part of the

jack. Then turn the Jack Screw clockwise to secure it

in place.

NOTE: Stow the foam tray and components in the cargo

area.

Storing The Jack

1 — Jack Screw

2 — Jack

3 — Stud

570 IN CASE OF EMERGENCY

Page 579 of 828

WARNING!(Continued)

•Tire Service Kit Sealant solution contains latex. In

case of an allergic reaction or rash, consult a phy-

sician immediately. Keep Tire Service Kit out of

reach of children. If swallowed, rinse mouth imme-

diately with plenty of water and drink plenty of

water. Do not induce vomiting! Consult a physician

immediately.

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hose to reach the

valve stem and keep the Tire Service Kit flat on the

ground. This will provide the best positioning of the kit when running the air pump. Move the vehicle as

necessary to place the valve stem in this position

before proceeding.

3. Place the transmission in PARK and cycle the ignition in the OFF position.

4. Ensure the park brake is engaged.

Setting Up To Use Tire Service Kit:

1. Remove the Tire Service Kit from the storage location. 2. Uncoil the Sealant/Air Hose. Re-move the cap from the valve stem

and then screw the fitting in at the

end of the Sealant/Air Hose clock-

wise onto the valve stem.

7

IN CASE OF EMERGENCY 577

Page 582 of 828

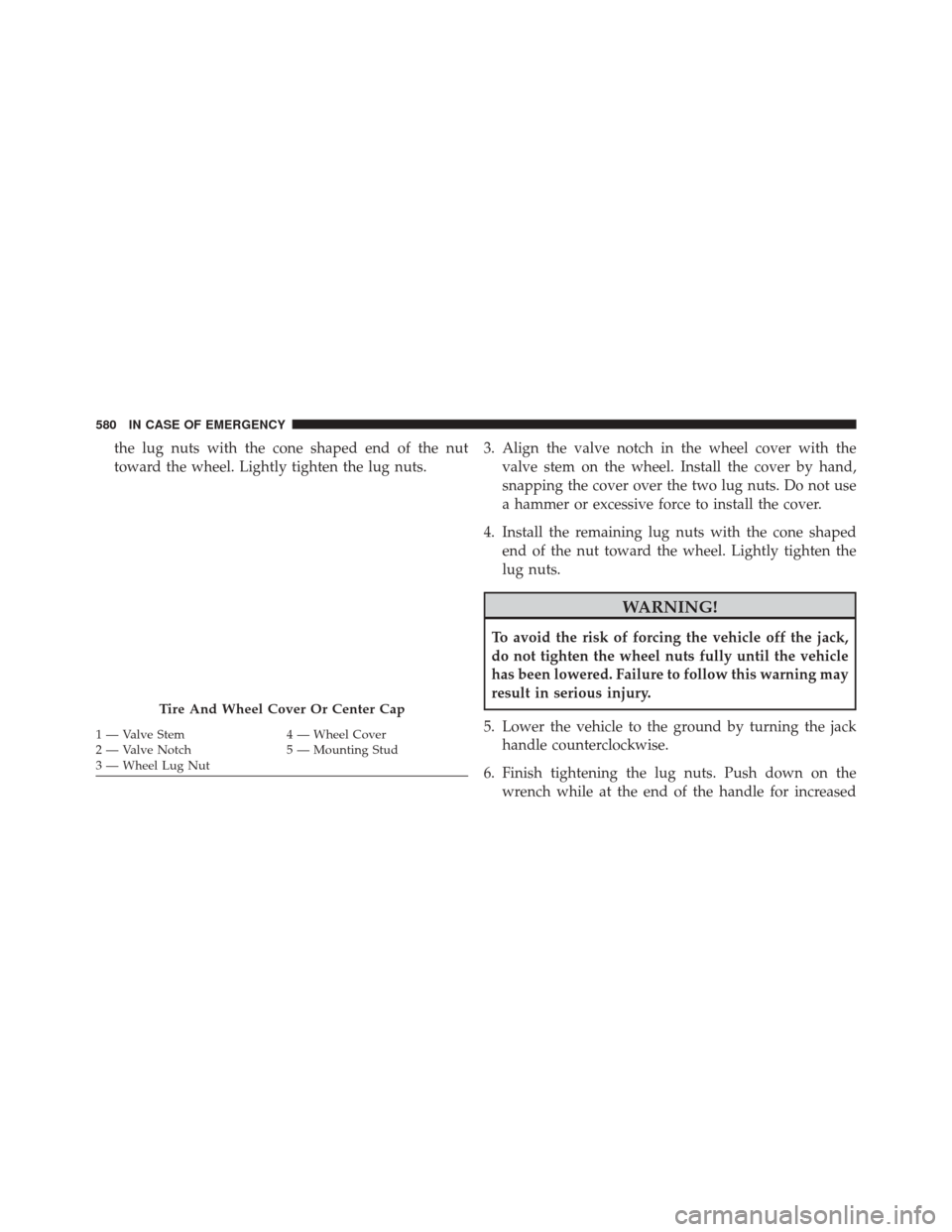

the lug nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug nuts.3. Align the valve notch in the wheel cover with the

valve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not use

a hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

Tire And Wheel Cover Or Center Cap

1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut 580 IN CASE OF EMERGENCY

Page 583 of 828

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. Refer to “Torque

Specifications” in the “Technical Data” section for

proper wheel lug nut torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shapedend of the nut toward the wheel. Lightly tighten the

lug nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack,

do not tighten the wheel nuts fully until the vehicle

has been lowered. Failure to follow this warning may

result in serious injury.

3. Lower the vehicle to the ground by turning the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. Refer to “Torque

Specifications” in the “Technical Data” section for

proper wheel lug nut torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service

station.

7

IN CASE OF EMERGENCY 581