wheel torque CHRYSLER PACIFICA 2018 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2018, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2018Pages: 696, PDF Size: 8.48 MB

Page 217 of 696

WARNING!(Continued)

•The capabilities of an ABS equipped vehicle must

never be exploited in a reckless or dangerous manner

that could jeopardize the user ’s safety or the safety of

others.

ABS is designed to function with the OEM tires. Modifica-

tion may result in degraded ABS performance.

Anti-Lock Brake Warning Light

The yellow “Anti-Lock Brake Warning Light” will turn on

when the ignition is turned to the ON/RUN mode and

may stay on for as long as four seconds.

If the “Anti-Lock Brake Warning Light” remains on or

comes on while driving, it indicates that the anti-lock

portion of the brake system is not functioning and that

service is required. However, the conventional brake sys-

tem will continue to operate normally if the “Anti-Lock

Brake Warning Light” is on.

If the “Anti-Lock Brake Warning Light” is on, the brake

system should be serviced as soon as possible to restore the

benefits of anti-lock brakes. If the “Anti-Lock Brake Warning

Light” does not come on when the ignition is turned to the

ON/RUN mode, have the light repaired as soon as possible.

Electronic Brake Control System

Your vehicle is equipped with an advanced Electronic

Brake Control system (EBC). This system includes Elec-

tronic Brake Force Distribution (EBD), Anti-Lock Brake

System (ABS), Brake Assist System (BAS), Hill Start Assist

(HSA), Traction Control System (TCS), Electronic Stability

Control (ESC), and Electronic Roll Mitigation (ERM). These

systems work together to enhance both vehicle stability

and control in various driving conditions.

Your vehicle may also be equipped with Ready Alert

Braking (RAB), Rain Brake Support (RBS), Trailer Sway

Control (TSC), and Dynamic Steering Torque (DST).

Traction Control System (TCS)

This system monitors the amount of wheel spin of each of

the driven wheels. If wheel spin is detected, the TCS may

apply brake pressure to the spinning wheel(s) and/or

reduce vehicle power to provide enhanced acceleration

and stability. A feature of the TCS, Brake Limited Differen-

tial (BLD), functions similar to a limited slip differential

and controls the wheel spin across a driven axle. If one

wheel on a driven axle is spinning faster than the other, the

system will apply the brake of the spinning wheel. This

5

SAFETY 215

Page 218 of 696

will allow more vehicle torque to be applied to the wheel

that is not spinning. BLD may remain enabled even if TCS

and ESC are in a reduced mode.

Brake Assist System (BAS)

The BAS is designed to optimize the vehicle’s braking

capability during emergency braking maneuvers. The sys-

tem detects an emergency braking situation by sensing the

rate and amount of brake application and then applies

optimum pressure to the brakes. This can help reduce

braking distances. The BAS complements the anti-lock

brake system (ABS). Applying the brakes very quickly

results in the best BAS assistance. To receive the benefit of

the system, you must apply continuous braking pressure

during the stopping sequence, (do not “pump” the brakes).

Do not reduce brake pedal pressure unless braking is no

longer desired. Once the brake pedal is released, the BAS is

deactivated.

WARNING!

The Brake Assist System (BAS) cannot prevent the

natural laws of physics from acting on the vehicle, nor

can it increase the traction afforded by prevailing road

(Continued)

WARNING!(Continued)

conditions. BAS cannot prevent collisions, including

those resulting from excessive speed in turns, driving

on very slippery surfaces, or hydroplaning. The capa-

bilities of a BAS-equipped vehicle must never be

exploited in a reckless or dangerous manner, which

could jeopardize the user’s safety or the safety of

others.

Brake System Warning Light

The red “Brake System Warning Light” will turn on when

the ignition is turned to the ON/RUN mode and may stay

on for as long as four seconds.

If the “Brake System Warning Light” remains on or comes

on while driving, it indicates that the brake system is not

functioning properly and that immediate service is re-

quired. If the “Brake System Warning Light” does not come

on when the ignition is turned to the ON/RUN mode, have

the light repaired as soon as possible.

Dynamic Steering Torque (DST)

Dynamic Steering Torque is a feature of the ESC and

Electric Power Steering (EPS) modules that provides

torque at the steering wheel for certain driving conditions

216 SAFETY

Page 219 of 696

in which the ESC module is detecting vehicle instability.

The torque that the steering wheel receives is only meant to

help the driver realize optimal steering behavior in order to

reach/maintain vehicle stability. The only notification the

driver receives that the feature is active is the torque

applied to the steering wheel.

NOTE:The DST feature is only meant to help the driver

realize the correct course of action through small torques

on the steering wheel, which means the effectiveness of the

DST feature is highly dependent on the driver ’s sensitivity

and overall reaction to the applied torque. It is very

important to realize that this feature will not steer the

vehicle, meaning the driver is still responsible for steering

the vehicle.

Electronic Brake Force Distribution (EBD)

This function manages the distribution of the braking

torque between the front and rear axles by limiting braking

pressure to the rear axle. This is done to prevent overslip of

the rear wheels to avoid vehicle instability, and to prevent

the rear axle from entering ABS before the front axle.

Electronic Roll Mitigation (ERM)

This system anticipates the potential for wheel lift by

monitoring the driver ’s steering wheel input and the speed

of the vehicle. When ERM determines that the rate of

change of the steering wheel angle and vehicle’s speed are

sufficient to potentially cause wheel lift, it then applies the

appropriate brake and may also reduce engine power to

lessen the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during severe or

evasive driving maneuvers; it cannot prevent wheel lift

due to other factors, such as road conditions, leaving the

roadway, or striking objects or other vehicles.

WARNING!

Many factors, such as vehicle loading, road conditions

and driving conditions, influence the chance that

wheel lift or rollover may occur. ERM cannot prevent

all wheel lift or roll overs, especially those that involve

leaving the roadway or striking objects or other ve-

hicles. The capabilities of an ERM-equipped vehicle

must never be exploited in a reckless or dangerous

manner which could jeopardize the user’s safety or the

safety of others.

5

SAFETY 217

Page 396 of 696

CAUTION!

•The ParkSense Active Park Assist system is only a

parking aid and it is unable to recognize every

obstacle, including small obstacles. Parking curbs

might be temporarily detected or not detected at all.

Obstacles located above or below the sensors will

not be detected when they are in close proximity.

• The vehicle must be driven slowly when using the

ParkSense Active Park Assist system in order to be

able to stop in time when an obstacle is detected. It is

recommended that the driver looks over his/her

shoulder when using the ParkSense Active Park

Assist system.

LANESENSE — IF EQUIPPED

LaneSense Operation

The LaneSense system is operational at speeds above

37 mph (60 km/h) and below 112 mph (180 km/h). It uses

a forward looking camera to detect lane markings and

measure vehicle position within the lane boundaries.

When both lane markings are detected and the driver

unintentionally drifts out of the lane (no turn signal

applied), the LaneSense system provides a haptic warning in the form of torque applied to the steering wheel to

prompt the driver to remain within the lane boundaries.

The LaneSense system will also provide a visual warning

through the instrument cluster display to prompt the

driver to remain within the lane boundaries.

The driver may manually override the haptic warning by

applying torque into the steering wheel at any time.

When only a single lane marking is detected and the driver

unintentionally drifts across that lane marking (no turn

signal applied), the LaneSense system provides a visual

warning through the instrument cluster display to prompt

the driver to remain within the lane. When only a single

lane marking is detected, a haptic (torque) warning will not

be provided.

NOTE:

When operating conditions have been met, the

LaneSense system will monitor if the driver ’s hands are on

the steering wheel and provides an audible and visual

warning to the driver when the driver ’s hands are not

detected on the steering wheel. The system will cancel if

the driver does not return their hands to the wheel.

394 STARTING AND OPERATING

Page 399 of 696

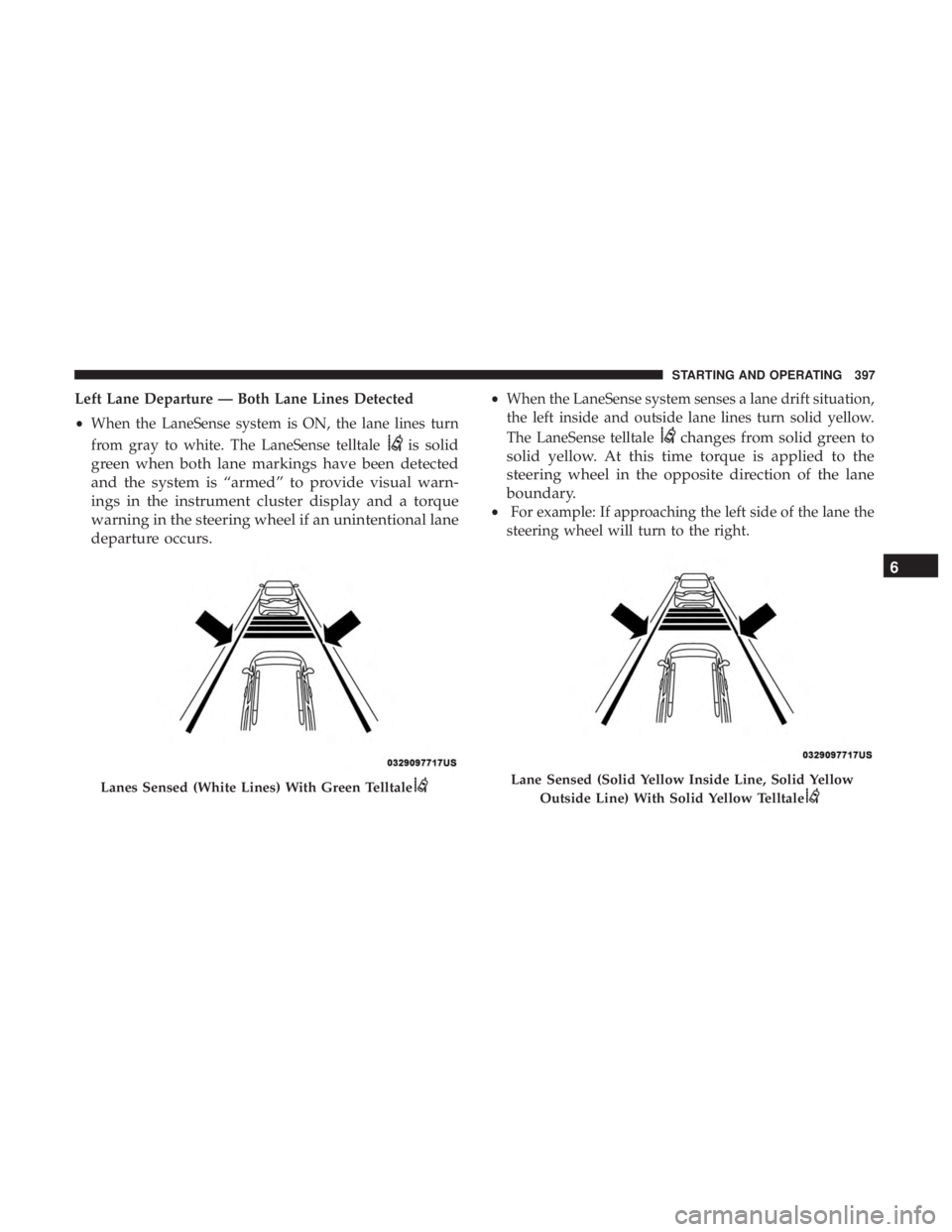

Left Lane Departure — Both Lane Lines Detected

•When the LaneSense system is ON, the lane lines turn

from gray to white. The LaneSense telltale

is solid

green when both lane markings have been detected

and the system is “armed” to provide visual warn-

ings in the instrument cluster display and a torque

warning in the steering wheel if an unintentional lane

departure occurs.

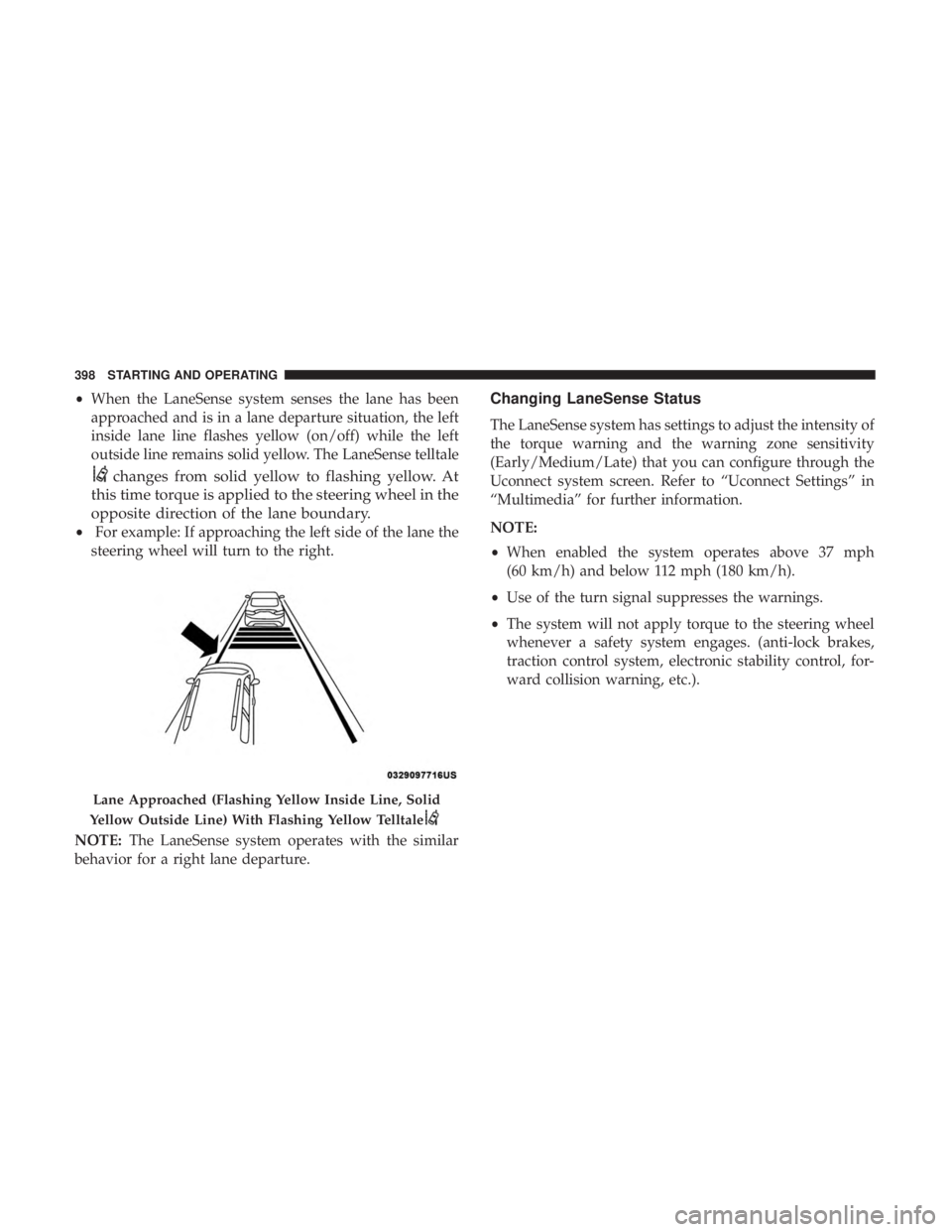

• When the LaneSense system senses a lane drift situation,

the left inside and outside lane lines turn solid yellow.

The LaneSense telltale

changes from solid green to

solid yellow. At this time torque is applied to the

steering wheel in the opposite direction of the lane

boundary.

• For example: If approaching the left side of the lane the

steering wheel will turn to the right.

Lanes Sensed (White Lines) With Green TelltaleLane Sensed (Solid Yellow Inside Line, Solid Yellow

Outside Line) With Solid Yellow Telltale

6

STARTING AND OPERATING 397

Page 400 of 696

•When the LaneSense system senses the lane has been

approached and is in a lane departure situation, the left

inside lane line flashes yellow (on/off) while the left

outside line remains solid yellow. The LaneSense telltale

changes from solid yellow to flashing yellow. At

this time torque is applied to the steering wheel in the

opposite direction of the lane boundary.

• For example: If approaching the left side of the lane the

steering wheel will turn to the right.

NOTE: The LaneSense system operates with the similar

behavior for a right lane departure.

Changing LaneSense Status

The LaneSense system has settings to adjust the intensity of

the torque warning and the warning zone sensitivity

(Early/Medium/Late) that you can configure through the

Uconnect system screen. Refer to “Uconnect Settings” in

“Multimedia” for further information.

NOTE:

• When enabled the system operates above 37 mph

(60 km/h) and below 112 mph (180 km/h).

• Use of the turn signal suppresses the warnings.

• The system will not apply torque to the steering wheel

whenever a safety system engages. (anti-lock brakes,

traction control system, electronic stability control, for-

ward collision warning, etc.).

Lane Approached (Flashing Yellow Inside Line, Solid

Yellow Outside Line) With Flashing Yellow Telltale

398 STARTING AND OPERATING

Page 455 of 696

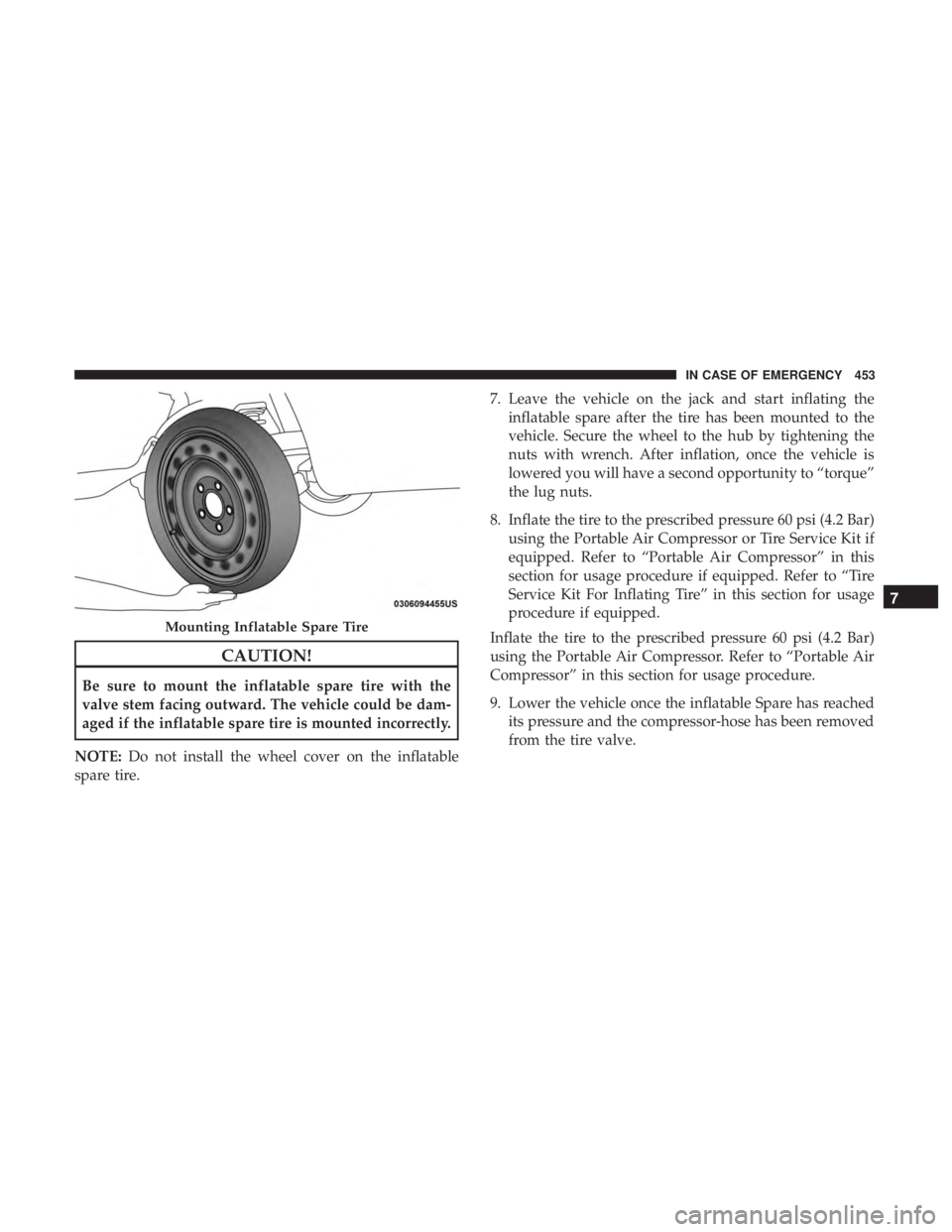

CAUTION!

Be sure to mount the inflatable spare tire with the

valve stem facing outward. The vehicle could be dam-

aged if the inflatable spare tire is mounted incorrectly.

NOTE: Do not install the wheel cover on the inflatable

spare tire. 7. Leave the vehicle on the jack and start inflating the

inflatable spare after the tire has been mounted to the

vehicle. Secure the wheel to the hub by tightening the

nuts with wrench. After inflation, once the vehicle is

lowered you will have a second opportunity to “torque”

the lug nuts.

8. Inflate the tire to the prescribed pressure 60 psi (4.2 Bar) using the Portable Air Compressor or Tire Service Kit if

equipped. Refer to “Portable Air Compressor” in this

section for usage procedure if equipped. Refer to “Tire

Service Kit For Inflating Tire” in this section for usage

procedure if equipped.

Inflate the tire to the prescribed pressure 60 psi (4.2 Bar)

using the Portable Air Compressor. Refer to “Portable Air

Compressor” in this section for usage procedure.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the compressor-hose has been removed

from the tire valve.

Mounting Inflatable Spare Tire

7

IN CASE OF EMERGENCY 453

Page 456 of 696

10. Finish tightening the lug nuts. Push down on thewrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice. Refer to “Torque

Specifications” in “Technical Specifications” for proper

wheel lug nut torque. If in doubt about the correct

tightness, have them checked with a torque wrench by

your authorized dealer or at a service station.

11. Lower the jack to its fully-closed position.

WARNING!

A loose tire or jack thrown forward in a collision or

hard stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired

or replaced immediately.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do not stow the

deflated tire in the inflatable spare tire location. Have

the full-sized tire repaired or replaced, as soon as

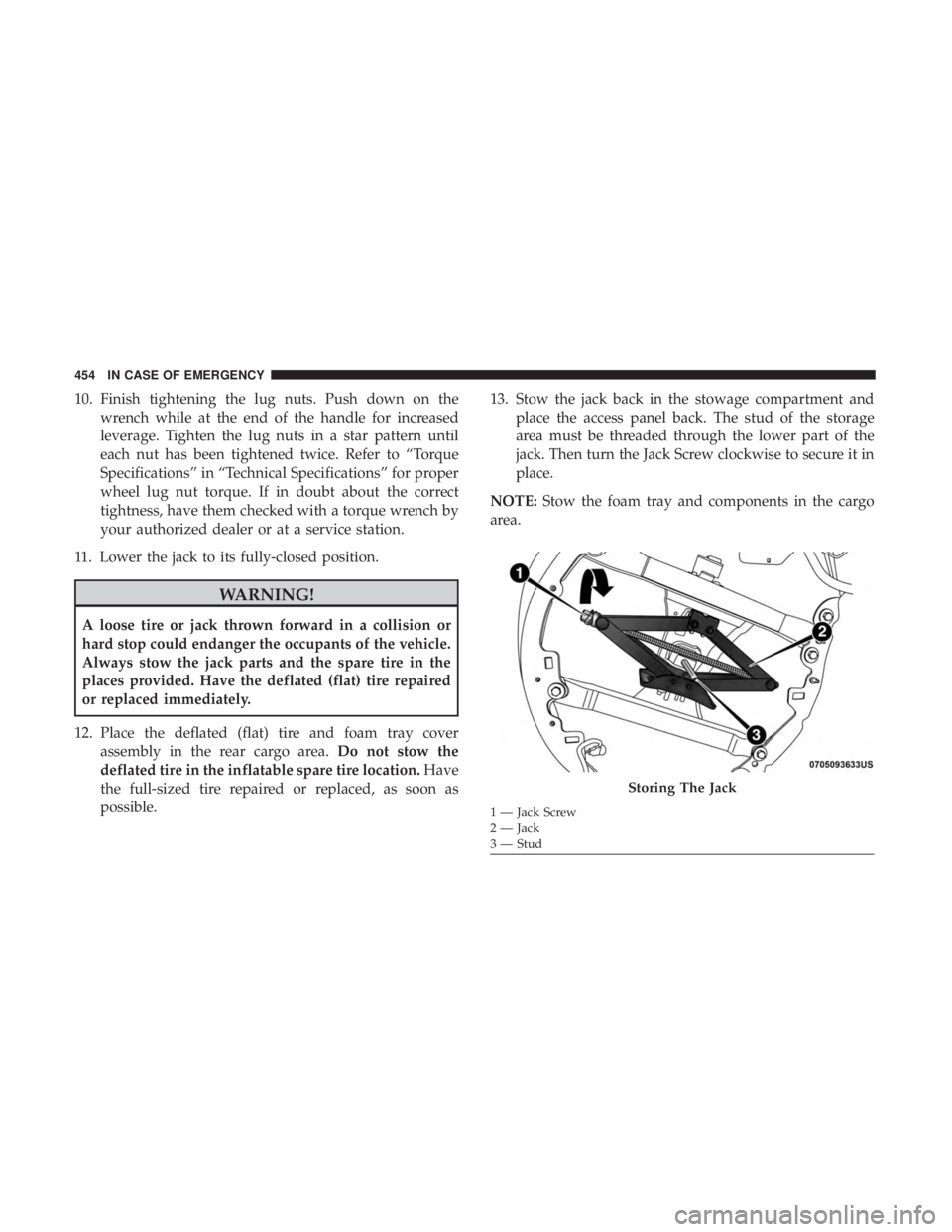

possible. 13. Stow the jack back in the stowage compartment and

place the access panel back. The stud of the storage

area must be threaded through the lower part of the

jack. Then turn the Jack Screw clockwise to secure it in

place.

NOTE: Stow the foam tray and components in the cargo

area.

Storing The Jack

1 — Jack Screw

2 — Jack

3 — Stud

454 IN CASE OF EMERGENCY

Page 457 of 696

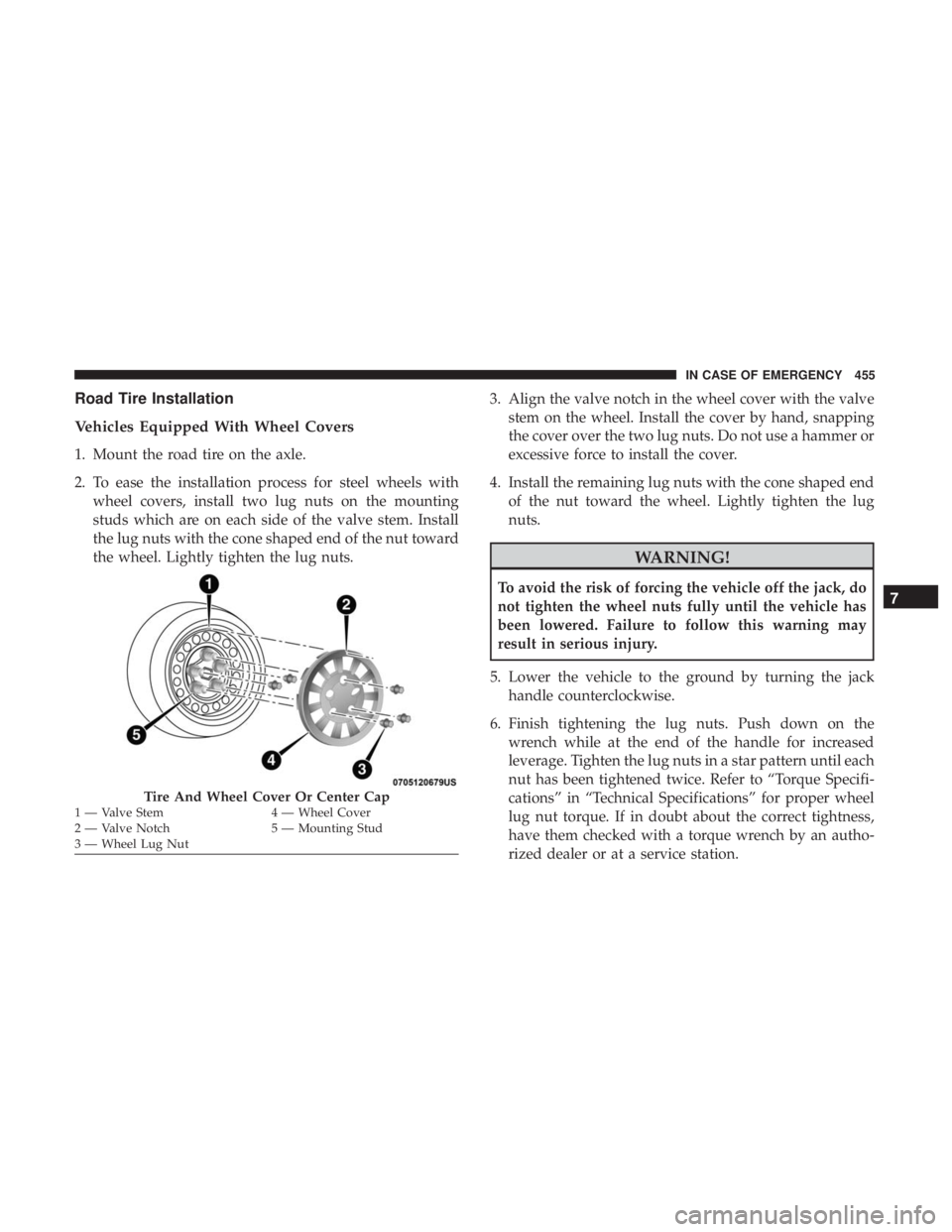

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels withwheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut toward

the wheel. Lightly tighten the lug nuts. 3. Align the valve notch in the wheel cover with the valve

stem on the wheel. Install the cover by hand, snapping

the cover over the two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in “Technical Specifications” for proper wheel

lug nut torque. If in doubt about the correct tightness,

have them checked with a torque wrench by an autho-

rized dealer or at a service station.

Tire And Wheel Cover Or Center Cap1 — Valve Stem 4 — Wheel Cover

2 — Valve Notch 5 — Mounting Stud

3 — Wheel Lug Nut

7

IN CASE OF EMERGENCY 455

Page 458 of 696

7. After 25 miles (40 km) check the lug nut torque with atorque wrench to ensure that all lug nuts are properly

seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped endof the nut toward the wheel. Lightly tighten the lug

nuts.

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may

result in serious injury. 3. Lower the vehicle to the ground by turning the jack

handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until each

nut has been tightened twice. Refer to “Torque Specifi-

cations” in the “Technical Specifications” section for

proper wheel lug nut torque. If in doubt about the

correct tightness, have them checked with a torque

wrench by your authorized dealer or at a service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are properly

seated against the wheel.

456 IN CASE OF EMERGENCY