ABS CHRYSLER PACIFICA 2020 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2020, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2020Pages: 516, PDF Size: 28.69 MB

Page 270 of 516

268STARTING AND OPERATING

PARKSENSE ACTIVE PARK ASSIST SYSTEM

— IF EQUIPPED

The ParkSense Active Park Assist system is

intended to assist the driver during parallel and

perpendicular parking maneuvers by identifying

a proper parking space, providing audible/

visual instructions, and controlling the steering

wheel. The ParkSense Active Park Assist system

is defined as “semi-automatic” since the driver

maintains control of the accelerator, gear

selector and brakes. Depending on the driver's

parking maneuver selection, the ParkSense Active Park Assist system is capable of

maneuvering a vehicle into a parallel or a

perpendicular parking space on either side (i.e.,

driver side or passenger side).

NOTE:

The driver is always responsible for

controlling the vehicle, responsible for any

surrounding objects, and must intervene as

required.

The system is provided to assist the driver

and not to substitute the driver.

During a semi-automatic maneuver, if the

driver touches the steering wheel after being

instructed to remove their hands from the

steering wheel, the system will cancel, and

the driver will be required to manually

complete the parking maneuver.

The system may not work in all conditions

(e.g. environmental conditions such as heavy

rain, snow, etc., or if searching for a parking

space that has surfaces that will absorb the

ultrasonic sensor waves).

New vehicles from the dealership must have

at least 30 miles (48 km) accumulated

before the ParkSense Active Park Assist system is fully calibrated and performs accu

-

rately. This is due to the system’s dynamic

vehicle calibration to improve the perfor -

mance of the feature. The system will also

continuously perform the dynamic vehicle

calibration to account for differences such as

over or under inflated tires and new tires.

Enabling And Disabling The ParkSense

Active Park Assist System

The ParkSense Active Park Assist

system can be enabled and disabled

with the ParkSense Active Park Assist

switch, located on the switch panel

below the Uconnect display.

To enable the ParkSense Active Park Assist

system, push the ParkSense Active Park Assist

switch once (LED turns on).

To disable the ParkSense Active Park Assist

system, push the ParkSense Active Park Assist

switch again (LED turns off).

The ParkSense Active Park Assist system will

turn off automatically for any of the following

conditions:

The parking maneuver is completed.

Vehicle speed greater than 18 mph (30 km/h)

when searching for a parking space.

CAUTION!

ParkSense is only a parking aid and it is

unable to recognize every obstacle,

including small obstacles. Parking curbs

might be temporarily detected or not

detected at all. Obstacles located above or

below the sensors will not be detected

when they are in close proximity.

The vehicle must be driven slowly when

using ParkSense in order to be able to stop

in time when an obstacle is detected. It is

recommended that the driver looks over

his/her shoulder when using ParkSense.

20_RU_OM_EN_US_t.book Page 268

Page 331 of 516

IN CASE OF EMERGENCY329

(Continued)

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the vehicle’s Hazard Warning Flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service

Kit Hose to reach the valve stem and keep

the Tire Service Kit flat on the ground. This

will provide the best positioning of the kit

when running the air pump. Move the

vehicle as necessary to place the valve

stem in this position before proceeding.

3. Place the transmission in PARK (P) and cycle the ignition in the OFF position.

4. Ensure the park brake is engaged. Setting Up To Use Tire Service Kit:

1. Remove the Tire Service Kit from the

storage location.

2. Uncoil the Sealant/Air Hose.

Remove the cap from the valve stem

and then screw the fitting in at the

end of the Sealant/Air Hose clockwise

onto the valve stem.

3. Place the Tire Service Kit on the ground next

to the deflated tire.

4. Uncoil the Power Plug and insert

the plug into the vehicle’s 12 Volt

power outlet.

5. Engage parking brake before turning the

engine ON. 6. Always start the engine before

turning ON the Tire Service Kit.

7. Turn the Mode Select Knob to Air

Mode position.

WARNING!

Keep Tire Service Kit away from open

flames or heat source.

A loose Tire Service Kit thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the

Tire Service Kit in the place provided.

Failure to follow these warnings can result

in injuries that are serious or fatal to you,

your passengers, and others around you.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair, eyes,

or clothing. Tire Service Kit sealant is

harmful if inhaled, swallowed, or absorbed

through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately with

plenty of water if there is any contact with

eyes or skin. Change clothing as soon as

possible, if there is any contact with clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty

of water and drink plenty of water. Do not

induce vomiting! Consult a physician imme -

diately.

WARNING! (Continued)

6

20_RU_OM_EN_US_t.book Page 329

Page 335 of 516

IN CASE OF EMERGENCY333

Sealing A Tire With Tire Service Kit

Whenever You Stop To Use Tire Service Kit:

1. Pull over to a safe location and turn on the

vehicle’s Hazard Warning flashers.

2. Verify that the valve stem (on the wheel with the deflated tire) is in a position that is near

to the ground. This will allow the Tire Service

Kit Hose to reach the valve stem and keep

the Tire Service Kit flat on the ground. This

will provide the best positioning of the kit

when injecting the sealant into the deflated

tire and running the air pump. Move the

vehicle as necessary to place the valve

stem in this position before proceeding.

3. Place the transmission in PARK (P) and cycle the ignition in the OFF position.

4. Apply the parking brake. Setting Up To Use Tire Service Kit:

1. Uncoil the Sealant Hose and then remove

the cap from the fitting at the end of the

hose.

2. Place the Tire Service Kit flat on the

ground next to the deflated tire.

3. Remove the cap from the valve stem and then screw the fitting at the end of the

Sealant Hose onto the valve stem.

4. Uncoil the Power Plug and insert

the plug into the vehicle’s 12 Volt

power outlet.

NOTE:

Do not remove foreign objects (e.g., screws or

nails) from the tire.

Take care not to allow the contents of Tire

Service Kit to come in contact with hair,

eyes, or clothing. Tire Service Kit sealant is

harmful if inhaled, swallowed, or absorbed

through the skin. It causes skin, eye, and

respiratory irritation. Flush immediately

with plenty of water if there is any contact

with eyes or skin. Change clothing as soon

as possible, if there is any contact with

clothing.

Tire Service Kit Sealant solution contains

latex. In case of an allergic reaction or rash,

consult a physician immediately. Keep Tire

Service Kit out of reach of children. If swal -

lowed, rinse mouth immediately with plenty

of water and drink plenty of water. Do not

induce vomiting! Consult a physician imme -

diately.

WARNING! (Continued)

6

20_RU_OM_EN_US_t.book Page 333

Page 357 of 516

SERVICING AND MAINTENANCE355

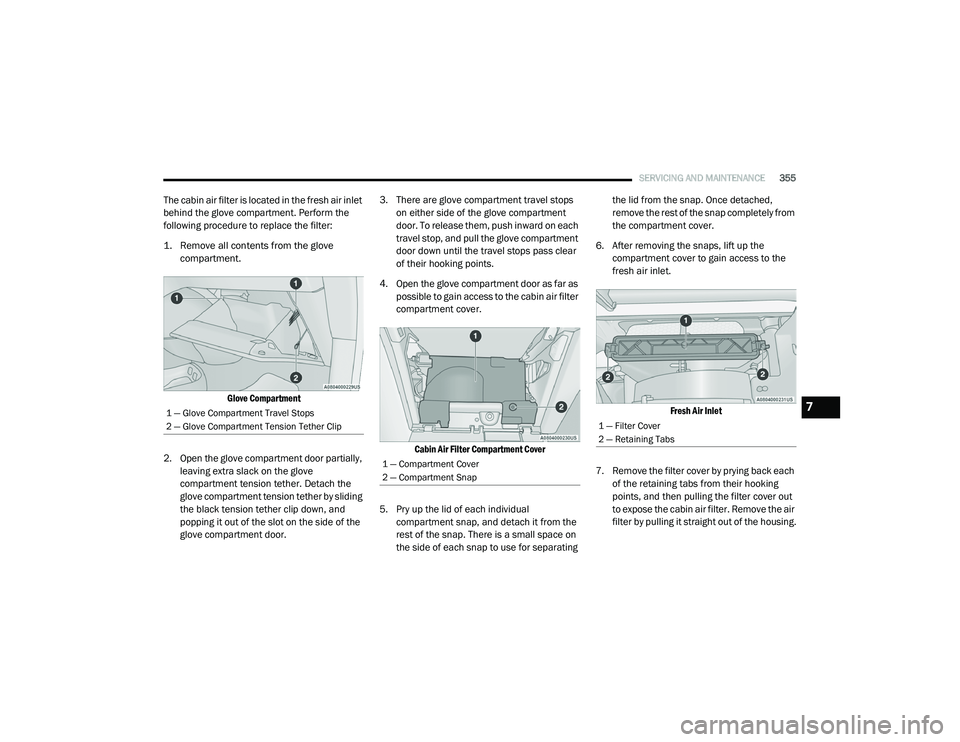

The cabin air filter is located in the fresh air inlet

behind the glove compartment. Perform the

following procedure to replace the filter:

1. Remove all contents from the glove

compartment.

Glove Compartment

2. Open the glove compartment door partially, leaving extra slack on the glove

compartment tension tether. Detach the

glove compartment tension tether by sliding

the black tension tether clip down, and

popping it out of the slot on the side of the

glove compartment door. 3. There are glove compartment travel stops

on either side of the glove compartment

door. To release them, push inward on each

travel stop, and pull the glove compartment

door down until the travel stops pass clear

of their hooking points.

4. Open the glove compartment door as far as possible to gain access to the cabin air filter

compartment cover.

Cabin Air Filter Compartment Cover

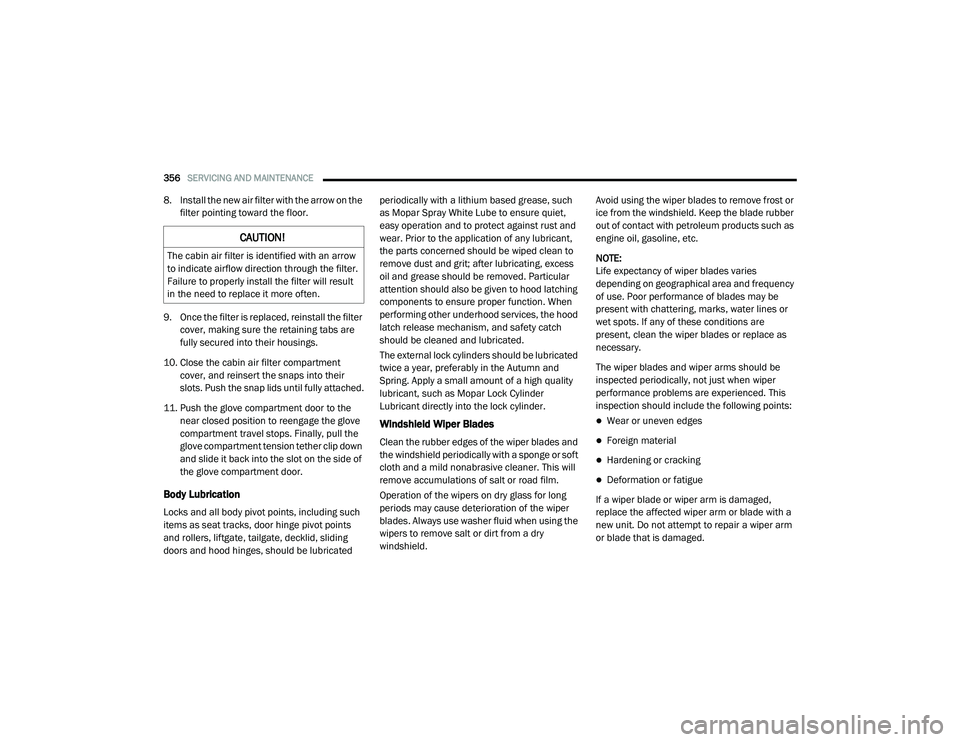

5. Pry up the lid of each individual compartment snap, and detach it from the

rest of the snap. There is a small space on

the side of each snap to use for separating the lid from the snap. Once detached,

remove the rest of the snap completely from

the compartment cover.

6. After removing the snaps, lift up the compartment cover to gain access to the

fresh air inlet.

Fresh Air Inlet

7. Remove the filter cover by prying back each of the retaining tabs from their hooking

points, and then pulling the filter cover out

to expose the cabin air filter. Remove the air

filter by pulling it straight out of the housing.

1 — Glove Compartment Travel Stops

2 — Glove Compartment Tension Tether Clip

1 — Compartment Cover

2 — Compartment Snap

1 — Filter Cover

2 — Retaining Tabs

7

20_RU_OM_EN_US_t.book Page 355

Page 358 of 516

356SERVICING AND MAINTENANCE

8. Install the new air filter with the arrow on the

filter pointing toward the floor.

9. Once the filter is replaced, reinstall the filter cover, making sure the retaining tabs are

fully secured into their housings.

10. Close the cabin air filter compartment cover, and reinsert the snaps into their

slots. Push the snap lids until fully attached.

11. Push the glove compartment door to the near closed position to reengage the glove

compartment travel stops. Finally, pull the

glove compartment tension tether clip down

and slide it back into the slot on the side of

the glove compartment door.

Body Lubrication

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points

and rollers, liftgate, tailgate, decklid, sliding

doors and hood hinges, should be lubricated periodically with a lithium based grease, such

as Mopar Spray White Lube to ensure quiet,

easy operation and to protect against rust and

wear. Prior to the application of any lubricant,

the parts concerned should be wiped clean to

remove dust and grit; after lubricating, excess

oil and grease should be removed. Particular

attention should also be given to hood latching

components to ensure proper function. When

performing other underhood services, the hood

latch release mechanism, and safety catch

should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and

Spring. Apply a small amount of a high quality

lubricant, such as Mopar Lock Cylinder

Lubricant directly into the lock cylinder.

Windshield Wiper Blades

Clean the rubber edges of the wiper blades and

the windshield periodically with a sponge or soft

cloth and a mild nonabrasive cleaner. This will

remove accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry

windshield.

Avoid using the wiper blades to remove frost or

ice from the windshield. Keep the blade rubber

out of contact with petroleum products such as

engine oil, gasoline, etc.

NOTE:

Life expectancy of wiper blades varies

depending on geographical area and frequency

of use. Poor performance of blades may be

present with chattering, marks, water lines or

wet spots. If any of these conditions are

present, clean the wiper blades or replace as

necessary.

The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged,

replace the affected wiper arm or blade with a

new unit. Do not attempt to repair a wiper arm

or blade that is damaged.

CAUTION!

The cabin air filter is identified with an arrow

to indicate airflow direction through the filter.

Failure to properly install the filter will result

in the need to replace it more often.

20_RU_OM_EN_US_t.book Page 356

Page 366 of 516

364SERVICING AND MAINTENANCE

(Continued)

Maintain engine coolant (antifreeze) concen-

tration at a minimum of 50% OAT coolant

(conforming to MS.90032) and distilled

water for proper corrosion protection of your

engine which contains aluminum compo -

nents.

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning,

keep the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever

necessary, install ONLY the correct type ther -

mostat. Other designs may result in unsatis -

factory engine coolant (antifreeze)

performance, poor gas mileage, and

increased emissions.

Brake System

In order to ensure brake system performance,

all brake system components should be

inspected periodically. Refer to the

“Maintenance Plan” in this section for the

proper maintenance intervals.

Brake Master Cylinder

The fluid in the master cylinder should be

checked when performing under hood services

or immediately if the “Brake Warning Light” is

illuminated.

Be sure to clean the top of the master cylinder

area before removing the cap. If necessary, add

fluid to bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer's recommended brake

fluid. Refer to “Fluids And Lubricants” in

“Technical Specifications” for further information.

WARNING!

Riding the brakes can lead to brake failure

and possibly a collision. Driving with your foot

resting or riding on the brake pedal can result

in abnormally high brake temperatures,

excessive lining wear, and possible brake

damage. You would not have your full braking

capacity in an emergency.

WARNING!

Use only manufacturer's recommended

brake fluid. Refer to “Fluids And Lubricants”

in “Technical Specifications” for further infor-

mation. Using the wrong type of brake fluid

can severely damage your brake system

and/or impair its performance. The proper

type of brake fluid for your vehicle is also

identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter

or moisture, use only new brake fluid or fluid

that has been in a tightly closed container.

Keep the master cylinder reservoir cap

secured at all times. Brake fluid in a open

container absorbs moisture from the air

resulting in a lower boiling point. This may

cause it to boil unexpectedly during hard or

prolonged braking, resulting in sudden brake

failure. This could result in a collision.

20_RU_OM_EN_US_t.book Page 364

Page 368 of 516

366SERVICING AND MAINTENANCE

Fluid And Filter Changes

Under normal operating conditions, the fluid

installed at the factory will provide satisfactory

lubrication for the life of the vehicle.

Routine fluid and filter changes are not

required. However, change the fluid and filter if

the fluid becomes contaminated (with water,

etc.), or if the transmission is disassembled for

any reason.

RAISING THE VEHICLE

In the case where it is necessary to raise the

vehicle, go to an authorized dealer or service

station.

TIRES

Tire Safety Information

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

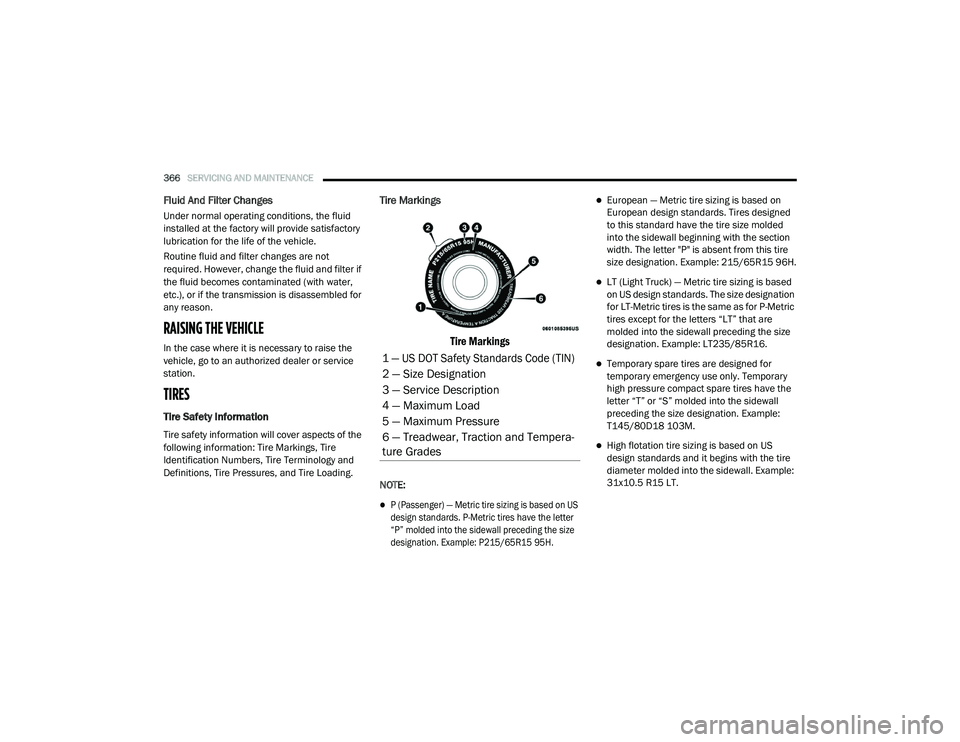

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on

European design standards. Tires designed

to this standard have the tire size molded

into the sidewall beginning with the section

width. The letter "P" is absent from this tire

size designation. Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based

on US design standards. The size designation

for LT-Metric tires is the same as for P-Metric

tires except for the letters “LT” that are

molded into the sidewall preceding the size

designation. Example: LT235/85R16.

Temporary spare tires are designed for

temporary emergency use only. Temporary

high pressure compact spare tires have the

letter “T” or “S” molded into the sidewall

preceding the size designation. Example:

T145/80D18 103M.

High flotation tire sizing is based on US

design standards and it begins with the tire

diameter molded into the sidewall. Example:

31x10.5 R15 LT.

1 — US DOT Safety Standards Code (TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

20_RU_OM_EN_US_t.book Page 366

Page 370 of 516

368SERVICING AND MAINTENANCE

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle

loading, road conditions, and posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

20_RU_OM_EN_US_t.book Page 368

Page 444 of 516

442MULTIMEDIA

The Program Information is displayed at the

bottom of the Channel Number.

The SiriusXM® function buttons are

displayed below the Program Information.

Tuning is done by operating the Tune Knob or by

Direct Tune, similar to other Radio Bands, see

Presets, browse, Tune Knob, and Direct Tune.

In addition to the tuning Operation functions

common to all Radio modes, the replay, Traffic/

Weather Jump, and fav button functions are

available in SiriusXM® Mode.

Replay

The replay function provides a means to store

and replay up to 22 minutes of music audio and

48 minutes of talk radio. Once the channel is

switched, content in replay memory is lost.

Press the Replay button on the touchscreen.

The play/pause, rewind/forward and live

buttons will display at the top of the screen,

along with the replay time.

You can exit by pressing the Replay button on the

touchscreen, any time during the Replay mode.

Play/Pause

Press the Pause/Play button on the

touchscreen to pause the playing of live or

rewound content at any time. Play can be

resumed again by pressing of the Pause/Play

button on the touchscreen.

Rewind

Press the RW button on the touchscreen to

rewind the content in steps of five seconds.

Pressing the RW button on the touchscreen for

more than two seconds rewinds the content.

The Radio begins playing the content at the

point at which the press is released.

Forward

Each press of the FW button on the touchscreen

forwards the content in steps of five seconds.

Forwarding of the content can only be done

when the content is previously rewound, and

therefore, can not be done for live content. A

continuous press of the FW button on the

touchscreen also forwards the content. The

Radio begins playing the content at the point at

which the press is released.

Live

Press the Live button on the touchscreen to

resume playing of Live content.

Favorites

Press the Fav button on the touchscreen to

activate the favorites menu, which will time out

in five seconds in absence of user interaction.

You can exit the Favorites Menu by a press of

the X in the top right corner.

The favorites feature enables you to set a

favorite artist, or song that is currently playing.

The Radio then uses this information to alert

you when either the favorite song, or favorite

artist are being played at any time by any of the

SiriusXM® Channels.

The maximum number of favorites that can be

stored in the Radio is 50.

Fav. Artist:

While the song is playing to set a

Favorite Artist, press the Fav button on the

touchscreen and then the Fav. Artist button on

the touchscreen.

Fav. Song: While the song is playing to set a

Favorite Song, press the Fav button on the

touchscreen and then the Fav Song button on

the touchscreen.

20_RU_OM_EN_US_t.book Page 442

Page 489 of 516

MULTIMEDIA487

AAC (MPEG-4 AAC, Low Complexity Profile)

support.

AAC HE v1 (AAC High Efficiency v1 aka. AAC/

MPEG4v2 AAC+) support.

HE-AAC v1, v2 support.

Disc Errors

If the Blu-ray™ Disc player is unable to read the

disc, a "Disc Error" message is displayed on the

rear screen and Radio displays. A dirty,

damaged, or incompatible disc format are all

potential causes for a "Disc Error" message.

If a disc has a damaged track which results in

audible or visible errors that persists for two

seconds, the Blu-ray™ Disc player will attempt

to continue playing the disc by skipping forward

one to three seconds at a time. If the end of the

disc is reached, the Blu-ray™ Disc player will

return to the beginning of the disc and attempt

to play the start of the first track. The Blu-ray™ Disc player may shut down during

extremely hot conditions, such as when the

vehicle’s interior temperature is above 140°F

(60.0°C). When this occurs, the player will

display "High Temp" and will shut off the Rear

Seat displays until a safe temperature is

reached. This shutdown is necessary to protect

the optics of the Blu-ray™ Disc player.

Product Agreement

Open Source Software

The software built into this product, are

composed of multiple software components,

and there are the copyrights of our company or

third parties in each software component. Also,

in this product, the following open source

software has been installed.

The licensed software for our company is based

on GNU GENERAL PUBLIC LICENSE V2.0 ("GPL").

The licensed software for our company is

based on GNU LESSER GENERAL PUBLIC

LICENSE V2.1 ("LGPL").

The software which has the copyrights of a

third party and is distributed as free software.Please refer the contract details which are

disclosed in the following websites, for

example, concerning these above software.

http://www.gnu.org/licenses/old-licenses/

gpl-2.0-standalone.html, http://www.gnu.org/

licenses/lgpl-2.1-standalone.html.

You have the right of acquisition, modification,

and distribution of the source code of the GPL/

LGPL software. These are distributed in the

hope that it will be useful by itself. However,

including the absence of an implied warranty on

the "suitability for a particular purpose" or

"merchantability", the warranty of any kind will

not be made. You may download Source Code

from the indicating URL by the pressed button

of “Open Source Software” on the Setup Menu.

Also, please refrain from contact about the

contents of the source code of open source. The

source code of the software in which there are

the copyrights of our company or third parties, is

not subject to distribution.

9

20_RU_OM_EN_US_t.book Page 487