torque CHRYSLER PACIFICA 2020 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2020, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2020Pages: 516, PDF Size: 28.69 MB

Page 283 of 516

STARTING AND OPERATING281

LaneSense Warning Message

The LaneSense system will indicate the current

lane drift condition through the instrument

cluster display.

Instrument Cluster Display

When the LaneSense system is on, the lane

lines are gray when both of the lane boundaries

have not been detected and the LaneSense

telltale is solid white.

System ON (Gray Lines) With White Telltale

Left Lane Departure — Only Left Lane Detected

When the LaneSense system is on, the Lane -

Sense Telltale is solid white only when the

left lane marking has been detected and the

system is ready to provide visual warnings in

the instrument cluster display if an uninten -

tional lane departure occurs on the left side.

When the LaneSense system senses the lane

has been approached and is in a lane depar -

ture situation, the visual warning in the

instrument cluster display will show the left

inside lane line flashing yellow (on/off), while

the outside lane line on the left of the display

will remain solid yellow. The LaneSense tell -

tale changes from solid white to flashing

yellow.

Lane Approached (Flashing Yellow Inside Line, Solid

Yellow Outside Line/Flashing) With Yellow Telltale

NOTE:

The LaneSense system operates with similar

behavior for a right lane departure when only

the right lane marking has been detected. Left Lane Departure — Both Lane Lines

Detected

When the LaneSense system is on, the lane

lines turn from gray to white. The LaneSense

telltale is solid green when both lane

markings have been detected and the

system is “armed” to provide visual warnings

in the instrument cluster display and a torque

warning in the steering wheel if an uninten

-

tional lane departure occurs.

Lanes Sensed (White Lines) With Green Telltale

When the LaneSense system senses a lane

drift situation, the left inside and outside lane

lines turn solid yellow. The LaneSense telltale changes from solid green to solid yellow. At

this time torque is applied to the steering wheel

in the opposite direction of the lane boundary.

5

20_RU_OM_EN_US_t.book Page 281

Page 284 of 516

282STARTING AND OPERATING

For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Sensed (Solid Yellow Inside Line, Solid Yellow Outside Line) With Solid Yellow Telltale

When the LaneSense system senses the lane

has been approached and is in a lane depar -

ture situation, the left inside lane line flashes

yellow (on/off) while the left outside line

remains solid yellow. The LaneSense telltale

changes from solid yellow to flashing

yellow. At this time torque is applied to the

steering wheel in the opposite direction of

the lane boundary.

For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Approached (Flashing Yellow Inside Line, Solid

Yellow Outside Line) With Flashing Yellow Telltale

NOTE:

The LaneSense system operates with similar

behavior for a right lane departure.

Changing LaneSense Status

The LaneSense system has settings to adjust

the intensity of the torque warning and the

warning zone sensitivity (Early/Medium/Late)

that you can configure through the Uconnect

system screen. Refer to “Uconnect Settings” in

“Multimedia” for further information.

NOTE:

When enabled the system operates above

37 mph (60 km/h) and below 112 mph (180 km/h).

Use of the turn signal suppresses the warn -

ings.

The system will not apply torque to the

steering wheel whenever a safety system

engages (Anti-Lock Brakes, Traction Control

System, Electronic Stability Control, Forward

Collision Warning, etc.).

20_RU_OM_EN_US_t.book Page 282

Page 326 of 516

324IN CASE OF EMERGENCY

3. Place the wrench on the jack screw and turn

clockwise until the jack head is properly

engaged in the described location. Do not

raise the vehicle until you are sure the jack

is securely engaged.

4. Raise the vehicle by turning the jack screw clockwise, using the swivel wrench. Raise

the vehicle only until the tire just clears the

surface and enough clearance is obtained

to install the compact spare tire. Minimum

tire lift provides maximum stability.

5. Remove the wheel lug nuts, for vehicles with wheel covers, remove the cover from

the wheel by hand. Do not pry the wheel

cover off. Then pull the wheel off the hub.

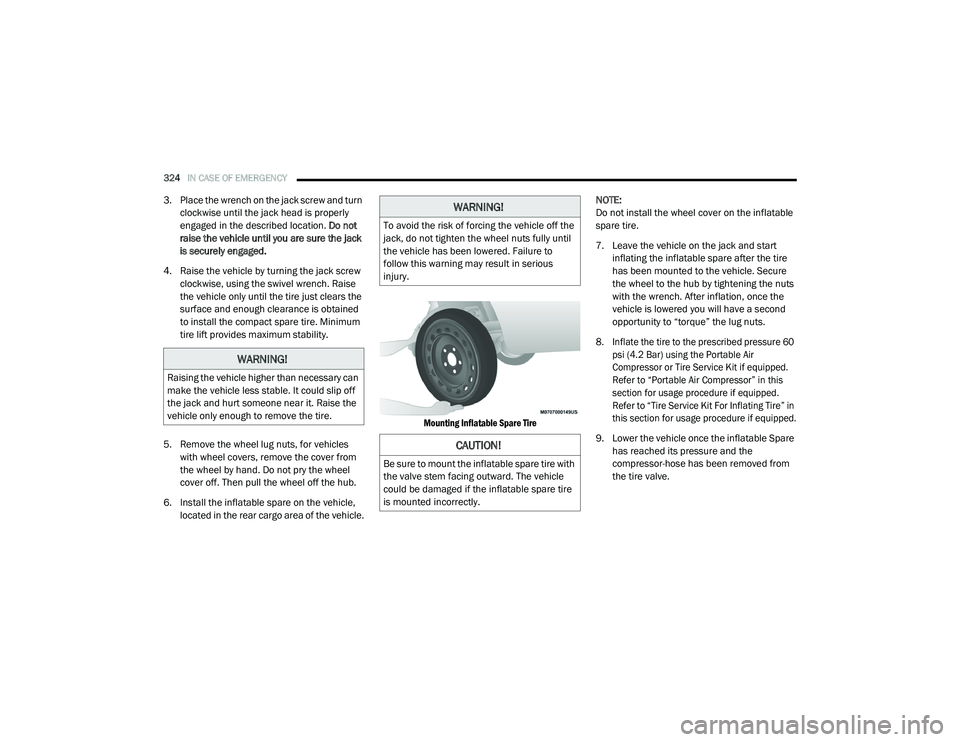

6. Install the inflatable spare on the vehicle, located in the rear cargo area of the vehicle.

Mounting Inflatable Spare Tire

NOTE:

Do not install the wheel cover on the inflatable

spare tire.

7. Leave the vehicle on the jack and start

inflating the inflatable spare after the tire

has been mounted to the vehicle. Secure

the wheel to the hub by tightening the nuts

with the wrench. After inflation, once the

vehicle is lowered you will have a second

opportunity to “torque” the lug nuts.

8. Inflate the tire to the prescribed pressure 60 psi (4.2 Bar) using the Portable Air

Compressor or Tire Service Kit if equipped.

Refer to “Portable Air Compressor” in this

section for usage procedure if equipped.

Refer to “Tire Service Kit For Inflating Tire” in

this section for usage procedure if equipped.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the

compressor-hose has been removed from

the tire valve.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off

the jack and hurt someone near it. Raise the

vehicle only enough to remove the tire.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

CAUTION!

Be sure to mount the inflatable spare tire with

the valve stem facing outward. The vehicle

could be damaged if the inflatable spare tire

is mounted incorrectly.

20_RU_OM_EN_US_t.book Page 324

Page 327 of 516

IN CASE OF EMERGENCY325

10. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in “Technical

Specifications” for proper wheel lug nut

torque. If in doubt about the correct

tightness, have them checked with a torque

wrench by an authorized dealer or at a

service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do

not stow the deflated tire in the inflatable

spare tire location. Have the full-sized tire

repaired or replaced, as soon as possible. 13. Stow the jack back in the stowage

compartment and place the access panel

back. The stud of the storage area must be

threaded through the lower part of the jack.

Then turn the Jack Screw clockwise to

secure it in place.

NOTE:

Stow the foam tray and components in the

cargo area.

Storing The Jack

Road Tire Installation

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug

nuts on the mounting studs which are on

each side of the valve stem. Install the lug

nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug

nuts.

Tire And Wheel Cover Or Center Cap

WARNING!

A loose tire or jack thrown forward in a

collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack

parts and the spare tire in the places

provided. Have the deflated (flat) tire repaired

or replaced immediately.

1 — Jack Screw

2 — Jack

3 — Stud

1 — Valve Stem

2 — Valve Notch

3 — Wheel Lug Nut

4 — Wheel Cover

5 — Mounting Stud

6

20_RU_OM_EN_US_t.book Page 325

Page 328 of 516

326IN CASE OF EMERGENCY

3. Align the valve notch in the wheel cover with

the valve stem on the wheel. Install the

cover by hand, snapping the cover over the

two lug nuts. Do not use a hammer or

excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the

wheel sits flush onto the hub and there is no

play. The nuts will have to be fully tightened

once the vehicle is lowered. Tightening an

improperly seated wheel under vehicle load

can damage the threads, cause vibration,

and undermine safety.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been

tightened twice. Refer to “Wheel And Tire

Torque Specifications” in “Technical Specifi -

cations” for proper wheel lug nut torque. If in

doubt about the correct tightness, have them

checked with a torque wrench by an

authorized dealer or at a service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts

are properly seated against the wheel.

Vehicles Without Wheel Covers

1. Mount the road tire on the axle.

2. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the

wheel sits flush onto the hub and there is no

play. The nuts will have to be fully tightened

once the vehicle is lowered. Tightening an

improperly seated wheel under vehicle load

can damage the threads, cause vibration,

and undermine safety. 3. Lower the vehicle to the ground by turning

the jack handle counterclockwise.

4. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle

for increased leverage. Tighten the lug nuts

in a star pattern until each nut has been

tightened twice. Refer to “Torque Specifi -

cations” in the “Technical Specifications”

section for proper wheel lug nut torque. If in

doubt about the correct tightness, have

them checked with a torque wrench by an

authorized dealer or at a service station.

5. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that

all lug nuts are properly seated against the

wheel.WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until

the vehicle has been lowered. Failure to

follow this warning may result in serious

injury.

20_RU_OM_EN_US_t.book Page 326

Page 367 of 516

SERVICING AND MAINTENANCE365

Automatic Transmission

Selection Of Lubricant

It is important to use the proper transmission

fluid to ensure optimum transmission

performance and life. Use only the

manufacturer's specified transmission fluid.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications. It is

important to maintain the transmission fluid at

the correct level using the recommended fluid. NOTE:

No chemical flushes should be used in any

transmission; only the approved lubricant

should be used.

Special Additives

The manufacturer strongly recommends

against using any special additives in the

transmission. Automatic Transmission Fluid

(ATF) is an engineered product and its

performance may be impaired by supplemental

additives. Therefore, do not add any fluid

additives to the transmission. Avoid using

transmission sealers as they may adversely

affect seals.

Fluid Level Check

The fluid level is preset at the factory and does

not require adjustment under normal operating

conditions. Routine fluid level checks are not

required; therefore the transmission has no

dipstick. An authorized dealer can check your

transmission fluid level using special service

tools. If you notice fluid leakage or transmission

malfunction, visit an authorized dealer

immediately to have the transmission fluid level

checked. Operating the vehicle with an

improper fluid level can cause severe

transmission damage.

Overfilling the brake fluid reservoir can

result in spilling brake fluid on hot engine

parts, causing the brake fluid to catch fire.

Brake fluid can also damage painted and

vinyl surfaces, care should be taken to

avoid its contact with these surfaces.

Do not allow petroleum based fluid to

contaminate the brake fluid. Brake seal

components could be damaged, causing

partial or complete brake failure. This could

result in a collision.

WARNING!

(Continued)

CAUTION!

Using a transmission fluid other than the

manufacturer’s recommended fluid may

cause deterioration in transmission shift

quality and/or torque converter shudder.

Refer to “Fluids And Lubricants” in “Technical

Specifications” for fluid specifications.

CAUTION!

Do not use chemical flushes in your

transmission as the chemicals can damage

your transmission components. Such damage

is not covered by the New Vehicle Limited

Warranty.

CAUTION!

If a transmission fluid leak occurs, visit an

authorized dealer immediately. Severe

transmission damage may occur. An

authorized dealer has the proper tools to

adjust the fluid level accurately.

7

20_RU_OM_EN_US_t.book Page 365

Page 390 of 516

388

TECHNICAL SPECIFICATIONS

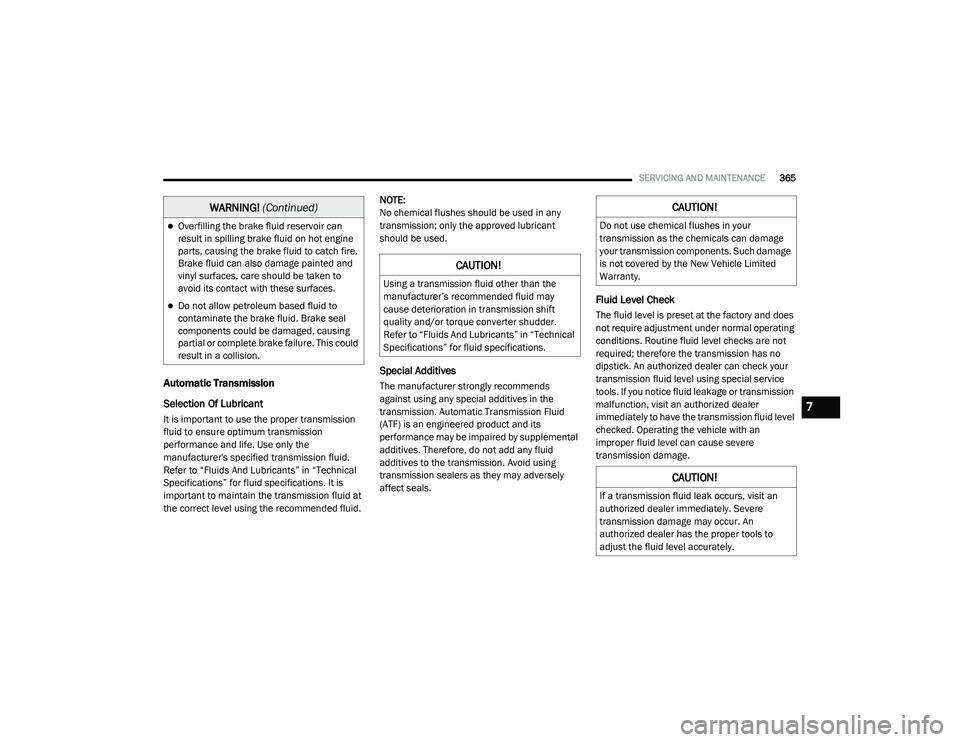

IDENTIFICATION DATA

Vehicle Identification Number

The Vehicle Identification Number (VIN) is on

the left front corner of the instrument panel and

is visible from outside of the vehicle through the

windshield.

Vehicle Identification Number

NOTE:

It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic

brake systems. If either of the two hydraulic

systems loses normal capability, the remaining

system will still function. However, there will be

some loss of overall braking effectiveness. You

may notice increased pedal travel during

application, greater pedal force required to slow

or stop, and potential activation of the Brake

Warning Light.

In the event power assist is lost for any reason

(i.e., repeated brake applications with the

engine off) the brakes will still function.

However, the effort required to brake the

vehicle will be much greater than that required

with the power system operating.

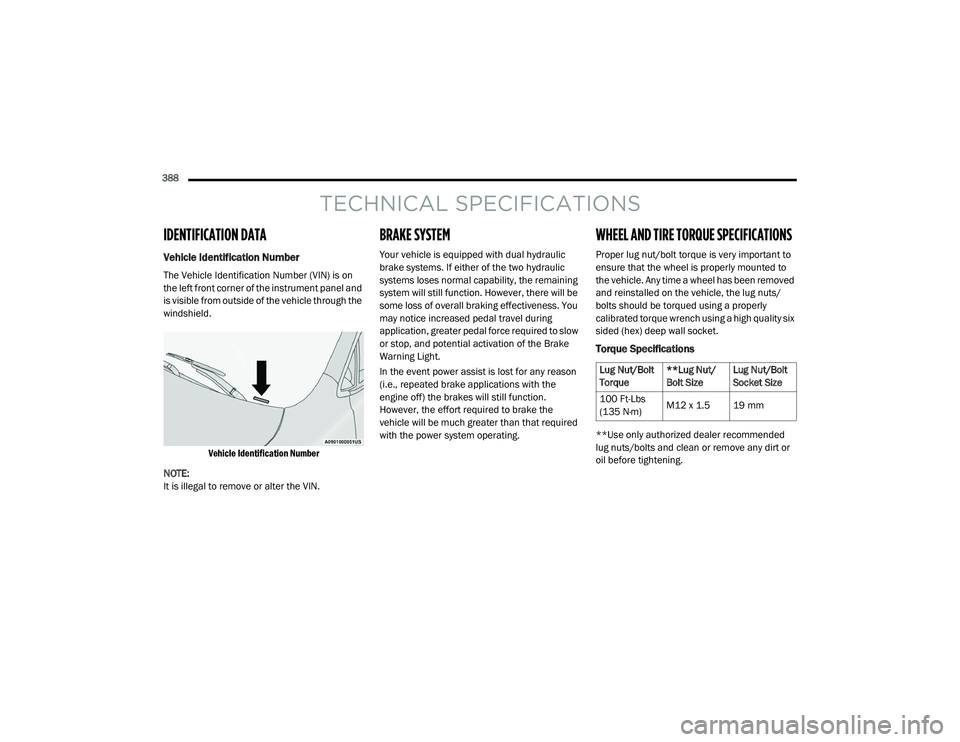

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to

the vehicle. Any time a wheel has been removed

and reinstalled on the vehicle, the lug nuts/

bolts should be torqued using a properly

calibrated torque wrench using a high quality six

sided (hex) deep wall socket.

Torque Specifications

**Use only authorized dealer recommended

lug nuts/bolts and clean or remove any dirt or

oil before tightening.

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 Ft-Lbs

(135 N·m) M12 x 1.5 19 mm

20_RU_OM_EN_US_t.book Page 388

Page 391 of 516

TECHNICAL SPECIFICATIONS389

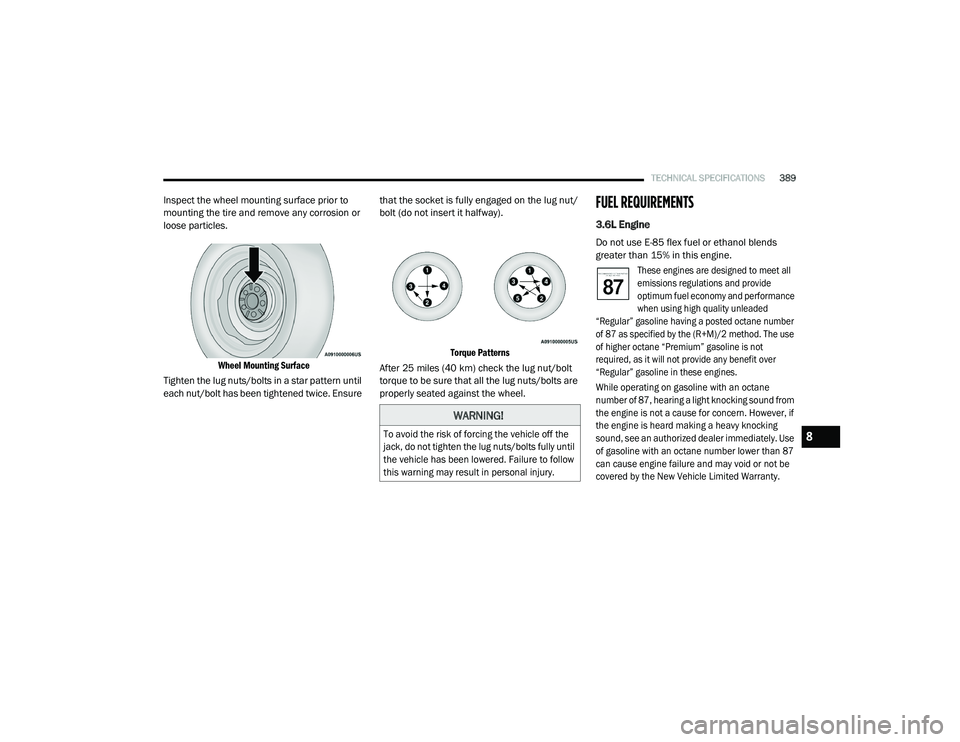

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Tighten the lug nuts/bolts in a star pattern until

each nut/bolt has been tightened twice. Ensure that the socket is fully engaged on the lug nut/

bolt (do not insert it halfway).

Torque Patterns

After 25 miles (40 km) check the lug nut/bolt torque to be sure that all the lug nuts/bolts are

properly seated against the wheel.FUEL REQUIREMENTS

3.6L Engine

Do not use E-85 flex fuel or ethanol blends

greater than 15% in this engine.

These engines are designed to meet all

emissions regulations and provide

optimum fuel economy and performance

when using high quality unleaded

“Regular” gasoline having a posted octane number

of 87 as specified by the (R+M)/2 method. The use

of higher octane “Premium” gasoline is not

required, as it will not provide any benefit over

“Regular” gasoline in these engines.

While operating on gasoline with an octane

number of 87, hearing a light knocking sound from

the engine is not a cause for concern. However, if

the engine is heard making a heavy knocking

sound, see an authorized dealer immediately. Use

of gasoline with an octane number lower than 87

can cause engine failure and may void or not be

covered by the New Vehicle Limited Warranty.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the lug nuts/bolts fully until

the vehicle has been lowered. Failure to follow

this warning may result in personal injury.

8

20_RU_OM_EN_US_t.book Page 389

Page 513 of 516

511

Tire Stowage

.................................................. 330Tires................................... 218, 374, 379, 383Aging (Life Of Tires)................................... 377Air Pressure............................................... 374Chains....................................................... 382Changing......................................... 320, 366Compact Spare......................................... 379General Information........................ 374, 379High Speed................................................ 375Inflation Pressure...................................... 375Jacking................................... 320, 322, 366Life Of Tires............................................... 377Load Capacity............................................ 371Pressure Monitoring System (TPMS)............................... 131, 146, 167Quality Grading.......................................... 383Radial........................................................ 376Replacement............................................. 377Rotation.................................................... 382Safety.............................................. 366, 374Sizes.......................................................... 367Snow Tires................................................. 379Spare Tires............................. 320, 379, 380Spinning.................................................... 376Trailer Towing............................................ 295Tread Wear Indicators............................... 377Wheel Nut Torque..................................... 388To Open Hood.................................................. 97Tongue Weight/Trailer Weight....................... 294

Towing.......................................................... 289Disabled Vehicle....................................... 342Guide........................................................ 291Recreational............................................. 298Weight...................................................... 291Towing Behind A Motorhome........................ 298Traction......................................................... 299Traction Control............................................ 158Trailer Sway Control (TSC)............................. 158Trailer Towing............................................... 289Cooling System Tips................................. 297Hitches..................................................... 291Minimum Requirements........................... 294Tips........................................................... 297Trailer And Tongue Weight........................ 294Wiring....................................................... 296Trailer Towing Guide..................................... 291Trailer Weight................................................ 291TransaxleAutomatic................................................. 228Operation................................................. 228Transmission................................................ 230Automatic........................................ 230, 365Maintenance............................................ 365Transporting Pets.......................................... 215Tread Wear Indicators.................................. 377Turn Signals.................................. 63, 149, 309

U

UconnectAdvanced Phone Connectivity

................... 465Phone Call Features................................. 462Theater..................................................... 469Things You Should Know About Your Uconnect Phone................................... 465Uconnect Settings.......................................21Uconnect 4 With 7-Inch Display.................... 398Uconnect 4C/4C Nav With 8.4-Inch Display.. 415Uconnect Phone................ 456, 457, 459, 460Answer Or Ignore An Incoming Call — Call Currently In Progress..................... 464Answer Or Ignore An Incoming Call — No Call Currently In Progress................ 464Bluetooth Communication Link................ 466Call By Saying A Phonebook Name........... 463Call Continuation...................................... 465Call Controls............................................. 463Call Termination....................................... 465Cancel Command..................................... 457Connect Or Disconnect Link Between The Uconnect Phone And Mobile

Phone

................................................... 465Connecting To A Particular Mobile Phone Or Audio Device After Pairing................ 460

11

20_RU_OM_EN_US_t.book Page 511