lock CHRYSLER PACIFICA 2022 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2022Pages: 384, PDF Size: 23.92 MB

Page 289 of 384

IN CASE OF EMERGENCY287

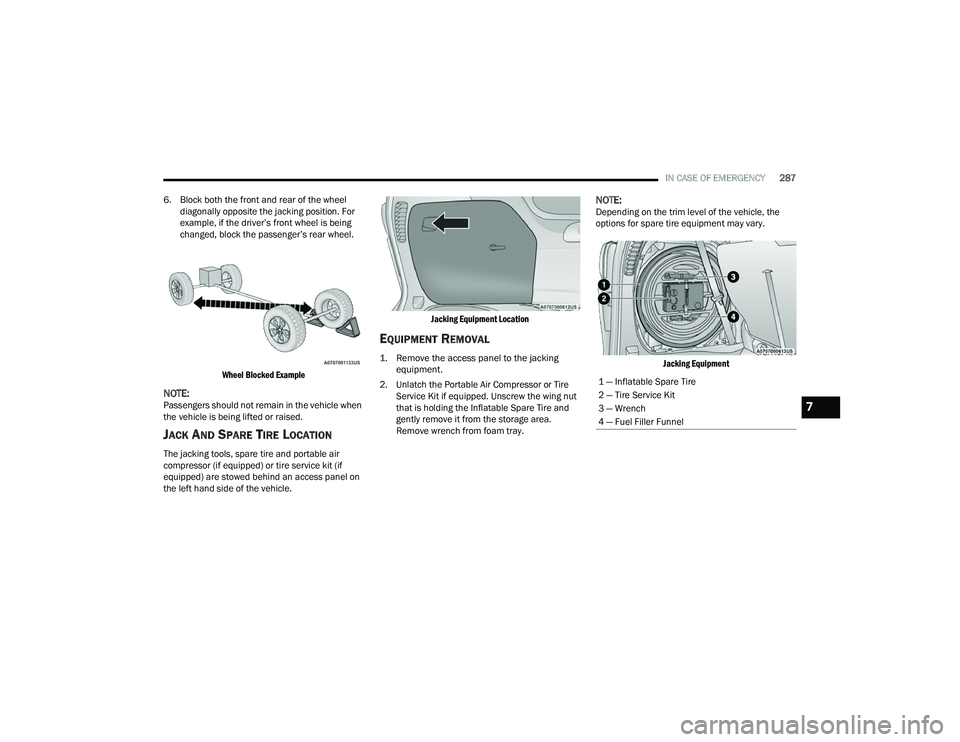

6. Block both the front and rear of the wheel diagonally opposite the jacking position. For

example, if the driver’s front wheel is being

changed, block the passenger’s rear wheel.

Wheel Blocked Example

NOTE:Passengers should not remain in the vehicle when

the vehicle is being lifted or raised.

JACK AND SPARE TIRE LOCATION

The jacking tools, spare tire and portable air

compressor (if equipped) or tire service kit (if

equipped) are stowed behind an access panel on

the left hand side of the vehicle.

Jacking Equipment Location

EQUIPMENT REMOVAL

1. Remove the access panel to the jacking

equipment.

2. Unlatch the Portable Air Compressor or Tire Service Kit if equipped. Unscrew the wing nut

that is holding the Inflatable Spare Tire and

gently remove it from the storage area.

Remove wrench from foam tray.

NOTE:Depending on the trim level of the vehicle, the

options for spare tire equipment may vary.

Jacking Equipment

1 — Inflatable Spare Tire

2 — Tire Service Kit

3 — Wrench

4 — Fuel Filler Funnel

7

22_RUP_OM_EN_USC_t.book Page 287

Page 290 of 384

288IN CASE OF EMERGENCY

(Continued)

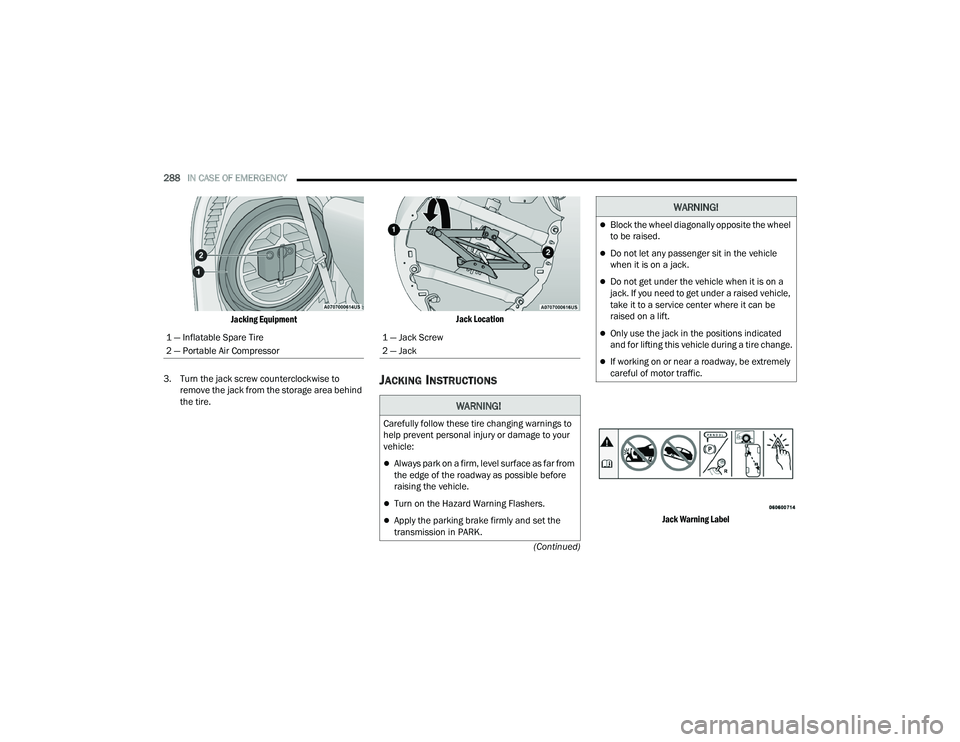

Jacking Equipment

3. Turn the jack screw counterclockwise to remove the jack from the storage area behind

the tire.

Jack Location

JACKING INSTRUCTIONS

Jack Warning Label

1 — Inflatable Spare Tire

2 — Portable Air Compressor

1 — Jack Screw

2 — Jack

WARNING!

Carefully follow these tire changing warnings to

help prevent personal injury or damage to your

vehicle:

Always park on a firm, level surface as far from

the edge of the roadway as possible before

raising the vehicle.

Turn on the Hazard Warning Flashers.

Apply the parking brake firmly and set the

transmission in PARK.

Block the wheel diagonally opposite the wheel

to be raised.

Do not let any passenger sit in the vehicle

when it is on a jack.

Do not get under the vehicle when it is on a

jack. If you need to get under a raised vehicle,

take it to a service center where it can be

raised on a lift.

Only use the jack in the positions indicated

and for lifting this vehicle during a tire change.

If working on or near a roadway, be extremely

careful of motor traffic.

WARNING!

22_RUP_OM_EN_USC_t.book Page 288

Page 292 of 384

290IN CASE OF EMERGENCY

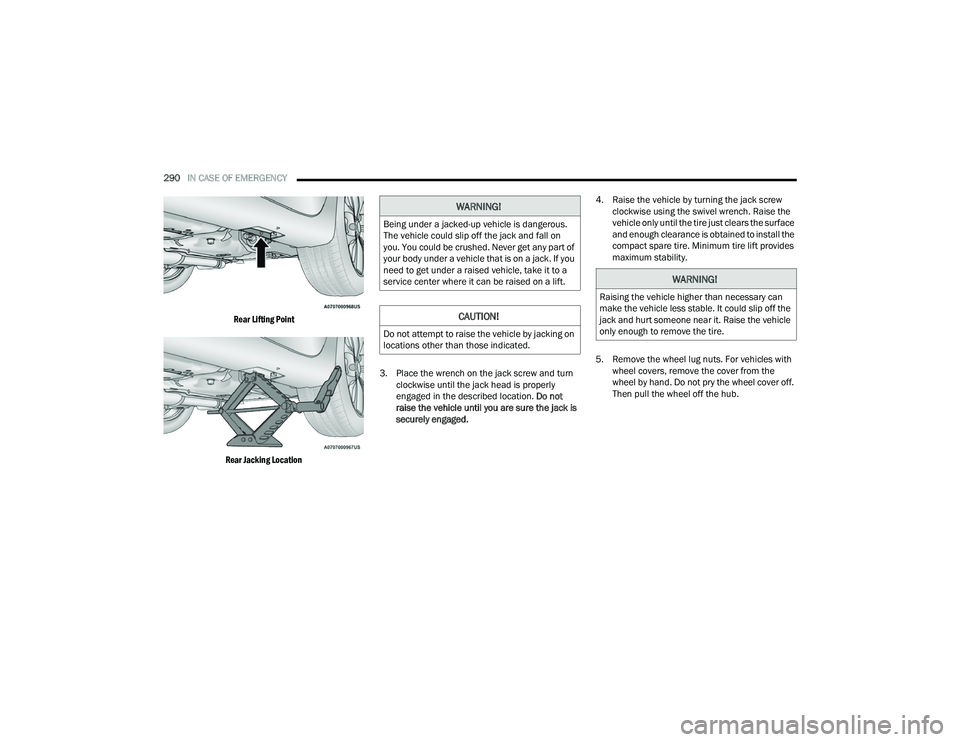

Rear Lifting Point

Rear Jacking Location

3. Place the wrench on the jack screw and turn

clockwise until the jack head is properly

engaged in the described location. Do not

raise the vehicle until you are sure the jack is

securely engaged. 4. Raise the vehicle by turning the jack screw

clockwise using the swivel wrench. Raise the

vehicle only until the tire just clears the surface

and enough clearance is obtained to install the

compact spare tire. Minimum tire lift provides

maximum stability.

5. Remove the wheel lug nuts. For vehicles with wheel covers, remove the cover from the

wheel by hand. Do not pry the wheel cover off.

Then pull the wheel off the hub.

WARNING!

Being under a jacked-up vehicle is dangerous.

The vehicle could slip off the jack and fall on

you. You could be crushed. Never get any part of

your body under a vehicle that is on a jack. If you

need to get under a raised vehicle, take it to a

service center where it can be raised on a lift.

CAUTION!

Do not attempt to raise the vehicle by jacking on

locations other than those indicated.

WARNING!

Raising the vehicle higher than necessary can

make the vehicle less stable. It could slip off the

jack and hurt someone near it. Raise the vehicle

only enough to remove the tire.

22_RUP_OM_EN_USC_t.book Page 290

Page 294 of 384

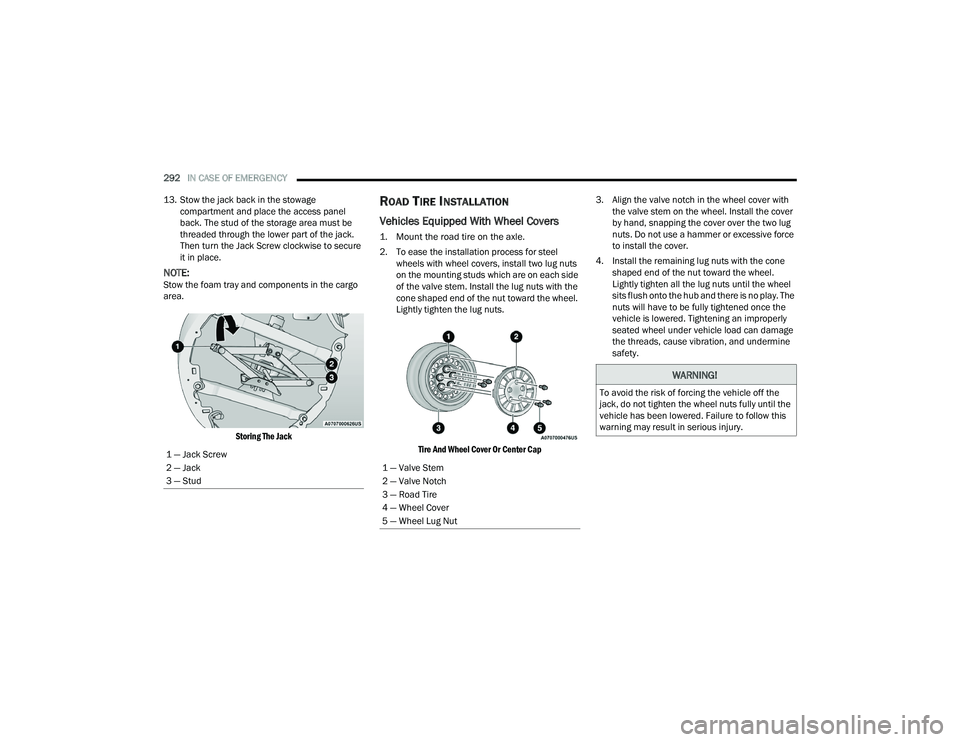

292IN CASE OF EMERGENCY

13. Stow the jack back in the stowage compartment and place the access panel

back. The stud of the storage area must be

threaded through the lower part of the jack.

Then turn the Jack Screw clockwise to secure

it in place.

NOTE:Stow the foam tray and components in the cargo

area.

Storing The Jack

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts

on the mounting studs which are on each side

of the valve stem. Install the lug nuts with the

cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

3. Align the valve notch in the wheel cover with

the valve stem on the wheel. Install the cover

by hand, snapping the cover over the two lug

nuts. Do not use a hammer or excessive force

to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the wheel

sits flush onto the hub and there is no play. The

nuts will have to be fully tightened once the

vehicle is lowered. Tightening an improperly

seated wheel under vehicle load can damage

the threads, cause vibration, and undermine

safety.

1 — Jack Screw

2 — Jack

3 — Stud

1 — Valve Stem

2 — Valve Notch

3 — Road Tire

4 — Wheel Cover

5 — Wheel Lug Nut

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

22_RUP_OM_EN_USC_t.book Page 292

Page 295 of 384

IN CASE OF EMERGENCY293

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tightened

twice Ú page 360. If in doubt about the

correct tightness, have them checked with a

torque wrench by an authorized dealer or at a

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all

lug nuts are properly seated against the wheel.

PORTABLE AIR COMPRESSOR —

I

F EQUIPPED

Your vehicle may be equipped with a Portable Air

Compressor. Use the Portable Air Compressor

located in the side compartment of the cargo area

to inflate the inflatable tire to 60 psi (4.2 Bar).

Portable Air Compressor

Portable Air Compressor Usage With Inflatable

Spare Tire

1. Remove the Portable Air Compressor from the storage location.

2. Raise the vehicle as described in

the Jacking Instructions within this

section. 3. Install the Inflatable Spare tire as

described in the Jack Instructions

section in this manual. Make sure

that the valve stem is located near

the ground, and then screw the air hose of the

Portable Air Compressor to the valve stem.

4. Uncoil the power plug and connect

it the vehicles 12 Volt power Outlet.

5. Always start the engine before

turning ON the Portable Air

Compressor.

6. Switch the power button ON.

7. Inflate the tire to 60 psi (4.2 Bar)

recommended as per the label on

the wheel or if the vehicle equipped

with the inflatable spare tire

pressure indicated on the Tire and Loading

information label located on the driver-side

door opening.

NOTE:If the tire is overinflated, use the deflation button

to reduce the tire air pressure.

1 — Power Plug

2 — Deflation Button

3 — Pressure Gauge

4 — Power Button

5 — Air Hose

7

22_RUP_OM_EN_USC_t.book Page 293

Page 306 of 384

304IN CASE OF EMERGENCY

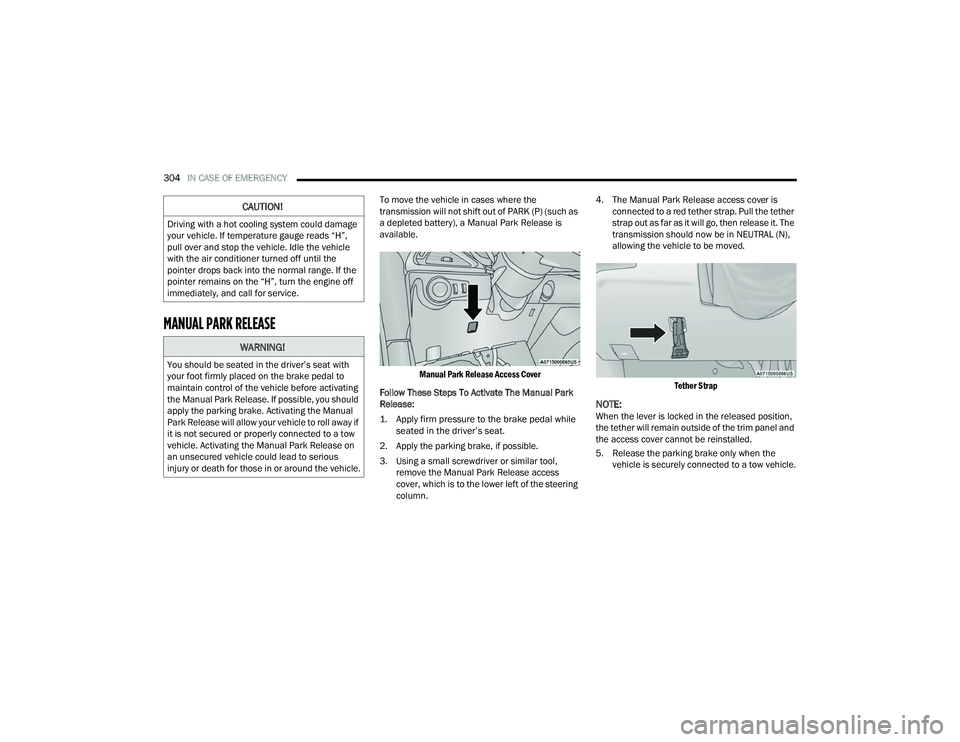

MANUAL PARK RELEASE

To move the vehicle in cases where the

transmission will not shift out of PARK (P) (such as

a depleted battery), a Manual Park Release is

available.

Manual Park Release Access Cover

Follow These Steps To Activate The Manual Park

Release:

1. Apply firm pressure to the brake pedal while seated in the driver’s seat.

2. Apply the parking brake, if possible.

3. Using a small screwdriver or similar tool, remove the Manual Park Release access

cover, which is to the lower left of the steering

column. 4. The Manual Park Release access cover is

connected to a red tether strap. Pull the tether

strap out as far as it will go, then release it. The

transmission should now be in NEUTRAL (N),

allowing the vehicle to be moved.

Tether Strap

NOTE:When the lever is locked in the released position,

the tether will remain outside of the trim panel and

the access cover cannot be reinstalled.

5. Release the parking brake only when the vehicle is securely connected to a tow vehicle.

CAUTION!

Driving with a hot cooling system could damage

your vehicle. If temperature gauge reads “H”,

pull over and stop the vehicle. Idle the vehicle

with the air conditioner turned off until the

pointer drops back into the normal range. If the

pointer remains on the “H”, turn the engine off

immediately, and call for service.

WARNING!

You should be seated in the driver’s seat with

your foot firmly placed on the brake pedal to

maintain control of the vehicle before activating

the Manual Park Release. If possible, you should

apply the parking brake. Activating the Manual

Park Release will allow your vehicle to roll away if

it is not secured or properly connected to a tow

vehicle. Activating the Manual Park Release on

an unsecured vehicle could lead to serious

injury or death for those in or around the vehicle.

22_RUP_OM_EN_USC_t.book Page 304

Page 322 of 384

320SERVICING AND MAINTENANCE

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically. Use

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating, excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch release mechanism, and

safety catch should be cleaned and lubricated.

The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film. Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. If chat

-

tering, marks, water lines or wet spots are present,

clean the wiper blades or replace as necessary.

The wiper blades and wiper arms should be

inspected periodically, not just when wiper

performance problems are experienced. This

inspection should include the following points:

Wear or uneven edges

Foreign material

Hardening or cracking

Deformation or fatigue

If a wiper blade or wiper arm is damaged, replace

the affected wiper arm or blade with a new unit. Do

not attempt to repair a wiper arm or blade that is

damaged.

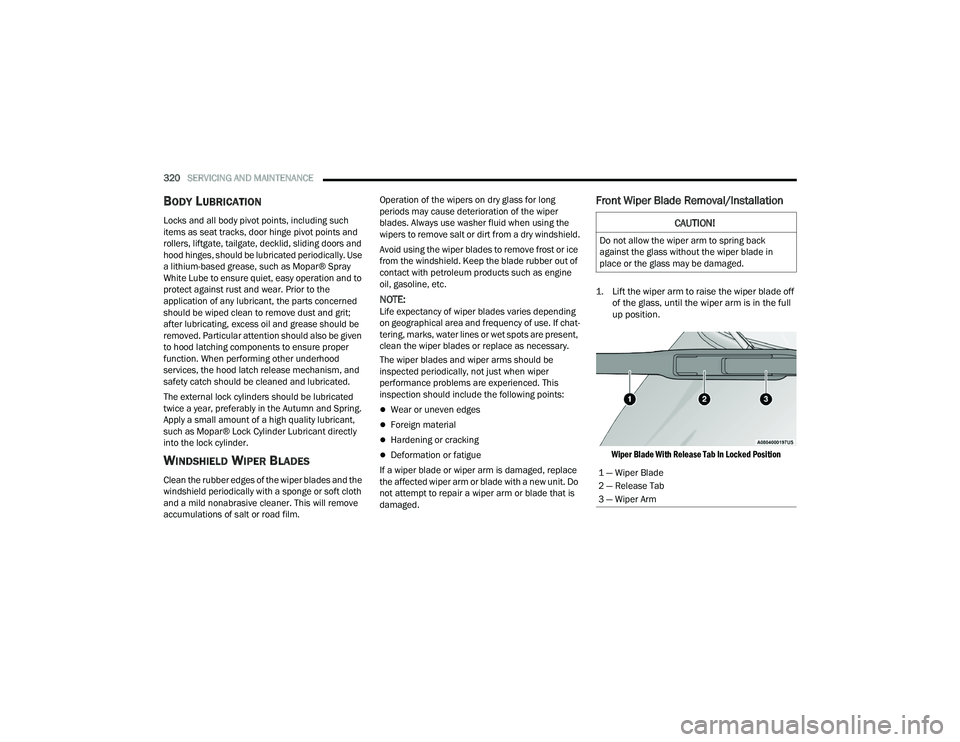

Front Wiper Blade Removal/Installation

1. Lift the wiper arm to raise the wiper blade off of the glass, until the wiper arm is in the full

up position.

Wiper Blade With Release Tab In Locked Position

CAUTION!

Do not allow the wiper arm to spring back

against the glass without the wiper blade in

place or the glass may be damaged.

1 — Wiper Blade

2 — Release Tab

3 — Wiper Arm

22_RUP_OM_EN_USC_t.book Page 320

Page 323 of 384

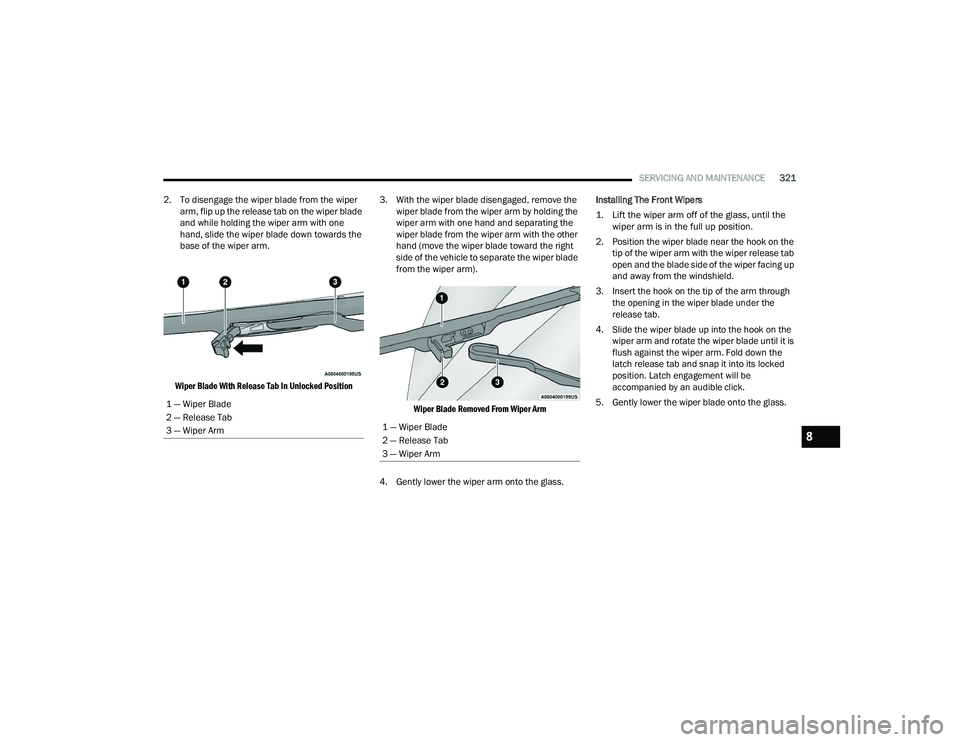

SERVICING AND MAINTENANCE321

2. To disengage the wiper blade from the wiper arm, flip up the release tab on the wiper blade

and while holding the wiper arm with one

hand, slide the wiper blade down towards the

base of the wiper arm.

Wiper Blade With Release Tab In Unlocked Position

3. With the wiper blade disengaged, remove the

wiper blade from the wiper arm by holding the

wiper arm with one hand and separating the

wiper blade from the wiper arm with the other

hand (move the wiper blade toward the right

side of the vehicle to separate the wiper blade

from the wiper arm).

Wiper Blade Removed From Wiper Arm

4. Gently lower the wiper arm onto the glass. Installing The Front Wipers

1. Lift the wiper arm off of the glass, until the

wiper arm is in the full up position.

2. Position the wiper blade near the hook on the tip of the wiper arm with the wiper release tab

open and the blade side of the wiper facing up

and away from the windshield.

3. Insert the hook on the tip of the arm through the opening in the wiper blade under the

release tab.

4. Slide the wiper blade up into the hook on the wiper arm and rotate the wiper blade until it is

flush against the wiper arm. Fold down the

latch release tab and snap it into its locked

position. Latch engagement will be

accompanied by an audible click.

5. Gently lower the wiper blade onto the glass.

1 — Wiper Blade

2 — Release Tab

3 — Wiper Arm

1 — Wiper Blade

2 — Release Tab

3 — Wiper Arm8

22_RUP_OM_EN_USC_t.book Page 321

Page 324 of 384

322SERVICING AND MAINTENANCE

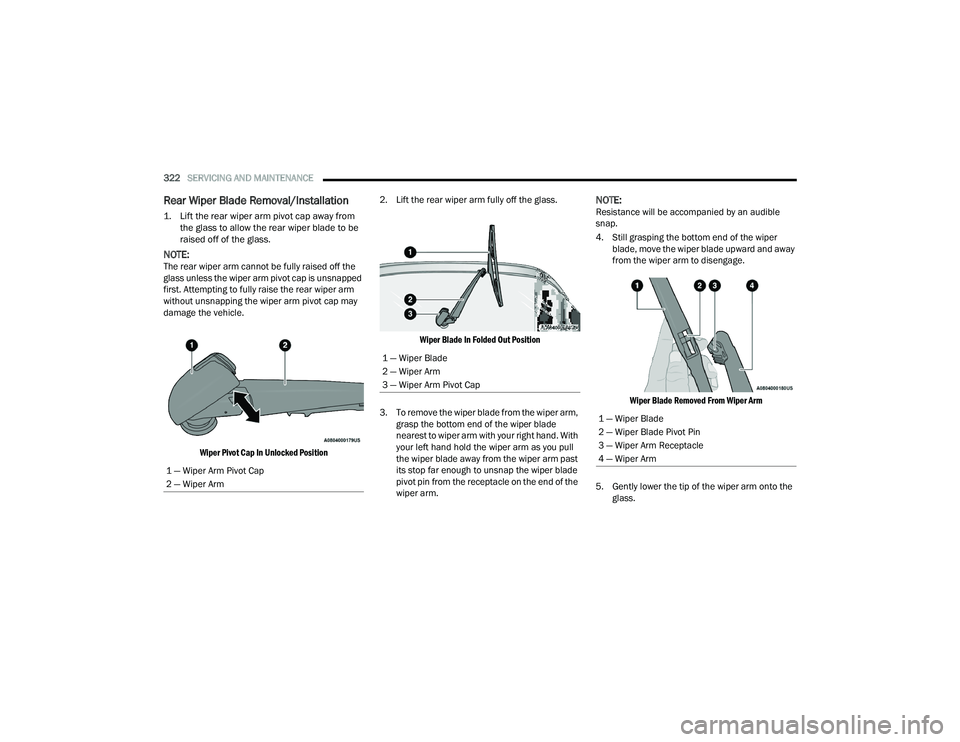

Rear Wiper Blade Removal/Installation

1. Lift the rear wiper arm pivot cap away from

the glass to allow the rear wiper blade to be

raised off of the glass.

NOTE:The rear wiper arm cannot be fully raised off the

glass unless the wiper arm pivot cap is unsnapped

first. Attempting to fully raise the rear wiper arm

without unsnapping the wiper arm pivot cap may

damage the vehicle.

Wiper Pivot Cap In Unlocked Position

2. Lift the rear wiper arm fully off the glass.

Wiper Blade In Folded Out Position

3. To remove the wiper blade from the wiper arm, grasp the bottom end of the wiper blade

nearest to wiper arm with your right hand. With

your left hand hold the wiper arm as you pull

the wiper blade away from the wiper arm past

its stop far enough to unsnap the wiper blade

pivot pin from the receptacle on the end of the

wiper arm.

NOTE:Resistance will be accompanied by an audible

snap.

4. Still grasping the bottom end of the wiper blade, move the wiper blade upward and away

from the wiper arm to disengage.

Wiper Blade Removed From Wiper Arm

5. Gently lower the tip of the wiper arm onto the glass.

1 — Wiper Arm Pivot Cap

2 — Wiper Arm

1 — Wiper Blade

2 — Wiper Arm

3 — Wiper Arm Pivot Cap

1 — Wiper Blade

2 — Wiper Blade Pivot Pin

3 — Wiper Arm Receptacle

4 — Wiper Arm

22_RUP_OM_EN_USC_t.book Page 322

Page 331 of 384

SERVICING AND MAINTENANCE329

FUSES

General Information

The fuses protect electrical systems against

excessive current. When a device does not work, you must check the

fuse element inside the blade fuse for a break/

melt.

Also, please be aware that using power outlets for

extended periods of time with the engine off may

result in vehicle battery discharge.

Blade Fuses

Underhood Fuses

The Power Distribution Center (PDC) is located in

the engine compartment near the battery. This

center contains cartridge fuses, mini-fuses,

micro-fuses, circuit breakers and relays. A label

that identifies each component is printed on the

inside of the cover.

Before any procedure is done on the PDC, make

sure engine is turned off.

Remove the cover by unlatching the two locks

located at each side of the PDC cover, avoid using

screwdrivers or any other tool to remove the cover,

since they may apply excessive force and result in

a broken/damaged part.

After service is done, secure the cover with its two

locks.

NOTE:The function and amperage of the following fuses

are different, depending on vehicle trim level and

content.

WARNING!

When replacing a blown fuse, always use an

appropriate replacement fuse with the same

amp rating as the original fuse. Never replace

a fuse with another fuse of higher amp rating.

Never replace a blown fuse with metal wires or

any other material. Do not place a fuse inside

a circuit breaker cavity or vice versa. Failure to

use proper fuses may result in serious

personal injury, fire and/or property damage.

Before replacing a fuse, make sure that the

ignition is off and that all the other services

are switched off and/or disengaged.

If the replaced fuse blows again, contact an

authorized dealer.

If a general protection fuse for safety systems

(air bag system, braking system), power unit

systems (engine system, transmission

system) or steering system blows, contact an

authorized dealer.

1 — Fuse Element

2 — Blade Fuse with a good/functional fuse

element

3 — Blade fuse with a bad/not functional fuse

element (blown fuse)CAUTION!

When installing the power distribution center

cover, it is important to ensure the cover is

properly positioned and fully latched. Failure to

do so may allow water to get into the power

distribution center and possibly result in an

electrical system failure.8

22_RUP_OM_EN_USC_t.book Page 329