light CHRYSLER PACIFICA 2022 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2022Pages: 384, PDF Size: 23.92 MB

Page 294 of 384

292IN CASE OF EMERGENCY

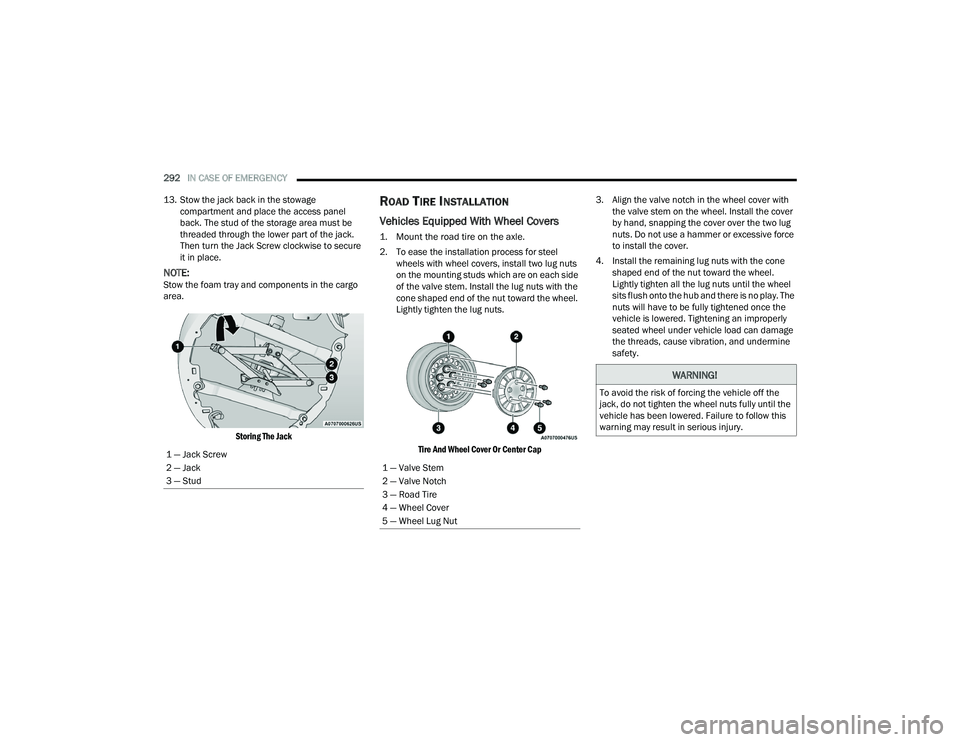

13. Stow the jack back in the stowage compartment and place the access panel

back. The stud of the storage area must be

threaded through the lower part of the jack.

Then turn the Jack Screw clockwise to secure

it in place.

NOTE:Stow the foam tray and components in the cargo

area.

Storing The Jack

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

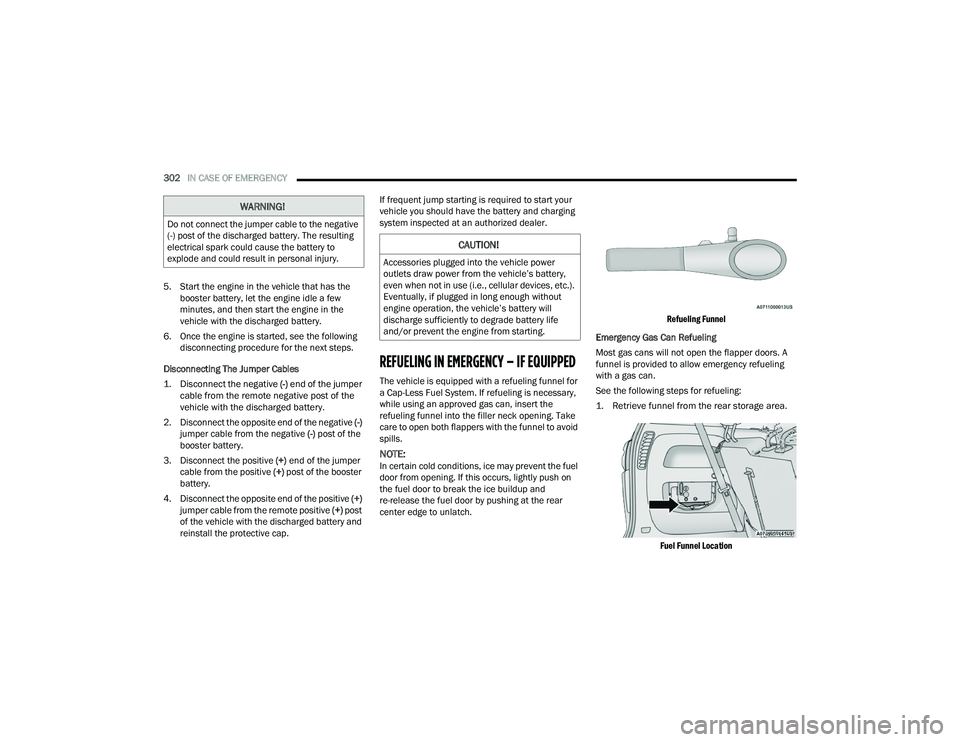

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with wheel covers, install two lug nuts

on the mounting studs which are on each side

of the valve stem. Install the lug nuts with the

cone shaped end of the nut toward the wheel.

Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

3. Align the valve notch in the wheel cover with

the valve stem on the wheel. Install the cover

by hand, snapping the cover over the two lug

nuts. Do not use a hammer or excessive force

to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel.

Lightly tighten all the lug nuts until the wheel

sits flush onto the hub and there is no play. The

nuts will have to be fully tightened once the

vehicle is lowered. Tightening an improperly

seated wheel under vehicle load can damage

the threads, cause vibration, and undermine

safety.

1 — Jack Screw

2 — Jack

3 — Stud

1 — Valve Stem

2 — Valve Notch

3 — Road Tire

4 — Wheel Cover

5 — Wheel Lug Nut

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

22_RUP_OM_EN_USC_t.book Page 292

Page 304 of 384

302IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, see the following disconnecting procedure for the next steps.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the jumper

cable from the remote negative post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the vehicle with the discharged battery and

reinstall the protective cap. If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

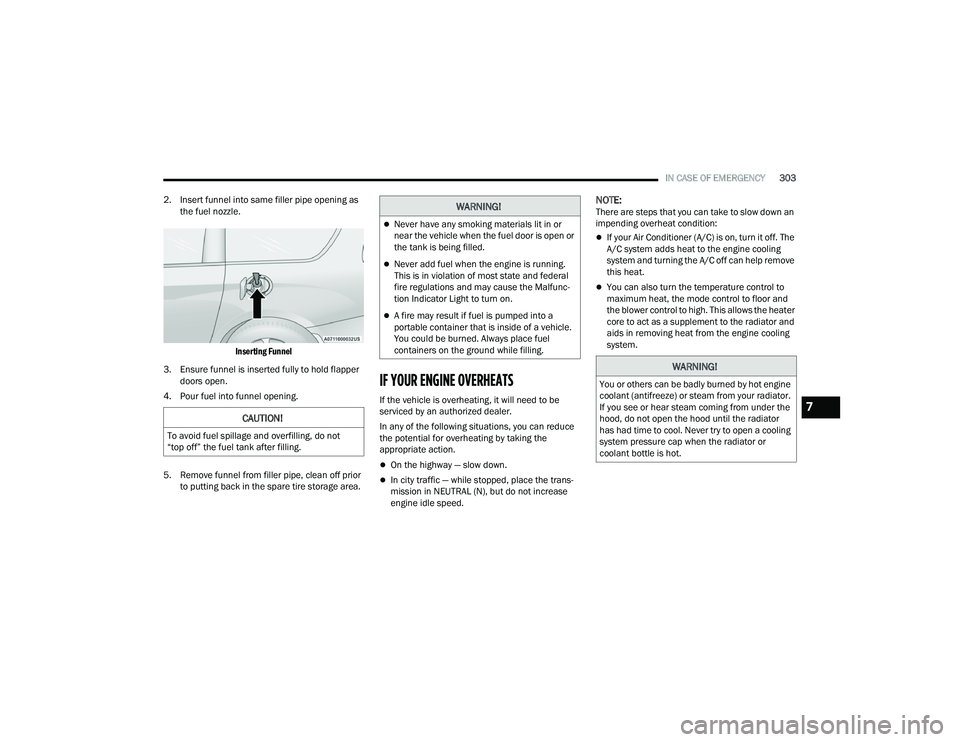

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. If refueling is necessary,

while using an approved gas can, insert the

refueling funnel into the filler neck opening. Take

care to open both flappers with the funnel to avoid

spills.

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door by pushing at the rear

center edge to unlatch.

Refueling Funnel

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the rear storage area.

Fuel Funnel Location

WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

22_RUP_OM_EN_USC_t.book Page 302

Page 305 of 384

IN CASE OF EMERGENCY303

2. Insert funnel into same filler pipe opening as the fuel nozzle.

Inserting Funnel

3. Ensure funnel is inserted fully to hold flapper doors open.

4. Pour fuel into funnel opening.

5. Remove funnel from filler pipe, clean off prior to putting back in the spare tire storage area.

IF YOUR ENGINE OVERHEATS

If the vehicle is overheating, it will need to be

serviced by an authorized dealer.

In any of the following situations, you can reduce

the potential for overheating by taking the

appropriate action.

On the highway — slow down.

In city traffic — while stopped, place the trans -

mission in NEUTRAL (N), but do not increase

engine idle speed.

NOTE:There are steps that you can take to slow down an

impending overheat condition:

If your Air Conditioner (A/C) is on, turn it off. The

A/C system adds heat to the engine cooling

system and turning the A/C off can help remove

this heat.

You can also turn the temperature control to

maximum heat, the mode control to floor and

the blower control to high. This allows the heater

core to act as a supplement to the radiator and

aids in removing heat from the engine cooling

system.

CAUTION!

To avoid fuel spillage and overfilling, do not

“top off” the fuel tank after filling.

WARNING!

Never have any smoking materials lit in or

near the vehicle when the fuel door is open or

the tank is being filled.

Never add fuel when the engine is running.

This is in violation of most state and federal

fire regulations and may cause the Malfunc -

tion Indicator Light to turn on.

A fire may result if fuel is pumped into a

portable container that is inside of a vehicle.

You could be burned. Always place fuel

containers on the ground while filling.

WARNING!

You or others can be badly burned by hot engine

coolant (antifreeze) or steam from your radiator.

If you see or hear steam coming from under the

hood, do not open the hood until the radiator

has had time to cool. Never try to open a cooling

system pressure cap when the radiator or

coolant bottle is hot.

7

22_RUP_OM_EN_USC_t.book Page 303

Page 311 of 384

309

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures will influence when the “Oil Change

Required” message is displayed. Have your vehicle

serviced as soon as possible, within the next

500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change. If a scheduled oil change is performed

by someone other than an authorized dealer

Ú

page 113.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for fleet

customers. Once A Month Or Before A Long Trip:

Check engine oil level.

Check windshield washer fluid level.

Check tire pressure and look for unusual wear

or damage. Rotate tires at the first sign of irreg

-

ular wear, even if it occurs before the oil indi -

cator system turns on.

Check the fluid levels of the coolant reservoir

and brake master cylinder, fill as needed.

Check function of all interior and exterior lights.

8

22_RUP_OM_EN_USC_t.book Page 309

Page 329 of 384

SERVICING AND MAINTENANCE327

(Continued)

Make sure that the coolant expansion bottle

overflow hoses are not kinked or obstructed.

Keep the front of the radiator clean. If your

vehicle is equipped with air conditioning, keep

the front of the condenser clean.

Do not change the thermostat for Summer or

Winter operation. If replacement is ever neces -

sary, install ONLY the correct type thermostat.

Other designs may result in unsatisfactory

engine cooling performance, poor gas mileage,

and increased emissions.

BRAKE SYSTEM

In order to ensure brake system performance, all

brake system components should be inspected

periodically. For the proper maintenance intervals

Ú page 310.

Brake Master Cylinder

The fluid in the master cylinder should be checked

when performing under hood services or

immediately if the Brake Warning Light is

illuminated.

Be sure to clean the top of the master cylinder area

before removing the cap. If necessary, add fluid to

bring the fluid level up to the requirements

described on the brake fluid reservoir. With disc

brakes, fluid level can be expected to fall as the

brake pads wear. Brake fluid level should be

checked when pads are replaced. However, low

fluid level may be caused by a leak and a checkup

may be needed.

Use only manufacturer recommended brake fluid

Úpage 366.

WARNING!

Riding the brakes can lead to brake failure and

possibly a collision. Driving with your foot resting

or riding on the brake pedal can result in

abnormally high brake temperatures, excessive

lining wear, and possible brake damage. You

would not have your full braking capacity in an

emergency.

WARNING!

Use only manufacturer recommended brake

fluid Ú page 366. Using the wrong type of

brake fluid can severely damage your brake

system and/or impair its performance. The

proper type of brake fluid for your vehicle is

also identified on the original factory installed

hydraulic master cylinder reservoir.

To avoid contamination from foreign matter or

moisture, use only new brake fluid or fluid that

has been in a tightly closed container. Keep

the master cylinder reservoir cap secured at

all times. Brake fluid in an open container

absorbs moisture from the air resulting in a

lower boiling point. This may cause it to boil

unexpectedly during hard or prolonged

braking, resulting in sudden brake failure. This

could result in a collision.

Overfilling the brake fluid reservoir can result

in spilling brake fluid on hot engine parts,

causing the brake fluid to catch fire. Brake

fluid can also damage painted and vinyl

surfaces, care should be taken to avoid its

contact with these surfaces.

Do not allow petroleum-based fluid to contam -

inate the brake fluid. Brake seal components

could be damaged, causing partial or

complete brake failure. This could result in a

collision.

WARNING!

8

22_RUP_OM_EN_USC_t.book Page 327

Page 333 of 384

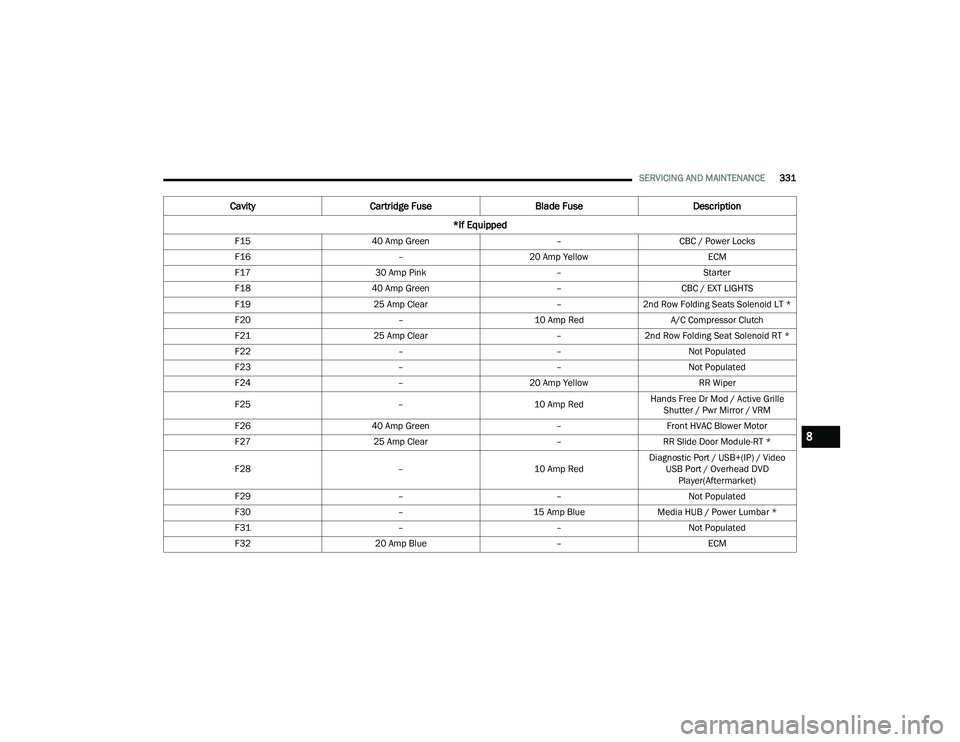

SERVICING AND MAINTENANCE331

F15 40 Amp Green –CBC / Power Locks

F16 –20 Amp Yellow ECM

F17 30 Amp Pink –Starter

F18 40 Amp Green –CBC / EXT LIGHTS

F19 25 Amp Clear –2nd Row Folding Seats Solenoid LT *

F20 –10 Amp Red A/C Compressor Clutch

F21 25 Amp Clear –2nd Row Folding Seat Solenoid RT *

F22 ––Not Populated

F23 ––Not Populated

F24 –20 Amp Yellow RR Wiper

F25 –10 Amp RedHands Free Dr Mod / Active Grille

Shutter / Pwr Mirror / VRM

F26 40 Amp Green –Front HVAC Blower Motor

F27 25 Amp Clear –RR Slide Door Module-RT *

F28 –10 Amp RedDiagnostic Port / USB+(IP) / Video

USB Port / Overhead DVD Player(Aftermarket)

F29 ––Not Populated

F30 –15 Amp BlueMedia HUB / Power Lumbar *

F31 ––Not Populated

F32 20 Amp Blue –ECM

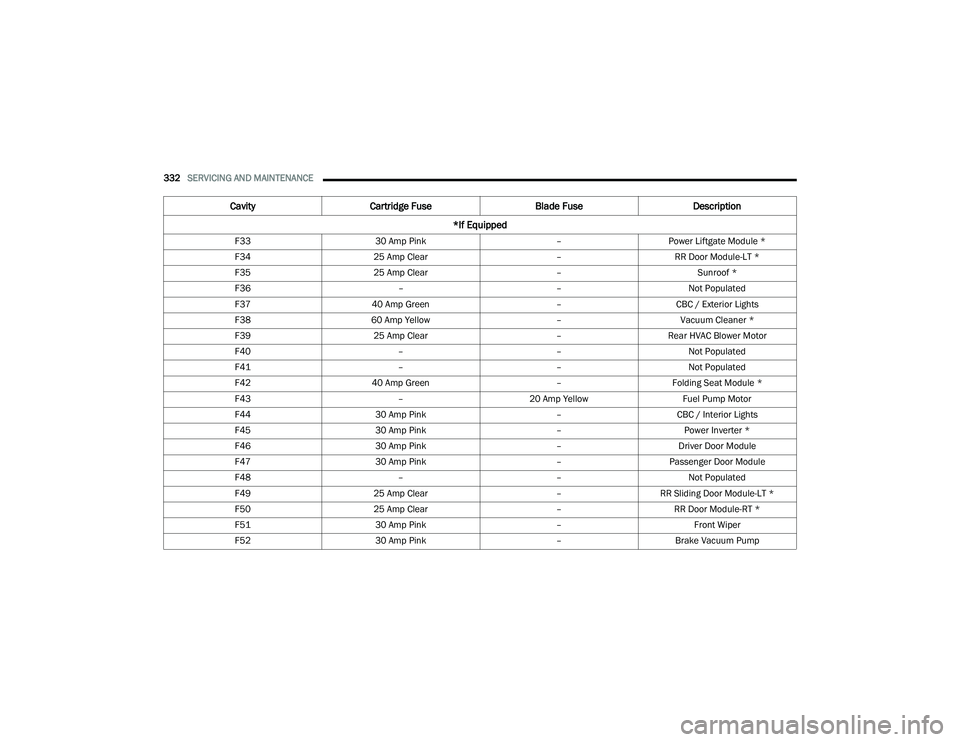

CavityCartridge Fuse Blade FuseDescription

*If Equipped

8

22_RUP_OM_EN_USC_t.book Page 331

Page 334 of 384

332SERVICING AND MAINTENANCE

F33 30 Amp Pink –Power Liftgate Module *

F34 25 Amp Clear –RR Door Module-LT *

F35 25 Amp Clear –Sunroof *

F36 ––Not Populated

F37 40 Amp Green –CBC / Exterior Lights

F38 60 Amp Yellow –Vacuum Cleaner *

F39 25 Amp Clear –Rear HVAC Blower Motor

F40 ––Not Populated

F41 ––Not Populated

F42 40 Amp Green –Folding Seat Module *

F43 –20 Amp Yellow Fuel Pump Motor

F44 30 Amp Pink –CBC / Interior Lights

F45 30 Amp Pink –Power Inverter *

F46 30 Amp Pink –Driver Door Module

F47 30 Amp Pink –Passenger Door Module

F48 ––Not Populated

F49 25 Amp Clear –RR Sliding Door Module-LT *

F50 25 Amp Clear –RR Door Module-RT *

F51 30 Amp Pink –Front Wiper

F52 30 Amp Pink –Brake Vacuum Pump

Cavity Cartridge Fuse Blade FuseDescription

*If Equipped

22_RUP_OM_EN_USC_t.book Page 332

Page 336 of 384

334SERVICING AND MAINTENANCE

F68 ––Not Populated

F69 ––Not Populated

F70 ––Not Populated

F71 –20 Amp Yellow Horn

F72 –10 Amp Red Heated Mirror *

F73 30 Amp Pink –Rear Defroster

F74 20 Amp Blue –Trailer Tow Backup Lights*

F75 –5 Amp TanOverhead Console / RR Center Stack

F76 –20 Amp Yellow Uconnect / Center Display /

Telematics

F77 –10 Amp RedRR Entertainment / Media HUB /

USB(S) / Rain Sensor / Sunroof / RR View Mirror/ Overhead DVD Player / INT Monitoring Camera / Wireless Charging Pad

F78 –15 Amp BlueTCM (ZF) / E-Shifter / Cluster

F79 –10 Amp RedICS / HVAC / SCCM/ EPB SW

F80 ––Not Populated

F81 ––Not Populated

F82 ––Not Populated

CavityCartridge Fuse Blade FuseDescription

*If Equipped

22_RUP_OM_EN_USC_t.book Page 334

Page 337 of 384

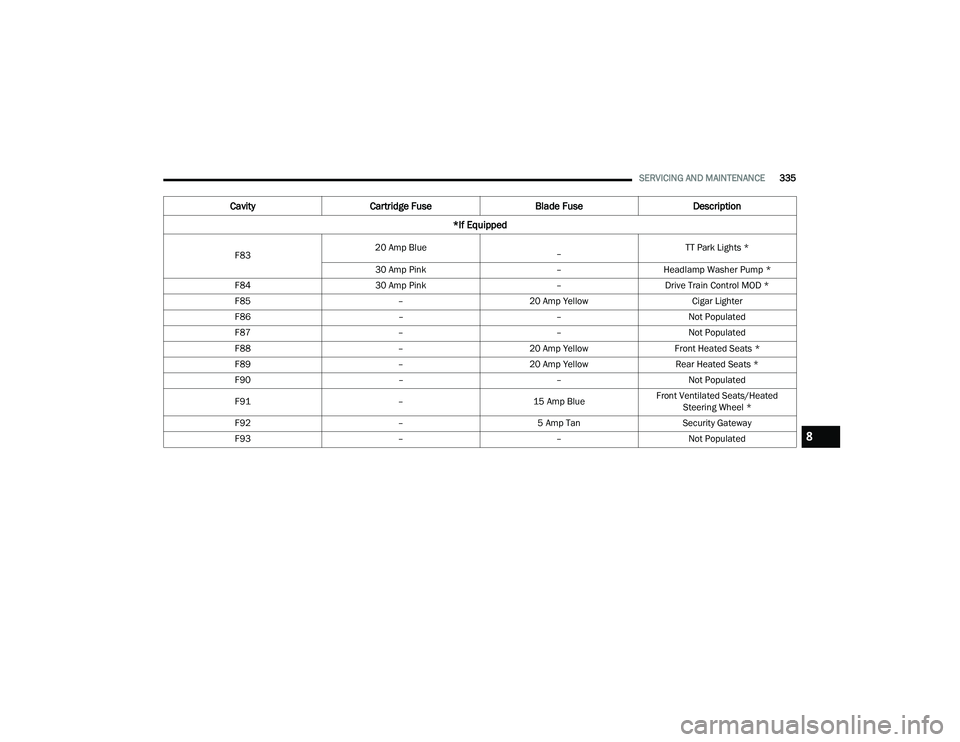

SERVICING AND MAINTENANCE335

F83 20 Amp Blue

– TT Park Lights *

30 Amp Pink –Headlamp Washer Pump *

F84 30 Amp Pink –Drive Train Control MOD *

F85 –20 Amp Yellow Cigar Lighter

F86 ––Not Populated

F87 ––Not Populated

F88 –20 Amp Yellow Front Heated Seats *

F89 –20 Amp Yellow Rear Heated Seats *

F90 ––Not Populated

F91 –15 Amp BlueFront Ventilated Seats/Heated

Steering Wheel *

F92 –5 Amp Tan Security Gateway

F93 ––Not Populated

CavityCartridge Fuse Blade FuseDescription

*If Equipped

8

22_RUP_OM_EN_USC_t.book Page 335

Page 341 of 384

SERVICING AND MAINTENANCE339

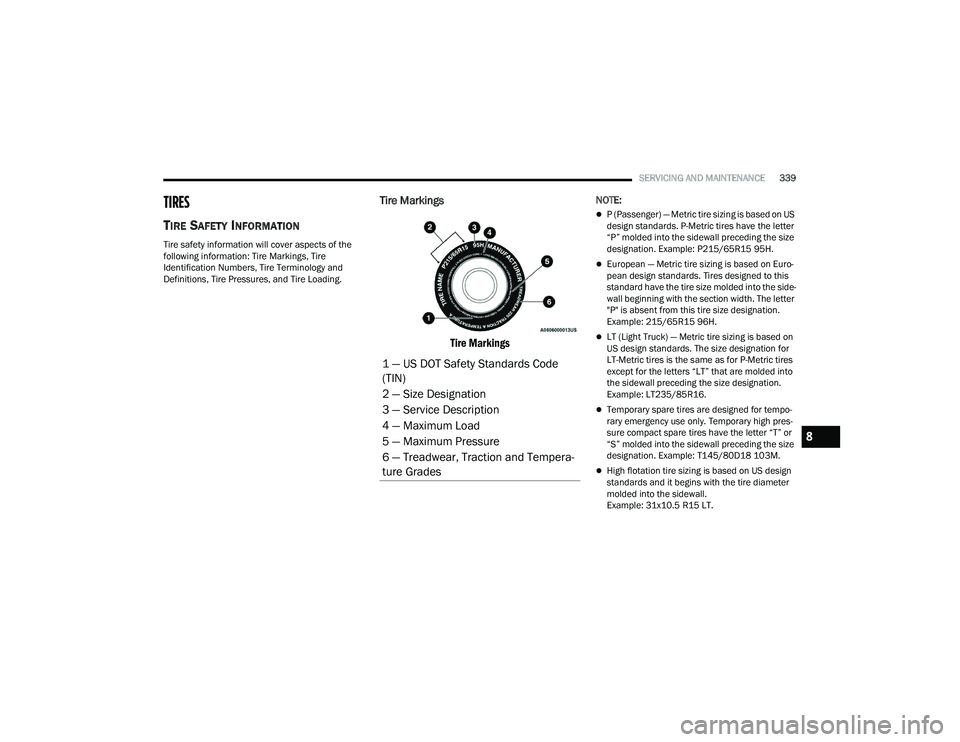

TIRES

TIRE SAFETY INFORMATION

Tire safety information will cover aspects of the

following information: Tire Markings, Tire

Identification Numbers, Tire Terminology and

Definitions, Tire Pressures, and Tire Loading.

Tire Markings

Tire Markings

NOTE:

P (Passenger) — Metric tire sizing is based on US

design standards. P-Metric tires have the letter

“P” molded into the sidewall preceding the size

designation. Example: P215/65R15 95H.

European — Metric tire sizing is based on Euro -

pean design standards. Tires designed to this

standard have the tire size molded into the side -

wall beginning with the section width. The letter

"P" is absent from this tire size designation.

Example: 215/65R15 96H.

LT (Light Truck) — Metric tire sizing is based on

US design standards. The size designation for

LT-Metric tires is the same as for P-Metric tires

except for the letters “LT” that are molded into

the sidewall preceding the size designation.

Example: LT235/85R16.

Temporary spare tires are designed for tempo -

rary emergency use only. Temporary high pres -

sure compact spare tires have the letter “T” or

“S” molded into the sidewall preceding the size

designation. Example: T145/80D18 103M.

High flotation tire sizing is based on US design

standards and it begins with the tire diameter

molded into the sidewall.

Example: 31x10.5 R15 LT.

1 — US DOT Safety Standards Code

(TIN)

2 — Size Designation

3 — Service Description

4 — Maximum Load

5 — Maximum Pressure

6 — Treadwear, Traction and Tempera -

ture Grades

8

22_RUP_OM_EN_USC_t.book Page 339