Start CHRYSLER PACIFICA 2022 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2022Pages: 384, PDF Size: 23.92 MB

Page 302 of 384

300IN CASE OF EMERGENCY

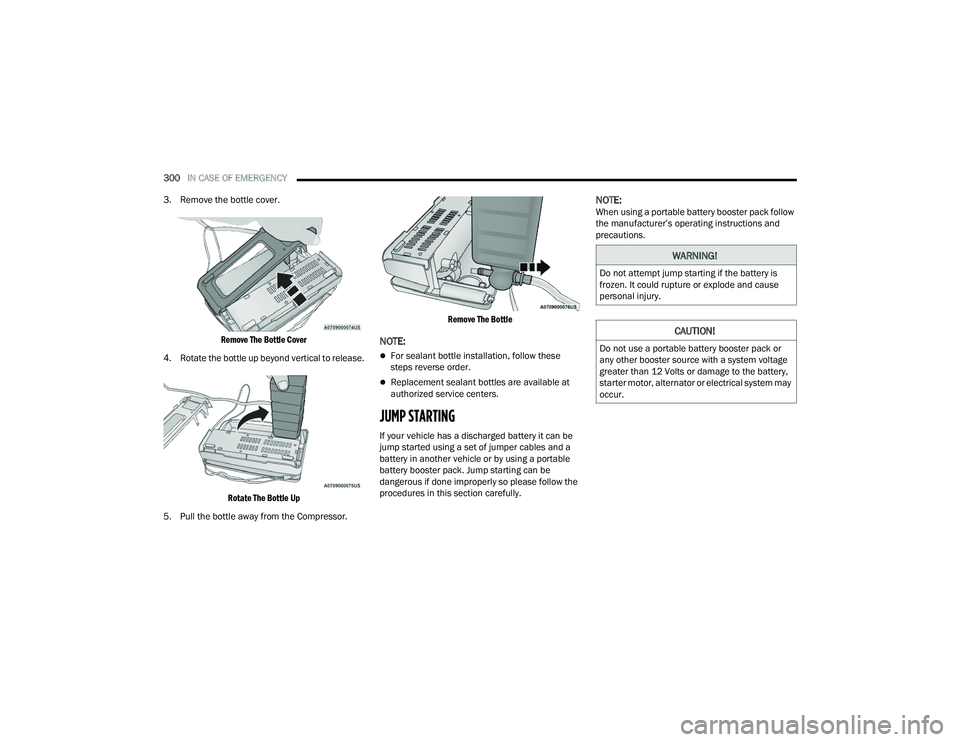

3. Remove the bottle cover.

Remove The Bottle Cover

4. Rotate the bottle up beyond vertical to release.

Rotate The Bottle Up

5. Pull the bottle away from the Compressor.

Remove The Bottle

NOTE:

For sealant bottle installation, follow these

steps reverse order.

Replacement sealant bottles are available at

authorized service centers.

JUMP STARTING

If your vehicle has a discharged battery it can be

jump started using a set of jumper cables and a

battery in another vehicle or by using a portable

battery booster pack. Jump starting can be

dangerous if done improperly so please follow the

procedures in this section carefully.

NOTE:When using a portable battery booster pack follow

the manufacturer’s operating instructions and

precautions.

WARNING!

Do not attempt jump starting if the battery is

frozen. It could rupture or explode and cause

personal injury.

CAUTION!

Do not use a portable battery booster pack or

any other booster source with a system voltage

greater than 12 Volts or damage to the battery,

starter motor, alternator or electrical system may

occur.

22_RUP_OM_EN_USC_t.book Page 300

Page 303 of 384

IN CASE OF EMERGENCY301

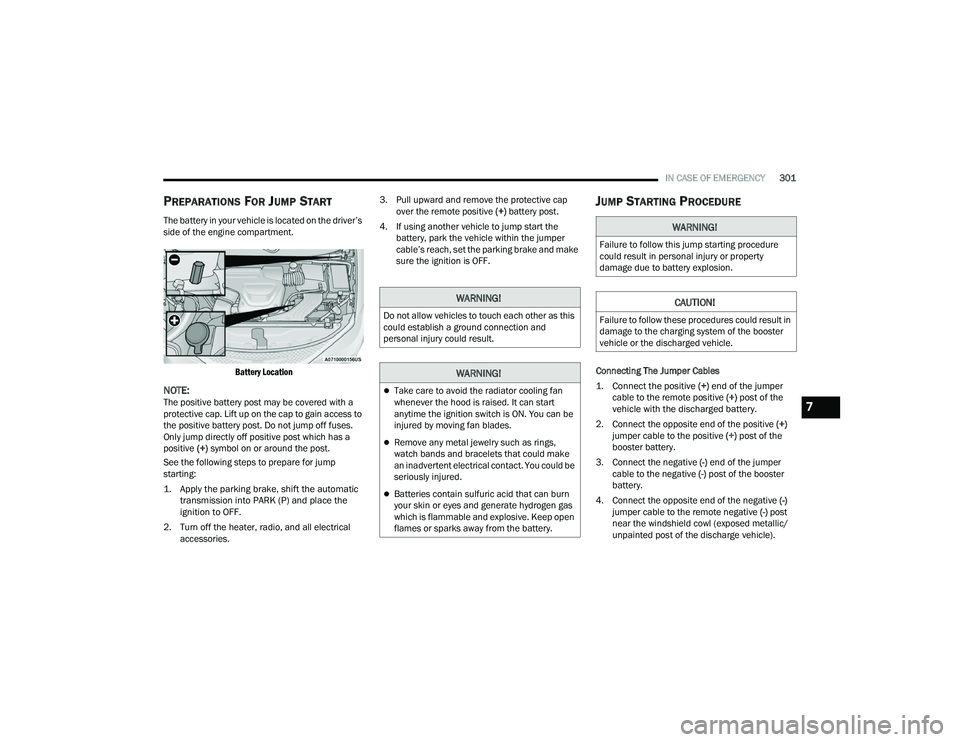

PREPARATIONS FOR JUMP START

The battery in your vehicle is located on the driver’s

side of the engine compartment.

Battery Location

NOTE:The positive battery post may be covered with a

protective cap. Lift up on the cap to gain access to

the positive battery post. Do not jump off fuses.

Only jump directly off positive post which has a

positive (+) symbol on or around the post.

See the following steps to prepare for jump

starting:

1. Apply the parking brake, shift the automatic transmission into PARK (P) and place the

ignition to OFF.

2. Turn off the heater, radio, and all electrical accessories. 3. Pull upward and remove the protective cap

over the remote positive (+) battery post.

4. If using another vehicle to jump start the battery, park the vehicle within the jumper

cable’s reach, set the parking brake and make

sure the ignition is OFF.

JUMP STARTING PROCEDURE

Connecting The Jumper Cables

1. Connect the positive

(+) end of the jumper

cable to the remote positive (+)

post of the

vehicle with the discharged battery.

2. Connect the opposite end of the positive (+)

jumper cable to the positive (+) post of the

booster battery.

3. Connect the negative (-) end of the jumper

cable to the negative (-) post of the booster

battery.

4. Connect the opposite end of the negative (-)

jumper cable to the remote negative (-) post

near the windshield cowl (exposed metallic/

unpainted post of the discharge vehicle).

WARNING!

Do not allow vehicles to touch each other as this

could establish a ground connection and

personal injury could result.

WARNING!

Take care to avoid the radiator cooling fan

whenever the hood is raised. It can start

anytime the ignition switch is ON. You can be

injured by moving fan blades.

Remove any metal jewelry such as rings,

watch bands and bracelets that could make

an inadvertent electrical contact. You could be

seriously injured.

Batteries contain sulfuric acid that can burn

your skin or eyes and generate hydrogen gas

which is flammable and explosive. Keep open

flames or sparks away from the battery.

WARNING!

Failure to follow this jump starting procedure

could result in personal injury or property

damage due to battery explosion.

CAUTION!

Failure to follow these procedures could result in

damage to the charging system of the booster

vehicle or the discharged vehicle.

7

22_RUP_OM_EN_USC_t.book Page 301

Page 304 of 384

302IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, see the following disconnecting procedure for the next steps.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the jumper

cable from the remote negative post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the vehicle with the discharged battery and

reinstall the protective cap. If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

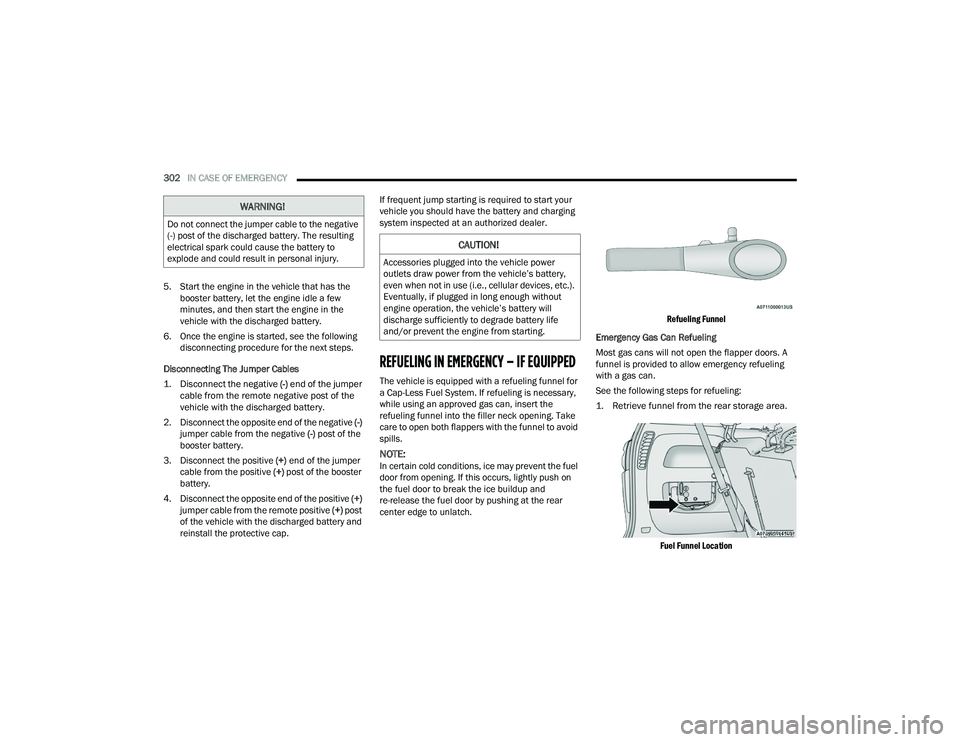

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. If refueling is necessary,

while using an approved gas can, insert the

refueling funnel into the filler neck opening. Take

care to open both flappers with the funnel to avoid

spills.

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door by pushing at the rear

center edge to unlatch.

Refueling Funnel

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the rear storage area.

Fuel Funnel Location

WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

22_RUP_OM_EN_USC_t.book Page 302

Page 317 of 384

SERVICING AND MAINTENANCE315

PRESSURE WASHING

Cleaning the engine compartment with a high

pressure washer is not recommended.

VEHICLE MAINTENANCE

An authorized dealer has the qualified service

personnel, special tools, and equipment to

perform all service operations in an expert

manner. Service Manuals are available which

include detailed service information for your

vehicle. Refer to these Service Manuals before

attempting any procedure yourself.

NOTE:Intentional tampering with emissions control

systems may void your warranty and could result in

civil penalties being assessed against you.

ENGINE OIL

Engine Oil Selection

Use only the manufacturer's recommended fluids

Úpage 365.

Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not

use a booster battery or any other booster

source with an output greater than 12 Volts.

Do not allow cable clamps to touch each

other.

Battery posts, terminals, and related accesso -

ries contain lead and lead compounds. Wash

hands after handling.

CAUTION!

It is essential when replacing the cables on

the battery that the positive cable is attached

to the positive post and the negative cable is

attached to the negative post. Battery posts

are marked positive (+) and negative (-) and

are identified on the battery case. Cable

clamps should be tight on the terminal posts

and free of corrosion.

If a “fast charger” is used while the battery is

in the vehicle, disconnect both vehicle battery

cables before connecting the charger to the

battery. Do not use a “fast charger” to provide

starting voltage.

WARNING!

CAUTION!

Precautions have been taken to safeguard all

parts and connections however, the pressures

generated by these machines is such that

complete protection against water ingress

cannot be guaranteed.

WARNING!

You can be badly injured working on or around a

motor vehicle. Only do service work for which

you have the knowledge and the proper

equipment. If you have any doubt about your

ability to perform a service job, take your vehicle

to a competent mechanic.

8

22_RUP_OM_EN_USC_t.book Page 315

Page 318 of 384

316SERVICING AND MAINTENANCE

American Petroleum Institute (API)

Approved Engine Oil

These symbols mean that the oil has been certified

by the API. The manufacturer only recommends API

trademark oils.

The API Starburst trademark certifies

0W-20, 0W-30 and 5W-30 engine oils.

The API Donut trademark certifies 0W-40

and 5W-40 engine oil.

Synthetic Engine Oils

Your engine was designed for synthetic engine oils,

only use synthetic API approved engine oils.

Synthetic engine oils which do not have both the

correct API trademark and the correct SAE viscosity

grade numbers should not be used.

Materials Added To Engine Oil

The manufacturer strongly recommends against

the addition of any additives (other than leak

detection dyes) to the engine oil. Engine oil is an

engineered product and its performance may be

impaired by supplemental additives.

Disposing Of Used Engine Oil And Oil

Filters

Care should be taken in disposing of used engine

oil and oil filters from your vehicle. Used oil and oil

filters, indiscriminately discarded, can present a

problem to the environment. Contact an

authorized dealer, service station or governmental

agency for advice on how and where used oil and

oil filters can be safely discarded in your area.

ENGINE OIL FILTER

The engine oil filter should be replaced with a new

filter at every engine oil change.

Engine Oil Filter Selection

A full-flow type disposable oil filter should be used

for replacement. The quality of replacement filters

varies considerably. Only high quality Mopar®

certified filters should be used.

ENGINE AIR CLEANER FILTER

For the proper maintenance intervals Úpage 310.

Engine Air Cleaner Filter Selection

The quality of replacement filters varies

considerably. Only high quality Mopar® certified

filters should be used.

CAUTION!

Do not use chemical flushes in your engine oil as

the chemicals can damage your engine. Such

damage is not covered by the New Vehicle

Limited Warranty.

WARNING!

The air induction system (air cleaner, hoses,

etc.) can provide a measure of protection in the

case of engine backfire. Do not remove the air

induction system (air cleaner, hoses, etc.) unless

such removal is necessary for repair or

maintenance. Make sure that no one is near the

engine compartment before starting the vehicle

with the air induction system (air cleaner, hoses,

etc.) removed. Failure to do so can result in

serious personal injury.

22_RUP_OM_EN_USC_t.book Page 316

Page 319 of 384

SERVICING AND MAINTENANCE317

ACCESSORY DRIVE BELT INSPECTION

When inspecting accessory drive belts, small

cracks that run across the ribbed surface of a belt

from rib to rib, are considered normal. These are

not a reason to replace belt. However, cracks

running along a rib (not across) are not normal. Any

belt with cracks running along a rib must be

replaced. Also, have the belt replaced if it has

excessive wear, frayed cords, or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking

(cracks between two ribs)

Belt slips

“Groove jumping"

(belt does not maintain correct position

on pulley)

Belt broken

NOTE:Identify and correct problem before new belt is

installed

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation).

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools; we recommend having your

vehicle serviced at an authorized dealer.

AIR CONDITIONER MAINTENANCE

For best possible performance, your air conditioner

should be checked and serviced by an authorized

dealer at the start of each warm season. This

service should include cleaning of the condenser

fins and a performance test. Drive belt tension

should also be checked at this time.

WARNING!

Do not attempt to inspect an accessory drive

belt with vehicle running.

When working near the radiator cooling fan,

disconnect the fan motor lead. The fan is

temperature controlled and can start at any

time regardless of ignition mode. You could be

injured by the moving fan blades.

You can be badly injured working on or around

a motor vehicle. Only do service work for which

you have the knowledge and the proper equip -

ment. If you have any doubt about your ability

to perform a service job, take your vehicle to a

competent mechanic.

8

22_RUP_OM_EN_USC_t.book Page 317

Page 325 of 384

SERVICING AND MAINTENANCE323

Installing The Rear Wiper

1. Lift the rear wiper arm pivot cap away from the glass to allow the rear wiper blade to be

raised off of the glass.

NOTE:The rear wiper arm cannot be fully raised off the

glass unless the wiper arm pivot cap is unsnapped

first. Attempting to fully raise the rear wiper arm

without unsnapping the wiper arm pivot cap may

damage the vehicle.

2. Lift the rear wiper arm fully off the glass.

3. Insert the wiper blade pivot pin into the opening on the end of the wiper arm. Grab the

bottom end of the wiper arm with one hand,

and press the wiper blade flush with the wiper

arm until it snaps into place.

4. Lower the wiper blade onto the glass and snap the wiper arm pivot cap back into place.

EXHAUST SYSTEM

The best protection against carbon monoxide entry

into the vehicle body is a properly maintained

engine exhaust system. If you notice a change in the sound of the exhaust

system; or if the exhaust fumes can be detected

inside the vehicle; or when the underside or rear of

the vehicle is damaged; have an authorized

technician inspect the complete exhaust system

and adjacent body areas for broken, damaged,

deteriorated, or mispositioned parts. Open seams

or loose connections could permit exhaust fumes

to seep into the passenger compartment. In

addition, have the exhaust system inspected each

time the vehicle is raised for lubrication or oil

change. Replace as required.

Under normal operating conditions, the catalytic

converter will not require maintenance. However, it

is important to keep the engine properly tuned to

ensure proper catalyst operation and prevent

possible catalyst damage.

WARNING!

Exhaust gases can injure or kill. They contain

carbon monoxide (CO), which is colorless and

odorless. Breathing it can make you uncon-

scious and can eventually poison you

Ú page 278.

A hot exhaust system can start a fire if you

park over materials that can burn, such as

grass or leaves, and those items can come

into contact with your exhaust system. Do not

park or operate your vehicle in areas where

your exhaust system can contact anything that

can burn.

CAUTION!

The catalytic converter requires the use of

unleaded fuel only. Leaded gasoline will

destroy the effectiveness of the catalyst as an

emissions control device and may seriously

reduce engine performance and cause

serious damage to the engine.

Damage to the catalytic converter can result if

your vehicle is not kept in proper operating

condition. In the event of engine malfunction,

particularly involving engine misfire or other

apparent loss of performance, have your

vehicle serviced promptly. Continued opera -

tion of your vehicle with a severe malfunction

could cause the converter to overheat,

resulting in possible damage to the converter

and vehicle.

8

22_RUP_OM_EN_USC_t.book Page 323

Page 326 of 384

324SERVICING AND MAINTENANCE

NOTE:Intentional tampering with emissions control

systems can result in civil penalties being

assessed against you.

In unusual situations involving grossly

malfunctioning engine operation, a scorching odor

may suggest severe and abnormal catalyst

overheating. If this occurs, stop the vehicle, turn off

the engine and allow it to cool. Service, including a

tune-up to the manufacturer specifications, should

be obtained immediately.

To minimize the possibility of catalytic converter

damage:

Do not interrupt the ignition when the transmis -

sion is in gear and the vehicle is in motion.

Do not try to start the vehicle by pushing or

towing the vehicle.

Do not idle the engine with any ignition compo -

nents disconnected or removed, such as when

diagnostic testing, or for prolonged periods

during very rough idle or malfunctioning oper -

ating conditions.

COOLING SYSTEM

Engine Coolant Checks

Check the engine coolant (antifreeze) protection

every 12 months (before the onset of freezing

weather, where applicable). If the engine coolant is

dirty, the system should be drained, flushed, and

refilled with fresh Organic Additive Technology

(OAT) coolant (conforming to MS.90032) by an authorized dealer. Check the front of the A/C

condenser for any accumulation of bugs, leaves,

etc. If dirty, clean by gently spraying water from a

garden hose vertically down the face of the

condenser.

Check the engine cooling system hoses for brittle

rubber, cracking, tears, cuts, and tightness of the

connection at the coolant recovery bottle and

radiator. Inspect the entire system for leaks. DO

NOT REMOVE THE COOLANT PRESSURE CAP

WHEN THE COOLING SYSTEM IS HOT.

Cooling System — Drain, Flush And Refill

NOTE:Some vehicles require special tools to add coolant

properly. Failure to fill these systems properly

could lead to severe internal engine damage. If any

coolant is needed to be added to the system

please contact an authorized dealer.

If the engine coolant (antifreeze) is dirty or

contains visible sediment, have an authorized

dealer clean and flush with Organic Additive

Technology (OAT) coolant (conforming to

MS.90032).

For the proper maintenance intervals

Úpage 310.

WARNING!

You or others can be badly burned by hot

engine coolant (antifreeze) or steam from your

radiator. If you see or hear steam coming from

under the hood, do not open the hood until the

radiator has had time to cool. Never open a

cooling system pressure cap when the radi -

ator or coolant bottle is hot.

Keep hands, tools, clothing, and jewelry away

from the radiator cooling fan when the hood is

raised. The fan starts automatically and may

start at any time, whether the engine is

running or not.

When working near the radiator cooling fan,

disconnect the fan motor lead or turn the igni -

tion to the OFF mode. The fan is temperature

controlled and can start at any time the igni -

tion is in the ON mode.

22_RUP_OM_EN_USC_t.book Page 324

Page 333 of 384

SERVICING AND MAINTENANCE331

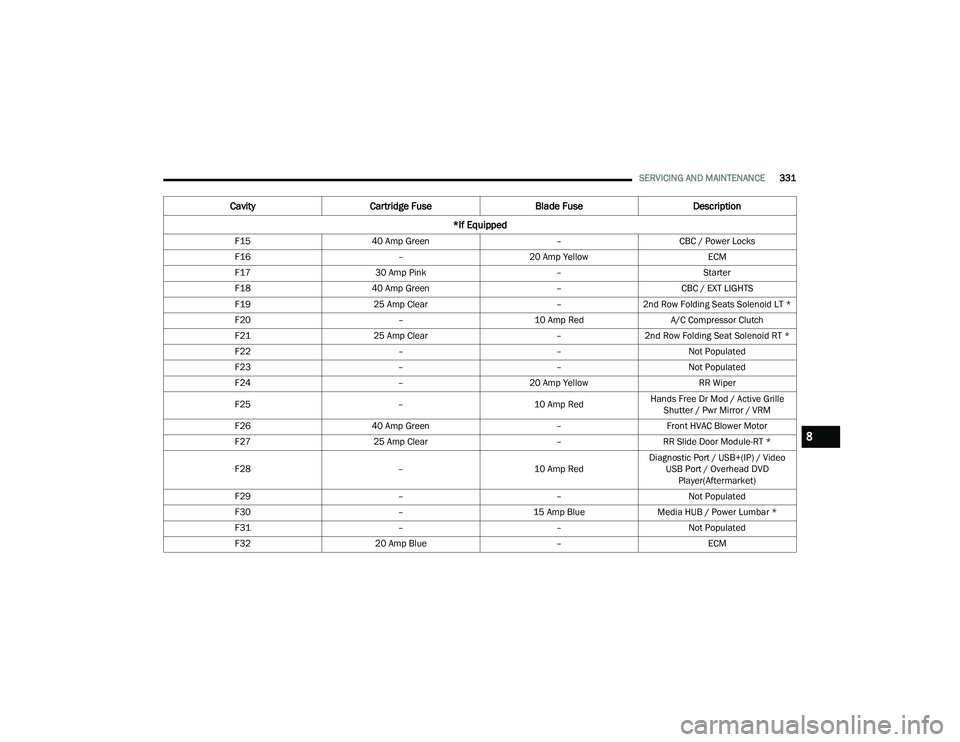

F15 40 Amp Green –CBC / Power Locks

F16 –20 Amp Yellow ECM

F17 30 Amp Pink –Starter

F18 40 Amp Green –CBC / EXT LIGHTS

F19 25 Amp Clear –2nd Row Folding Seats Solenoid LT *

F20 –10 Amp Red A/C Compressor Clutch

F21 25 Amp Clear –2nd Row Folding Seat Solenoid RT *

F22 ––Not Populated

F23 ––Not Populated

F24 –20 Amp Yellow RR Wiper

F25 –10 Amp RedHands Free Dr Mod / Active Grille

Shutter / Pwr Mirror / VRM

F26 40 Amp Green –Front HVAC Blower Motor

F27 25 Amp Clear –RR Slide Door Module-RT *

F28 –10 Amp RedDiagnostic Port / USB+(IP) / Video

USB Port / Overhead DVD Player(Aftermarket)

F29 ––Not Populated

F30 –15 Amp BlueMedia HUB / Power Lumbar *

F31 ––Not Populated

F32 20 Amp Blue –ECM

CavityCartridge Fuse Blade FuseDescription

*If Equipped

8

22_RUP_OM_EN_USC_t.book Page 331

Page 359 of 384

SERVICING AND MAINTENANCE357

STORING THE VEHICLE

If you are storing your vehicle for more than three

weeks, we recommend that you take the following

steps to minimize the drain on your vehicle's

battery:

Disconnect the negative cable from battery.

Any time you store your vehicle or keep it out of

service (i.e., vacation) for two weeks or more,

run the air conditioning system at idle for about

five minutes in the fresh air and high blower

setting. This will ensure adequate system lubri-

cation to minimize the possibility of compressor

damage when the system is started again.

BODYWORK

PROTECTION FROM ATMOSPHERIC

A

GENTS

Vehicle body care requirements vary according to

geographic locations and usage. Chemicals that

make roads passable in snow and ice and those

that are sprayed on trees and road surfaces during

other seasons are highly corrosive to the metal in

your vehicle. Outside parking, which exposes your

vehicle to airborne contaminants, road surfaces on

which the vehicle is operated, extreme hot or cold

weather and other extreme conditions will have an

adverse effect on paint, metal trim, and underbody

protection. The following maintenance recommendations will

enable you to obtain maximum benefit from the

corrosion resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal

of paint and protective coatings from your vehicle.

The most common causes are:

Road salt, dirt and moisture accumulation

Stone and gravel impact

Insects, tree sap and tar

Salt in the air near seacoast localities

Atmospheric fallout/industrial pollutants

BODY AND UNDERBODY MAINTENANCE

Cleaning Headlights

Your vehicle is equipped with plastic headlights

and fog lights that are lighter and less susceptible

to stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and

therefore different lens cleaning procedures must

be followed.

To minimize the possibility of scratching the lenses

and reducing light output, avoid wiping with a dry

cloth. To remove road dirt, wash with a mild soap

solution followed by rinsing.

Do not use abrasive cleaning components,

solvents, steel wool or other aggressive material to

clean the lenses.

PRESERVING THE BODYWORK

Washing

Wash your vehicle regularly. Always wash your

vehicle in the shade using Mopar® Car Wash, or

a mild car wash soap, and rinse the panels

completely with water.

If insects, tar, or other similar deposits have

accumulated on your vehicle, use Mopar®

Super Kleen Bug and Tar Remover to remove.

Use a high quality cleaner wax, such as Mopar®

Cleaner Wax to remove road film, stains and to

protect your paint finish. Use precautions to not

scratch the paint.

Avoid using abrasive compounds and power

buffing that may diminish the gloss or thin out

the paint finish.

CAUTION!

Do not use abrasive or strong cleaning mate

-

rials such as steel wool or scouring powder

that will scratch metal and painted surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or removal

of paint and decals.

8

22_RUP_OM_EN_USC_t.book Page 357