minutes CHRYSLER PACIFICA 2022 Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2022Pages: 384, PDF Size: 23.92 MB

Page 241 of 384

SAFETY239

Once the system receives the updated tire

pressures, the system will automatically update,

the pressure values in the graphic display in the

instrument cluster will return to their original color,

and the TPMS Warning Light will turn off. The

vehicle may need to be driven for up to 20 minutes

above 15 mph (24 km/h) in order for the TPMS to

receive this information.

TPMS DEACTIVATION — IF EQUIPPED

The Tire Pressure Monitoring System (TPMS) can

be deactivated if replacing all four wheel and tire

assemblies (road tires) with wheel and tire

assemblies that do not have TPMS sensors, such

as when installing winter wheel and tire

assemblies on your vehicle.

To deactivate the TPMS, first, replace all four wheel

and tire assemblies (road tires) with tires not

equipped with Tire Pressure Monitoring System

(TPMS) sensors. Then, drive the vehicle for

20 minutes above 15 mph (24 km/h). The TPMS

will chime, the TPMS Warning Light will flash on

and off for 75 seconds and then remain on. The

instrument cluster will display the “SERVICE TPM

SYSTEM” message and then display dashes (--) in

place of the pressure values. Beginning with the next ignition cycle, the TPMS

will no longer chime or display the “SERVICE TPM

SYSTEM” message in the instrument cluster but

dashes (--) will remain in place of the pressure

values.

To reactivate the TPMS, replace all four wheel and

tire assemblies (road tires) with tires equipped with

TPMS sensors. Then, drive the vehicle for up to

20 minutes above 15 mph (24 km/h). The TPMS

will chime, the TPMS Warning Light will flash on

and off for 75 seconds and then turn off. The

instrument cluster will display the “SERVICE TPM

SYSTEM” message and then display pressure

values in place of the dashes. On the next ignition

cycle the "SERVICE TPM SYSTEM" message will no

longer be displayed as long as no system fault

exists.

OCCUPANT RESTRAINT SYSTEMS

Some of the most important safety features in your

vehicle are the restraint systems:

OCCUPANT RESTRAINT SYSTEMS

F

EATURES

Seat Belt Systems

Supplemental Restraint Systems (SRS) Air Bags

Child Restraints Some of the safety features described in this

section may be standard equipment on some

models, or may be optional equipment on others.

If you are not sure, ask an authorized dealer.

IMPORTANT SAFETY PRECAUTIONS

Please pay close attention to the information in

this section. It tells you how to use your restraint

system properly, to keep you and your passengers

as safe as possible.

Here are some simple steps you can take to

minimize the risk of harm from a deploying air bag:

1. Children 12 years old and under should

always ride buckled up in the rear seat of a

vehicle with a rear seat.

2. A child who is not big enough to wear the vehicle seat belt properly must be secured in

the appropriate child restraint or

belt-positioning booster seat in a rear seating

position Ú page 262.

3. If a child from 2 to 12 years old (not in a rear-facing child restraint) must ride in the

front passenger seat, move the seat as far

back as possible and use the proper child

restraint Ú page 262.

6

22_RUP_OM_EN_USC_t.book Page 239

Page 262 of 384

260SAFETY

As the air bags deflate, you may see some

smoke-like particles. The particles are a normal

by-product of the process that generates the

non-toxic gas used for air bag inflation. These

airborne particles may irritate the skin, eyes,

nose, or throat. If you have skin or eye irritation,

rinse the area with cool water. For nose or throat

irritation, move to fresh air. If the irritation

continues, see your doctor. If these particles

settle on your clothing, follow the garment

manufacturer’s instructions for cleaning.

Do not drive your vehicle after the air bags have

deployed. If you are involved in another collision,

the air bags will not be in place to protect you.NOTE:

Air bag covers may not be obvious in the interior

trim, but they will open during air bag deploy -

ment.

After any collision, the vehicle should be taken

to an authorized dealer immediately.

Enhanced Accident Response System

In the event of an impact, if the communication

network remains intact, and the power remains

intact, depending on the nature of the event, the

Occupant Restraint Controller (ORC) will determine

whether to have the Enhanced Accident Response

System perform the following functions:

Cut off fuel to the engine (if equipped).

Cut off battery power to the electric motor (if

equipped).

Flash hazard lights as long as the battery has

power.

Turn on the interior lights, which remain on as

long as the battery has power or for 15 minutes

from the intervention of the Enhanced Accident

Response System.

Unlock the power door locks. Your vehicle may also be designed to perform any

of these other functions in response to the

Enhanced Accident Response System:

Turn off the Fuel Filter Heater, Turn off the HVAC

Blower Motor, Close the HVAC Circulation Door

Cut off battery power to the:

Engine

Electric Motor (if equipped)

Electric power steering

Brake booster

Electric park brake

Automatic transmission gear selector

Horn

Front wiper

Headlamp washer pump (if equipped)

WARNING!

Deployed air bags and seat belt pretensioners

cannot protect you in another collision. Have the

air bags, seat belt pretensioners, and the seat

belt retractor assemblies replaced by an

authorized dealer immediately. Also, have the

Occupant Restraint Controller System serviced

as well.

22_RUP_OM_EN_USC_t.book Page 260

Page 300 of 384

298IN CASE OF EMERGENCY

If the sealant (white fluid) does flow through the

Sealant Hose:

1. Continue to operate the pump

until sealant is no longer flowing

through hose (typically takes 30 - 70

seconds). As the sealant flows

through the Sealant Hose, the Pressure

Gauge can read as high as 70 psi (4.8 bar).

The Pressure Gauge will decrease quickly

from approximately 70 psi (4.8 bar) to the

actual tire pressure when the Sealant Bottle

is empty.

2. The pump will start to inject air into

the tire immediately after the

Sealant Bottle is empty. Continue to

operate the pump and inflate the tire

to the cold tire inflation pressure found on the

tire and loading information label located in

the driver-side door opening. Check the tire

pressure by looking at the Pressure Gauge.

If the tire does not inflate to at least 26 psi

(1.8 bar) within 15 minutes:

The tire is too badly damaged. Do not attempt to

drive the vehicle further. Call for assistance. If the tire inflates to the recommended pressure or

is at least 26 psi (1.8 bar) within 15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation

Button to reduce the tire pressure to the recom

-

mended inflation pressure before continuing.

1. Push the Power Button to turn the

Tire Service Kit off.

2. Remove the speed limit label from

the Tire Service Kit and place sticker

on the steering wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the

fitting at the end of the hose, and place the Tire

Service Kit in the vehicle storage location.

Drive Vehicle: Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of the Tire Service Kit Sealant

within the tire. Do not exceed 50 mph (80 km/h). After Driving:

Pull over to a safe location and turn on the

vehicle’s Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the

ground. This will allow the Tire Service Kit Hose

to reach the valve stem and keep the Tire

Service Kit flat on the ground. This will provide

the best positioning of the kit when injecting the

sealant into the deflated tire and running the air

pump. Move the vehicle as necessary to place

the valve stem in this position before

proceeding.

Place the transmission in PARK (P) and cycle the

ignition in the OFF position.

Apply the parking brake.

WARNING!

The Tire Service Kit is not a permanent flat tire

repair. Have the tire inspected and repaired or

replaced after using the Tire Service Kit. Do not

exceed 50 mph (80 km/h) until the tire is

repaired or replaced. Failure to follow this

warning can result in injuries that are serious or

fatal to you, your passengers, and others around

you. Have the tire checked as soon as possible

at an authorized dealer.

22_RUP_OM_EN_USC_t.book Page 298

Page 304 of 384

302IN CASE OF EMERGENCY

5. Start the engine in the vehicle that has the booster battery, let the engine idle a few

minutes, and then start the engine in the

vehicle with the discharged battery.

6. Once the engine is started, see the following disconnecting procedure for the next steps.

Disconnecting The Jumper Cables

1. Disconnect the negative

(-)

end of the jumper

cable from the remote negative post of the

vehicle with the discharged battery.

2. Disconnect the opposite end of the negative (-)

jumper cable from the negative (-) post of the

booster battery.

3. Disconnect the positive (+) end of the jumper

cable from the positive (+) post of the booster

battery.

4. Disconnect the opposite end of the positive (+)

jumper cable from the remote positive (+) post

of the vehicle with the discharged battery and

reinstall the protective cap. If frequent jump starting is required to start your

vehicle you should have the battery and charging

system inspected at an authorized dealer.

REFUELING IN EMERGENCY – IF EQUIPPED

The vehicle is equipped with a refueling funnel for

a Cap-Less Fuel System. If refueling is necessary,

while using an approved gas can, insert the

refueling funnel into the filler neck opening. Take

care to open both flappers with the funnel to avoid

spills.

NOTE:In certain cold conditions, ice may prevent the fuel

door from opening. If this occurs, lightly push on

the fuel door to break the ice buildup and

re-release the fuel door by pushing at the rear

center edge to unlatch.

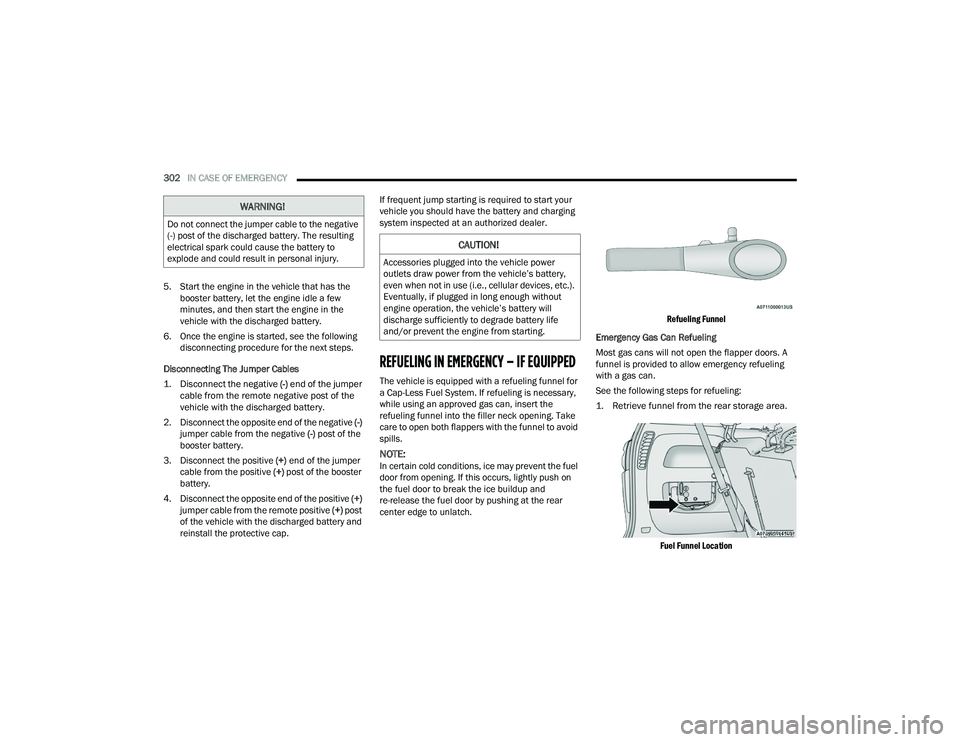

Refueling Funnel

Emergency Gas Can Refueling

Most gas cans will not open the flapper doors. A

funnel is provided to allow emergency refueling

with a gas can.

See the following steps for refueling:

1. Retrieve funnel from the rear storage area.

Fuel Funnel Location

WARNING!

Do not connect the jumper cable to the negative

(-) post of the discharged battery. The resulting

electrical spark could cause the battery to

explode and could result in personal injury.

CAUTION!

Accessories plugged into the vehicle power

outlets draw power from the vehicle’s battery,

even when not in use (i.e., cellular devices, etc.).

Eventually, if plugged in long enough without

engine operation, the vehicle’s battery will

discharge sufficiently to degrade battery life

and/or prevent the engine from starting.

22_RUP_OM_EN_USC_t.book Page 302

Page 316 of 384

314SERVICING AND MAINTENANCE

(Continued)

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the

oil level at regular intervals, such as every fuel

stop. The best time to check the engine oil level is

about five minutes after a fully warmed up engine

is shut off.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the low

end of the range and MAX at the high end of the

range.

Crosshatched zone marked with dimples at the

MIN and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 quart (1.0 liter) of oil when the reading is

at the low end of the dipstick range will raise the oil

level to the high end of the range marking.

ADDING WASHER FLUID

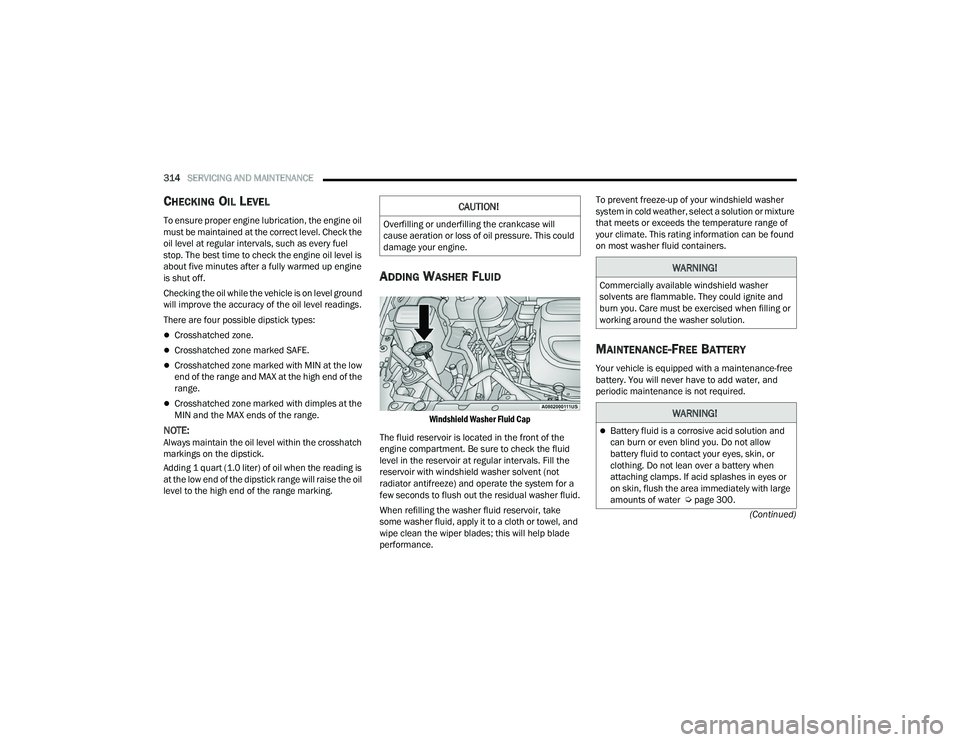

Windshield Washer Fluid Cap

The fluid reservoir is located in the front of the

engine compartment. Be sure to check the fluid

level in the reservoir at regular intervals. Fill the

reservoir with windshield washer solvent (not

radiator antifreeze) and operate the system for a

few seconds to flush out the residual washer fluid.

When refilling the washer fluid reservoir, take

some washer fluid, apply it to a cloth or towel, and

wipe clean the wiper blades; this will help blade

performance. To prevent freeze-up of your windshield washer

system in cold weather, select a solution or mixture

that meets or exceeds the temperature range of

your climate. This rating information can be found

on most washer fluid containers.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free

battery. You will never have to add water, and

periodic maintenance is not required.

CAUTION!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling or

working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps. If acid splashes in eyes or

on skin, flush the area immediately with large

amounts of water Ú

page 300.

22_RUP_OM_EN_USC_t.book Page 314

Page 359 of 384

SERVICING AND MAINTENANCE357

STORING THE VEHICLE

If you are storing your vehicle for more than three

weeks, we recommend that you take the following

steps to minimize the drain on your vehicle's

battery:

Disconnect the negative cable from battery.

Any time you store your vehicle or keep it out of

service (i.e., vacation) for two weeks or more,

run the air conditioning system at idle for about

five minutes in the fresh air and high blower

setting. This will ensure adequate system lubri-

cation to minimize the possibility of compressor

damage when the system is started again.

BODYWORK

PROTECTION FROM ATMOSPHERIC

A

GENTS

Vehicle body care requirements vary according to

geographic locations and usage. Chemicals that

make roads passable in snow and ice and those

that are sprayed on trees and road surfaces during

other seasons are highly corrosive to the metal in

your vehicle. Outside parking, which exposes your

vehicle to airborne contaminants, road surfaces on

which the vehicle is operated, extreme hot or cold

weather and other extreme conditions will have an

adverse effect on paint, metal trim, and underbody

protection. The following maintenance recommendations will

enable you to obtain maximum benefit from the

corrosion resistance built into your vehicle.

What Causes Corrosion?

Corrosion is the result of deterioration or removal

of paint and protective coatings from your vehicle.

The most common causes are:

Road salt, dirt and moisture accumulation

Stone and gravel impact

Insects, tree sap and tar

Salt in the air near seacoast localities

Atmospheric fallout/industrial pollutants

BODY AND UNDERBODY MAINTENANCE

Cleaning Headlights

Your vehicle is equipped with plastic headlights

and fog lights that are lighter and less susceptible

to stone breakage than glass headlights.

Plastic is not as scratch resistant as glass and

therefore different lens cleaning procedures must

be followed.

To minimize the possibility of scratching the lenses

and reducing light output, avoid wiping with a dry

cloth. To remove road dirt, wash with a mild soap

solution followed by rinsing.

Do not use abrasive cleaning components,

solvents, steel wool or other aggressive material to

clean the lenses.

PRESERVING THE BODYWORK

Washing

Wash your vehicle regularly. Always wash your

vehicle in the shade using Mopar® Car Wash, or

a mild car wash soap, and rinse the panels

completely with water.

If insects, tar, or other similar deposits have

accumulated on your vehicle, use Mopar®

Super Kleen Bug and Tar Remover to remove.

Use a high quality cleaner wax, such as Mopar®

Cleaner Wax to remove road film, stains and to

protect your paint finish. Use precautions to not

scratch the paint.

Avoid using abrasive compounds and power

buffing that may diminish the gloss or thin out

the paint finish.

CAUTION!

Do not use abrasive or strong cleaning mate

-

rials such as steel wool or scouring powder

that will scratch metal and painted surfaces.

Use of power washers exceeding 1,200 psi

(8,274 kPa) can result in damage or removal

of paint and decals.

8

22_RUP_OM_EN_USC_t.book Page 357