tow bar CHRYSLER PACIFICA 2023 User Guide

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2023, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2023Pages: 328, PDF Size: 16.37 MB

Page 150 of 328

148STARTING AND OPERATING

Gross Trailer Weight (GTW)

GTW is the weight of the trailer plus the weight of all cargo,

consumables and equipment (permanent or temporary)

loaded in or on the trailer in its "loaded and ready for

operation" condition.

The recommended way to measure GTW is to put your fully

loaded trailer on a vehicle scale. The entire weight of the

trailer must be supported by the scale.

Gross Combination Weight Rating (GCWR)

The GCWR is the total permissible weight of your vehicle

and trailer when weighed in combination.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front and rear

axles. Distribute the load over the front and rear axles

evenly. Make sure that you do not exceed either front or

rear GAWR

Úpage 146.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch ball by

the trailer. You must consider this as part of the load on

your vehicle.

Trailer Frontal Area

The Frontal Area is the maximum height multiplied by the

maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that can be

installed between the hitch receiver and the trailer tongue

that typically provides adjustable friction associated with

the telescoping motion to dampen any unwanted trailer

swaying motions while traveling.

The electronic TSC (if equipped), recognizes a swaying

trailer and automatically applies individual wheel brakes

and/or reduces engine power to attempt to eliminate the

trailer sway.

Weight-Carrying Hitch

A Weight-Carrying Hitch supports the trailer tongue weight,

just as if it were luggage located at a hitch ball or some

other connecting point of the vehicle. These kinds of

hitches are commonly used to tow small and medium

sized trailers.

Weight-Distributing Hitch

A weight-distributing hitch works by applying leverage

through spring (load) bars. They are typically used for

heavier loads to distribute trailer tongue weight to the tow

vehicle's front axle and the trailer axle(s). When used in

accordance with the manufacturer’s directions, it provides

for a more level ride, offering more consistent steering and

brake control thereby enhancing towing safety. The

addition of a friction/hydraulic sway control also dampens

sway caused by traffic and crosswinds and contributes

positively to tow vehicle and trailer stability. TSC and a

weight-distributing (load equalizing) hitch are

recommended for heavier TW and may be required

depending on vehicle and trailer configuration/loading to

comply with GAWR requirements.

WARNING!

It is important that you do not exceed the maximum

front or rear GAWR. A dangerous driving condition can

result if either rating is exceeded. You could lose control

of the vehicle and have a collision.

WARNING!

An improperly adjusted weight-distributing hitch

system may reduce handling, stability, braking

performance, and could result in a collision.

Weight-distributing systems may not be compatible

with surge brake couplers. Consult with your hitch

and trailer manufacturer or a reputable Recreational

Vehicle dealer for additional information.

23_RUP_OM_EN_USC_t.book Page 148

Page 227 of 328

SAFETY225

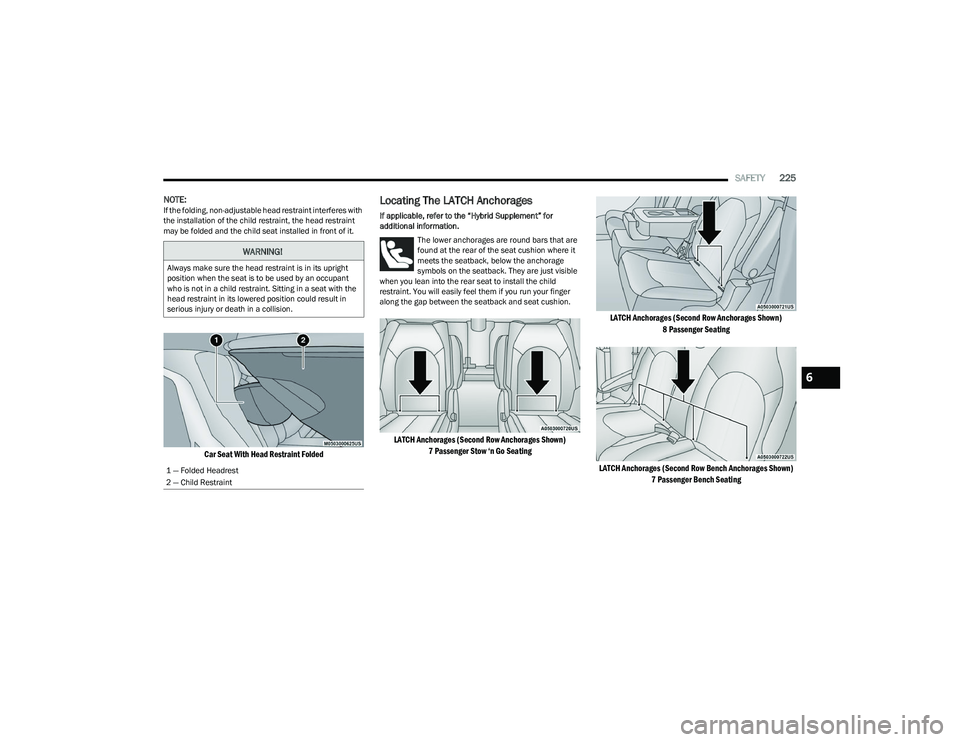

NOTE:If the folding, non-adjustable head restraint interferes with

the installation of the child restraint, the head restraint

may be folded and the child seat installed in front of it.

Car Seat With Head Restraint Folded

Locating The LATCH Anchorages

If applicable, refer to the “Hybrid Supplement” for

additional information.

The lower anchorages are round bars that are

found at the rear of the seat cushion where it

meets the seatback, below the anchorage

symbols on the seatback. They are just visible

when you lean into the rear seat to install the child

restraint. You will easily feel them if you run your finger

along the gap between the seatback and seat cushion.

LATCH Anchorages (Second Row Anchorages Shown)

7 Passenger Stow ‘n Go Seating LATCH Anchorages (Second Row Anchorages Shown)

8 Passenger Seating

LATCH Anchorages (Second Row Bench Anchorages Shown) 7 Passenger Bench Seating

WARNING!

Always make sure the head restraint is in its upright

position when the seat is to be used by an occupant

who is not in a child restraint. Sitting in a seat with the

head restraint in its lowered position could result in

serious injury or death in a collision.

1 — Folded Headrest

2 — Child Restraint

6

23_RUP_OM_EN_USC_t.book Page 225

Page 228 of 328

226SAFETY

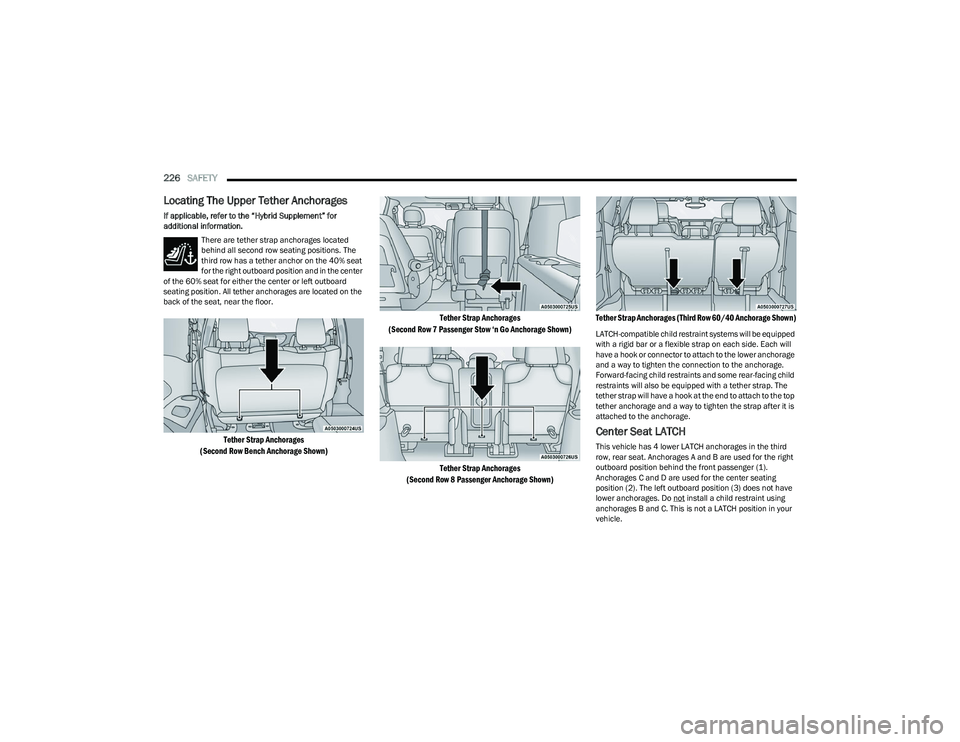

Locating The Upper Tether Anchorages

If applicable, refer to the “Hybrid Supplement” for

additional information.

There are tether strap anchorages located

behind all second row seating positions. The

third row has a tether anchor on the 40% seat

for the right outboard position and in the center

of the 60% seat for either the center or left outboard

seating position. All tether anchorages are located on the

back of the seat, near the floor.

Tether Strap Anchorages

(Second Row Bench Anchorage Shown) Tether Strap Anchorages

(Second Row 7 Passenger Stow ‘n Go Anchorage Shown)

Tether Strap Anchorages

(Second Row 8 Passenger Anchorage Shown) Tether Strap Anchorages (Third Row 60/40 Anchorage Shown)

LATCH-compatible child restraint systems will be equipped

with a rigid bar or a flexible strap on each side. Each will

have a hook or connector to attach to the lower anchorage

and a way to tighten the connection to the anchorage.

Forward-facing child restraints and some rear-facing child

restraints will also be equipped with a tether strap. The

tether strap will have a hook at the end to attach to the top

tether anchorage and a way to tighten the strap after it is

attached to the anchorage.

Center Seat LATCH

This vehicle has 4 lower LATCH anchorages in the third

row, rear seat. Anchorages A and B are used for the right

outboard position behind the front passenger (1).

Anchorages C and D are used for the center seating

position (2). The left outboard position (3) does not have

lower anchorages. Do not

install a child restraint using

anchorages B and C. This is not a LATCH position in your

vehicle.

23_RUP_OM_EN_USC_t.book Page 226

Page 245 of 328

IN CASE OF EMERGENCY243

Mounting Inflatable Spare Tire

NOTE:

Do not install the wheel cover on the inflatable spare tire.

7. Leave the vehicle on the jack and start inflating the inflatable spare after the tire has been mounted to

the vehicle. Secure the wheel to the hub by tightening

the nuts with the wrench. After inflation, once the

vehicle is lowered you will have a second opportunity

to torque the lug nuts

Úpage 303. 8. Inflate the tire to the prescribed pressure 60 psi

(4.2 Bar) using the Portable Air Compressor

Úpage 244 or Tire Service Kit if equipped Úpage 245.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the compressor-hose has

been removed from the tire valve.

10. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice

Úpage 303. If in

doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do not stow the

deflated tire in the inflatable spare tire location. Have

the full-sized tire repaired or replaced, as soon as

possible. 13. Stow the jack back in the stowage compartment and

place the access panel back. The stud of the storage

area must be threaded through the lower part of the

jack. Then turn the Jack Screw clockwise to secure it

in place.

NOTE:Stow the foam tray and components in the cargo area.

Storing The Jack

CAUTION!

Be sure to mount the inflatable spare tire with the valve

stem facing outward. The vehicle could be damaged if

the inflatable spare tire is mounted incorrectly.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

1 — Jack Screw

2 — Jack

3 — Stud7

23_RUP_OM_EN_USC_t.book Page 243

Page 246 of 328

244IN CASE OF EMERGENCY

ROAD TIRE INSTALLATION

Vehicles Equipped With Wheel Covers

1. Mount the road tire on the axle.

2. To ease the installation process for steel wheels with

wheel covers, install two lug nuts on the mounting

studs which are on each side of the valve stem. Install

the lug nuts with the cone shaped end of the nut

toward the wheel. Lightly tighten the lug nuts.

Tire And Wheel Cover Or Center Cap

3. Align the valve notch in the wheel cover with the valve stem on the wheel. Install the cover by hand,

snapping the cover over the two lug nuts. Do not use

a hammer or excessive force to install the cover.

4. Install the remaining lug nuts with the cone shaped end of the nut toward the wheel. Lightly tighten all the

lug nuts until the wheel sits flush onto the hub and

there is no play. The nuts will have to be fully

tightened once the vehicle is lowered. Tightening an

improperly seated wheel under vehicle load can

damage the threads, cause vibration, and undermine

safety.

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice

Úpage 303. If in

doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all lug nuts are

properly seated against the wheel.

PORTABLE AIR COMPRESSOR —

I

F EQUIPPED

Your vehicle may be equipped with a Portable Air

Compressor. Use the Portable Air Compressor located in

the side compartment of the cargo area to inflate the

inflatable tire to 60 psi (4.2 Bar).

Portable Air Compressor

1 — Valve Stem

2 — Valve Notch

3 — Road Tire

4 — Wheel Cover

5 — Wheel Lug Nut

WARNING!

To avoid the risk of forcing the vehicle off the jack, do

not tighten the wheel nuts fully until the vehicle has

been lowered. Failure to follow this warning may result

in serious injury.

1 — Power Plug

2 — Deflation Button

3 — Pressure Gauge

4 — Power Button

5 — Air Hose

23_RUP_OM_EN_USC_t.book Page 244

Page 247 of 328

IN CASE OF EMERGENCY245

Portable Air Compressor Usage With Inflatable Spare Tire

1. Remove the Portable Air Compressor from the

storage location.

2. Raise the vehicle as described in the

Jacking Instructions within this section.

3. Install the Inflatable Spare tire as

described in the Jack Instructions section

in this manual. Make sure that the valve

stem is located near the ground, and

then screw the air hose of the Portable Air

Compressor to the valve stem.

4. Uncoil the power plug and connect it

the vehicles 12 Volt power Outlet.

5. Always start the engine before turning

ON the Portable Air Compressor.

6. Switch the power button ON.

7. Inflate the tire to 60 psi (4.2 Bar)

recommended as per the label on the

wheel or if the vehicle equipped with the

inflatable spare tire pressure indicated

on the Tire and Loading information label

located on the driver-side door opening.

NOTE:If the tire is overinflated, use the deflation button to

reduce the tire air pressure. 8. After the tire reaches the

recommended pressure, lower the

vehicle with the jack as described in the

Jack Instructions section in this manual.

9. Remove the speed limit label sticker

from the Portable Air Compressor and

place it on the center of the steering

wheel.

10. Return the Portable Air Compressor to the foam tray and secure it with the strap. Store the foam tray in the

cargo area.

RETURN INFLATABLE SPARE TIRE

To return Inflatable Spare Tire to its storage location.

1. Return the Jack.

2. Deflate the spare tire. Use the Tire Service Kit or Portable Air Compressor and push the deflation

button to do this step. See the Portable Air

Compressor in this section for additional information. The inflatable spare tire will return to its original

shape.

3. Install the inflatable spare tire back into its original stowage location and position facing outward.

4. Install the foam tray with wrench and funnel installed.

5. Install and tighten the wing nut by hand.

6. Install the Tire Service Kit or Portable Air Compressor (if equipped) and tighten the strap.

7. Install access panel door.

TIRE SERVICE KIT — IF EQUIPPED

Use this QR code to access your digital

experience.

Your vehicle may be equipped with a

Tire Service Kit. Small punctures up to

1/4 inch (6 mm) in the tire tread can

be sealed with Tire Service Kit. Foreign

objects (e.g., screws or nails) should

not be removed from the tire. Tire

Service Kit can be used in outside temperatures down to

approximately -4°F (-20°C). This kit will provide a

temporary tire seal, allowing you to drive your vehicle up to

100 miles (160 km) with a maximum speed of 50 mph

(80 km/h).WARNING!

Do not lift or carry the Portable Air Compressor by the

hose.

Always stow the Portable Air Compressor only in the

provided place.

The metal end fitting from Power Plug may get hot

after use, so it should be handled carefully.

Keep the Portable Air Compressor away from open

flames or heat source.

7

23_RUP_OM_EN_USC_t.book Page 245

Page 258 of 328

256IN CASE OF EMERGENCY

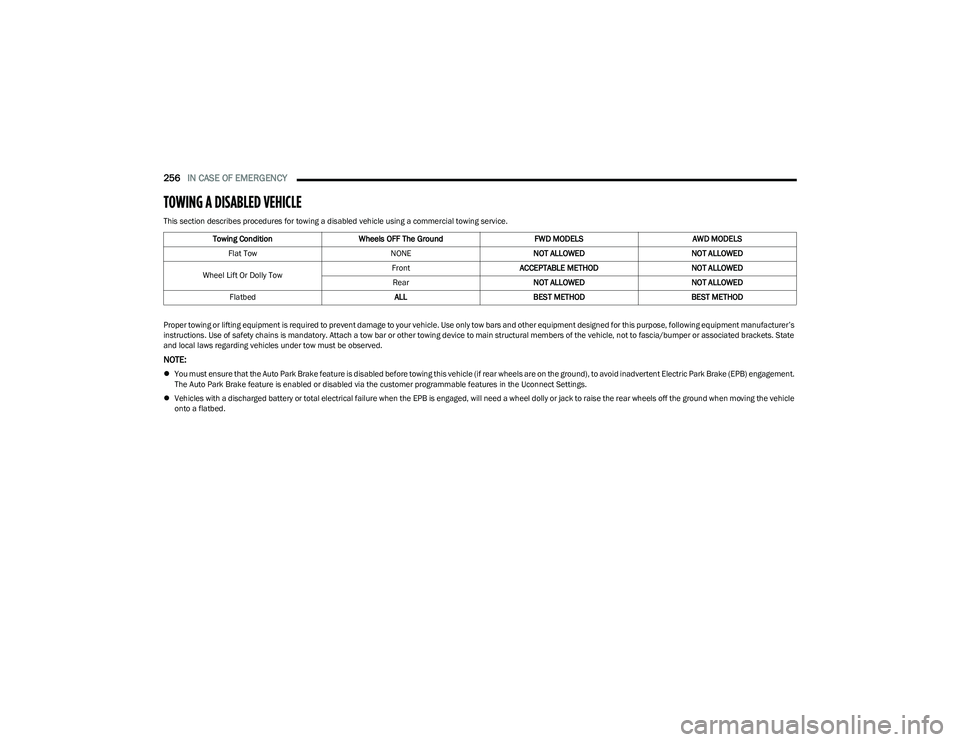

TOWING A DISABLED VEHICLE

This section describes procedures for towing a disabled vehicle using a commercial towing service.

Proper towing or lifting equipment is required to prevent damage to your vehicle. Use only tow bars and other equipment designed for this purpose, following equipment manufacturer’s

instructions. Use of safety chains is mandatory. Attach a tow bar or other towing device to main structural members of the vehicle, not to fascia/bumper or associated brackets. State

and local laws regarding vehicles under tow must be observed.

NOTE:

You must ensure that the Auto Park Brake feature is disabled before towing this vehicle (if rear wheels are on the ground), to avoid inadvertent Electric Park Brake (EPB) engagement.

The Auto Park Brake feature is enabled or disabled via the customer programmable features in the Uconnect Settings.

Vehicles with a discharged battery or total electrical failure when the EPB is engaged, will need a wheel dolly or jack to raise the rear wheels off the ground when moving the vehicle

onto a flatbed. Towing Condition

Wheels OFF The Ground FWD MODELS AWD MODELS

Flat Tow NONENOT ALLOWED NOT ALLOWED

Wheel Lift Or Dolly Tow Front

ACCEPTABLE METHOD NOT ALLOWED

Rear NOT ALLOWED NOT ALLOWED

Flatbed ALLBEST METHOD BEST METHOD

23_RUP_OM_EN_USC_t.book Page 256