inflation pressure CHRYSLER PACIFICA 2023 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2023, Model line: PACIFICA, Model: CHRYSLER PACIFICA 2023Pages: 328, PDF Size: 16.37 MB

Page 109 of 328

GETTING TO KNOW YOUR INSTRUMENT PANEL107

Each tire, including the spare (if provided), should be

checked monthly when cold and inflated to the inflation

pressure recommended by the vehicle manufacturer on

the vehicle placard or tire inflation pressure label. If your

vehicle has tires of a different size than the size indicated

on the vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure for

those tires.

As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire pressure

telltale when one or more of your tires is significantly

underinflated. Accordingly, when the low tire pressure

telltale illuminates, you should stop and check your tires

as soon as possible, and inflate them to the proper

pressure. Driving on a significantly underinflated tire

causes the tire to overheat and can lead to tire failure.

Underinflation also reduces fuel efficiency and tire tread

life, and may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for proper

tire maintenance, and it is the driver’s responsibility to

maintain correct tire pressure, even if underinflation has

not reached the level to trigger illumination of the TPMS

low tire pressure telltale. Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system is not

operating properly. The TPMS malfunction indicator is

combined with the low tire pressure telltale. When the

system detects a malfunction, the telltale will flash for

approximately one minute and then remain continuously

illuminated. This sequence will continue upon subsequent

vehicle start-ups as long as the malfunction exists. When

the malfunction indicator is illuminated, the system may

not be able to detect or signal low tire pressure as

intended. TPMS malfunctions may occur for a variety of

reasons, including the installation of replacement or

alternate tires or wheels on the vehicle that prevent the

TPMS from functioning properly. Always check the TPMS

malfunction telltale after replacing one or more tires or

wheels on your vehicle to ensure that the replacement or

alternate tires and wheels allow the TPMS to continue to

function properly.

YELLOW INDICATOR LIGHTS

Forward Collision Warning (FCW) or

Pedestrian Emergency Braking (PEB) OFF

Indicator Light — If Equipped

This indicator light illuminates to indicate that

Forward Collision Warning (FCW) or Pedestrian

Emergency Braking (PEB) is off.

GREEN INDICATOR LIGHTS

Adaptive Cruise Control (ACC) Set With

Target Vehicle Detected Indicator Light —

If Equipped

This indicator light will illuminate when the

Adaptive Cruise Control speed is SET and the

vehicle in front is detected

Úpage 124.

Adaptive Cruise Control (ACC) Set With No

Target Detected Indicator Light —

If Equipped

This indicator light will illuminate when the

Adaptive Cruise Control speed is SET and there

is no vehicle in front detected

Úpage 124.

Cruise Control Set Indicator Light —

If Equipped

This indicator light will illuminate when the

cruise control is set to the desired speed

Úpage 123.

CAUTION!

Do not continue driving with one or more flat tires as

handling may be compromised. Stop the vehicle,

avoiding sharp braking and steering. If a tire puncture

occurs, repair immediately using the dedicated tire

repair kit and contact an authorized dealer as soon as

possible.

CAUTION!

The TPMS has been optimized for the original

equipment tires and wheels. TPMS pressures and

warning have been established for the tire size

equipped on your vehicle. Undesirable system

operation or sensor damage may result when using

replacement equipment that is not of the same size,

type, and/or style. Aftermarket wheels can cause

sensor damage. Using aftermarket tire sealants may

cause the Tire Pressure Monitoring System (TPMS)

sensor to become inoperable. After using an

aftermarket tire sealant it is recommended that you

take your vehicle to an authorized dealer to have your

sensor function checked.

3

23_RUP_OM_EN_USC_t.book Page 107

Page 149 of 328

STARTING AND OPERATING147

Each axle GAWR is determined by the components in the

system with the lowest load carrying capacity (axle,

springs, tires or wheels). Heavier axles or suspension

components sometimes specified by purchasers for

increased durability do not necessarily increase the

vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label represents

the actual tire size on your vehicle. Replacement tires

must be equal to the load capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire size

listed.

Inflation Pressure

This is the cold tire inflation pressure for your vehicle for

all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total weight

of the vehicle with all fluids, including vehicle fuel, at full

capacity conditions, and with no occupants or cargo

loaded into the vehicle. The front and rear curb weight

values are determined by weighing your vehicle on a

commercial scale before any occupants or cargo are

added.

Loading

The actual total weight and the weight of the front and rear

of your vehicle at the ground can best be determined by

weighing it when it is loaded and ready for operation.

The entire vehicle should first be weighed on a commercial

scale to ensure that the GVWR has not been exceeded.

The weight on the front and rear of the vehicle should then

be determined separately to be sure that the load is

properly distributed over the front and rear axle. Weighing

the vehicle may show that the GAWR of either the front or

rear axles has been exceeded but the total load is within

the specified GVWR. If so, weight must be shifted from

front to rear or rear to front as appropriate until the

specified weight limitations are met. Store the heavier

items down low and be sure that the weight is distributed

equally. Stow all loose items securely before driving.

Improper weight distributions can have an adverse effect

on the way your vehicle steers and handles and the way

the brakes operate.TRAILER TOWING

NOTE:Trailer towing is not permitted for the Plug-in Hybrid

Electric Vehicle (PHEV).

In this section you will find safety tips and information on

limits to the type of towing you can reasonably do with your

vehicle. Before towing a trailer, carefully review this

information to tow your load as efficiently and safely as

possible.

To maintain the New Vehicle Limited Warranty coverage,

follow the requirements and recommendations in this

manual concerning vehicles used for trailer towing.

COMMON TOWING DEFINITIONS

The following trailer towing related definitions will assist

you in understanding the following information:

Gross Vehicle Weight Rating (GVWR)

GVWR is the total allowable weight of your vehicle. This

includes driver, passengers, cargo and tongue weight. The

total load must be limited so that you do not exceed the

GVWR

Úpage 146.

WARNING!

Do not load your vehicle any heavier than the GVWR or

the maximum front and rear GAWR. If you do, parts on

your vehicle can break, or it can change the way your

vehicle handles. This could cause you to lose control.

Overloading can shorten the life of your vehicle.

4

23_RUP_OM_EN_USC_t.book Page 147

Page 154 of 328

152STARTING AND OPERATING

Towing Requirements — Tires

Do not attempt to tow a trailer while using a compact

spare tire.

Do not drive more than 50 mph (80 km/h) when towing

while using a full size spare tire.

Proper tire inflation pressures are essential to the safe

and satisfactory operation of your vehicle.

Check the trailer tires for proper tire inflation pressures

before trailer usage.

Check for signs of tire wear or visible tire damage

before towing a trailer.

Replacing tires with a higher load carrying capacity will

not increase the vehicle's GVWR and GAWR limits.

For further information

Úpage 291.

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system or

vacuum system of your vehicle with that of the trailer.

This could cause inadequate braking and possible

personal injury.

An electronically actuated trailer brake controller is

required when towing a trailer with electronically actu -

ated brakes. When towing a trailer equipped with a

hydraulic surge actuated brake system, an electronic

brake controller is not required.

Trailer brakes are recommended for trailers over

1,000 lb (453 kg) and required for trailers in excess of

2,000 lb (907 kg).

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer size,

stop lights and turn signals on the trailer are required for

motoring safety.

The Trailer Tow Package may include a four and seven-pin

wiring harness. Use a factory approved trailer harness and

connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your brake

system and cause it to fail. You might not have brakes

when you need them and could have an accident.

Towing any trailer will increase your stopping distance.

When towing, you should allow for additional space

between your vehicle and the vehicle in front of you.

Failure to do so could result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they should

be of adequate capacity. Failure to do this could lead to

accelerated brake lining wear, higher brake pedal

effort, and longer stopping distances.

23_RUP_OM_EN_USC_t.book Page 152

Page 199 of 328

SAFETY197

This indicates there is an internal system fault. Although

the vehicle is still drivable under normal conditions, have

the system checked by an authorized dealer.

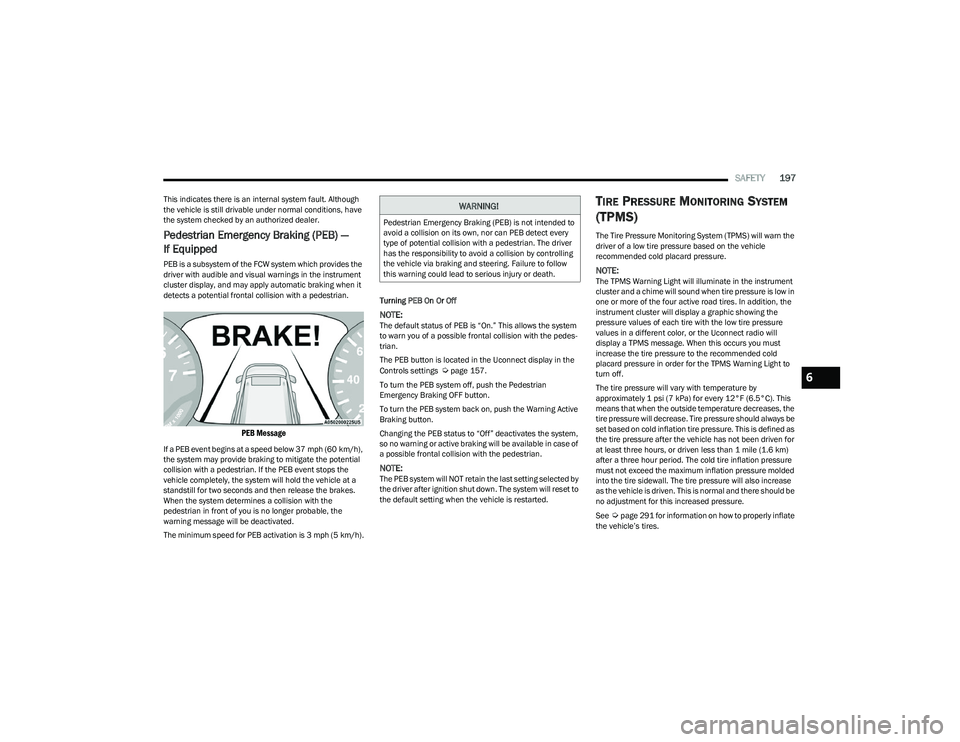

Pedestrian Emergency Braking (PEB) —

If Equipped

PEB is a subsystem of the FCW system which provides the

driver with audible and visual warnings in the instrument

cluster display, and may apply automatic braking when it

detects a potential frontal collision with a pedestrian.

PEB Message

If a PEB event begins at a speed below 37 mph (60 km/h),

the system may provide braking to mitigate the potential

collision with a pedestrian. If the PEB event stops the

vehicle completely, the system will hold the vehicle at a

standstill for two seconds and then release the brakes.

When the system determines a collision with the

pedestrian in front of you is no longer probable, the

warning message will be deactivated.

The minimum speed for PEB activation is 3 mph (5 km/h). Turning PEB On Or Off

NOTE:The default status of PEB is “On.” This allows the system

to warn you of a possible frontal collision with the pedes

-

trian.

The PEB button is located in the Uconnect display in the

Controls settings

Úpage 157.

To turn the PEB system off, push the Pedestrian

Emergency Braking OFF button.

To turn the PEB system back on, push the Warning Active

Braking button.

Changing the PEB status to “Off” deactivates the system,

so no warning or active braking will be available in case of

a possible frontal collision with the pedestrian.

NOTE:The PEB system will NOT retain the last setting selected by

the driver after ignition shut down. The system will reset to

the default setting when the vehicle is restarted.

TIRE PRESSURE MONITORING SYSTEM

(TPMS)

The Tire Pressure Monitoring System (TPMS) will warn the

driver of a low tire pressure based on the vehicle

recommended cold placard pressure.

NOTE:The TPMS Warning Light will illuminate in the instrument

cluster and a chime will sound when tire pressure is low in

one or more of the four active road tires. In addition, the

instrument cluster will display a graphic showing the

pressure values of each tire with the low tire pressure

values in a different color, or the Uconnect radio will

display a TPMS message. When this occurs you must

increase the tire pressure to the recommended cold

placard pressure in order for the TPMS Warning Light to

turn off.

The tire pressure will vary with temperature by

approximately 1 psi (7 kPa) for every 12°F (6.5°C). This

means that when the outside temperature decreases, the

tire pressure will decrease. Tire pressure should always be

set based on cold inflation tire pressure. This is defined as

the tire pressure after the vehicle has not been driven for

at least three hours, or driven less than 1 mile (1.6 km)

after a three hour period. The cold tire inflation pressure

must not exceed the maximum inflation pressure molded

into the tire sidewall. The tire pressure will also increase

as the vehicle is driven. This is normal and there should be

no adjustment for this increased pressure.

See

Úpage 291 for information on how to properly inflate

the vehicle’s tires.

WARNING!

Pedestrian Emergency Braking (PEB) is not intended to

avoid a collision on its own, nor can PEB detect every

type of potential collision with a pedestrian. The driver

has the responsibility to avoid a collision by controlling

the vehicle via braking and steering. Failure to follow

this warning could lead to serious injury or death.

6

23_RUP_OM_EN_USC_t.book Page 197

Page 200 of 328

198SAFETY

The TPMS will warn the driver of a low tire pressure if the

tire pressure falls below the low-pressure warning limit for

any reason, including low temperature effects and natural

pressure loss through the tire.

The TPMS will continue to warn the driver of low tire

pressure as long as the condition exists, and will not turn

off until the tire pressure is at or above the recommended

cold placard pressure. Once the low tire pressure warning

(TPMS Warning Light) illuminates, you must increase the

tire pressure to the recommended cold placard pressure

in order for the TPMS Warning Light to turn off.

The system will automatically update and the TPMS

Warning Light will turn off once the system receives the

updated tire pressures. The vehicle may need to be driven

for up to 20 minutes above 15 mph (24 km/h) in order for

the TPMS to receive this information.

For example, your vehicle may have a recommended cold

(parked for more than three hours) placard pressure of

33 psi (227 kPa). If the ambient temperature is 68°F

(20°C) and the measured tire pressure is 28 psi

(193 kPa), a temperature drop to 20°F (-7°C) will

decrease the tire pressure to approximately 24 psi

(165 kPa). This tire pressure is low enough to turn on the

TPMS Warning Light. Driving the vehicle may cause the tire

pressure to rise to approximately 28 psi (193 kPa), but the

TPMS Warning Light will still be on. In this situation, the

TPMS Warning Light will turn off only after the tires are

inflated to the vehicle’s recommended cold placard

pressure value

Úpage 312.

NOTE:When filling warm tires, the tire pressure may need to be

increased up to an additional 4 psi (28 kPa) above the

recommended cold placard pressure in order to turn the

TPMS Warning Light off.NOTE:

The TPMS is not intended to replace normal tire care

and maintenance, or to provide warning of a tire failure

or condition.

The TPMS should not be used as a tire pressure gauge

while adjusting your tire pressure.

Driving on a significantly underinflated tire causes the

tire to overheat and can lead to tire failure. Underinfla -

tion also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping ability.

The TPMS is not a substitute for proper tire mainte -

nance, and it is the driver’s responsibility to maintain

correct tire pressure using an accurate tire pressure

gauge, even if underinflation has not reached the level

to trigger illumination of the TPMS Warning Light.

Seasonal temperature changes will affect tire pres -

sure, and the TPMS will monitor the actual tire pres -

sure in the tire.

Premium System

The Tire Pressure Monitoring System (TPMS) uses wireless

technology with wheel rim mounted electronic sensors to

monitor tire pressure levels. Sensors, mounted to each

wheel as part of the valve stem, transmit tire pressure

readings to the receiver module.

NOTE:It is particularly important for you to check the tire

pressure in all of the tires on your vehicle monthly and to

maintain the proper pressure.

CAUTION!

The TPMS has been optimized for the original equip -

ment tires and wheels. TPMS pressures and warning

have been established for the tire size equipped on

your vehicle. Undesirable system operation or sensor

damage may result when using replacement equip -

ment that is not of the same size, type, and/or style.

The TPMS sensor is not designed for use on after -

market wheels and may contribute to a poor overall

system performance or sensor damage. Customers

are encouraged to use Original Equipment Manufac -

turer (OEM) wheels to ensure proper TPMS feature

operation.

Using aftermarket tire sealants may cause the Tire

Pressure Monitoring System (TPMS) sensor to

become inoperable. After using an aftermarket tire

sealant it is recommended that you take your vehicle

to an authorized dealer to have your sensor function

checked.

After inspecting or adjusting the tire pressure always

reinstall the valve stem cap. This will prevent mois -

ture and dirt from entering the valve stem, which

could damage the TPMS sensor.

23_RUP_OM_EN_USC_t.book Page 198

Page 236 of 328

234SAFETY

(Continued)

(Continued)

Defroster

Check operation by selecting the defrost mode and place

the blower control on high speed. You should be able to

feel the air directed against the windshield. See an

authorized dealer for service if your defroster is

inoperable.

Floor Mat Safety Information

Always use floor mats designed to fit your vehicle. Only use

a floor mat that does not interfere with the operation of the

accelerator, brake or clutch pedals. Only use a floor mat

that is securely attached using the floor mat fasteners so

it cannot slip out of position and interfere with the

accelerator, brake or clutch pedals or impair safe

operation of your vehicle in other ways.

PERIODIC SAFETY CHECKS YOU SHOULD

M

AKE OUTSIDE THE VEHICLE

Tires

Examine tires for excessive tread wear and uneven wear

patterns. Check for stones, nails, glass, or other objects

lodged in the tread or sidewall. Inspect the tread for cuts

and cracks. Inspect sidewalls for cuts, cracks, and bulges.

Check the lug nut/bolt torque for tightness. Check the

tires (including spare) for proper cold inflation pressure.

WARNING!

An improperly attached, damaged, folded, or stacked

floor mat, or damaged floor mat fasteners may cause

your floor mat to interfere with the accelerator, brake, or

clutch pedals and cause a loss of vehicle control. To

prevent SERIOUS INJURY or DEATH:

ALWAYS securely attach your floor mat

using the floor mat fasteners. DO NOT

install your floor mat upside down or turn

your floor mat over. Lightly pull to confirm

mat is secured using the floor mat

fasteners on a regular basis.

ALWAYS REMOVE THE EXISTING FLOOR

MAT FROM THE VEHICLE before installing

any other floor mat. NEVER install or stack

an additional floor mat on top of an existing

floor mat.

ONLY install floor mats designed to fit your vehicle.

NEVER install a floor mat that cannot be properly

attached and secured to your vehicle. If a floor mat

needs to be replaced, only use a FCA US LLC

approved floor mat for the specific make, model, and

year of your vehicle.

ONLY use the driver’s side floor mat on the driver’s

side floor area. To check for interference, with the

vehicle properly parked with the engine off, fully

depress the accelerator, the brake, and the clutch

pedal (if present) to check for interference. If your

floor mat interferes with the operation of any pedal,

or is not secure to the floor, remove the floor mat

from the vehicle and place the floor mat in your

trunk.

ONLY use the passenger’s side floor mat on the

passenger’s side floor area.

ALWAYS make sure objects cannot fall or slide into

the driver’s side floor area when the vehicle is

moving. Objects can become trapped under acceler -

ator, brake, or clutch pedals and could cause a loss

of vehicle control.

WARNING!

NEVER place any objects under the floor mat (e.g.,

towels, keys, etc.). These objects could change the

position of the floor mat and may cause interference

with the accelerator, brake, or clutch pedals.

If the vehicle carpet has been removed and

re-installed, always properly attach carpet to the floor

and check the floor mat fasteners are secure to the

vehicle carpet. Fully depress each pedal to check for

interference with the accelerator, brake, or clutch

pedals then re-install the floor mats.

It is recommended to only use mild soap and water

to clean your floor mats. After cleaning, always check

your floor mat has been properly installed and is

secured to your vehicle using the floor mat fasteners

by lightly pulling mat.

WARNING!

23_RUP_OM_EN_USC_t.book Page 234

Page 245 of 328

IN CASE OF EMERGENCY243

Mounting Inflatable Spare Tire

NOTE:

Do not install the wheel cover on the inflatable spare tire.

7. Leave the vehicle on the jack and start inflating the inflatable spare after the tire has been mounted to

the vehicle. Secure the wheel to the hub by tightening

the nuts with the wrench. After inflation, once the

vehicle is lowered you will have a second opportunity

to torque the lug nuts

Úpage 303. 8. Inflate the tire to the prescribed pressure 60 psi

(4.2 Bar) using the Portable Air Compressor

Úpage 244 or Tire Service Kit if equipped Úpage 245.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the compressor-hose has

been removed from the tire valve.

10. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for increased

leverage. Tighten the lug nuts in a star pattern until

each nut has been tightened twice

Úpage 303. If in

doubt about the correct tightness, have them

checked with a torque wrench by an authorized

dealer or at a service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do not stow the

deflated tire in the inflatable spare tire location. Have

the full-sized tire repaired or replaced, as soon as

possible. 13. Stow the jack back in the stowage compartment and

place the access panel back. The stud of the storage

area must be threaded through the lower part of the

jack. Then turn the Jack Screw clockwise to secure it

in place.

NOTE:Stow the foam tray and components in the cargo area.

Storing The Jack

CAUTION!

Be sure to mount the inflatable spare tire with the valve

stem facing outward. The vehicle could be damaged if

the inflatable spare tire is mounted incorrectly.

WARNING!

A loose tire or jack thrown forward in a collision or hard

stop could endanger the occupants of the vehicle.

Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or

replaced immediately.

1 — Jack Screw

2 — Jack

3 — Stud7

23_RUP_OM_EN_USC_t.book Page 243

Page 251 of 328

IN CASE OF EMERGENCY249

2. The pump will start to inject air into the

tire immediately after the Sealant Bottle

is empty. Continue to operate the pump

and inflate the tire to the cold tire

inflation pressure found on the tire and

loading information label located in the driver-side

door opening. Check the tire pressure by looking at

the Pressure Gauge.

If the tire does not inflate to at least 26 psi (1.8 bar) within

15 minutes:

The tire is too badly damaged. Do not attempt to drive

the vehicle further. Call for assistance.

If the tire inflates to the recommended pressure or is at

least 26 psi (1.8 bar) within 15 minutes:

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

1. Push the Power Button to turn the Tire

Service Kit off.

2. Remove the speed limit label from the

Tire Service Kit and place sticker on the

steering wheel.

3. Immediately disconnect the Sealant Hose from the valve stem, reinstall the cap on the fitting at the end

of the hose, and place the Tire Service Kit in the

vehicle storage location. Drive Vehicle:

Immediately after injecting sealant and

inflating the tire, drive the vehicle 5 miles

(8 km) or 10 minutes to ensure distribution of

the Tire Service Kit Sealant within the tire. Do

not exceed 50 mph (80 km/h).

After Driving:

Pull over to a safe location and turn on the vehicle’s

Hazard Warning Flashers.

Verify that the valve stem (on the wheel with the

deflated tire) is in a position that is near to the ground.

This will allow the Tire Service Kit Hose to reach the

valve stem and keep the Tire Service Kit flat on the

ground. This will provide the best positioning of the kit

when injecting the sealant into the deflated tire and

running the air pump. Move the vehicle as necessary to

place the valve stem in this position before proceeding.

Place the transmission in PARK (P) and cycle the igni -

tion in the OFF position.

Apply the parking brake.

NOTE:If tire has improper inflation follow these next steps:

1. Uncoil the Sealant Hose, and then remove the cap

from the fitting at the end of the hose.

2. Place the Tire Service Kit flat on the

ground next to the deflated tire.

3. Remove the cap from the valve stem, and then screw the fitting at the end of the Sealant Hose onto the

valve stem.

4. Uncoil the Power Plug and insert the

plug into the vehicle's 12 Volt power

outlet.

5. Uncoil the Hose and screw the fitting at

the end of the hose onto the valve stem.

6. Turn the Mode Select Knob and turn to

the Air Mode position.

7. Check the pressure in the tire by reading the Pressure Gauge.

If tire pressure is less than 19 psi (1.3 bar):

The tire is too badly damaged. Do not attempt to drive the

vehicle further. Call for assistance.

WARNING!

The Tire Service Kit is not a permanent flat tire repair.

Have the tire inspected and repaired or replaced after

using the Tire Service Kit. Do not exceed 50 mph

(80 km/h) until the tire is repaired or replaced. Failure

to follow this warning can result in injuries that are

serious or fatal to you, your passengers, and others

around you. Have the tire checked as soon as possible

at an authorized dealer.

7

23_RUP_OM_EN_USC_t.book Page 249

Page 252 of 328

250IN CASE OF EMERGENCY

If the tire pressure is 19 psi (1.3 bar) or higher:

1. Push the Power Button to turn on Tire

Service Kit and inflate the tire to the cold

tire inflation pressure found on the tire

and loading information label located in

the driver-side door opening.

NOTE:If the tire becomes overinflated, push the Deflation Button

to reduce the tire pressure to the recommended inflation

pressure before continuing.

2. Disconnect the Tire Service Kit from the valve stem, reinstall the cap on the valve stem and unplug from

12 Volt outlet.

3. Place the Tire Service Kit in its proper storage area in the vehicle.

4. Have the tire inspected and repaired or replaced at the earliest opportunity at an authorized dealer or tire

service center.

5. Remove the Speed Limit sticker from the steering wheel after the tire has been repaired.

6. Replace the Sealant Bottle at an authorized dealer as soon as possible.

NOTE:When having the tire serviced, advise the authorized

dealer or service center that the tire has been sealed

using the Tire Service Kit.

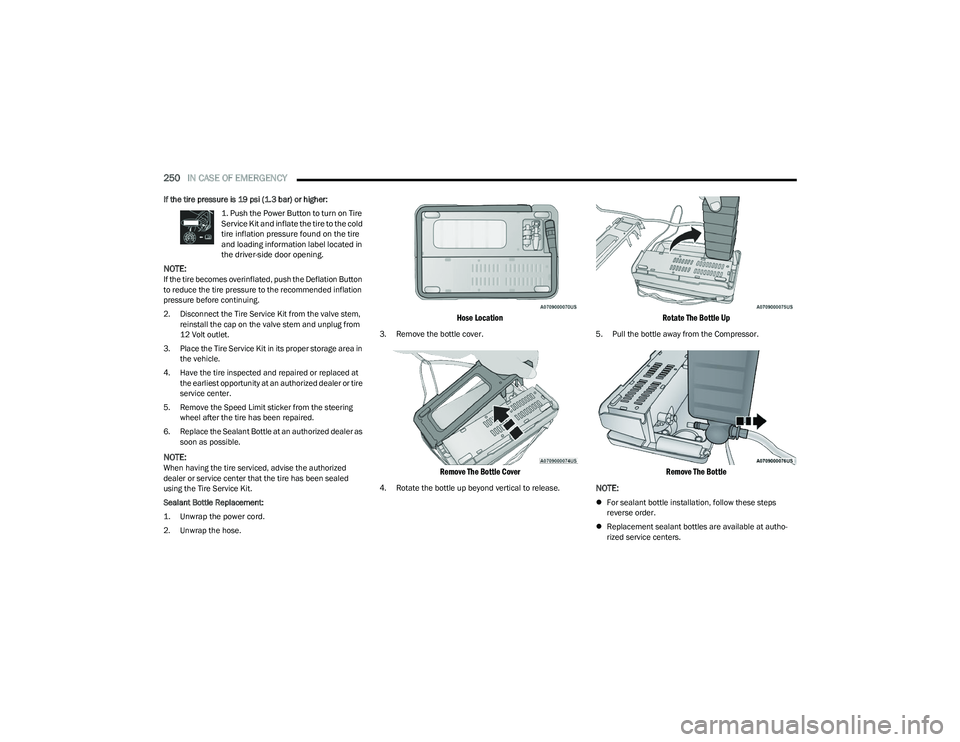

Sealant Bottle Replacement:

1. Unwrap the power cord.

2. Unwrap the hose.

Hose Location

3. Remove the bottle cover.

Remove The Bottle Cover

4. Rotate the bottle up beyond vertical to release.

Rotate The Bottle Up

5. Pull the bottle away from the Compressor.

Remove The Bottle

NOTE:

For sealant bottle installation, follow these steps

reverse order.

Replacement sealant bottles are available at autho -

rized service centers.

23_RUP_OM_EN_USC_t.book Page 250

Page 287 of 328

SERVICING AND MAINTENANCE285

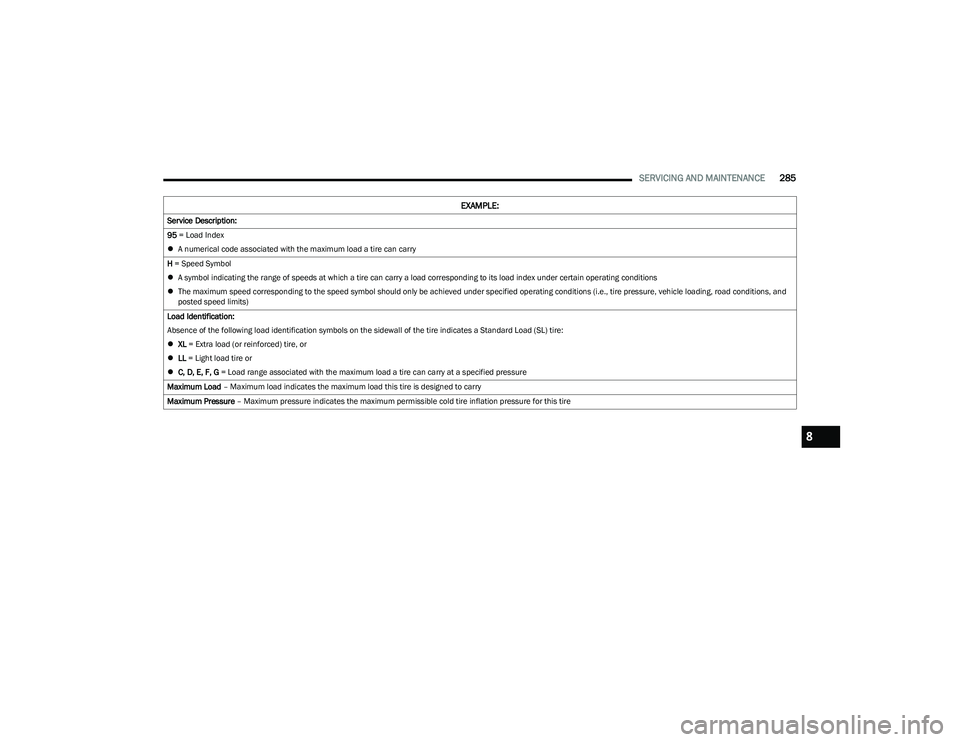

Service Description:

95 = Load Index

A numerical code associated with the maximum load a tire can carry

H = Speed Symbol

A symbol indicating the range of speeds at which a tire can carry a load corresponding to its load index under certain operating conditions

The maximum speed corresponding to the speed symbol should only be achieved under specified operating conditions (i.e., tire pressure, vehicle loading, road conditions, and

posted speed limits)

Load Identification:

Absence of the following load identification symbols on the sidewall of the tire indicates a Standard Load (SL) tire:

XL = Extra load (or reinforced) tire, or

LL = Light load tire or

C, D, E, F, G = Load range associated with the maximum load a tire can carry at a specified pressure

Maximum Load – Maximum load indicates the maximum load this tire is designed to carry

Maximum Pressure – Maximum pressure indicates the maximum permissible cold tire inflation pressure for this tire

EXAMPLE:

8

23_RUP_OM_EN_USC_t.book Page 285