capacity CHRYSLER PACIFICA HYBRID 2022 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA HYBRID, Model: CHRYSLER PACIFICA HYBRID 2022Pages: 384, PDF Size: 23.92 MB

Page 108 of 384

106GETTING TO KNOW YOUR VEHICLE

STOW ‘N PLACE ROOF RACK — IF EQUIPPED

The crossbars and side rails are designed to carry

weight on vehicles equipped with a luggage rack.

The load must not exceed 150 lb (68 kg), and

should be uniformly distributed over the luggage

rack crossbars.

The crossbars on your vehicle are delivered stowed

within the roof rack side rails. Crossbars should

always be used whenever cargo is placed on the

roof rack. Check the straps frequently to be sure

that the load remains securely attached.

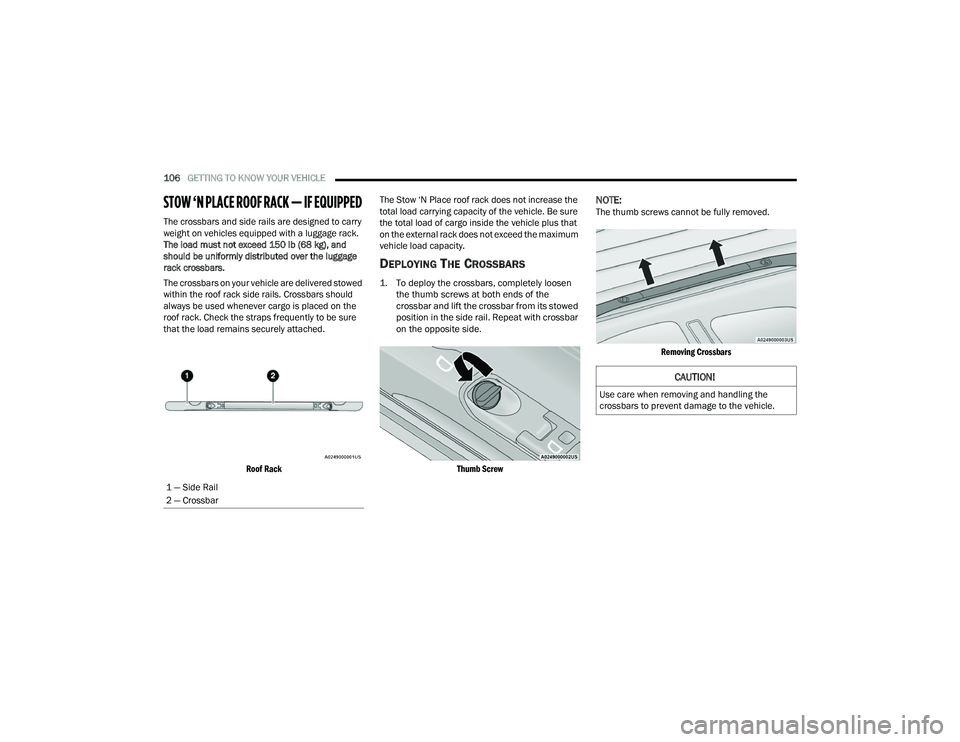

Roof Rack

The Stow ‘N Place roof rack does not increase the

total load carrying capacity of the vehicle. Be sure

the total load of cargo inside the vehicle plus that

on the external rack does not exceed the maximum

vehicle load capacity.

DEPLOYING THE CROSSBARS

1. To deploy the crossbars, completely loosen

the thumb screws at both ends of the

crossbar and lift the crossbar from its stowed

position in the side rail. Repeat with crossbar

on the opposite side.

Thumb Screw

NOTE:The thumb screws cannot be fully removed.

Removing Crossbars

1 — Side Rail

2 — Crossbar

CAUTION!

Use care when removing and handling the

crossbars to prevent damage to the vehicle.

22_RUP_OM_EN_USC_t.book Page 106

Page 111 of 384

GETTING TO KNOW YOUR VEHICLE109

(Continued)

NOTE:

To help control wind noise, stow the crossbars in

the side rails when they are not in use.

If any metallic object is placed over the satellite

radio antenna (if equipped), you may experience

interruption of satellite radio reception.

WARNING!

Cargo must be securely tied down before driving

your vehicle. Improperly secured loads can fly off

the vehicle, particularly at high speeds, resulting

in personal injury or property damage. Follow

the roof rack cautions when carrying cargo on

your roof rack.

CAUTION!

To prevent damage to the roof of your vehicle,

DO NOT carry any loads on the roof rack

without the crossbars deployed. The load

should be secured and placed on top of the

crossbars, not directly on the roof. If it is

necessary to place the load on the roof, place

a blanket or other protective layer between

the load and the roof surface.

To avoid damage to the roof rack and vehicle,

do not exceed the maximum roof rack load

capacity of 150 lb (68 kg). Always distribute

heavy loads as evenly as possible and secure

the load appropriately.

Load should always be secured to cross bars

first, with tie down loops used as additional

securing points if needed. Tie loops are

intended as supplementary tie down points

only. Do not use ratcheting mechanisms with

the tie loops. Check the straps and thumb

wheels frequently to be sure that the load

remains securely attached.

Long loads that extend over the windshield,

such as wood panels or surfboards, or loads

with large frontal area should be secured to

both the front and rear of the vehicle.

Travel at reduced speeds and turn corners

carefully when carrying large or heavy loads

on the roof rack. Wind forces, due to natural

causes or nearby truck traffic, can add sudden

upward lift to a load. This is especially true on

large flat loads and may result in damage to

the cargo or your vehicle.

CAUTION!

2

22_RUP_OM_EN_USC_t.book Page 109

Page 124 of 384

122GETTING TO KNOW YOUR INSTRUMENT PANEL

Brake Warning Light

This warning light monitors various brake

functions, including brake fluid level and

parking brake application. If the brake

light turns on it may indicate that the

parking brake is applied, that the brake fluid level

is low, or that there is a problem with the Anti-Lock

Brake System reservoir.

If the light remains on when the parking brake has

been disengaged, and the fluid level is at the full

mark on the master cylinder reservoir, it indicates

a possible brake hydraulic system malfunction or

that a problem with the Brake Booster has been

detected by the Anti-Lock Brake System (ABS) /

Electronic Stability Control (ESC) system. In this

case, the light will remain on until the condition has

been corrected. If the problem is related to the

brake booster, the ABS pump will run when

applying the brake, and a brake pedal pulsation

may be felt during each stop.

The dual brake system provides a reserve braking

capacity in the event of a failure to a portion of the

hydraulic system. A leak in either half of the dual

brake system is indicated by the Brake Warning

Light, which will turn on when the brake fluid level

in the master cylinder has dropped below a

specified level.

The light will remain on until the cause is corrected.

NOTE:The light may flash momentarily during sharp

cornering maneuvers, which change fluid level

conditions. The vehicle should have service

performed, and the brake fluid level checked.

If brake failure is indicated, immediate repair is

necessary.

Vehicles equipped with the Anti-Lock Brake System

(ABS) are also equipped with Electronic Brake

Force Distribution (EBD). In the event of an EBD

failure, the Brake Warning Light will turn on along

with the ABS Light. Immediate repair to the ABS

system is required.

Operation of the Brake Warning Light can be

checked by turning the ignition switch from the OFF

position to the ON/RUN position. The light should

illuminate for approximately two seconds. The light

should then turn off unless the parking brake is

applied or a brake fault is detected. If the light does

not illuminate, have the light inspected by an

authorized dealer. The light also will turn on when the parking brake

is applied with the ignition switch in the ON/RUN

position.

NOTE:This light shows only that the parking brake is

applied. It does not show the degree of brake appli

-

cation.

Door Open Warning Light — If Equipped

This warning light will illuminate when a

door is ajar/open and not fully closed.

This indicator will reflect which doors

are open.

NOTE:If the vehicle is moving, there will also be a single

chime.

Electric Power Steering Fault Warning

Light

This warning light will turn on when

there's a fault with the Electric Power

Steering (EPS) system Ú page 143.

WARNING!

Driving a vehicle with the red brake light on is

dangerous. Part of the brake system may have

failed. It will take longer to stop the vehicle. You

could have a collision. Have the vehicle checked

immediately.

WARNING!

Continued operation with reduced assist could

pose a safety risk to yourself and others. Service

should be obtained as soon as possible.

22_RUP_OM_EN_USC_t.book Page 122

Page 154 of 384

152STARTING AND OPERATING

When ACC Is Active

When you use the SET (-) button to decelerate, if

the engine’s braking power does not slow the

vehicle sufficiently to reach the set speed, the

brake system will automatically slow the

vehicle.

The ACC system decelerates the vehicle to a full

stop when following the vehicle in front. If your

vehicle follows the vehicle in front to a standstill,

after two seconds the driver will either have to

push the RES (resume) button, or apply the

accelerator pedal to reengage the ACC to the

existing set speed.

The ACC system maintains set speed when

driving uphill and downhill. However, a slight

speed change on moderate hills is normal. In

addition, downshifting may occur while climbing

uphill or descending downhill. This is normal

operation and necessary to maintain set speed.

When driving uphill and downhill, the ACC

system will cancel if the braking temperature

exceeds normal range (overheated).

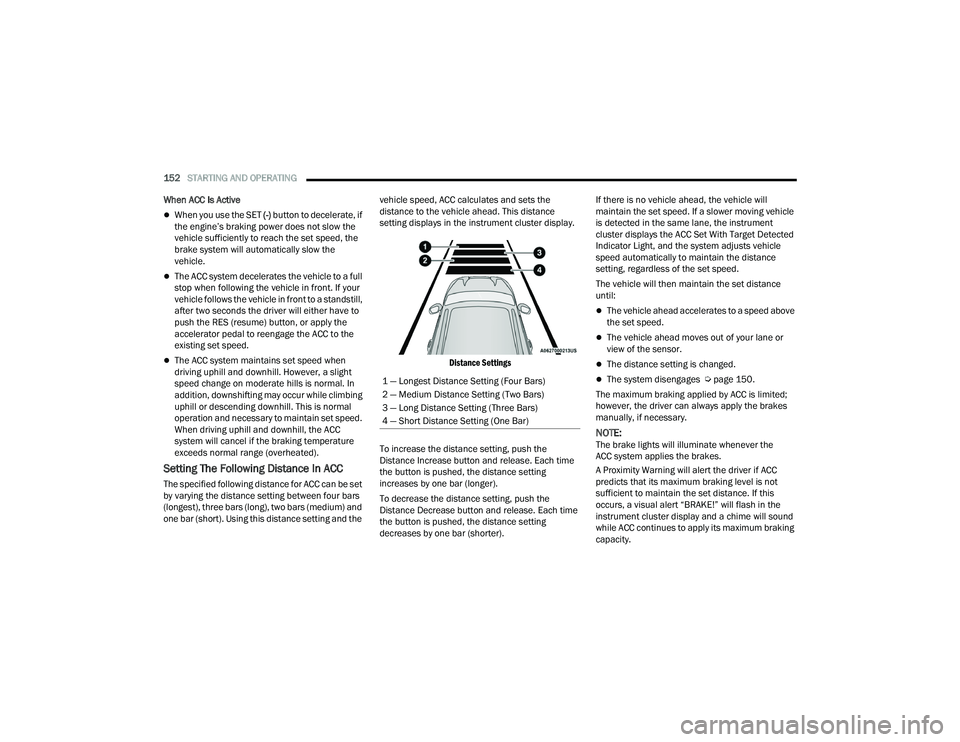

Setting The Following Distance In ACC

The specified following distance for ACC can be set

by varying the distance setting between four bars

(longest), three bars (long), two bars (medium) and

one bar (short). Using this distance setting and the vehicle speed, ACC calculates and sets the

distance to the vehicle ahead. This distance

setting displays in the instrument cluster display.

Distance Settings

To increase the distance setting, push the

Distance Increase button and release. Each time

the button is pushed, the distance setting

increases by one bar (longer).

To decrease the distance setting, push the

Distance Decrease button and release. Each time

the button is pushed, the distance setting

decreases by one bar (shorter). If there is no vehicle ahead, the vehicle will

maintain the set speed. If a slower moving vehicle

is detected in the same lane, the instrument

cluster displays the ACC Set With Target Detected

Indicator Light, and the system adjusts vehicle

speed automatically to maintain the distance

setting, regardless of the set speed.

The vehicle will then maintain the set distance

until:

The vehicle ahead accelerates to a speed above

the set speed.

The vehicle ahead moves out of your lane or

view of the sensor.

The distance setting is changed.

The system disengages Ú

page 150.

The maximum braking applied by ACC is limited;

however, the driver can always apply the brakes

manually, if necessary.

NOTE:The brake lights will illuminate whenever the

ACC system applies the brakes.

A Proximity Warning will alert the driver if ACC

predicts that its maximum braking level is not

sufficient to maintain the set distance. If this

occurs, a visual alert “BRAKE!” will flash in the

instrument cluster display and a chime will sound

while ACC continues to apply its maximum braking

capacity.

1 — Longest Distance Setting (Four Bars)

2 — Medium Distance Setting (Two Bars)

3 — Long Distance Setting (Three Bars)

4 — Short Distance Setting (One Bar)

22_RUP_OM_EN_USC_t.book Page 152

Page 158 of 384

156STARTING AND OPERATING

NARROW VEHICLES

Some narrow vehicles traveling near the outer

edges of the lane or edging into the lane are not

detected until they have moved fully into the lane.

There may not be sufficient distance to the vehicle

ahead.

Narrow Vehicle Example

STATIONARY OBJECTS AND VEHICLES

ACC does not react to stationary objects or

vehicles. For example, ACC will not react in

situations where the vehicle you are following exits

your lane and the vehicle ahead is stopped in your

lane. It will consider this stopped vehicle a

stationary object as it did not previously detect

movement from it. Always be attentive and ready

to apply the brakes if necessary.

Stationary Object And Stationary Vehicle Example

PARKSENSE FRONT/REAR PARK ASSIST

SYSTEM — IF EQUIPPED

The ParkSense Park Assist system provides visual

and audible indications of the distance between

the rear, and if equipped, the front fascia/bumper

and a detected obstacle when backing up or

moving forward (e.g. during a parking maneuver).

The vehicle brakes may be automatically applied

and released when performing a reverse parking

maneuver if the system detects a possible collision

with an obstacle.

NOTE:

The driver can override the automatic braking

function by pressing the gas pedal over 90% of

its capacity during the braking event, turning

ParkSense off via the ParkSense switch, or

changing the gear while the automatic brakes

are being applied.

Automatic brakes will not be available if ESC is

not available.

Automatic brakes will not be available if there is

a faulted condition detected with the ParkSense

Park Assist system or the Braking System

Module.

22_RUP_OM_EN_USC_t.book Page 156

Page 175 of 384

STARTING AND OPERATING173

6. Remove the fuel filler nozzle.

7. To close the fuel filler door, push the center-rear edge (3 o’clock position) of the fuel

filler door and then release. The fuel filler door

will latch closed.

NOTE:In certain cold conditions, ice may prevent the fuel

filler door from opening. If this occurs, lightly push

on the fuel filler door around the perimeter to

break the ice buildup.

VEHICLE LOADING

CERTIFICATION LABEL

As required by National Highway Traffic Safety

Administration regulations, your vehicle has a

certification label affixed to the driver's side door or

pillar.

This label contains the month and year of

manufacture, Gross Vehicle Weight Rating

(GVWR), front and rear Gross Axle Weight Rating

(GAWR), and Vehicle Identification Number (VIN). A

Month-Day-Hour (MDH) number is included on this

label and indicates the Month, Day and Hour of

manufacture. The bar code that appears on the

bottom of the label is your VIN.

Gross Vehicle Weight Rating (GVWR)

The GVWR is the total permissible weight of your

vehicle including driver, passengers, vehicle,

options and cargo. The label also specifies

maximum capacities of front and rear GAWR.

Total load must be limited so GVWR and front and

rear GAWR are not exceeded.

Payload

The payload of a vehicle is defined as the allowable

load weight a truck can carry, including the weight

of the driver, all passengers, options and cargo.

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum permissible load on the

front and rear axles. The load must be distributed

in the cargo area so that the GAWR of each axle is

not exceeded.

Each axle GAWR is determined by the components

in the system with the lowest load carrying capacity

(axle, springs, tires or wheels). Heavier axles or

suspension components sometimes specified by

purchasers for increased durability does not

necessarily increase the vehicle's GVWR.

Tire Size

The tire size on the Vehicle Certification Label

represents the actual tire size on your vehicle.

Replacement tires must be equal to the load

capacity of this tire size.

Rim Size

This is the rim size that is appropriate for the tire

size listed.

Inflation Pressure

This is the cold tire inflation pressure for your

vehicle for all loading conditions up to full GAWR.

Curb Weight

The curb weight of a vehicle is defined as the total

weight of the vehicle with all fluids, including

vehicle fuel, at full capacity conditions, and with no

occupants or cargo loaded into the vehicle. The

front and rear curb weight values are determined

by weighing your vehicle on a commercial scale

before any occupants or cargo are added.

4

22_RUP_OM_EN_USC_t.book Page 173

Page 177 of 384

STARTING AND OPERATING175

Gross Axle Weight Rating (GAWR)

The GAWR is the maximum capacity of the front

and rear axles. Distribute the load over the front

and rear axles evenly. Make sure that you do not

exceed either front or rear GAWR Ú page 173.

Tongue Weight (TW)

The TW is the downward force exerted on the hitch

ball by the trailer. You must consider this as part of

the load on your vehicle.

Trailer Frontal Area

The Frontal Area is the maximum height multiplied

by the maximum width of the front of a trailer.

Trailer Sway Control (TSC)

The TSC can be a mechanical telescoping link that

can be installed between the hitch receiver and the

trailer tongue that typically provides adjustable

friction associated with the telescoping motion to

dampen any unwanted trailer swaying motions

while traveling.

The electronic TSC (if equipped), recognizes a

swaying trailer and automatically applies individual

wheel brakes and/or reduces engine power to

attempt to eliminate the trailer sway.

Weight-Carrying Hitch

A Weight-Carrying Hitch supports the trailer tongue

weight, just as if it were luggage located at a hitch

ball or some other connecting point of the vehicle.

These kinds of hitches are commonly used to tow

small and medium sized trailers.

Weight-Distributing Hitch

A weight-distributing hitch works by applying

leverage through spring (load) bars. They are

typically used for heavier loads to distribute trailer

tongue weight to the tow vehicle's front axle and

the trailer axle(s). When used in accordance with

the manufacturer’s directions, it provides for a

more level ride, offering more consistent steering

and brake control thereby enhancing towing safety. The addition of a friction/hydraulic sway

control also dampens sway caused by traffic and

crosswinds and contributes positively to tow

vehicle and trailer stability. TSC and a

weight-distributing (load equalizing) hitch are

recommended for heavier TW and may be required

depending on vehicle and trailer configuration/

loading to comply with GAWR requirements.

WARNING!

It is important that you do not exceed the

maximum front or rear GAWR. A dangerous

driving condition can result if either rating is

exceeded. You could lose control of the vehicle

and have a collision.

WARNING!

An improperly adjusted weight-distributing

hitch system may reduce handling, stability,

braking performance, and could result in a

collision.

Weight-distributing systems may not be

compatible with surge brake couplers. Consult

with your hitch and trailer manufacturer or a

reputable Recreational Vehicle dealer for

additional information.

4

22_RUP_OM_EN_USC_t.book Page 175

Page 180 of 384

178STARTING AND OPERATING

VEHICLE LOADING CHART

Follow these steps to determine the total weight the vehicle can carry:

1. Determine the cargo capacity of your vehicle.

Load Capacity = GVWR – Curb (weight of vehicle, full fluids, no occupants).

2. Determine occupant count.

For calculation purposes, average weight of an occupant is 150 lb (68 kg).

EXAMPLE:

GVWR = 6,005 lb (2,723 kg)

CURB = 4,500 lb (2,041 kg)

Load Capacity = GVWR – CURB = 6,005 lb (2,723 kg) - 4,500 lb (2,041 kg) = 1,505 lb (682 kg)

4 Occupants (at 150 lb [68 kg]) + Max Trailer =

1,505 lb (682 kg) – 600 lb (272 kg) (4 x 150 lb [68 kg]) – 360 lb (163 kg) (10% of 3,600 lb [1,632 kg]) = 545 lb (247 kg) of cargo in vehicle

22_RUP_OM_EN_USC_t.book Page 178

Page 183 of 384

STARTING AND OPERATING181

(Continued)

Towing Requirements — Tires

Do not attempt to tow a trailer while using a

compact spare tire.

Do not drive more than 50 mph (80 km/h) when

towing while using a full size spare tire.

Proper tire inflation pressures are essential to

the safe and satisfactory operation of your

vehicle.

Check the trailer tires for proper tire inflation

pressures before trailer usage.

Check for signs of tire wear or visible tire

damage before towing a trailer.

Replacing tires with a higher load carrying

capacity will not increase the vehicle's GVWR

and GAWR limits.

For further information Ú page 346.

WARNING!

Make certain that the load is secured in the

trailer and will not shift during travel. When

trailering cargo that is not fully secured,

dynamic load shifts can occur that may be

difficult for the driver to control. You could lose

control of your vehicle and have a collision.

When hauling cargo or towing a trailer, do not

overload your vehicle or trailer. Overloading

can cause a loss of control, poor performance

or damage to brakes, axle, engine, transmis -

sion, steering, suspension, chassis structure

or tires.

Safety chains must always be used between

your vehicle and trailer. Always connect the

chains to the hook retainers of the vehicle

hitch. Cross the chains under the trailer

tongue and allow enough slack for turning

corners.

Vehicles with trailers should not be parked on

a grade. When parking, apply the parking

brake on the tow vehicle. Put the tow vehicle

transmission in PARK. For four-wheel drive

vehicles, make sure the transfer case is not in

NEUTRAL. Always, block or "chock" the trailer

wheels.

GCWR must not be exceeded.

Total weight must be distributed between the

tow vehicle and the trailer such that the

following four ratings are not exceeded :

GVWR

GTW

GAWR

Tongue weight rating for the trailer hitch

utilized.

WARNING!

4

22_RUP_OM_EN_USC_t.book Page 181

Page 184 of 384

182STARTING AND OPERATING

Towing Requirements — Trailer Brakes

Do not interconnect the hydraulic brake system

or vacuum system of your vehicle with that of

the trailer. This could cause inadequate braking

and possible personal injury.

An electronically actuated trailer brake

controller is required when towing a trailer with

electronically actuated brakes. When towing a

trailer equipped with a hydraulic surge actuated

brake system, an electronic brake controller is

not required.

Trailer brakes are recommended for trailers

over 1,000 lb (453 kg) and required for trailers

in excess of 2,000 lb (907 kg).

Towing Requirements — Trailer Lights And

Wiring

Whenever you pull a trailer, regardless of the trailer

size, stop lights and turn signals on the trailer are

required for motoring safety.

The Trailer Tow Package may include a four and

seven-pin wiring harness. Use a factory approved

trailer harness and connector.

NOTE:Do not cut or splice wiring into the vehicle’s wiring

harness.

The electrical connections are all complete to the

vehicle but you must mate the harness to a trailer

connector. Refer to the following illustrations.

NOTE:

Disconnect trailer wiring connector from the

vehicle before launching a boat (or any other

device plugged into vehicle’s electrical connect)

into water.

Be sure to reconnect once clear from water

area.

WARNING!

Do not connect trailer brakes to your vehicle's

hydraulic brake lines. It can overload your

brake system and cause it to fail. You might

not have brakes when you need them and

could have an accident.

Towing any trailer will increase your stopping

distance. When towing, you should allow for

additional space between your vehicle and the

vehicle in front of you. Failure to do so could

result in an accident.

CAUTION!

If the trailer weighs more than 1,000 lb (453 kg)

loaded, it should have its own brakes and they

should be of adequate capacity. Failure to do

this could lead to accelerated brake lining wear,

higher brake pedal effort, and longer stopping

distances.

22_RUP_OM_EN_USC_t.book Page 182