wheel torque CHRYSLER PACIFICA HYBRID 2022 Owners Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2022, Model line: PACIFICA HYBRID, Model: CHRYSLER PACIFICA HYBRID 2022Pages: 384, PDF Size: 23.92 MB

Page 9 of 384

7

JUMP STARTING................................................... 300 Preparations For Jump Start......................... 301Jump Starting Procedure .............................. 301

REFUELING IN EMERGENCY –

IF EQUIPPED ......................................................... 302

IF YOUR ENGINE OVERHEATS ............................ 303

MANUAL PARK RELEASE .................................. 304

FREEING A STUCK VEHICLE .............................. 305

TOWING A DISABLED VEHICLE .......................... 306

All Wheel Drive (AWD) Models ...................... 308

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .................................................................. 308

EVENT DATA RECORDER (EDR) ......................... 308

SERVICING AND MAINTENANCE

SCHEDULED SERVICING ..................................... 309

Maintenance Plan ......................................... 310

ENGINE COMPARTMENT .................................... 313

3.6L Engine.................................................... 313

Checking Oil Level ......................................... 314

Adding Washer Fluid .................................... 314

Maintenance-Free Battery ........................... 314

Pressure Washing ......................................... 315 VEHICLE MAINTENANCE..................................... 315

Engine Oil ...................................................... 315

Engine Oil Filter ............................................. 316Engine Air Cleaner Filter ............................... 316

Accessory Drive Belt Inspection ................... 317Air Conditioner Maintenance........................ 317

Body Lubrication ........................................... 320Windshield Wiper Blades.............................. 320Exhaust System ............................................ 323

Cooling System .............................................. 324

Brake System ............................................... 327

Automatic Transmission .............................. 328Fuses.............................................................. 329

Bulb Replacement......................................... 337

TIRES ................................................................... 339

Tire Safety Information ................................. 339

Tires — General Information ......................... 346

Tire Types....................................................... 350

Spare Tires — If Equipped ............................ 350

Wheel And Wheel Trim Care ........................ 352

Snow Traction Devices ................................. 353

Tire Rotation Recommendations ................. 355 DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................... 355

Treadwear...................................................... 356

Traction Grades ............................................. 356Temperature Grades..................................... 356

STORING THE VEHICLE ....................................... 357

BODYWORK .......................................................... 357

Protection From Atmospheric Agents ......... 357

Body And Underbody Maintenance ............. 357

Preserving The Bodywork ............................. 357

INTERIORS ........................................................... 358

Seats And Fabric Parts ................................. 358

Plastic And Coated Parts .............................. 359

Leather Surfaces........................................... 359

Glass Surfaces ............................................. 359TECHNICAL SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER

(VIN) ....................................................................... 360

BRAKE SYSTEM ................................................... 360

WHEEL AND TIRE TORQUE

SPECIFICATIONS .................................................. 360Torque Specifications ................................... 360

22_RUP_OM_EN_USC_t.book Page 7

Page 145 of 384

STARTING AND OPERATING143

ALL-WHEEL DRIVE (AWD) — IF EQUIPPED

This feature provides on-demand All-Wheel Drive

(AWD). The system is automatic with no driver

inputs or additional driving skills required. Under

normal driving conditions, the front wheels provide

most of the traction. If the front wheels begin to

lose traction, power is shifted automatically to the

rear wheels. The greater the front wheel traction

loss, the greater the power transfer to the rear

wheels.

Additionally, on dry pavement under heavy throttle

input (where one may have no wheel spin), torque

will be sent to the rear in a preemptive effort to

improve vehicle launch and performance

characteristics.

ACTIVE NOISE CANCELLATION

Your vehicle is equipped with an Active Noise

Cancellation system. This system is designed to

address exhaust and engine noise. The system

relies on four microphones embedded in the

headliner, which monitor exhaust and engine noise, and assists an onboard frequency

generator, which creates counteracting sound

waves in the audio system’s speakers. This helps

keep the vehicle quiet at idle and during drive.

POWER STEERING

The electric power steering system will provide

increased vehicle response and ease of

maneuverability. The power steering system

adapts to different driving conditions.

If the Steering icon is displayed and the “POWER

STEERING SYSTEM OVER TEMP” message is

displayed on the instrument cluster screen, this

indicates an over temperature condition in the

power steering system. Once driving conditions are

safe, pull over and let the vehicle idle for a few

moments until the icon and message turn off

Ú

page 121.

If the “SERVICE POWER STEERING" or

"POWER STEERING ASSIST OFF -

SERVICE SYSTEM” message and a

steering wheel icon are displayed on the

instrument cluster screen, it indicates that the vehicle needs to be taken to an authorized dealer

for service. It is likely the vehicle has lost power

steering assistance Ú

page 121.

NOTE:

Even if the power steering assistance is no

longer operational, it is still possible to steer

the vehicle. Under these conditions there will be

a substantial increase in steering effort,

especially at low speeds and during parking

maneuvers.

The power steering system is fully electric; it

requires no power steering fluid.

If the condition persists, see an authorized

dealer for service.

STOP/START SYSTEM — IF EQUIPPED

The Stop/Start function is developed to reduce

fuel consumption. The system will stop the engine

automatically during a vehicle stop if the required

conditions are met. Releasing the brake pedal,

pressing the accelerator pedal or shifting out of

DRIVE (D) will automatically re-start the engine.

This vehicle has been upgraded with a heavy-duty

starter, enhanced battery, and other upgraded

engine parts to handle the additional engine starts.CAUTION!

All wheels must have the same size and type

tires. Unequal tire sizes must not be used.

Unequal tire size may cause premature wear of

the driveline components.

WARNING!

Continued operation with reduced assist could

pose a safety risk to yourself and others. Service

should be obtained as soon as possible.

4

22_RUP_OM_EN_USC_t.book Page 143

Page 168 of 384

166STARTING AND OPERATING

LANESENSE — IF EQUIPPED

LANESENSE OPERATION

The LaneSense system is operational at speeds

above 37 mph (60 km/h) and below 112 mph

(180 km/h). It uses a forward-looking camera to

detect lane markings and measure vehicle

position within the lane boundaries.

When both lane markings are detected and the

driver drifts out of the lane (no turn signal applied),

the LaneSense system provides a haptic warning

in the form of torque applied to the steering wheel,

as well as a visual warning in the instrument

cluster display, to prompt the driver to remain

within the lane boundaries.

The driver may manually override the haptic

warning by applying force to the steering wheel at

any time.

When only a single lane marking is detected and

the driver unintentionally drifts across that lane

marking (no turn signal applied), the LaneSense

system provides a visual warning through the

instrument cluster display to prompt the driver to

remain within the lane. When only a single lane

marking is detected, a haptic or a torque warning

will not be provided.

NOTE:When operating conditions have been met, the

LaneSense system will monitor if the driver’s

hands are on the steering wheel and provide an

audible and visual warning to the driver when the

driver’s hands are not detected on the steering

wheel. The system will cancel if the driver does not

return their hands to the wheel.

TURNING LANESENSE ON OR OFF

The LaneSense button is located on the

switch panel below the Uconnect display.

To turn the LaneSense system on, push the

LaneSense button (LED turns off). A “LaneSense

On” message is shown in the instrument cluster

display.

To turn the LaneSense system off, push the

LaneSense button again (LED turns on).

NOTE:The LaneSense system will retain the last system

state on or off from the last ignition cycle when the

ignition is changed to the ON/RUN position.

LANESENSE WARNING MESSAGE

The LaneSense system will indicate the current

lane drift condition through the instrument cluster

display.

When the LaneSense system is on, the lane lines

are gray when both of the lane boundaries have

not been detected and the LaneSense telltale

is solid white.

System ON (Gray Lines) With White Telltale

22_RUP_OM_EN_USC_t.book Page 166

Page 169 of 384

STARTING AND OPERATING167

Left Lane Departure — Only Left Lane Detected

When the LaneSense system is on, the Lane -

Sense Telltale is solid white only when the

left lane marking has been detected and the

system is ready to provide visual warnings in the

instrument cluster display if an unintentional

lane departure occurs on the left side.

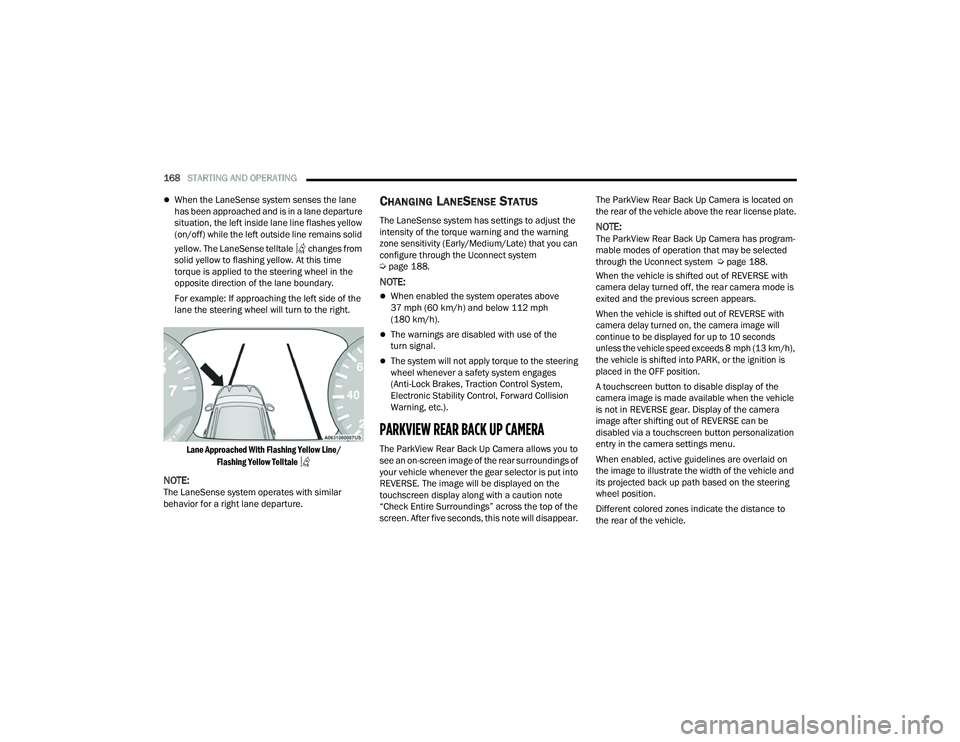

When the LaneSense system senses the lane

has been approached and is in a lane departure

situation, the visual warning in the instrument

cluster display will show the left inside lane line

flashing yellow (on/off), while the outside lane

line on the left of the display will remain solid

yellow. The LaneSense telltale changes from

solid white to flashing yellow.

Lane Approached With Flashing Yellow Line/ Flashing Yellow Telltale

NOTE:The LaneSense system operates with similar

behavior for a right lane departure when only the

right lane marking has been detected.

Left Lane Departure — Both Lane Lines Detected

When the LaneSense system is on, the lane

lines turn from gray to white. The LaneSense

telltale is solid green when both lane mark -

ings have been detected and the system is

“armed” to provide visual warnings in the instru -

ment cluster display and a torque warning in the

steering wheel if an unintentional lane depar -

ture occurs.

Lanes Sensed (White Lines) With Green Telltale

When the LaneSense system senses a lane drift

situation, the left inside and outside lane lines

turn solid yellow. The LaneSense telltale

changes from solid green to solid yellow. At this

time torque is applied to the steering wheel in

the opposite direction of the lane boundary.

For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Drift With Solid Yellow Line/Solid Yellow Telltale

4

22_RUP_OM_EN_USC_t.book Page 167

Page 170 of 384

168STARTING AND OPERATING

When the LaneSense system senses the lane

has been approached and is in a lane departure

situation, the left inside lane line flashes yellow

(on/off) while the left outside line remains solid

yellow. The LaneSense telltale changes from

solid yellow to flashing yellow. At this time

torque is applied to the steering wheel in the

opposite direction of the lane boundary.

For example: If approaching the left side of the

lane the steering wheel will turn to the right.

Lane Approached With Flashing Yellow Line/ Flashing Yellow Telltale

NOTE:The LaneSense system operates with similar

behavior for a right lane departure.

CHANGING LANESENSE STATUS

The LaneSense system has settings to adjust the

intensity of the torque warning and the warning

zone sensitivity (Early/Medium/Late) that you can

configure through the Uconnect system

Úpage 188.

NOTE:

When enabled the system operates above

37 mph (60 km/h) and below 112 mph

(180 km/h).

The warnings are disabled with use of the

turn signal.

The system will not apply torque to the steering

wheel whenever a safety system engages

(Anti-Lock Brakes, Traction Control System,

Electronic Stability Control, Forward Collision

Warning, etc.).

PARKVIEW REAR BACK UP CAMERA

The ParkView Rear Back Up Camera allows you to

see an on-screen image of the rear surroundings of

your vehicle whenever the gear selector is put into

REVERSE. The image will be displayed on the

touchscreen display along with a caution note

“Check Entire Surroundings” across the top of the

screen. After five seconds, this note will disappear. The ParkView Rear Back Up Camera is located on

the rear of the vehicle above the rear license plate.

NOTE:The ParkView Rear Back Up Camera has program

-

mable modes of operation that may be selected

through the Uconnect system Ú page 188.

When the vehicle is shifted out of REVERSE with

camera delay turned off, the rear camera mode is

exited and the previous screen appears.

When the vehicle is shifted out of REVERSE with

camera delay turned on, the camera image will

continue to be displayed for up to 10 seconds

unless the vehicle speed exceeds 8 mph (13 km/h),

the vehicle is shifted into PARK, or the ignition is

placed in the OFF position.

A touchscreen button to disable display of the

camera image is made available when the vehicle

is not in REVERSE gear. Display of the camera

image after shifting out of REVERSE can be

disabled via a touchscreen button personalization

entry in the camera settings menu.

When enabled, active guidelines are overlaid on

the image to illustrate the width of the vehicle and

its projected back up path based on the steering

wheel position.

Different colored zones indicate the distance to

the rear of the vehicle.

22_RUP_OM_EN_USC_t.book Page 168

Page 227 of 384

SAFETY225

Dynamic Steering Torque (DST)

DST is a feature of the ESC and Electric Power

Steering (EPS) modules that provides torque at the

steering wheel for certain driving conditions in

which the ESC module is detecting vehicle

instability. The torque that the steering wheel

receives is only meant to help the driver

realize optimal steering behavior in order to

reach/maintain vehicle stability. The only

notification the driver receives that the feature is

active, is the torque applied to the steering wheel.

NOTE:The DST feature is only meant to help the driver

realize the correct course of action through small

torques on the steering wheel, which means the

effectiveness of the DST feature is highly

dependent on the driver’s sensitivity and overall

reaction to the applied torque. It is very important

to realize that this feature will not steer the vehicle,

meaning the driver is still responsible for steering

the vehicle.

Electronic Brake Force Distribution (EBD)

The EBD function manages the distribution of the

braking torque between the front and rear axles by

limiting braking pressure to the rear axle. This is

done to prevent overslip of the rear wheels to avoid

vehicle instability, and to prevent the rear axle from

entering the Anti-Lock Brake System (ABS) before

the front axle.

Electronic Roll Mitigation (ERM)

ERM anticipates the potential for wheel lift by

monitoring the driver’s steering wheel input and

the speed of the vehicle. When ERM determines

that the rate of change of the steering wheel angle

and vehicle’s speed are sufficient to potentially

cause wheel lift, it then applies the appropriate

brake and may also reduce engine power to lessen

the chance that wheel lift will occur. ERM can only

reduce the chance of wheel lift occurring during

severe or evasive driving maneuvers; it cannot

prevent wheel lift due to other factors, such as

road conditions, leaving the roadway, striking

objects or other vehicles.

Electronic Stability Control (ESC)

ESC enhances directional control and stability of

the vehicle under various driving conditions. ESC

corrects for oversteering or understeering of the

vehicle by applying the brake of the appropriate

wheel(s) to assist in counteracting the above

conditions. Engine power may also be reduced to

help the vehicle maintain the desired path.

Oversteer — when the vehicle is turning more

than appropriate for the steering wheel position.

Understeer — when the vehicle is turning less

than appropriate for the steering wheel position.

ESC uses sensors in the vehicle to determine the

vehicle path intended by the driver and compares

it to the actual path of the vehicle. When the actual

path does not match the intended path, ESC

applies the brake of the appropriate wheel to

assist in counteracting the oversteer or understeer

condition.

WARNING!

Many factors, such as vehicle loading, road

conditions and driving conditions, influence the

chance that wheel lift or rollover may occur. ERM

cannot prevent all wheel lift or rollovers,

especially those that involve leaving the roadway

or striking objects or other vehicles. The

capabilities of an ERM-equipped vehicle must

never be exploited in a reckless or dangerous

manner which could jeopardize the user's safety

or the safety of others.

6

22_RUP_OM_EN_USC_t.book Page 225

Page 231 of 384

SAFETY229

If one wheel on a driven axle is spinning faster than

the other, the system will apply the brake of the

spinning wheel. This will allow more vehicle torque

to be applied to the wheel that is not spinning. BLD

may remain enabled even if TCS and the Electronic

Stability Control (ESC) are in reduced modes.

Trailer Sway Control (TSC)

TSC uses sensors in the vehicle to recognize an

excessively swaying trailer and will take the

appropriate actions to attempt to stop the sway.

Note that TSC cannot stop all trailers from swaying.

Always use caution when towing a trailer and follow

the trailer tongue weight recommendations

Ú page 174.

When TSC is functioning, the ESC Activation/

Malfunction Indicator Light will flash, the engine

power may be reduced and you may feel the

brakes being applied to individual wheels to

attempt to stop the trailer from swaying. TSC is

disabled when the ESC system is in the “Partial

Off” mode.

AUXILIARY DRIVING SYSTEMS

BLIND SPOT MONITORING (BS M) —

I

F EQUIPPED

The BSM system uses two radar sensors, located

inside the rear fascia/bumper, to detect highway

licensable vehicles (automobiles, trucks,

motorcycles, etc.) that enter the blind spot zones

from the rear/front/side of the vehicle.

Rear Detection Zones

When the vehicle is started, the BSM Warning Light

will momentarily illuminate in both outside

rearview mirrors to let the driver know that the

system is operational. The BSM system sensors

operate when the vehicle is in any forward gear

and enters standby mode when the vehicle is in

PARK (P). The BSM detection zone covers approximately one

lane width on both sides of the vehicle 12 ft

(3.7 m). The zone length starts at the outside

rearview mirror and extends approximately 10 ft

(3 m) beyond the rear fascia/bumper of the

vehicle. The BSM system monitors the detection

zones on both sides of the vehicle when the vehicle

speed reaches approximately 6 mph (10 km/h) or

higher and will alert the driver of vehicles in these

areas.

NOTE:

The BSM system DOES NOT alert the driver

about rapidly approaching vehicles that are

outside the detection zones.

The BSM system detection zone DOES NOT

change if your vehicle is towing a trailer. There

-

fore, visually verify the adjacent lane is clear for

both your vehicle and trailer before making a

lane change. If the trailer or other object

(i.e., bicycle, sports equipment) extends beyond

the side of your vehicle, this may result in false

detections. The BSM Warning Light may even

remain illuminated the entire time the vehicle is

in a forward gear.

WARNING!

If TSC activates while driving, slow the vehicle

down, stop at the nearest safe location, and

adjust the trailer load to eliminate trailer sway.

6

22_RUP_OM_EN_USC_t.book Page 229

Page 293 of 384

IN CASE OF EMERGENCY291

6. Install the inflatable spare on the vehicle, located in the rear cargo area of the vehicle.

Mounting Inflatable Spare Tire

NOTE:Do not install the wheel cover on the inflatable

spare tire.

7. Leave the vehicle on the jack and start inflating the inflatable spare after the tire has

been mounted to the vehicle. Secure the

wheel to the hub by tightening the nuts with

the wrench. After inflation, once the vehicle is

lowered you will have a second opportunity to

torque the lug nuts Ú page 360.

8. Inflate the tire to the prescribed pressure 60 psi (4.2 Bar) using the Portable Air

Compressor Ú page 293 or Tire Service Kit if

equipped Ú page 294.

9. Lower the vehicle once the inflatable Spare has reached its pressure and the

compressor-hose has been removed from the

tire valve. 10. Finish tightening the lug nuts. Push down on

the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tightened

twice Ú page 360. If in doubt about the

correct tightness, have them checked with a

torque wrench by an authorized dealer or at a

service station.

11. Lower the jack to its fully-closed position.

12. Place the deflated (flat) tire and foam tray cover assembly in the rear cargo area. Do not

stow the deflated tire in the inflatable spare

tire location. Have the full-sized tire repaired or

replaced, as soon as possible.

WARNING!

To avoid the risk of forcing the vehicle off the

jack, do not tighten the wheel nuts fully until the

vehicle has been lowered. Failure to follow this

warning may result in serious injury.

CAUTION!

Be sure to mount the inflatable spare tire with

the valve stem facing outward. The vehicle could

be damaged if the inflatable spare tire is

mounted incorrectly.

WARNING!

A loose tire or jack thrown forward in a collision

or hard stop could endanger the occupants of

the vehicle. Always stow the jack parts and the

spare tire in the places provided. Have the

deflated (flat) tire repaired or replaced

immediately.

7

22_RUP_OM_EN_USC_t.book Page 291

Page 295 of 384

IN CASE OF EMERGENCY293

5. Lower the vehicle to the ground by turning the jack handle counterclockwise.

6. Finish tightening the lug nuts. Push down on the wrench while at the end of the handle for

increased leverage. Tighten the lug nuts in a

star pattern until each nut has been tightened

twice Ú page 360. If in doubt about the

correct tightness, have them checked with a

torque wrench by an authorized dealer or at a

service station.

7. After 25 miles (40 km) check the lug nut torque with a torque wrench to ensure that all

lug nuts are properly seated against the wheel.

PORTABLE AIR COMPRESSOR —

I

F EQUIPPED

Your vehicle may be equipped with a Portable Air

Compressor. Use the Portable Air Compressor

located in the side compartment of the cargo area

to inflate the inflatable tire to 60 psi (4.2 Bar).

Portable Air Compressor

Portable Air Compressor Usage With Inflatable

Spare Tire

1. Remove the Portable Air Compressor from the storage location.

2. Raise the vehicle as described in

the Jacking Instructions within this

section. 3. Install the Inflatable Spare tire as

described in the Jack Instructions

section in this manual. Make sure

that the valve stem is located near

the ground, and then screw the air hose of the

Portable Air Compressor to the valve stem.

4. Uncoil the power plug and connect

it the vehicles 12 Volt power Outlet.

5. Always start the engine before

turning ON the Portable Air

Compressor.

6. Switch the power button ON.

7. Inflate the tire to 60 psi (4.2 Bar)

recommended as per the label on

the wheel or if the vehicle equipped

with the inflatable spare tire

pressure indicated on the Tire and Loading

information label located on the driver-side

door opening.

NOTE:If the tire is overinflated, use the deflation button

to reduce the tire air pressure.

1 — Power Plug

2 — Deflation Button

3 — Pressure Gauge

4 — Power Button

5 — Air Hose

7

22_RUP_OM_EN_USC_t.book Page 293

Page 362 of 384

360

TECHNICAL SPECIFICATIONS

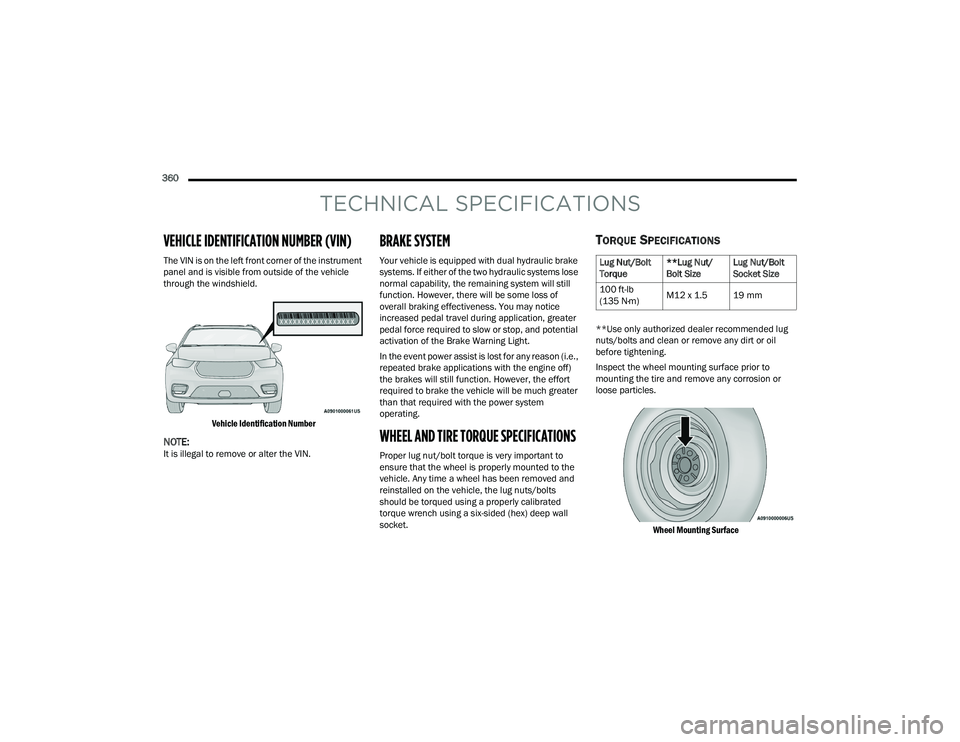

VEHICLE IDENTIFICATION NUMBER (VIN)

The VIN is on the left front corner of the instrument

panel and is visible from outside of the vehicle

through the windshield.

Vehicle Identification Number

NOTE:It is illegal to remove or alter the VIN.

BRAKE SYSTEM

Your vehicle is equipped with dual hydraulic brake

systems. If either of the two hydraulic systems lose

normal capability, the remaining system will still

function. However, there will be some loss of

overall braking effectiveness. You may notice

increased pedal travel during application, greater

pedal force required to slow or stop, and potential

activation of the Brake Warning Light.

In the event power assist is lost for any reason (i.e.,

repeated brake applications with the engine off)

the brakes will still function. However, the effort

required to brake the vehicle will be much greater

than that required with the power system

operating.

WHEEL AND TIRE TORQUE SPECIFICATIONS

Proper lug nut/bolt torque is very important to

ensure that the wheel is properly mounted to the

vehicle. Any time a wheel has been removed and

reinstalled on the vehicle, the lug nuts/bolts

should be torqued using a properly calibrated

torque wrench using a six-sided (hex) deep wall

socket.

TORQUE SPECIFICATIONS

**Use only authorized dealer recommended lug

nuts/bolts and clean or remove any dirt or oil

before tightening.

Inspect the wheel mounting surface prior to

mounting the tire and remove any corrosion or

loose particles.

Wheel Mounting Surface

Lug Nut/Bolt

Torque **Lug Nut/

Bolt SizeLug Nut/Bolt

Socket Size

100 ft-lb

(135 N·m) M12 x 1.5 19 mm

22_RUP_OM_EN_USC_t.book Page 360