tow CHRYSLER PT CRUISER 2010 1.G Owner's Manual

[x] Cancel search | Manufacturer: CHRYSLER, Model Year: 2010, Model line: PT CRUISER, Model: CHRYSLER PT CRUISER 2010 1.GPages: 60, PDF Size: 6.19 MB

Page 33 of 60

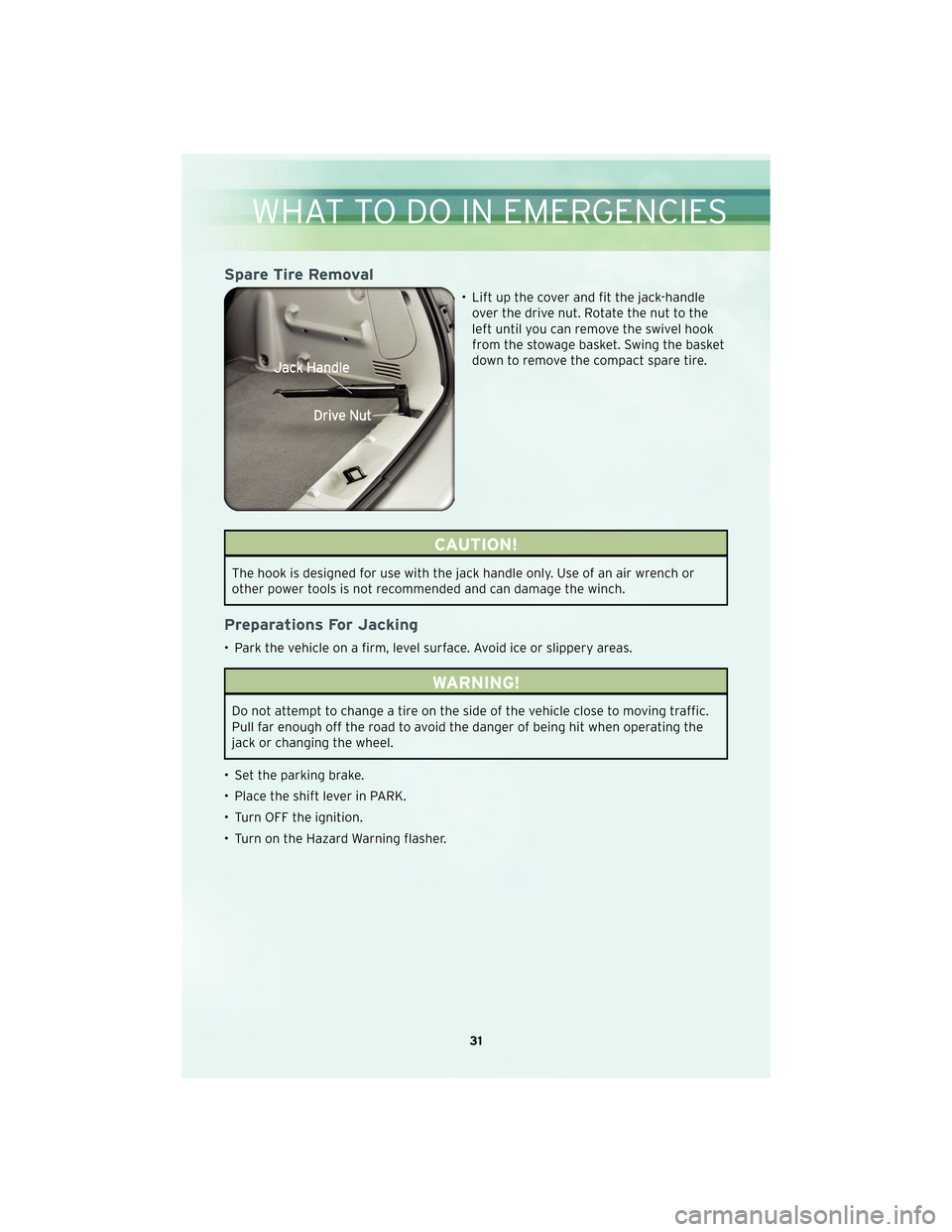

Spare Tire Removal

• Lift up the cover and fit the jack-handleover the drive nut. Rotate the nut to the

left until you can remove the swivel hook

from the stowage basket. Swing the basket

down to remove the compact spare tire.

CAUTION!

The hook is designed for use with the jack handle only. Use of an air wrench or

other power tools is not recommended and can damage the winch.

Preparations For Jacking

• Park the vehicle on a firm, level surface. Avoid ice or slippery areas.

WARNING!

Do not attempt to change a tire on the side of the vehicle close to moving traffic.

Pull far enough off the road to avoid the danger of being hit when operating the

jack or changing the wheel.

• Set the parking brake.

• Place the shift lever in PARK.

• Turn OFF the ignition.

• Turn on the Hazard Warning flasher.

31

WHAT TO DO IN EMERGENCIES

Page 34 of 60

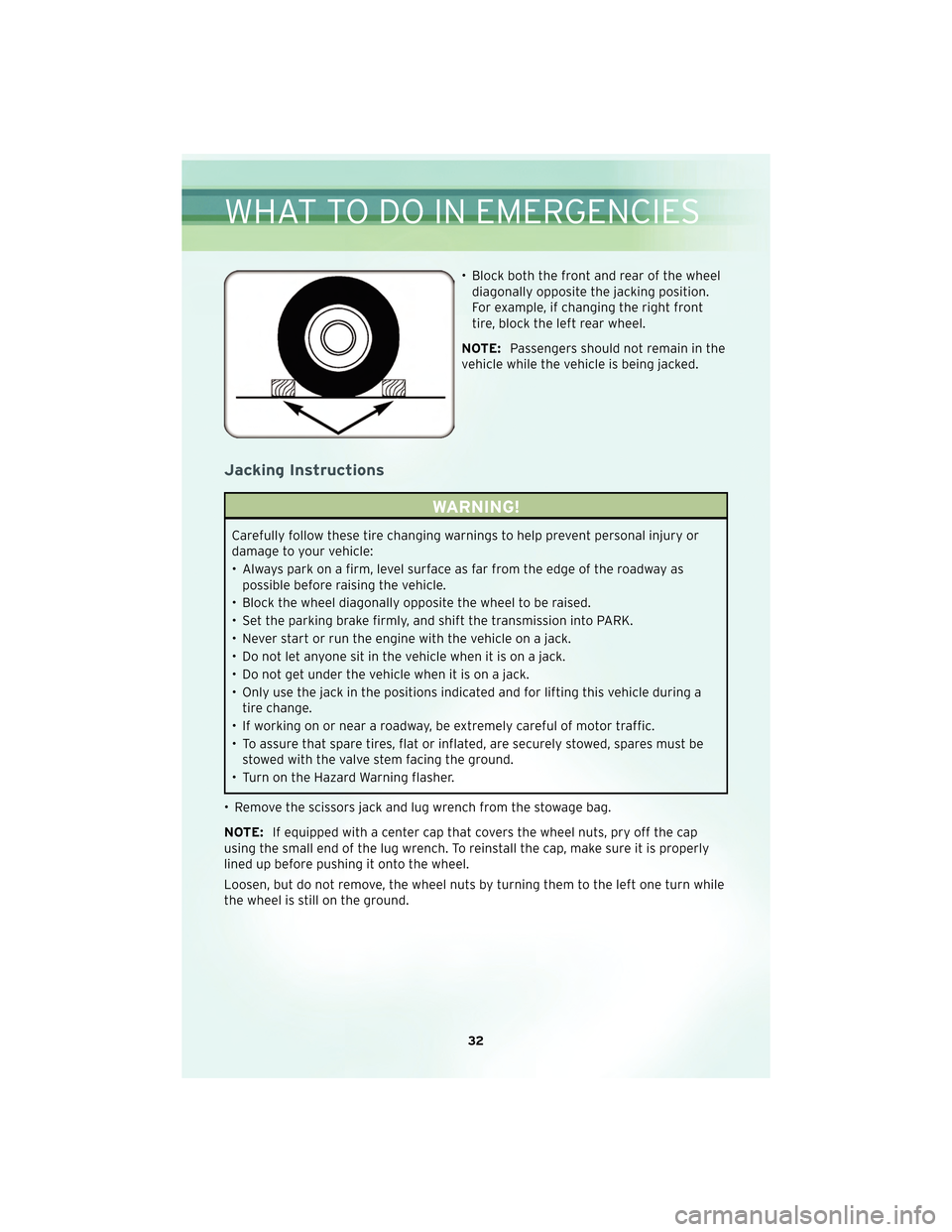

• Block both the front and rear of the wheeldiagonally opposite the jacking position.

For example, if changing the right front

tire, block the left rear wheel.

NOTE: Passengers should not remain in the

vehicle while the vehicle is being jacked.

Jacking Instructions

WARNING!

Carefully follow these tire changing warnings to help prevent personal injury or

damage to your vehicle:

• Always park on a firm, level surface as far from the edge of the roadway as possible before raising the vehicle.

• Block the wheel diagonally opposite the wheel to be raised.

• Set the parking brake firmly, and shift the transmission into PARK.

• Never start or run the engine with the vehicle on a jack.

• Do not let anyone sit in the vehicle when it is on a jack.

• Do not get under the vehicle when it is on a jack.

• Only use the jack in the positions indicated and for lifting this vehicle during a tire change.

• If working on or near a roadway, be extremely careful of motor traffic.

• To assure that spare tires, flat or inflated, are securely stowed, spares must be stowed with the valve stem facing the ground.

• Turn on the Hazard Warning flasher.

• Remove the scissors jack and lug wrench from the stowage bag.

NOTE: If equipped with a center cap that covers the wheel nuts, pry off the cap

using the small end of the lug wrench. To reinstall the cap, make sure it is properly

lined up before pushing it onto the wheel.

Loosen, but do not remove, the wheel nuts by turning them to the left one turn while

the wheel is still on the ground.

WHAT TO DO IN EMERGENCIES

32

Page 35 of 60

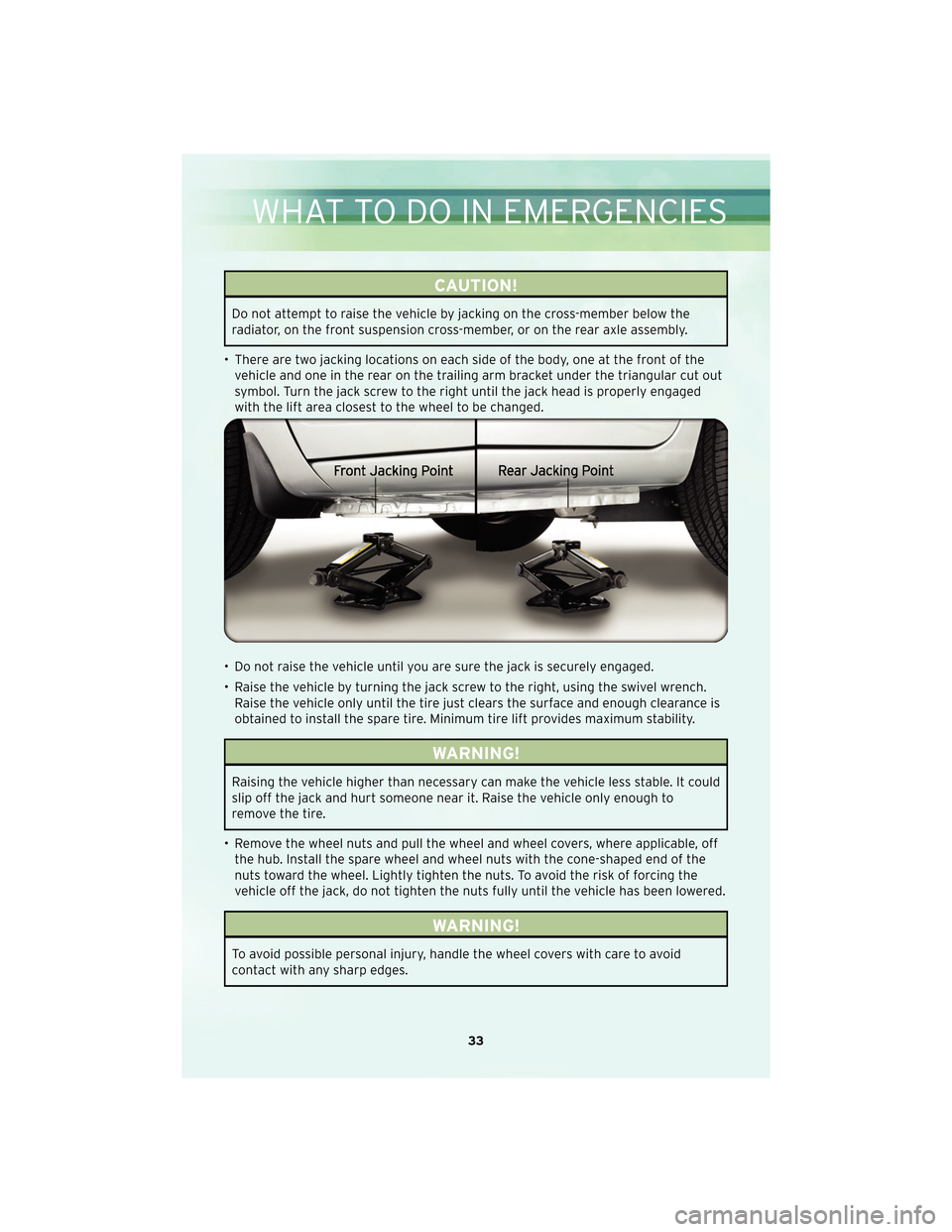

CAUTION!

Do not attempt to raise the vehicle by jacking on the cross-member below the

radiator, on the front suspension cross-member, or on the rear axle assembly.

• There are two jacking locations on each side of the body, one at the front of the vehicle and one in the rear on the trailing arm bracket under the triangular cut out

symbol. Turn the jack screw to the right until the jack head is properly engaged

with the lift area closest tothe wheel to be changed.

• Do not raise the vehicle until you are sure the jack is securely engaged.

• Raise the vehicle by turning the jack screw to the right, using the swivel wrench. Raise the vehicle only until the tire just clears the surface and enough clearance is

obtained to install the spare tire. Minimum tire lift provides maximum stability.

WARNING!

Raising the vehicle higher than necessary can make the vehicle less stable. It could

slip off the jack and hurt someone near it. Raise the vehicle only enough to

remove the tire.

• Remove the wheel nuts and pull the wheel and wheel covers, where applicable, off the hub. Install the spare wheel and wheel nuts with the cone-shaped end of the

nuts toward the wheel. Lightly tighten the nuts. To avoid the risk of forcing the

vehicle off the jack, do not tighten the nuts fully until the vehicle has been lowered.

WARNING!

To avoid possible personal injury, handle the wheel covers with care to avoid

contact with any sharp edges.

33

WHAT TO DO IN EMERGENCIES

Page 36 of 60

NOTE:The wheel cover is held on the wheel by the wheel nuts. When reinstalling

original wheel, properly align the wheel cover to the valve stem, place the wheel

cover onto the wheel, then install the wheel nuts.

• Lower the vehicle by turning the jack screw to the left.

• Finish tightening the nuts. Push down on the wrench while tightening the wheel nuts. Alternate nuts until each nut has been tightened twice. The correct wheel nut

torque is 100 ft lbs (135 N m). If you doubt that you have tightened the nuts

correctly, have them checked with a torque wrench by your authorized dealer or at

a qualified service station.

• Remove the wheel blocks and lower the jack until it is free. Stow the lug wrench and jack in their designated location. Secure all parts using the means provided.

WARNING!

A loose tire or jack thrown forward in a collision or hard stop could endanger the

occupants of the vehicle. Always stow the jack parts and the spare tire in the

places provided. Have the deflated (flat) tire repaired or replaced immediately.

• Place the deflated (flat) tire in the cargo area; have the tire repaired or replaced

as soon as possible.

• Check the tire pressure as soon as possible. Correct the pressure as required.

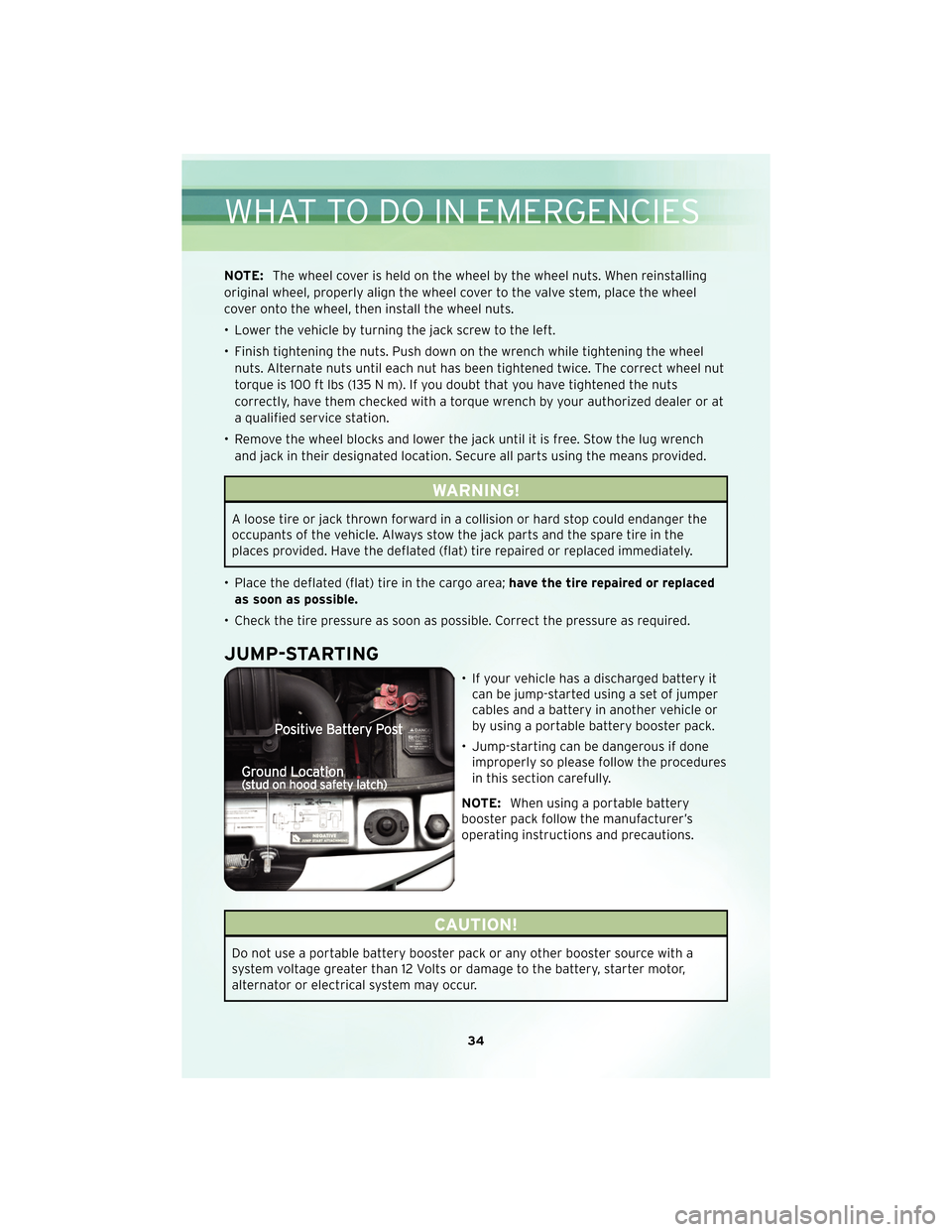

JUMP-STARTING

• If your vehicle has a discharged battery it can be jump-started using a set of jumper

cables and a battery in another vehicle or

by using a portable battery booster pack.

• Jump-starting can be dangerous if done improperly so please follow the procedures

in this section carefully.

NOTE: When using a portable battery

booster pack follow the manufacturer’s

operating instructions and precautions.

CAUTION!

Do not use a portable battery booster pack or any other booster source with a

system voltage greater than 12 Volts or damage to the battery, starter motor,

alternator or electrical system may occur.

WHAT TO DO IN EMERGENCIES

34

Page 40 of 60

TOWING A DISABLED VEHICLEModelFlat Towing (all four

wheels on the ground)Flatbed Towing (all

four wheels

suspended OFF the

ground)Front Wheels Raised,

Rear Wheels on the

Ground

Rear Wheels Raised,

Front Wheels on the

Ground

Without a Key NOT Permitted Recommended Method May Be Used

NOT Permitted without

a front end dolly

WithaKey Shift lever must be in

*NEUTRAL. The

distance to be traveled

must not exceed 15 mi

(25 km), and the

towing speed must not

exceed 25 mph

(40 km/h).Recommended Method May Be Used

NOT Permitted without

a front end dolly

38

WHAT TO DO IN EMERGENCIES

Page 46 of 60

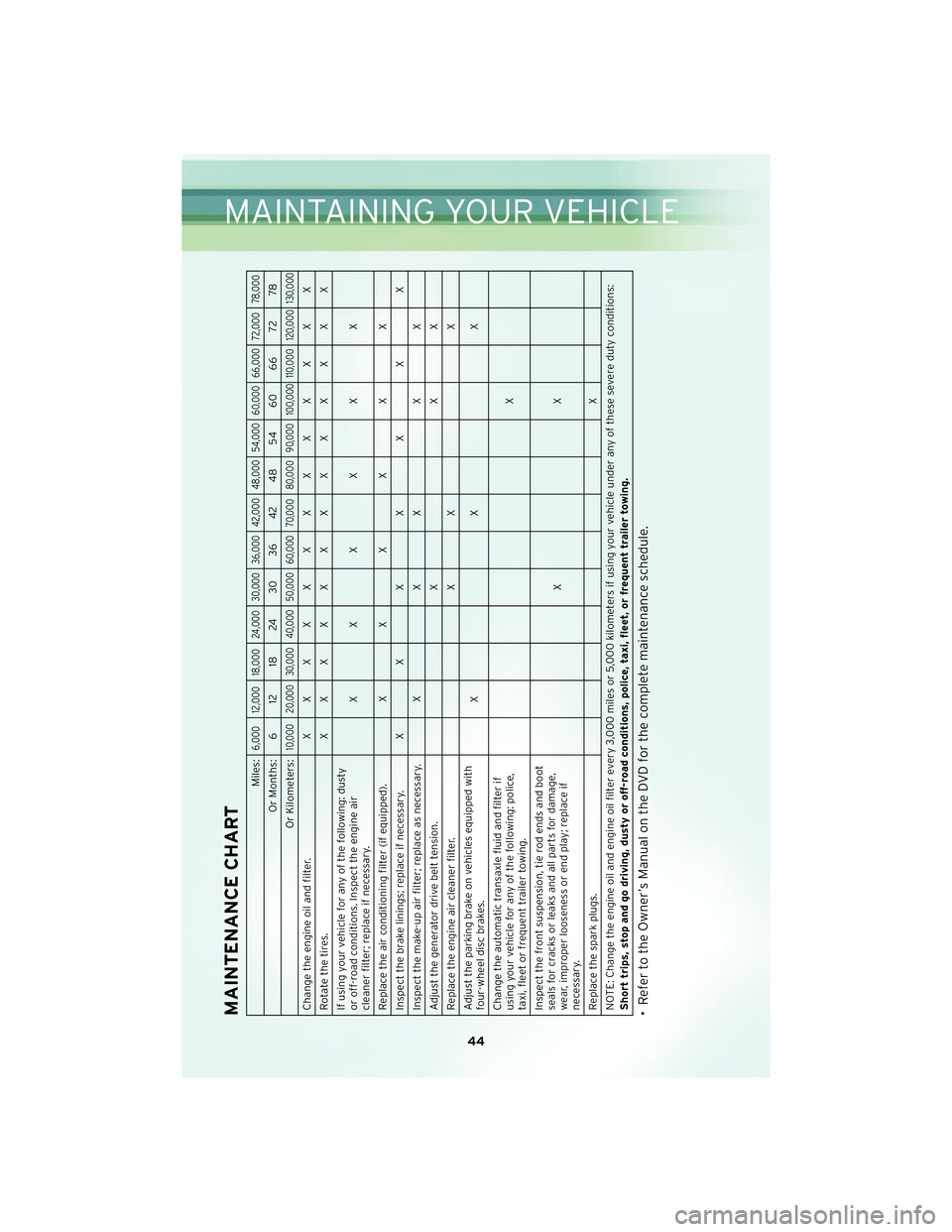

MAINTENANCE CHART

Miles:

6,000 12,000 18,000 24,000 30,000 36,000 42,000 48,000 54,000 60,000 66,000 72,000 78,000

Or Months: 6 12 18 24 30 36 42 48 54 60 66 72 78

Or Kilometers:

10,000 20,000 30,000 40,000 50,000 60,000 70,000 80,000 90,000 100,000 110,000 120,000 130,000

Change the engine oil and filter. XXXXXXXXXXXXX

Rotatethetires. XXXXXXXXXXXXX

If using your vehicle for any of the following: dusty

or off-road conditions. Inspect the engine air

cleaner filter; replace if necessary. XXXXXX

Replace the air conditioning filter (if equipped). X X X X X X

Inspect the brake linings; replace if necessary. X X X X X X X

Inspect the make-up air filter; replace as necessary. X X X X X

Adjust the generator drive belt tension. X X X

Replace the engine air cleaner filter. X X X

Adjust the parking brake on vehicles equipped with

four-wheel disc brakes. XXX

Change the automatic transaxle fluid and filter if

using your vehicle for any of the following: police,

taxi, fleet or frequent trailer towing. X

Inspect the front suspension, tie rod ends and boot

seals for cracks or leaks and all parts for damage,

wear, improper looseness or end play; replace if

necessary. XX

Replace the spark plugs. X

NOTE: Change the engine oil and engine oil filter every 3,000 miles or 5,000 kilometers if using your vehicle under any of these severe duty conditions:

Short trips, stop and go driving, dusty or off-road conditions, police, taxi, fleet, or frequent trailer towing.• Refer to the Owner’s Manual on the DVD for the complete maintenance schedule.

44

MAINTAINING YOUR VEHICLE

Page 48 of 60

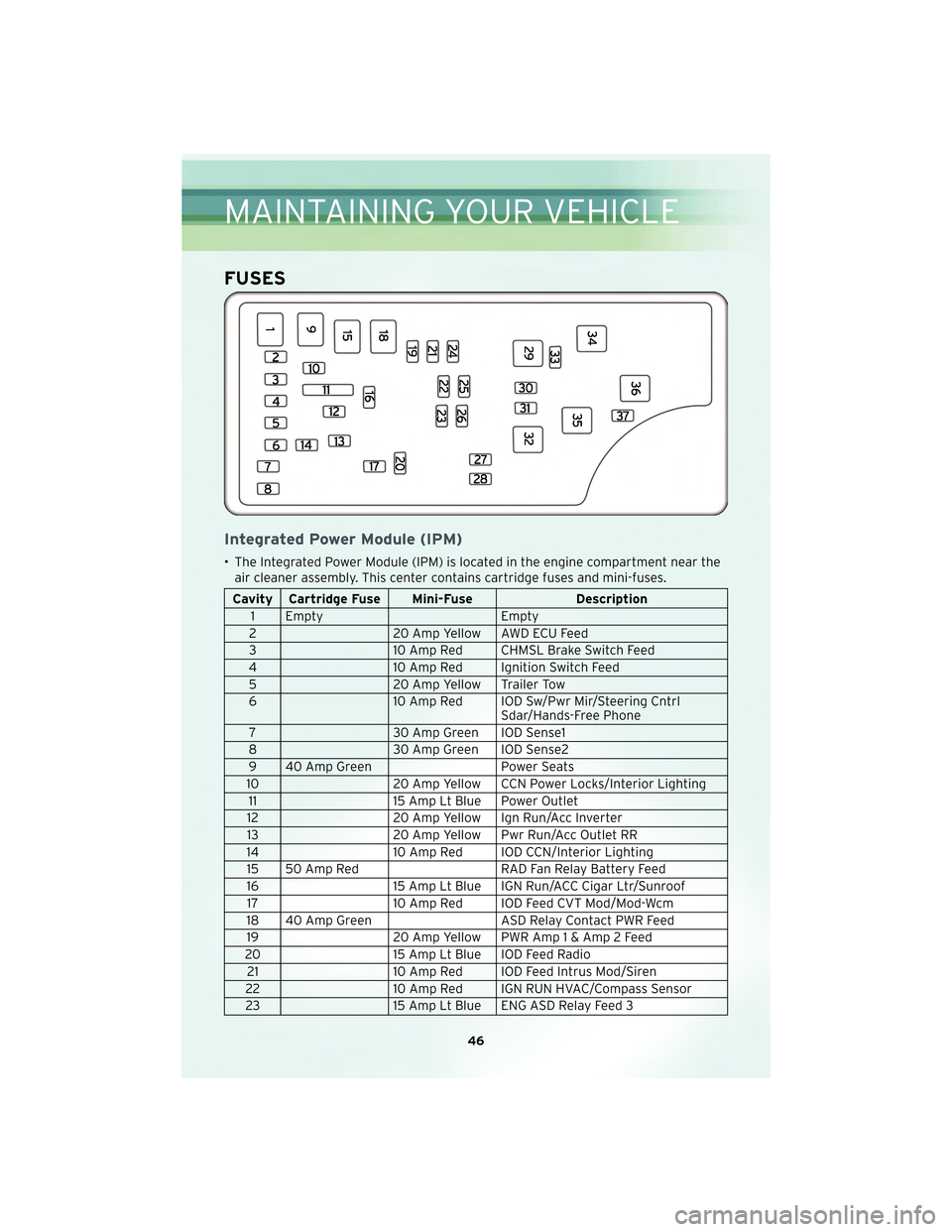

FUSES

Integrated Power Module (IPM)

• The Integrated Power Module (IPM) is located in the engine compartment near theair cleaner assembly. This center contains cartridge fuses and mini-fuses.

Cavity Cartridge Fuse Mini-Fuse Description

1 Empty Empty

2 20 Amp Yellow AWD ECU Feed

3 10 Amp Red CHMSL Brake Switch Feed

4 10 Amp Red Ignition Switch Feed

5 20 Amp Yellow Trailer Tow

6 10 Amp Red IOD Sw/Pwr Mir/Steering Cntrl

Sdar/Hands-Free Phone

7 30 Amp Green IOD Sense1

8 30 Amp Green IOD Sense2

9 40 Amp Green Power Seats

10 20 Amp Yellow CCN Power Locks/Interior Lighting

11 15 Amp Lt Blue Power Outlet

12 20 Amp Yellow Ign Run/Acc Inverter

13 20 Amp Yellow Pwr Run/Acc Outlet RR

14 10 Amp Red IOD CCN/Interior Lighting

15 50 Amp Red RAD Fan Relay Battery Feed

16 15 Amp Lt Blue IGN Run/ACC Cigar Ltr/Sunroof

17 10 Amp Red IOD Feed CVT Mod/Mod-Wcm

18 40 Amp Green ASD Relay Contact PWR Feed

19 20 Amp Yellow PWR Amp1&Amp2Feed

20 15 Amp Lt Blue IOD Feed Radio

21 10 Amp Red IOD Feed Intrus Mod/Siren

22 10 Amp Red IGN RUN HVAC/Compass Sensor

23 15 Amp Lt Blue ENG ASD Relay Feed 3

MAINTAINING YOUR VEHICLE

46